IEC 61788-17:2013

(Main)Superconductivity - Part 17: Electronic characteristic measurements - Local critical current density and its distribution in large-area superconducting films

Superconductivity - Part 17: Electronic characteristic measurements - Local critical current density and its distribution in large-area superconducting films

IEC 61788-17:2013 describes the measurements of the local critical current density (Jc) and its distribution in large-area high-temperature superconducting (HTS) films by an inductive method using third-harmonic voltages. The most important consideration for precise measurements is to determine Jc at liquid nitrogen temperatures by an electric-field criterion and obtain current-voltage characteristics from its frequency dependence. Although it is possible to measure Jc in applied DC magnetic fields, the scope of this standard is limited to the measurement without DC magnetic fields. This technique intrinsically measures the critical sheet current that is the product of Jc and the film thickness d. The range and measurement resolution for Jcd of HTS films are from 200 A/m to 32 kA/m, with a measurement resolution of 100 A/m.

Supraconductivité - Partie 17: Mesures de caractéristiques électroniques - Densité de courant critique local et sa distribution dans les films supraconducteurs de grande surface

La CEI 61788-17:2013 décrit les mesures de la densité de courant critique local (Jc) et sa distribution dans les films supraconducteurs à haute température (HTS) de grande surface par une méthode inductive utilisant les tensions de troisième harmonique. La considération la plus importante pour effectuer des mesures précises consiste à déterminer Jc aux températures de l'azote liquide au moyen d'un critère de champ électrique et obtenir des caractéristiques courant-tension d'après sa dépendance vis-à-vis de la fréquence. Bien qu'il soit possible de mesurer Jc dans des champs magnétiques en courant continu appliqués, le domaine d'application de la présente norme est limité à la mesure sans champ magnétique en courant continu. Cette technique mesure de façon intrinsèque le courant de feuille critique, qui est le produit de Jc par l'épaisseur d du film. La plage et la résolution de mesure pour Jcd des films HTS est de 200 A/m à 32 kA/m avec une résolution de mesure de 100 A/m.

General Information

- Status

- Published

- Publication Date

- 15-Jan-2013

- Technical Committee

- TC 90 - Superconductivity

- Drafting Committee

- WG 8 - TC 90/WG 8

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 28-Apr-2021

- Completion Date

- 29-Mar-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61788-17:2013 is an international standard published by the International Electrotechnical Commission (IEC) that focuses on the measurement of local critical current density (Jc) and its distribution across large-area high-temperature superconducting (HTS) films. This standard defines an inductive measurement method using third-harmonic voltages to assess superconducting films at liquid nitrogen temperatures without applied DC magnetic fields. The key parameter measured is the critical sheet current, which represents the product of local Jc and the film thickness.

Precise and reproducible evaluation of superconducting films is critical for advancing HTS applications in electronics, telecommunications, and energy systems. IEC 61788-17:2013 provides detailed procedures, apparatus specifications, and uncertainty analysis to support consistent testing and quality control in research and industrial environments.

Key Topics

Local Critical Current Density Measurement: The standard specifies an inductive method to evaluate the local critical current density, Jc, an essential parameter that characterizes the superconducting performance of HTS films.

Third-Harmonic Voltage Technique: Measurements use third-harmonic voltages induced in coils placed near the superconducting film, enabling non-contact analysis with high spatial resolution.

Frequency-Dependent Current-Voltage Characteristics: Accurate Jc determination relies on analyzing the frequency dependence of voltage responses, applying an electric-field criterion at liquid nitrogen temperatures (~77 K).

Measurement Range and Resolution: The standard covers sheet current densities (Jc × thickness) from 200 A/m to 32 kA/m with a measurement resolution of 100 A/m, supporting detailed mapping of film uniformity.

Measurement Setup and Calibration: IEC 61788-17 describes coil design, sample mounting, and calibration procedures using reference wafers to determine coil coefficients for precise quantification.

Uncertainty and Test Reporting: The document addresses systematic effects affecting measurement accuracy, including coil-to-film distance variations, and prescribes rigorous test reporting requirements for reproducibility.

Applications

IEC 61788-17:2013 is applicable to industries and research sectors utilizing high-temperature superconducting films, including:

Superconducting Electronics Manufacture: Supports development and quality assurance of HTS devices such as microwave filters, SQUIDs (superconducting quantum interference devices), and Josephson junctions.

Material Research and Development: Assists scientists in characterizing superconducting films for improved performance, durability, and fabrication methods.

Power Systems and Energy Storage: Enables evaluation of superconducting layers used in cables, fault current limiters, and magnetic energy storage systems.

Telecommunications Equipment: Facilitates reliable production of HTS filters and components that leverage low insertion loss and high frequency selectivity.

Standardized Testing Facilities: Provides a globally recognized method for uniform characterization, contributing to harmonized quality standards and certification processes.

By employing this standard, stakeholders can ensure consistent, accurate assessment of superconducting films' critical current properties, driving innovation and commercial adoption of HTS technologies.

Related Standards

IEC 61788-17:2013 is part of the broader IEC 61788 series on superconductivity, which includes multiple parts addressing various aspects of superconducting materials and technologies:

IEC 61788-1: General terms and definitions related to superconductivity.

IEC 61788-2: Measurement techniques for critical parameters of superconductors.

IEC 61788-13: Methods for characterizing critical current in coated conductors.

Other parts of IEC 61788: Cover additional electronic characteristic measurements and superconducting device testing protocols.

For comprehensive understanding and implementation, users should consult related IEC publications and standards addressing superconducting materials' terminology, calibration methods, and test system configurations. These harmonized standards support consistent global practices in the evaluation and utilization of superconducting films and devices.

Keywords: IEC 61788-17, superconductivity standard, local critical current density, HTS films, superconducting film measurement, third-harmonic voltage, inductive measurement, critical sheet current, high-temperature superconductors, superconductivity testing, liquid nitrogen temperature, measurement uncertainty, superconducting electronics, HTS device characterization.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61788-17:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Superconductivity - Part 17: Electronic characteristic measurements - Local critical current density and its distribution in large-area superconducting films". This standard covers: IEC 61788-17:2013 describes the measurements of the local critical current density (Jc) and its distribution in large-area high-temperature superconducting (HTS) films by an inductive method using third-harmonic voltages. The most important consideration for precise measurements is to determine Jc at liquid nitrogen temperatures by an electric-field criterion and obtain current-voltage characteristics from its frequency dependence. Although it is possible to measure Jc in applied DC magnetic fields, the scope of this standard is limited to the measurement without DC magnetic fields. This technique intrinsically measures the critical sheet current that is the product of Jc and the film thickness d. The range and measurement resolution for Jcd of HTS films are from 200 A/m to 32 kA/m, with a measurement resolution of 100 A/m.

IEC 61788-17:2013 describes the measurements of the local critical current density (Jc) and its distribution in large-area high-temperature superconducting (HTS) films by an inductive method using third-harmonic voltages. The most important consideration for precise measurements is to determine Jc at liquid nitrogen temperatures by an electric-field criterion and obtain current-voltage characteristics from its frequency dependence. Although it is possible to measure Jc in applied DC magnetic fields, the scope of this standard is limited to the measurement without DC magnetic fields. This technique intrinsically measures the critical sheet current that is the product of Jc and the film thickness d. The range and measurement resolution for Jcd of HTS films are from 200 A/m to 32 kA/m, with a measurement resolution of 100 A/m.

IEC 61788-17:2013 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.050 - Superconductivity and conducting materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61788-17:2013 has the following relationships with other standards: It is inter standard links to IEC 61788-17:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61788-17:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61788-17 ®

Edition 1.0 2013-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 17: Electronic characteristic measurements – Local critical current density

and its distribution in large-area superconducting films

Supraconductivité –

Partie 17: Mesures de caractéristiques électroniques – Densité de courant

critique local et sa distribution dans les films supraconducteurs de grande

surface

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 61788-17 ®

Edition 1.0 2013-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 17: Electronic characteristic measurements – Local critical current density

and its distribution in large-area superconducting films

Supraconductivité –

Partie 17: Mesures de caractéristiques électroniques – Densité de courant

critique local et sa distribution dans les films supraconducteurs de grande

surface

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX X

ICS 17.220.20; 29.050 ISBN 978-2-83220-583-9

– 2 – 61788-17 © IEC:2013

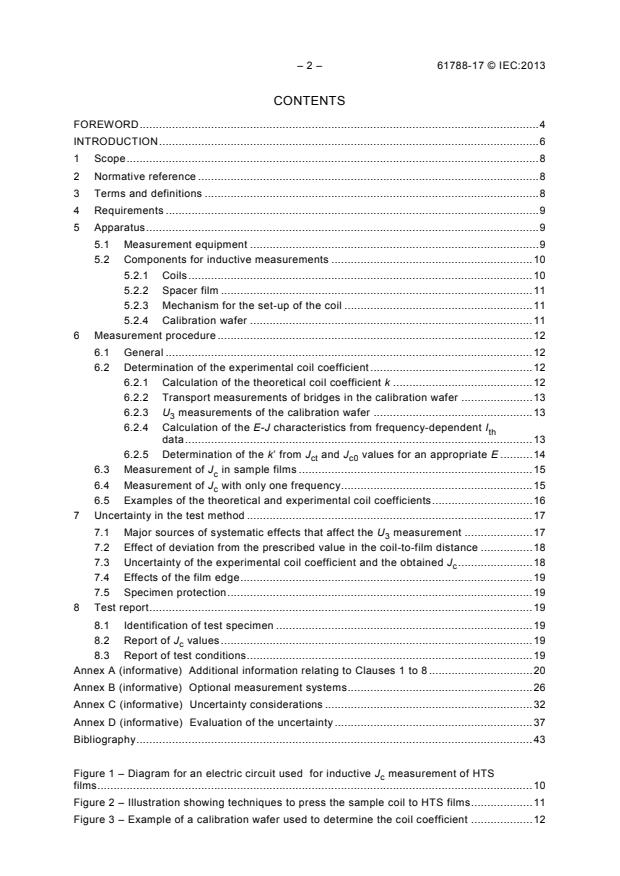

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 8

2 Normative reference . 8

3 Terms and definitions . 8

4 Requirements . 9

5 Apparatus . 9

5.1 Measurement equipment . 9

5.2 Components for inductive measurements . 10

5.2.1 Coils . 10

5.2.2 Spacer film . 11

5.2.3 Mechanism for the set-up of the coil . 11

5.2.4 Calibration wafer . 11

6 Measurement procedure . 12

6.1 General . 12

6.2 Determination of the experimental coil coefficient . 12

6.2.1 Calculation of the theoretical coil coefficient k . 12

6.2.2 Transport measurements of bridges in the calibration wafer . 13

6.2.3 U measurements of the calibration wafer . 13

6.2.4 Calculation of the E-J characteristics from frequency-dependent I

th

data . 13

6.2.5 Determination of the k’ from J and J values for an appropriate E . 14

ct c0

6.3 Measurement of J in sample films . 15

c

6.4 Measurement of J with only one frequency . 15

c

6.5 Examples of the theoretical and experimental coil coefficients . 16

7 Uncertainty in the test method . 17

7.1 Major sources of systematic effects that affect the U measurement . 17

7.2 Effect of deviation from the prescribed value in the coil-to-film distance . 18

7.3 Uncertainty of the experimental coil coefficient and the obtained J . 18

c

7.4 Effects of the film edge . 19

7.5 Specimen protection . 19

8 Test report . 19

8.1 Identification of test specimen . 19

8.2 Report of J values . 19

c

8.3 Report of test conditions . 19

Annex A (informative) Additional information relating to Clauses 1 to 8 . 20

Annex B (informative) Optional measurement systems . 26

Annex C (informative) Uncertainty considerations . 32

Annex D (informative) Evaluation of the uncertainty . 37

Bibliography . 43

Figure 1 – Diagram for an electric circuit used for inductive J measurement of HTS

c

films . 10

Figure 2 – Illustration showing techniques to press the sample coil to HTS films . 11

Figure 3 – Example of a calibration wafer used to determine the coil coefficient . 12

61788-17 © IEC:2013 – 3 –

Figure 4 – Illustration for the sample coil and the magnetic field during measurement . 13

Figure 5 – E-J characteristics measured by a transport method and the U inductive

method . 14

Figure 6 –Example of the normalized third-harmonic voltages (U /fI ) measured with

3 0

various frequencies . 15

Figure 7 – Illustration for coils 1 and 3 in Table 1 . 16

Figure 8 – The coil-factor function F(r) = 2H /I calculated for the three coils . 17

0 0

Figure 9 – The coil-to-film distance Z dependence of the theoretical coil coefficient k . 18

Figure A.1 – Illustration for the sample coil and the magnetic field during measurement . 22

Figure A.2 – (a) U and (b) U /I plotted against I in a YBCO thin film measured in

3 3 0 0

applied DC magnetic fields, and the scaling observed when normalized by I (insets) . 23

th

Figure B.1 – Schematic diagram for the variable-RL-cancel circuit . 27

Figure B.2 – Diagram for an electrical circuit used for the 2-coil method . 27

Figure B.3 – Harmonic noises arising from the power source . 28

Figure B.4 – Noise reduction using a cancel coil with a superconducting film . 28

Figure B.5 – Normalized harmonic noises (U /fI ) arising from the power source . 29

3 0

Figure B.6 – Normalized noise voltages after the reduction using a cancel coil with a

superconducting film . 29

Figure B.7 – Normalized noise voltages after the reduction using a cancel coil without

a superconducting film . 30

Figure B.8 – Normalized noise voltages with the 2-coil system shown in Figure B.2 . 30

Figure D.1 – Effect of the coil position against a superconducting thin film on the

measured J values . 41

c

Table 1 – Specifications and coil coefficients of typical sample coils . 16

Table C.1 – Output signals from two nominally identical extensometers . 33

Table C.2 – Mean values of two output signals . 33

Table C.3 – Experimental standard deviations of two output signals . 33

Table C.4 – Standard uncertainties of two output signals . 34

Table C.5 – Coefficient of variations of two output signals . 34

Table D.1 – Uncertainty budget table for the experimental coil coefficient k’ . 37

Table D.2 – Examples of repeated measurements of J and n-values . 40

c

– 4 – 61788-17 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SUPERCONDUCTIVITY –

Part 17: Electronic characteristic measurements –

Local critical current density and its distribution

in large-area superconducting films

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

International Standard IEC 61788-17 has been prepared by IEC technical committee 90:

Superconductivity.

The text of this standard is based on the following documents:

FDIS Report on voting

90/310/FDIS 90/319/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts of the IEC 61788 series, published under the general title

Superconductivity, can be found on the IEC website.

61788-17 © IEC:2013 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 61788-17 © IEC:2013

INTRODUCTION

Over twenty years after their discovery in 1986, high-temperature superconductors are now

finding their way into products and technologies that will revolutionize information

transmission, transportation, and energy. Among them, high-temperature superconducting

(HTS) microwave filters, which exploit the extremely low surface resistance of

superconductors, have already been commercialized. They have two major advantages over

conventional non-superconducting filters, namely: low insertion loss (low noise characteristics)

and high frequency selectivity (sharp cut) [1] . These advantages enable a reduced number of

base stations, improved speech quality, more efficient use of frequency bandwidths, and

reduced unnecessary radio wave noise.

Large-area superconducting thin films have been developed for use in microwave devices [2].

They are also used for emerging superconducting power devices, such as, resistive-type

superconducting fault-current limiters (SFCLs) [3–5], superconducting fault detectors used for

superconductor-triggered fault current limiters [6, 7] and persistent-current switches used for

persistent-current HTS magnets [8, 9]. The critical current density J is one of the key

c

parameters that describe the quality of large-area HTS films. Nondestructive, AC inductive

methods are widely used to measure J and its distribution for large-area HTS films [10–13],

c

among which the method utilizing third-harmonic voltages U cos(3ωt+θ) is the most popular

[10, 11], where ω, t and θ denote the angular frequency, time, and initial phase, respectively.

However, these conventional methods are not accurate because they have not considered the

electric-field E criterion of the J measurement [14, 15] and sometimes use an inappropriate

c

criterion to determine the threshold current I from which J is calculated [16]. A conventional

th c

method can obtain J values that differ from the accurate values by 10 % to 20 % [15]. It is

c

thus necessary to establish standard test methods to precisely measure the local critical

current density and its distribution, to which all involved in the HTS filter industry can refer for

quality control of the HTS films. Background knowledge on the inductive J measurements of

c

HTS thin films is summarized in Annex A.

In these inductive methods, AC magnetic fields are generated with AC currents I cosωt in a

small coil mounted just above the film, and J is calculated from the threshold coil current I ,

c th

at which full penetration of the magnetic field to the film is achieved [17]. For the inductive

method using third-harmonic voltages U , U is measured as a function of I , and the I is

3 3 0 th

determined as the coil current I at which U starts to emerge. The induced electric fields E in

0 3

the superconducting film at I = I , which are proportional to the frequency f of the AC current,

0 th

can be estimated by a simple Bean model [14]. A standard method has been proposed to

precisely measure J with an electric-field criterion by detecting U and obtaining the n-value

c 3

(index of the power-law E-J characteristics) by measuring I precisely at various frequencies

th

[14, 15, 18, 19]. This method not only obtains precise J values, but also facilitates the

c

detection of degraded parts in inhomogeneous specimens, because the decline of n-value is

more remarkable than the decrease of J in such parts [15]. It is noted that this standard

c

method is excellent for assessing homogeneity in large-area HTS films, although the relevant

parameter for designing microwave devices is not J , but the surface resistance. For

c

application of large-area superconducting thin films to SFCLs, knowledge on J distribution is

c

vital, because J distribution significantly affects quench distribution in SFCLs during faults.

c

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this document may involve the use of a patent concerning the

determination of the E-J characteristics by inductive J measurements as a function of

c

frequency, given in the Introduction, Clause 1, Clause 4 and 5.1.

IEC takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he is willing to negotiate licenses free

of charge with applicants throughout the world. In this respect, the statement of the holder of

this patent right is registered with the IEC. Information may be obtained from:

___________

Numbers in square brackets refer to the Bibliography.

61788-17 © IEC:2013 – 7 –

Name of holder of patent right:

National Institute of Advanced Industrial Science and Technology

Address:

Intellectual Property Planning Office, Intellectual Property Department

1-1-1, Umezono, Tsukuba, Ibaraki Prefecture, Japan

Attention is drawn to the possibility that some of the elements of this document may be

subject to patent rights other than those identified above. IEC shall not be held responsible for

identifying any or all such patent rights.

ISO (www.iso.org/patents) and IEC (http://patents.iec.ch) maintain on-line data bases of

patents relevant to their standards. Users are encouraged to consult the data bases for the

most up to date information concerning patents.

– 8 – 61788-17 © IEC:2013

SUPERCONDUCTIVITY –

Part 17: Electronic characteristic measurements –

Local critical current density and its distribution

in large-area superconducting films

1 Scope

This part of IEC 61788 describes the measurements of the local critical current density (J )

c

and its distribution in large-area high-temperature superconducting (HTS) films by an

inductive method using third-harmonic voltages. The most important consideration for precise

measurements is to determine J at liquid nitrogen temperatures by an electric-field criterion

c

and obtain current-voltage characteristics from its frequency dependence. Although it is

in applied DC magnetic fields [20, 21] , the scope of this standard is

possible to measure J

c

limited to the measurement without DC magnetic fields.

This technique intrinsically measures the critical sheet current that is the product of J and the

c

film thickness d. The range and measurement resolution for J d of HTS films are as follows:

c

– J d: from 200 A/m to 32 kA/m (based on results, not limitation);

c

– Measurement resolution: 100 A/m (based on results, not limitation).

2 Normative reference

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (available at

)

3 Terms and definitions

For the purposes of this document, the definitions given in IEC 60050-815:2000, some of

which are repeated here for convenience, apply.

3.1

critical current

I

c

maximum direct current that can be regarded as flowing without resistance

Note 1 to entry: I is a function of magnetic field strength and temperature.

c

[SOURCE: IEC 60050-815:2000, 815-03-01]

___________

Numbers in square brackets refer to the Bibliography.

61788-17 © IEC:2013 – 9 –

3.2

critical current criterion

I criterion

c

criterion to determine the critical current, I , based on the electric field strength, E or the

c

resistivity, ρ

-13

Note 1 to entry: E = 10 µV/m or E = 100 µV/m is often used as electric field criterion, and ρ = 10 Ω · m or

-14

ρ = 10 Ω · m is often used as resistivity criterion. (“E = 10 V/m or E = 100 V/m” in the current edition is mistaken

and is scheduled to be corrected in the second edition).

[SOURCE: IEC 60050-815:2000, 815-03-02]

3.3

critical current density

J

c

the electric current density at the critical current using either the cross-section of the whole

conductor (overall) or of the non-stabilizer part of the conductor if there is a stabilizer

Note 1 to entry: The overall current density is called in English, engineering current density (symbol: J ).

e

[SOURCE: IEC 60050-815:2000, 815-03-03]

3.4

transport critical current density

J

ct

critical current density obtained by a resistivity or a voltage measurement

[SOURCE: IEC 60050-815:2000, 815-03-04]

3.5

n-value (of a superconductor)

exponent obtained in a specific range of electric field strength or resistivity when the

n

voltage/current U (l) curve is approximated by the equation U ∝ I

[SOURCE: IEC 60050-815:2000, 815-03-10]

4 Requirements

The critical current density J is one of the most fundamental parameters that describe the

c

quality of large-area HTS films. In this standard, J and its distribution are measured non-

c

destructively via an inductive method by detecting third-harmonic voltages U cos(3ωt+θ). A

small coil, which is used both to generate AC magnetic fields and detect third-harmonic

voltages, is mounted just above the HTS film and used to scan the measuring area. To

measure J precisely with an electric-field criterion, the threshold coil currents I , at which U

c th 3

starts to emerge, are measured repeatedly at different frequencies and the E-J characteristics

are determined from their frequency dependencies.

The target relative combined standard uncertainty of the method used to determine the

absolute value of J is less than 10 %. However, the target uncertainty is less than 5 % for the

c

purpose of evaluating the homogeneity of J distribution in large-area superconducting thin

c

films.

5 Apparatus

5.1 Measurement equipment

Figure 1 shows a schematic diagram of a typical electric circuit used for the third-harmonic

voltage measurements. This circuit is comprised of a signal generator, power amplifier, digital

multimeter (DMM) to measure the coil current, band-ejection filter to reduce the fundamental

– 10 – 61788-17 © IEC:2013

wave signals and lock-in amplifier to measure the third-harmonic signals. It involves the

single-coil approach in which the coil is used to generate an AC magnetic field and detect the

inductive voltage. This method can also be applied to double-sided superconducting thin films

without hindrance. In the methods proposed here, however, there is an additional system to

reduce harmonic noise voltages generated from the signal generator and the power amplifier

[14]. In an example of Figure 1, a cancel coil of specification being the same as the sample

coil is used for canceling. The sample coil is mounted just above the superconducting film,

and a superconducting film with a J d sufficiently larger than that of the sample film is placed

c

below the cancel coil to adjust its inductance to that of the sample coil. Both coils and

superconducting films are immersed in liquid nitrogen (a broken line in Figure 1). Other

optional measurement systems are described in Annex B.

NOTE In this circuit coil currents of about 0,1 A (rms) and power source voltages of > 6 V (rms) are needed to

measure the superconducting film of J d ≈ 10 kA/m while using coil 1 or 2 of Table 1 (6.5). A power amplifier, such

c

as NF: HSA4011, is necessary to supply such large currents and voltages.

IEC 013/13

Figure 1 – Diagram for an electric circuit used

for inductive J measurement of HTS films

c

5.2 Components for inductive measurements

5.2.1 Coils

Currently available large-area HTS films are deposited on areas as large as about 25 cm in

diameter, while about 5 cm diameter films are commercially used to prepare microwave filters

[22]. Larger YBa Cu O (YBCO) films, about 10 cm diameter films and 2,7 cm × 20 cm films,

2 3 7

were used to fabricate fault current limiter modules [3–5]. For the J measurements of such

c

films, the appropriate outer diameter of the sample coils ranges from 2 mm to 5 mm. The

requirement for the sample coil is to generate as high a magnetic field as possible at the

upper surface of the superconducting film, for which flat coil geometry is suitable. Typical

specifications are as follows:

a) Inner winding diameter D : 0,9 mm, outer diameter D : 4,2 mm, height h: 1,0 mm,

1 2

400 turns of a 50 µm diameter copper wire;

b) D : 0,8 mm, D : 2,2 mm, h: 1,0 mm, 200 turns of a 50 µm diameter copper wire.

1 2

61788-17 © IEC:2013 – 11 –

5.2.2 Spacer film

Typically, a polyimide film with a thickness of 50 µm to 125 µm is used to protect the HTS

films. The coil has generally some protection layer below the coil winding, which also

insulates the thin film from Joule heat in the coil. The typical thickness is 100 µm to 150 µm,

and the coil-to-film distance Z is kept to be 200 µm.

5.2.3 Mechanism for the set-up of the coil

To maintain a prescribed value for the spacing Z between the bottom of the coil winding and

the film surface, the sample coil should be pressed to the film with sufficient pressure,

typically exceeding about 0,2 MPa [18]. Techniques to achieve this are to use a weight or

spring, as shown in Figure 2. The system schematically shown in the left figure is used to

scan wide area of the film. Before the U measurement the coil is initially moved up to some

distance, moved laterally to the target position, and then moved down and pressed to the film.

An appropriate pressure should be determined so that too high pressure does not damage the

bobbin, coil, HTS thin film or the substrate. It is reported that the YBCO deposited on

biaxially-textured pure Ni substrate was degraded by transverse compressive stress of about

20 MPa [23].

IEC 014/13

Figure 2 – Illustration showing techniques to press the sample coil to HTS films

5.2.4 Calibration wafer

A calibration wafer is used to determine the experimental coil coefficient k’ described in the

next section. It is made by using a homogeneous large-area (typically about 5 cm diameter)

YBCO thin film. It consists of bridges for transport measurement and an inductive

measurement area (Figure 3). Typical dimensions of the transport bridges are 20 µm to 70 µm

wide and 1 mm to 2 mm long, which were prepared either by UV photolithography technique

or by laser etching [24].

– 12 – 61788-17 © IEC:2013

IEC 015/13

Figure 3 – Example of a calibration wafer used to determine the coil coefficient

6 Measurement procedure

6.1 General

The procedures used to determine the experimental coil coefficient k’ and measure the J of

c

the films under test are described as follows, with the meaning of k’ expressed in A.5.

6.2 Determination of the experimental coil coefficient

6.2.1 Calculation of the theoretical coil coefficient k

Calculate the theoretical coil coefficient k = J d/I from

c th

k = F , (1)

m

where F is the maximum of F(r) that is a function of r, the distance from the central axis of

m

the coil (Figure 4). The coil-factor function F(r) = –2H (r, t)/I cosωt = 2H /I is obtained by

r 0 0 0

R 2π Z

N 2 2 r ′zcosθ

′

F(r ) = dr dθ dz , (2)

∫ ∫ ∫

2 2 2 3 / 2

2π S R 0 Z

′ ′

1 1 (z + r + r − 2rr cosθ )

where N is the number of windings, S = (R – R )h is the cross-sectional area, R = D /2 is

2 1 1 1

the inner radius, R = D /2 is the outer radius of the coil, Z is the coil-to-film distance, and Z

2 2 1 2

= Z + h [17]. The derivation of the Equation (2) is described in A.3.

61788-17 © IEC:2013 – 13 –

IEC 016/13

Figure 4 – Illustration for the sample coil and the magnetic field during measurement

6.2.2 Transport measurements of bridges in the calibration wafer

a) Measure the E-J characteristics of the transport bridges of the calibration wafer by a four-

probe method, and obtain the power-law E-J characteristics,

n

E = A × J . (3)

t 0t

b) Repeat the measurement for at least three different bridges. Three sets of data (n = 20,5

to 23,8) measured for three bridges are shown in the upper (high-E) part of Figure 5.

6.2.3 U measurements of the calibration wafer

a) Measure U in the inductive measurement area of the calibration wafer as a function of

using a

the coil current with three or four frequencies, and obtain the experimental I

th

constant-inductance criterion; namely, U /fI = 2πL . The criterion L should be as small

3 0 c c

as possible within the range with sufficiently large S/N ratios, in order to use the simple

Equation (4) for the electric-field calculation (7.1 c) and D.2). An example of the

measurement is shown in Figure 6 with 2πL = 2 µΩ•sec.

c

b) Repeat the measurement for at least three different points of the film.

6.2.4 Calculation of the E-J characteristics from frequency-dependent I data

th

(= kI /d) and the average E induced in the superconducting film at the full

a) Calculate J

c0 th

penetration threshold by

E ≈ 2,04µ fd J = 2,04µ kfdI , (4)

avg 0 c 0 th

from the obtained I at each frequency using the theoretical coefficient k calculated in

th

6.2.1. The derivation of Equation (4) is described in A.4.

b) Obtain the E-J characteristics

n

E = A × J (5)

i 0i

from the relation between E and J , and plot them in the same figure where the

avg c0

transport E-J characteristics data were plotted. Broken lines in Figure 5 show three sets of

– 14 – 61788-17 © IEC:2013

data measured at different points of the film. Transport data and U inductive data do not

yet match at this stage.

6.2.5 Determination of the k’ from J and J values for an appropriate E

ct c0

a) Choose an appropriate electric field that is within (or near to) both the transport

E-J curves and the inductive E-J curves, such as 200 µV/m in Figure 5.

b) At this electric field, calculate both the transport critical current densities J and the

ct

inductive J values from Equations (3) and (5) respectively.

c0

c) Determine the experimental coil coefficient k’ by k’ = (J /J )k, where J and J indicate

ct c0 ct c0

the average values of obtained J and J values, respectively. If the J (= k’I /d) values

ct c0 c th

are plotted against E = 2,04µ kfdI , the E-J characteristics from the U measurement

avg 0 th 3

match the transport data well (Figure 5).

-1

YBCO/CeO /Al O , 300 nm

2 2 3

(CalbWF5A3 & TH052Au)

-2

77,3 K, 0 T

transport

-3

"CalbWF5A3"

"TH052Au"

20 kHz

-4

5 kHz

U inductive

-5 3

1 kHz

"CalbWF5A3"

0,2 kHz

-6

E-J obtained using k' E-J obtained using k

10 10 10

2 10 3 10 4 10

J (A/m )

IEC 017/13

Figure 5 – E-J characteristics measured by a transport method and the U

inductive method

E (V/m)

61788-17 © IEC:2013 – 15 –

IEC 018/13

Figure 6 –Example of the normalized third-harmonic

voltages (U /fI ) measured with various frequencies

3 0

6.3 Measurement of J in sample films

c

a) Measure U with two, three or four frequencies in sample films, and obtain I with the

3 th

same criterion L as used in 6.2.3.

c

b) Use the obtained experimental coil coefficient k’ to calculate J (= k’I /d) at each

c th

frequency, and obtain the relation between J and E (= 2,04µ kfdI , using k because of

c avg 0 th

the underestimation as mentioned in 7.1 c). An example of the E-J characteristics is also

shown in Figure 5) measured for a sample film (TH052Au, solid symbols) with

n-values (36,0 and 40,4) exceeding those of the calibration wafer (n = 28,0 to 28,6).

c) From the obtained E-J characteristics, calculate the J value with an appropriate electric-

c

field criterion, such as E = 100 µV/m.

c

d) Measurement with three or four frequencies is beneficial to check the validity of the

measurement and sample by checking the power-law E-J characteristics. Measurement

with two frequencies can be used for routine samples in the interests of time.

6.4 Measurement of J with only one frequency

c

As mentioned in Clause 1 and Clause 3, J is a function of electric field, and it is

c

recommended to determine it with a constant electric-field criterion using a multi-frequency

approach through procedures described in 6.2 and 6.3. However, one frequency

measurement is sometimes desired for simplicity and inexpensiveness. In this case, the J

c

values are determined with variable electric-field criteria through the following procedures.

a) Calculate the theoretical coil coefficient k by Equation (1) in 6.2.1.

b) Obtain the E-J characteristics of the transport bridges of the calibration wafer (Equation

(3)) through the procedures of 6.2.2.

c) Measure U in the inductive measurement area of the calibration wafer as a function of the

coil current with one frequency, and obtain the experimental I using a constant-

th

inductance criterion; namely, U /fI = 2πL . The criterion L should be as small as possible

3 0 c c

within the range with sufficiently large S/N ratios, in order to use the simple Equation (4) in

6.2.4 for the electric-field calculation. Calculate J (= kI /d) and the average E induced in

c0 th

the superconducting film at the full penetration threshold by Equation (4). Repeat the

– 16 – 61788-17 © IEC:2013

measurement for at least three different points of the film, and obtain average J and

c0

E .

avg-U3

d) Using the transport E-J characteristics of Equation (3), calculate J for the average

ct

obtained in c).

E

avg-U3

e) Determine the experimental coil coefficient k’ by k’ = (J /J )k.

ct c0

with the same frequency in sample films, and obtain I with the same

f) Measure U

3 th

criterion L as used in c). Calculate J (= k’I /d) using the obtained experimental coil

c c th

coefficient k’. Calculate also E with Equation (4), and this value should be accompanied

avg

by each J value.

c

6.5 Examples of the theoretical and experimental coil coefficients

Some examples of the theoretical and experimental coil coefficients (k and k’) for typical

sample coils are shown in Table 1 with the specifications and recommended criteria for the I

th

determination, 2πL = U /fI . Note that the k’ depends on the criterion L . Coil 1 is wound with

c 3 0 c

a 50 µm diameter, self-bonding polyurethane enameled round copper winding wire, and

coils 2 and 3 are wound with a 50 µm diameter, polyurethane enameled round copper winding

wire. Measured resistances at 77,3 K and calculated self-inductances when a

superconducting film is placed below the coil are also shown. The coil-to-film distance Z is

fixed at 0,2 mm. The images of coils 1 and 3 are shown in Figure 7, and the coil-factor

functions F(r) for the three coils show that the peak magnetic field occurs near the mean coil

radius (Figure 8).

Table 1 – Specifications and coil coefficients of typical sample coils

D D h Turns k k’ U /fI R L

1 2 3 0

mm mm mm 1/mm 1/mm µΩ•sec Ω mH

1 0,9 4,2 1,0 400 106,6 82,2 2 4,1 0,165

2 1,0 3,6 1,0 400 117,4 89,1 2 3,4 0,163

3 0,8 2,2 1,0 200 63,2 47,0 0,6 1,6 0,028

IEC 019/13

Figure 7 – Illustration for coils 1 and 3 in Table 1

61788-17 © IEC:2013 – 17 –

IEC 020/13

Figure 8 – The coil-factor function F(r) = 2H /I calculated for the three coils

0 0

7 Uncertainty in the test method

7.1 Major sources of systematic effects that affect the U measurement

The most significant systematic effect on the U measurement is due to the deviation of the

coil-to-film distance Z from the prescribed value. Because the measured value J d in this

1 c

technique is directly proportional to the magnetic field at the upper surface of the

superconducting film, the deviation of the spacing Z directly affects the measurement. The

key origins of the uncertainty are listed bellow (a)–c)). Note that the general concept of the

“uncertainty” is summarized in Annex C.

a) Inadequate pressing of the coil to the film

As the measurement is performed in liquid nitrogen, the polyimide film placed above the

HTS thin film becomes brittle and liquid nitrogen may enter the space between the

polyimide and HTS films. Thus, sufficient pressure is necessary to keep the polyimide film

flat and avoid the deviation of Z . An experiment has shown that the required pressure is

about 0,2 MPa [18]. Here it is to be noted that thermal contraction of polyimide films at the

liquid nitrogen temperature is less than 0,002 × (300 – 77) ≈ 0,45 %, which leads to

negligible values of 0,2 µm to 0,6 µm compared with the total coil-to-film distance (about

200 µm) [25].

b) Ice layer formed between the coil and polyimide film

The liquid nitrogen inevitably contains powder-like ice. If the sample coil is moved to scan

the large-area HTS film area for an extended period, an ice layer is often formed between

the polyimide film and the sample coil, which increases the coil-to-film distance Z from

the prescribed value. As shown later in 7.2, this effect reduces coil coefficients (k and k’),

and the use of uncorrected k’ results in an overestimate in J . Special care should be

c

taken to keep the measurement environment as dry as possible. If the measurement

system is set in an open (ambient) environment,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...