IEC PAS 61249-6-3:2011

(Main)Specification for finished fabric woven from "E" glass for printed boards

Specification for finished fabric woven from "E" glass for printed boards

IEC/PAS 61249-6-3:2011(E) covers finished fabrics woven from "E" glass electrical grade glass fiber yarns that are intended as a reinforcing material in laminated plastics for electrical and electronic use. All fabrics covered by this specification are plain weave. This specification determines the nomenclature, definitions, general and chemical requirements for the glass, and physical requirements for finished woven glass fiber fabrics. Appendix II of this specification provides a style designator for each finished fabric glass style, with specifications on yarn, fabric count, thickness and weight in both SI and US system. Fabrics listed in Annex B also categorize fabrics by their current availability status.

General Information

- Status

- Replaced

- Publication Date

- 22-Sep-2011

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 4 - TC 91/WG 4

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 14-Jun-2023

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Frequently Asked Questions

IEC PAS 61249-6-3:2011 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Specification for finished fabric woven from "E" glass for printed boards". This standard covers: IEC/PAS 61249-6-3:2011(E) covers finished fabrics woven from "E" glass electrical grade glass fiber yarns that are intended as a reinforcing material in laminated plastics for electrical and electronic use. All fabrics covered by this specification are plain weave. This specification determines the nomenclature, definitions, general and chemical requirements for the glass, and physical requirements for finished woven glass fiber fabrics. Appendix II of this specification provides a style designator for each finished fabric glass style, with specifications on yarn, fabric count, thickness and weight in both SI and US system. Fabrics listed in Annex B also categorize fabrics by their current availability status.

IEC/PAS 61249-6-3:2011(E) covers finished fabrics woven from "E" glass electrical grade glass fiber yarns that are intended as a reinforcing material in laminated plastics for electrical and electronic use. All fabrics covered by this specification are plain weave. This specification determines the nomenclature, definitions, general and chemical requirements for the glass, and physical requirements for finished woven glass fiber fabrics. Appendix II of this specification provides a style designator for each finished fabric glass style, with specifications on yarn, fabric count, thickness and weight in both SI and US system. Fabrics listed in Annex B also categorize fabrics by their current availability status.

IEC PAS 61249-6-3:2011 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 61249-6-3:2011 has the following relationships with other standards: It is inter standard links to IEC 61249-6-3:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 61249-6-3:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/PAS 61249-6-3 ®

Edition 1.0 2011-09

PUBLICLY AVAILABLE

SPECIFICATION

Specification for finished fabric woven from “E”glass for printed boards

IEC/PAS 61249-6-3:2011(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/PAS 61249-6-3 ®

Edition 1.0 2011-09

PUBLICLY AVAILABLE

SPECIFICATION

Specification for finished fabric woven from “E”glass for printed boards

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

T

ICS 31.180 ISBN 978-2-88912-699-6

– 2 – PAS 61249-6-3 © IEC:2011(E)

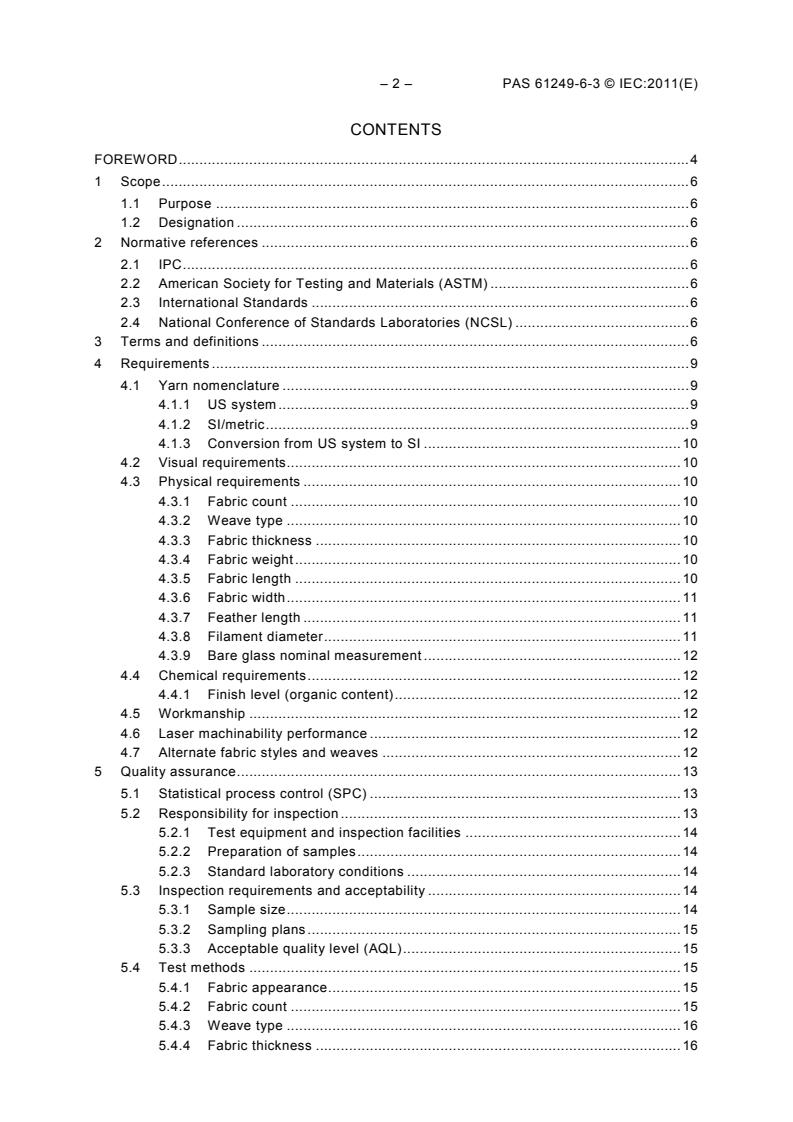

CONTENTS

FOREWORD . 4

1 Scope . 6

1.1 Purpose . 6

1.2 Designation . 6

2 Normative references . 6

2.1 IPC . 6

2.2 American Society for Testing and Materials (ASTM) . 6

2.3 International Standards . 6

2.4 National Conference of Standards Laboratories (NCSL) . 6

3 Terms and definitions . 6

4 Requirements . 9

4.1 Yarn nomenclature . 9

4.1.1 US system . 9

4.1.2 SI/metric . 9

4.1.3 Conversion from US system to SI . 10

4.2 Visual requirements . 10

4.3 Physical requirements . 10

4.3.1 Fabric count . 10

4.3.2 Weave type . 10

4.3.3 Fabric thickness . 10

4.3.4 Fabric weight . 10

4.3.5 Fabric length . 10

4.3.6 Fabric width . 11

4.3.7 Feather length . 11

4.3.8 Filament diameter . 11

4.3.9 Bare glass nominal measurement . 12

4.4 Chemical requirements . 12

4.4.1 Finish level (organic content) . 12

4.5 Workmanship . 12

4.6 Laser machinability performance . 12

4.7 Alternate fabric styles and weaves . 12

5 Quality assurance . 13

5.1 Statistical process control (SPC) . 13

5.2 Responsibility for inspection . 13

5.2.1 Test equipment and inspection facilities . 14

5.2.2 Preparation of samples . 14

5.2.3 Standard laboratory conditions . 14

5.3 Inspection requirements and acceptability . 14

5.3.1 Sample size . 14

5.3.2 Sampling plans . 15

5.3.3 Acceptable quality level (AQL) . 15

5.4 Test methods . 15

5.4.1 Fabric appearance . 15

5.4.2 Fabric count . 15

5.4.3 Weave type . 16

5.4.4 Fabric thickness . 16

PAS 61249-6-3 © IEC:2011(E) – 3 –

5.4.5 Weight per unit area . 16

5.4.6 Fabric length . 17

5.4.7 Fabric width . 17

5.4.8 Finish level (organic content) . 17

5.4.9 Bias or bowed filling . 17

6 Preparation for delivery . 18

6.1 Preservation and packaging . 18

6.2 Packing . 18

6.3 Marking . 18

7 Notes . 18

7.1 Ordering data . 18

7.2 New Styles . 18

Annex A . 19

Annex B Finished Fabric Glass Styles . 21

Table 1 – Classification of Defects . 11

Table 2 – Filament Diameter Designations . 11

Table 3 – Bare Glass Nominal Measurements . 12

Table 4 – Sample Size per Number of Rolls Shipped . 14

Table 5 – Sample size per yardage of individual roll shipped and the acceptable

quality level . 14

Table A.1 – Cross Reference Between IPC-4412, Standards Called Out by IPC-4412,

and ISO Documents . 19

Table A.2 – Cross Reference Between IPC-4412, ASTM and ISO Documents. 19

Table B.1 – Finished Fabric Glass Styles in SI Units . 21

Table B.2 – Finished Fabric Glass Styles for US System . 24

– 4 – PAS 61249-6-3 © IEC:2011(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SPECIFICATION FOR FINISHED FABRIC

WOVEN FROM “E”GLASS FOR PRINTED BOARDS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC-PAS 61249-6-3 has been processed by IEC technical committee 91: Electronics

assembly technology.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document

Draft PAS Report on voting

91/956/PAS 91/961/RVD

Following publication of this PAS the technical committee or subcommittee concerned may

transform it into an International Standard.

PAS 61249-6-3 © IEC:2011(E) – 5 –

This PAS shall remain valid for an initial maximum period of 3 years starting from the

publication date. The validity may be extended for a single period up to a maximum of

3 years, at the end of which it shall be published as another type of normative document, or

shall be withdrawn.

– 6 – PAS 61249-6-3 © IEC:2011(E)

SPECIFICATION FOR FINISHED FABRIC

WOVEN FROM “E”GLASS FOR PRINTED BOARDS

1 Scope

This specification covers finished fabrics woven from :E” glass electrical grade glass fiber

yarns that are intended as a reinforcing material in laminated plastics for electrical and

electronic use. All fabrics covered by this specification are plain weave.

1.1 Purpose

This specification determines the nomenclature, definitions, general and chemical

requirements for the glass, and physical requirements for finished woven glass fiber fabrics.

1.2 Designation

Appendix II of this standard provides a style designator for each finished fabric glass style,

with specifications on yarn, fabric count, thickness and weight in both SI and US system.

Fabrics listed in Appendix II also categorize fabrics by their current availability status.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

2.1 IPC

IPC-T-50, Terms and Definitions for Interconnecting and Packaging Electronic Circuits

IPC-9191, General Guidelines for Implementation of Statistical Process Control (SPC)

2.2 American Society for Testing and Materials (ASTM)

ASTM-D578, Standard Specification for Glass Fiber Strands

ASTM-D1776, Standard Practice for Conditioning Testing Textiles

2.3 International Standards

ISO 9001, Quality Management Systems – Requirements

2.4 National Conference of Standards Laboratories (NCSL)

NCSL Z 540-1, General Requirements for Calibration Laboratories and Measuring and Test

Equipment

3 Terms and definitions

The definition of terms shall be in accordance with IPC-T-50 and the following:

PAS 61249-6-3 © IEC:2011(E) – 7 –

3.1

AQL (Acceptable Quality Level)

maximum number of defects per hundred units that can be considered satisfactory as a

process average

3.2

bias

filling yarns are off-square to the warp ends

3.3

bow

filling yarns lie in an arc across the width of the fabric

3.4

creases

a ridge in the fabric caused by a fold or wrinkle being placed under pressure

3.5

defects

a substandard area in a fabric

3.6

major defect

a defect that is likely to result in failure, or to reduce materially the usability of the unit of

product for its intended purpose

3.7

minor defect

a defect that is not likely to reduce materially the usability of the unit of product for its

intended purpose.

3.8

defect per hundred units

3.9

E glass (electrical grade glass fiber)

E glass, which is to be used for PWB applications, is a continuous filament glass yarn with a

chemical composition by weight that is within the following limits:

B O 5 %–10 %

2 3

CaO 16 %–25 %

Al O 12 %–16 %

2 3

SiO 52 %–56 %

MgO 0 %–5 %

Na O and K O 0 %–2 %

2 2

TiO 0 %–0.8 %

Fe O 0.05 %–0.4 %

2 3

F 0 %–1.0 %

Composition is to be certified by yarn supplier as requested.

– 8 – PAS 61249-6-3 © IEC:2011(E)

3.10

end missing

a very small portion of the warp in the fabric that may have been broken in the pick-out of

waste

3.11

feather length

length of distance from last warp end to the end of the pick

3.12

fabric finish

treatment of fabric to aid in compatibility with resins

3.13

fish eye

small area of fabric which resists resin wetting and can be caused by the resin system, fabric

and treatment

3.14

leno end out

missing wrapper warp end from the edge of the fabric

3.15

lot or batch size

a collection of units produced in one continuous, uninterrupted finish run from which a sample

is drawn and inspected or tested to determine conformance with the acceptability criteria

3.16

mark

heavy or light area in fabric due to excessive or less filling yarns

3.17

heavy mark

a filling defect extending across the width of the fabric containing two picks/inch in excess of

the nominal count

3.18

light mark

a filling defect extending across the width of the fabric containing two picks/inch less than the

nominal count

3.19

pick

filling yarn running crosswise the entire width of a fabric

3.20

broken pick

a filling yarn missing from a portion of the width of the fabric

3.21

mis-picks

break in the pattern of cloth from selvage to selvage caused by a missing filling yarn

3.22

plain weave

a fabric configuration where each warp end should go over one pick and under the next, and

each pick should go over one warp end and under the next

PAS 61249-6-3 © IEC:2011(E) – 9 –

3.23

splits

an opening in the fabric resulting from either the pick or end breaking in two. This is usually

caused by the fabric folding over and creasing

3.24

tears

a large rip in the fabric usually caused by excessive tension being applied during processing.

Could be caused by weak fabric

3.25

TEX system

a system for expressing linear density of yarn or other textile strand. The unit is equivalent to

grams/kilometer.

3.26

waste

a lump or collection of yarn or filament woven into the fabric where accumulated

contamination off the loom has found its way into the fabric

3.27

waviness

cloth is woven under varying tensions preventing even placement of picks resulting in

alternating thick and thin places

4 Requirements

4.1 Yarn nomenclature

There are two systems of identifying fiber glass yarns: the US system and system

international (SI)/metric. Consider the following exmple: ECD 450 1/2 in US system or

EC5 11 1x2 in SI.

4.1.1 US system

For the ‘‘ECD’’ in ‘‘ECD 450 1/2,’’ the first letter represents the grade of glass; the second

indicates whether the yarn is continuous (“C”) or staple (“S” – fibers of a cut length), and the

third represents the filament diameter (see 3.4.8). “ECD” is then read as an “E” glass

electrical grade fiber of “C” (continuous) length and with the filament diameter of “D.” The

“450” in ECD 450 1/2 represents the linear density of the yarn in units of yards per pound

divided by 100. The 450 in ECD 450 ½ indicates that the nominal single yarn measuremet in

yards per pound is 450 x 100 = 45,000 yards per pound.

The “1/2” indicates the number of single yarns twisted together into a strand/the number of

twisted strands plied together. Thus, the “1/2” in ECD 450 1/2 indicates that one single yarn is

twisted (becomes the strand) and two twisted strands are plied together. By convention, a

“1/0” means that the yarn is a singles yarn (no or “zero” plying required).

Since this specification is for E grade glass where all yarns are continuous, the ECD 450 1/2

nomenclature can be shortened to the D 450 1/2 nomenclature.

4.1.2 SI/metric

For the “EC5” in EC5 11 1x2, the first letter represents the grade of glass; the second

indicates whether the yarn is continuous (“C”) or staple (“S” – fibers of a cut length). The

number represents the filament diameter (see 3.4.8). “EC5” is then read as an “E” glass

electrical grade fiber of “C” (continuous) length and with the nominal filament diameter of

5 µm (rounded to the nearest µm). The “11” in EC5 11 1x2 represents the TEX number of

– 10 – PAS 61249-6-3 © IEC:2011(E)

linear density. The 11 in EC5 11 1x2 indicates that the nominal single yarn measurement is

11 g/km or 90,716 m/kg.

The “1x2” indicates the number of single yarns twisted together into a strand x the number of

twisted strands plied together. Thus, the “1x2” in EC5 11 1x2 indicates that one single yarn is

twisted (becomes the strand) and two twisted strands are plied together. By convention, a

“1x0” means that the yarn is a singles yarn (no or “zero” plying required).

Since this specification is for E grade glass where all yarns are continuous, the EC5 11 1x2

nomenclature can be shortened to the 5 11 1x2 nomenclature.

4.1.3 Conversion from US system to SI

To convert from the US system to SI, the changes are:

1) The alphabetical filament diameter designation in US System to be changed to a

numerical designation (filament diameter in micrometers) in SI, e.g., “D” to be changed

to “5” {see 3.4.8).

2) The linear density indicator to be changed from a number with an unit of hundred yards

per pound in US System to a TEX number of grams per kilometer equivalent, e.g.,

“450” to be changed to “11” (see 3.4.9).

3) The “/” sign in the US System to be changed to a “x” sign in SI for the number of single

yarns twisted together into a strand and the number of twisted strands plied together.

e.g., “1/2” to be changed to “1x2.”

4.2 Visual requirements

When specified by purchase contract, fabric is examined in accordance with 4.4.1. Visual

defects shall be identified and classified per Table 1 and meet the AQL defined in 4.3.2 or

4.3.3 as specified.

4.3 Physical requirements

4.3.1 Fabric count

Fabric count shall be evaluated in accordance with 4.4.2. The nominal fabric count for each

style shall be as specified in Appendix II. For fabrics not listed, the nominal fabric count shall

be as agreed upon between user and supplier. The actual average count of warp ends or

filling picks shall be within ± 2/inch of the nominal count.

4.3.2 Weave type

Weave type shall be determined in accordance with 4.4.3. This specification only addresses

plain weave.

4.3.3 Fabric thickness

Fabric thickness shall be determined in accordance with 4.4.4. The nominal fabric thickness

for each style shall be as specified in Appendix II.

4.3.4 Fabric weight

Fabric weight shall be determined in accordance with 4.4.5. The nominal fabric weight for

each style shall be as specified in Appendix II and shall meet the tolerance listed.

4.3.5 Fabric length

Fabric length shall be determined in accordance with 4.4.6 and shall be as specified on the

purchase order. The length of the fabric shall be within ± 1 % of the value specified.

PAS 61249-6-3 © IEC:2011(E) – 11 –

4.3.6 Fabric width

Fabric width shall be determined in accordance with 4.4.7 and shall be as specified on the

purchase order. The width of the fabric shall be within -0/+13 mm [-0.000/+0.512 in] of the

value specified. If the fabric has coated and cut (C&C) edges, the width shall be -0/+5 mm

[-0.000/0.197 in] of value specified.

4.3.7 Feather length

Feather length shall not exceed 5.0 mm [0.197 in].

Table 1 – Classification of Defects

Visual Defect Description Classification

Bias or bowed filling* Pick line distortion from horizontal by more than Major

2.5 % for entire width

Baggy or wavy cloth Clearly noticeable per 4.4.1 Major

Cut or tear > 6.5 mm [0.256 in] in any direction (body only) Major

Spots, streaks, stains, foreign inclusions Clearly noticeable Major

Broken or missing ends or picks 2 or more continuous, regardless of length Major

Light marks > 6.5 mm [0.256 in] in width Major

2 picks/inch less than nominal Minor

Heavy marks Puckering clearly noticeable Major

2 picks/inch more than nominal Minor

Crease Hard embedded and folded over on self Major

Waste Clearly noticeable > 6.5 mm [0.256 in] Major

Clearly noticeable 6.5 mm [0.256 in] Minor

Weave Separation Clearly noticeable > 3.175 mm [0.125 in] Major

Leno ends out > 5 meters [5.47 yards] Major

5 meters [5.47 yards Minor

Feather length > 5 mm [0.197 in] running > 4.5 m [4.92 yards] Major

> 5 mm [0.197 in] running 4.5 m [4.92 yards] Minor

*It is important that as a target for the future the non-homogeneous bow (i.e., a bow not stretching across the width

of material) should be reduced.

4.3.8 Filament diameter

The filament diameters shall be determined in accordance with ASTM D578. The nominal

filament diameter and the range of averages for products used in electrical laminates are as

given in Table 2.

NOTE Filament diameters are to be certified by yarn supplier as requested.

Table 2 – Filament Diameter Designations

Designation Nominal Diameter Range of Averages

-5 -5

SI US System (µm) (10 in) (µm) (10 in)

4 BC 4 15.7 3.50 to 4.70 13.78 to 18.50

4.5 C 4.5 17.7 3.56 to 5.08 14.02 to 20.00

5 D 5 21.0 4.80 to 5.87 18.90 to 23.11

6 DE 6 25.6 5.84 to 7.16 22.99 to 28.19

7 E 7 28.0 6.40 to 7.82 25.20 to 30.79

9 G 9 37.0 8.46 to 10.34 33.31 to 40.709

– 12 – PAS 61249-6-3 © IEC:2011(E)

4.3.9 Bare glass nominal measurement

Bare glass nominal measurement (yardage) shall be as defined in Table 3.

4.4 Chemical requirements

4.4.1 Finish level (organic content)

The finish level of the fabric shall be determined in accordance with 4.4.8. The organic

content of the finish fabric shall be no less than 0.05 % and no more than 0.30 %, unless

otherwise agreed upon between user and supplier. See ASTM D-579 point 39 for additional

information.

4.5 Workmanship

Unless otherwise specified, the maximum allowable number of splices is one per 915 m

(1000 yd), with a minimum length between splices of 137 m (150 yd). All splices shall be

flagged and compatible with resin solvents. Splices shall not lose strength and shall withstand

coater stresses.

4.6 Laser machinability performance

Laser machinability performance is recognized as a significant fabric style attribute.

Requirements for laser machinability will be considered as a specification sheet element at

such time that a standardized test method and performance level requirements are

developed. Until then, the test method and performance level requirements shall be as agreed

upon between user and supplier.

4.7 Alternate fabric styles and weaves

For alternate fabric styles and weaves not covered by this specification, requirements shall be

as agreed upon between user and supplier.

Table 3 – Bare Glass Nominal Measurements

Yarn Nominal Length per Unit Weight

SI Nomenclature US System Nomenclature SI US System

m/kg yards/pound

4 2.20 1x0 BC 2250 1/0 453,571 225,000

4 3.31 1x0 BC 1500 1/0 302,385 150,000

4.5 2.76 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...