IEC 61189-5-504:2020

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-504: General test methods for materials and assemblies - Process ionic contamination testing (PICT)

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-504: General test methods for materials and assemblies - Process ionic contamination testing (PICT)

IEC 61189-5-504:2020 is a test method designed to determine the proportion of soluble ionic residues present upon a circuit board, electronic component or assembly. The conductivity of the solution used to dissolve the ionic residues is measured to evaluate the level of ionic residues.

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles - Partie 5-504: Méthodes d’essai générales pour les matériaux et les ensembles - Essai de contamination ionique des procédés (PICT)

L'IEC 61189-5-504:2020 est une méthode d'essai conçue pour déterminer la proportion de résidus ioniques solubles sur une carte à circuit imprimé, un composant électronique ou un ensemble. La conductivité de la solution utilisée pour dissoudre les résidus ioniques est mesurée afin d'évaluer le niveau des résidus ioniques.

General Information

- Status

- Published

- Publication Date

- 20-Apr-2020

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Apr-2020

- Completion Date

- 08-May-2020

Overview

IEC 61189-5-504:2020 is an international standard published by the International Electrotechnical Commission (IEC) that specifies process ionic contamination testing (PICT) for electrical materials, printed boards, and other interconnection structures and assemblies. As Part 5-504 within the IEC 61189 series, this document defines a general test method to determine the proportion of soluble ionic residues present on circuit boards, electronic components, or assemblies. The test involves measuring the conductivity of a solution used to dissolve ionic residues, enabling assessment of contamination levels that could impact the reliability and performance of electronic devices.

This standardized test method supports quality control and manufacturing process monitoring in electronics assembly by providing a repeatable and internationally recognized approach to evaluate ionic contamination risks.

Key Topics

- Test Purpose: Measuring soluble ionic residues on electrical assemblies to identify contamination.

- Test Principle: The ionic residues on a specimen are dissolved into a test solution whose electrical conductivity is then measured.

- Test Apparatus: Includes a test chamber, regeneration filter column, recirculating pump, and precise conductivity measurement system.

- Test Solutions: Use of deionized water combined with propan-2-ol as the solvent; includes detailed calibration procedures.

- Test Procedure: Two primary methods described-closed loop and open loop systems-with guidelines for system verification and specimen handling.

- Calibration and Verification: Ensures accuracy and repeatability by employing calibration solutions and correcting for temperature and DI water conductivity.

- Data Interpretation: Converting conductivity measurements into contamination levels, including influences of environmental factors like CO.

- Normative and Informative Annexes: Provide technical details on conductivity signals, temperature correction, and example pass/fail criteria.

Applications

IEC 61189-5-504:2020 is critical for industries and professionals engaged in:

- Printed Circuit Board (PCB) Manufacturing: Monitoring ionic contamination during and after production processes to ensure long-term reliability.

- Electronics Assembly Quality Control: Providing a reliable test to validate cleanliness of assemblies that might be prone to corrosion or electrical failures due to residual ions.

- Process Optimization: Allowing manufacturers to identify sources of contamination and refine cleaning or handling processes.

- Component and Assembly Testing: Confirming compliance with industry cleanliness standards as part of supplier qualification and incoming inspection.

- Failure Analysis: Assisting in diagnosing failures related to ionic contamination by quantifying residue levels.

The standard helps maintain product reliability in sectors like consumer electronics, automotive electronics, aerospace, telecommunication, and medical devices.

Related Standards

IEC 61189-5-504:2020 is part of the broader IEC 61189 series that defines test methods for various aspects of electrical materials and interconnection structures. Complementary standards include:

- IEC 61189-5-x parts: Covering other general test methods related to materials and assemblies.

- IPC-TR-579 (Process Ionic Contamination): Industry practices aligning with IEC methods for contamination testing.

- IPC-J-STD-001: Requirements for soldered electrical and electronic assemblies including cleanliness criteria.

- ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories, relevant for labs conducting IEC 61189 tests.

Using IEC 61189-5-504 alongside these standards supports comprehensive quality assurance and conformance to international best practices in electronics manufacturing and testing.

Keywords: IEC 61189-5-504, process ionic contamination testing, PICT, electrical materials testing, printed boards, ionic residue testing, circuit board cleanliness, conductivity measurement, electronic assembly quality, contamination test methods.

IEC 61189-5-504:2020 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-504: General test methods for materials and assemblies - Process ionic contamination testing (PICT)

Frequently Asked Questions

IEC 61189-5-504:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 5-504: General test methods for materials and assemblies - Process ionic contamination testing (PICT)". This standard covers: IEC 61189-5-504:2020 is a test method designed to determine the proportion of soluble ionic residues present upon a circuit board, electronic component or assembly. The conductivity of the solution used to dissolve the ionic residues is measured to evaluate the level of ionic residues.

IEC 61189-5-504:2020 is a test method designed to determine the proportion of soluble ionic residues present upon a circuit board, electronic component or assembly. The conductivity of the solution used to dissolve the ionic residues is measured to evaluate the level of ionic residues.

IEC 61189-5-504:2020 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-5-504:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-5-504 ®

Edition 1.0 2020-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed board and other interconnection

structures and assemblies –

Part 5-504: General test methods for materials and assemblies – Process ionic

contamination testing (PICT)

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 5-504: Méthodes d'essai générales pour les matériaux et les ensembles –

Essai de contamination ionique des procédés (PICT)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61189-5-504 ®

Edition 1.0 2020-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed board and other interconnection

structures and assemblies –

Part 5-504: General test methods for materials and assemblies – Process ionic

contamination testing (PICT)

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 5-504: Méthodes d'essai générales pour les matériaux et les ensembles –

Essai de contamination ionique des procédés (PICT)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-8111-6

– 2 – IEC 61189-5-504:2020 IEC 2020

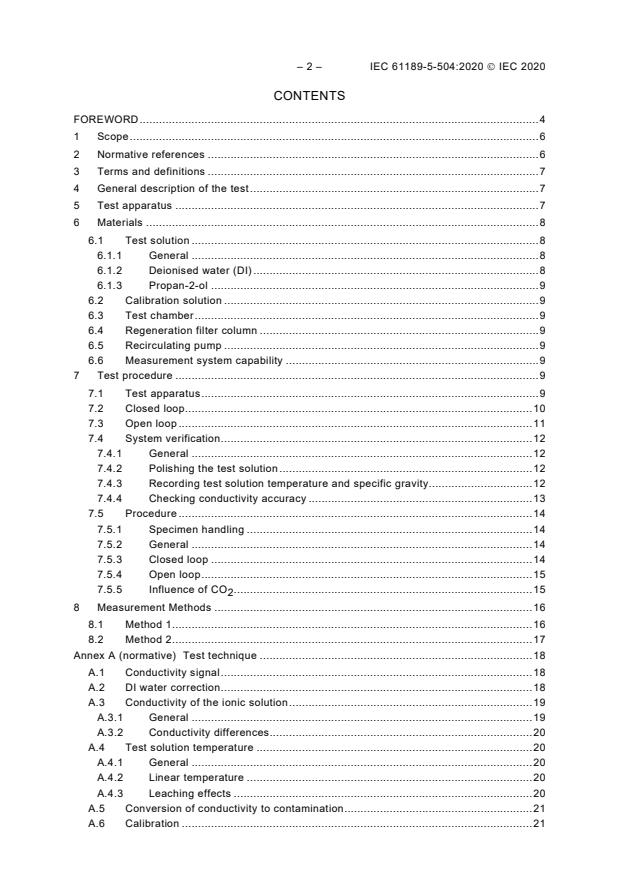

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General description of the test . 7

5 Test apparatus . 7

6 Materials . 8

6.1 Test solution . 8

6.1.1 General . 8

6.1.2 Deionised water (DI) . 8

6.1.3 Propan-2-ol . 9

6.2 Calibration solution . 9

6.3 Test chamber . 9

6.4 Regeneration filter column . 9

6.5 Recirculating pump . 9

6.6 Measurement system capability . 9

7 Test procedure . 9

7.1 Test apparatus . 9

7.2 Closed loop . 10

7.3 Open loop . 11

7.4 System verification . 12

7.4.1 General . 12

7.4.2 Polishing the test solution . 12

7.4.3 Recording test solution temperature and specific gravity. 12

7.4.4 Checking conductivity accuracy . 13

7.5 Procedure . 14

7.5.1 Specimen handling . 14

7.5.2 General . 14

7.5.3 Closed loop . 14

7.5.4 Open loop . 15

7.5.5 Influence of CO . 15

8 Measurement Methods . 16

8.1 Method 1. 16

8.2 Method 2. 17

Annex A (normative) Test technique . 18

A.1 Conductivity signal . 18

A.2 DI water correction . 18

A.3 Conductivity of the ionic solution . 19

A.3.1 General . 19

A.3.2 Conductivity differences. 20

A.4 Test solution temperature . 20

A.4.1 General . 20

A.4.2 Linear temperature . 20

A.4.3 Leaching effects . 20

A.5 Conversion of conductivity to contamination . 21

A.6 Calibration . 21

Annex B (informative) Measurement methods . 22

B.1 Method 1. 22

B.2 Method 2. 24

Bibliography . 25

Figure 1 – Typical test instrument . 8

Figure 2 – Closed-loop method in regeneration mode . 10

Figure 3 – Closed loop in test mode . 11

Figure 4 – Open loop method . 12

Figure 5 – 50 % specific gravity chart . 13

Figure 6 – 75 % specific gravity chart . 13

Figure 7 – Example of result measuring the influence of CO . 16

Figure A.1 – Conductivity against voltage curve . 18

Figure A.2 – Deionised water correction. 19

Figure B.1 – Test pass . 23

Figure B.2 – Test fail . 23

Table B.1 – Pass/Fail value method 1 worked example . 22

– 4 – IEC 61189-5-504:2020 IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-504: General test methods for materials and assemblies –

Process ionic contamination testing (PICT)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61189-5-504 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this International Standard is based on the following documents:

FDIS Report on voting

91/1639/FDIS 91/1644/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61189-5-504:2020 IEC 2020

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS

AND OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 5-504: General test methods for materials and assemblies –

Process ionic contamination testing (PICT)

1 Scope

This part of IEC 61189 is a test method designed to determine the proportion of soluble ionic

residues present upon a circuit board, electronic component or assembly. The conductivity of

the solution used to dissolve the ionic residues is measured to evaluate the level of ionic

residues.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1, Environmental testing – General and guidance

IEC 60068-2-20, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60079-7, Explosive atmospheres – Part 7: Equipment protection by increased safety "e"

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61189-5-502, Test methods for electrical materials, printed boards and other

interconnection structures and assemblies – Part 5-502: General test methods for materials

and assemblies – Surface insulation resistance (SIR) testing of assemblies

IEC 61190-1-3, Attachment materials for electronic assembly – Part 1-3: Requirements for

electronic grade solder alloys and fluxed and non-fluxed solid solder for electronic soldering

applications

IPC-TM-650 method 2.6.3.7, Surface Insulation Resistance

IPC 9202, Material and Process Characterisation / Qualification Test Protocol for Assessing

Electrochemical Performance

IPC 9203, Users Guide to IPC 9202 and the IPC-B-52 Standard Test Vehicle

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60068-1,

IEC 60068-2-20:2008, IEC 60068-2-58, IEC 60194, and IEC 61190-1-3 apply.

4 General description of the test

The test measures the conductivity of a test solution that comprises a mixture of de-ionised

water and alcohol (propan-2-ol). The test equipment shall measure the total current flow and

the result shall be expressed as an equivalence of sodium chloride (NaCl) mass per unit area

(μg/cm ≡ NaCl).

The test is used to monitor levels of ionic residues of printed circuit boards, electrical and

electronic components or printed circuit assemblies. The measured values are compared to

the user’s performance specification.

Ionic residues emanate from multiple processes during the manufacture of electronic circuit

boards, components and assemblies. Examples of ionic residues include: ammonium chloride

– citric acid – diethylamine hydrochloride – hydrochloric acid – methylamine hydrohalide –

sulphuric acid – finger salts – carboxilic acid.

When an ionic contaminant comes into contact with water, the conductance value of the water

will increase owing to the dissolution of the contaminant into the water. If the surface area and

the type of contamination are also known it is possible to express the amount of

contamination present, as a given weight per unit area of board.

This test does not measure any surface ionic materials that are not brought into solution

owing to insolubility, physical entrapment or inadequate exposure to the extracting solvent.

Additionally, non-ionic components of the soil are not measured. Not all ionic contaminants

are easily soluble in water, particularly those trapped within process residues such as solder

flux. These contaminants do however have increased solubility in alcohol.

The addition of a strongly ionized salt to deionized water will enhance its electrical

conductance to a degree that is nearly proportional to the concentration of the salt.

Conductance measurement can thus be used to indicate concentration of an ionic salt

extracted into a solution.

Amounts of ionic materials in the test solution are expressed by a conductivity factor that is

equivalent to the measured conductivity contributed by a known amount of a standard,

strongly ionized salt such as sodium chloride (NaCl). Ionic residues are therefore usually

expressed as equivalents of sodium chloride in micrograms per unit surface area (X μg/cm ≡

NaCl) of the sample under test. This does not imply that the contamination is NaCl, but that it

exhibits conductivity equivalence to that of the expressed amount of NaCl if it were in solution

instead of the ionic soil.

Measurements of ionic conductivity obtained by this test method do not differentiate between

different ionic species, they simply measure conductivity that can be related to the total

amounts of ionic materials present in the test solution.

5 Test apparatus

The test requires measurement apparatus, corresponding generally to that shown in Figure 1.

– 8 – IEC 61189-5-504:2020 IEC 2020

Key

1 test chamber

2 measurement cell

3 recirculation pump

4 control valve(s)

5 regeneration filter column

6 control valve(s)

Figure 1 – Typical test instrument

6 Materials

6.1 Test solution

6.1.1 General

Ionic soils can be dissociated in water, and the conductance measured to give an indication of

the contaminate level. The test solution however is more than just water; it contains propan-2-

ol, a non-polar liquid that aids the dissolution of the soil and, as a non-ionic hydrophilic

solvent, its presence does not influence the reading except insofar as it "dilutes" the water

bearing the dissociated ions. The test employs a test solution that comprises a specific ratio

of 50 % V/V propan-2-ol and 50 % V/V deionised water or 75 % V/V propan-2-ol and 25 % V/V

de-ionised water.

The 50:50 mixed solution is an optimal compromise between the sensitivity and the solvency

when using immersion test methods.

The 75:25 mixed solution with the higher alcohol content will reduce sensitivity but increase

solvency and vice versa with respect to water.

6.1.2 Deionised water (DI)

The detection of ionic impurities in water uses a well-established conductivity test method.

The electrical conductivity of pure water is 0,055 μS/cm at 25 °C. This value is temperature-

dependent.

−9

The addition of 1 × 10 parts of NaCl increases the conductivity of pure water from

0,055 µS/cm to 0,057 µS/cm at 25 °C [1] .

6.1.3 Propan-2-ol

Propan-2-ol, also commonly known as iso-propyl alcohol (IPA), is used to increase the

dissolution of ionic material that is inorganic in nature and trapped by an organic residue.

6.2 Calibration solution

The calibration solution contains a known value of NaCl, typically 0,1 %, and deionised water.

The calibration solution shall be marked with an expiry date and shall not be used beyond this

expiry date.

6.3 Test chamber

For optimum accuracy, the relationship between the test specimen surface area and the

volume of test solution in the test chamber should be 1cm per 10 ml [2].

When testing smaller specimens, the size criterion can be met by testing multiple specimens

simultaneously.

The test chamber should always have a lid to minimise the absorption effect of surrounding

CO and other pollutants.

6.4 Regeneration filter column

The regeneration filter column contains a pre-mixed de-ionising resin that comprises chelate,

cation and anion resins.

The test solution is pumped through the filter column where, by ionic exchange, the solution is

polished until it reaches a predetermined level of conductivity < 0,1 µS/cm.

6.5 Recirculating pump

The test solution is re-circulated by using a pump that shall comply with IEC 60079-7.

6.6 Measurement system capability

The measurement system shall have an accuracy of ±0,05 µS/cm.

The instrument should be capable of avoiding polarisation effects between electrodes such as

those that can occur when using DC test currents. Equally, error signals caused by both DC

and AC currents should be avoided to ensure optimum accuracy at low conductivity values.

7 Test procedure

7.1 Test apparatus

The test can be run using one of two variants of test apparatus:

• closed loop (preferred),

• open loop.

___________

Numbers in square brackets refer to the Bibliography.

– 10 – IEC 61189-5-504:2020 IEC 2020

7.2 Closed loop

The test solution in the test chamber is pumped via the regenerating filter, until it reaches a

predetermined level of conductivity.

The test specimen is introduced into the test chamber and the test solution begins to

recirculate, bypassing the filter (see Figure 2 and Figure 3).

Key

1 test chamber

2 measurement cell

3 recirculation pump

4 & 6 control valves

5 regeneration filter column

Figure 2 – Closed-loop method in regeneration mode

Key

1 test chamber

2 measurement cell

3 recirculation pump

4 & 6 control valves

5 regeneration filter column

Figure 3 – Closed loop in test mode

7.3 Open loop

The test solution in the test chamber is pumped via a regenerating filter comprising a mixture

of chelate, cation and anion resins, until it reaches a predetermined level of conductivity.

The test specimen is introduced into the test chamber and the test solution begins to

recirculate, through the filter (see Figure 4).

– 12 – IEC 61189-5-504:2020 IEC 2020

Key

1 test chamber

2 measurement cell

3 recirculation pump

4 & 6 control valve(s)

5 regeneration filter column

Figure 4 – Open loop method

7.4 System verification

7.4.1 General

The specific gravity and temperature of the test solution shall be checked at least once per

working shift before using the system.

7.4.2 Polishing the test solution

The test solution is re-circulated through the regeneration filter column containing mixed resin

that shall "polish" the solution to a conductivity level of 0,1 µS/cm.

7.4.3 Recording test solution temperature and specific gravity

Check and record the test solution temperature and verify the specific gravity (SG) using a

hydrometer. The SG for the 50 % V/V to 50 % V/V test solution should be at a density of 0,921

± 0,020 at 20 °C.

For other temperatures, refer to Figure 5.

Figure 5 – 50 % specific gravity chart

The SG for the 75 % V/V to 25 % V/V test solution should be at a density of 0,858 5 ± 0,020 at

20 °C .

For other temperatures refer to Figure 6.

Figure 6 – 75 % specific gravity chart

7.4.4 Checking conductivity accuracy

Cycle the instrument to the pre-test starting condition, as specified by the manufacturer, which

is typically lower than 0,05 µS/cm.

– 14 – IEC 61189-5-504:2020 IEC 2020

A calibration solution, as specified by the manufacturer, of a known concentration of NaCl,

typically 0,1 %, in de-ionised water is injected. The volume to be injected to the test cell is

provided by the manufacturer. For this calibration, other constants maybe provided, such as a

nominal board area. Run the measurement cycle for the time specified by the manufacturer,

typically 2 min, to achieve a stable reading, and log the result. Repeat this process three

times. All readings shall be within the calibrated value to ±0,05 µS/cm.

NOTE If this procedure cannot be completed, then it is likely the resin in the filter column needs to be replaced,

and that manufacturer needs to carry out a calibration.

7.5 Procedure

7.5.1 Specimen handling

All specimens should be handled with gloved hands to prevent contamination, and with

suitable precautions against electrostatic discharge. Gloves should be made of nitrile, latex,

or a similar material.

7.5.2 General

With the test solution at a conductivity level < 0,1 µS/cm, the instrument is ready to run a test.

Measure the dimensions of the specimen ensuring that proper allowance is made for the

surface area of the components. Refer to 6.3 for the relationship of test solution to surface

area.

Remove the lid and place the test specimen into the test chamber, replace the lid and initiate

the test programme.

The test time should not exceed 15 min, at the end of which the conductivity level should be

recorded.

Additional information can be found on the test technique in Annex A.

7.5.3 Closed loop

The test solution in the test chamber is pumped via the regenerating filter until it reaches a

predetermined level of conductivity. Refer to 6.4.

The test specimen is introduced into the test chamber and the test solution begins to

recirculate, bypassing the filter.

The measurement cell shall be situated in the recirculating circuit and record the conductivity

measurements.

After a maximum of 15 min, the test is terminated, and the conductivity measurements are

collected and converted.

Each equipment manufacturer may employ different formulae to express the results in

μg/cm ≡ NaCl.

Additional information can be found on the test technique in Annex A.

7.5.4 Open loop

The test solution in the test chamber is pumped via a regenerating filter until it reaches a

predetermined level of conductivity.

The test specimen is introduced into the test chamber and the test solution begins to

recirculate through the filter.

As this technique accumulates data, the test duration can need to be extended. There is a risk

of the leaching of ions from within the components, for example flame retardants used in the

printed circuit board dielectric, by the de-ionised solution on the test specimen.

The measurement cell shall be situated in the recirculating circuit and record the conductivity

measurements.

After a maximum 15 min, the test is terminated and the conductivity measurements are

collected and converted.

Each equipment manufacturer may employ different formulae to express the results in

μg/cm ≡ NaCl.

Additional information can be found on the test technique in Annex A.

7.5.5 Influence of CO

The test solution will dissolve carbon dioxide (CO ) from the atmosphere to form carbonic

acid and alter the test solution conductivity (see Figure 7). It is important to minimise the test

solution exposure to the surrounding atmosphere by keeping a lid on the test chamber (see

6.3).

If the test instrument is operated in a polluted atmosphere the potential to increase the

conductivity from atmospheric effects will be increased.

– 16 – IEC 61189-5-504:2020 IEC 2020

Test conditions and parameters

PCB Name : Low PCB Area test

PCB Reference : 50 ul

Test date and time : 28/10/2010 11:36:52

Area

: 2 500 mm

Component area : 0 mm

Solution temperature : 25,2 °C

Pass/fail

File name : D:\PROGRA∼1\XXSE∼1\Low PCB Area Test\Low PCB Area Test

Length of true measurement : 14 min 55 s

Value at cut

: 1,051 µg/cm equiv.NaCl

Def limit (Pass/fail)

: Pass :1,500 µg/cm equiv.NaCl

Mil limit (Pass/fail) : Pass :1,300 µg/cm equiv.NaCl

User limit (Pass/fail)

: Fail :1,050 µg/cm equiv.NaCl

Figure 7 – Example of result measuring the influence of CO

8 Measurement Methods

8.1 Method 1

Establish the standard deviation using an acceptable product from the production process.

NOTE A worked example of this method is in Annex B, Method 1.

8.2 Method 2

First characterise the board or assembly process by an independent quantitative method such

as SIR/ECM test method IEC 61189-5-502 or IPC-TM-650 2.3.6.7, together with IPC 9202 and

IPC 9203.

Once the assembly production process has been characterised, then a Pass/Fail value can be

determined by running this test on specimens that have provided satisfactory SIR results.

NOTE A worked example of this method is in Annex B, Method 2.

– 18 – IEC 61189-5-504:2020 IEC 2020

Annex A

(normative)

Test technique

A.1 Conductivity signal

Amplified signals are combined in a small analogue calculator circuit to produce a voltage in

relation to the temperature-compensated conductivity value. The function is non-linear, so

changes in the low end of the range will produce a significantly greater voltage change than

towards the high end, as shown in Figure A.1.

Figure A.1 – Conductivity against voltage curve

A.2 DI water correction

The DI water correction assumes that the sample is pure water contaminated with sodium

chloride (NaCl). The measured conductivity is the sum of the conductivity from water and the

conductivity from the sodium and chloride ions.

Figure A.2 shows how the high-purity water correction works.

Figure A.2 – Deionised water correction

Point 1 is the raw conductivity.

The procedure is to first subtract the conductivity of pure water at the measurement

temperature from the raw conductivity. Point 2 is the conductivity of sodium and chloride.

Next, the conductivity of sodium and chloride is converted to the value at 25 °C, point 3.

Finally, the conductivity of pure water is added to the result to give the corrected conductivity

at 25 °C, point 4.

The total conductivity is the sum of the conductivity from water and sodium chloride ions. The

large increase in the conductivity of water as temperature increases is caused primarily by the

increased ionization of water at high temperature.

A.3 Conductivity of the ionic solution

A.3.1 General

The conductive of an ionic solution is determined using the following formula:

all ions

−3

K•= 10 Λ C

∑ ° i

i

i

where

K is the conductivity (S/cm);

Λ is the molar conductivity (S-cm /mol) of ion i at infinite dilution;

i°

C is the concentration (mol/l) of ion i

i

The measured conductivity is the sum of the conductivity from water and the conductivity from

the sodium and chloride ions.

This does not imply that the contamination is NaCl, but that it exhibits a level of conductivity

equivalent to that of the expressed amount of NaCl if it were in solution instead of the ionic

soil.

– 20 – IEC 61189-5-504:2020 IEC 2020

A.3.2 Conductivity differences

The conductivity results from the test solution at a ratio of 50 % V/V propan-2-ol and 50 % V/V

deionised water will be different to those obtained from a 75 % V/V propan-2-ol and 25 % V/V

deionised water.

A.4 Test solution temperature

A.4.1 General

There have been arguments as to whether the test solution should be heated to enhance the

dissolution of the contaminants. Whilst there is no argument as to the effectiveness of

elevating the temperature, both for better temperature control and higher solubility of the

contaminants, caution shall be exercised on two counts outlined in A.4.2 and A.4.3.

A.4.2 Linear temperature

The linear temperature correction is widely used. It is based on the observation that the

conductivity of an electrolyte changes by about the same percentage for every °C change in

temperature. The equation (see [3]) is:

C

t

C =

1+ α(t− 25)

where

C is the calculated conductivity at 25 °C;

C is the conductivity at t °C;

t

α is the linear temperature coefficient expressed as a decimal fraction.

Although a single temperature coefficient can be used with reasonable accuracy over a range

of 22 °C to 29 °C, accuracy can be improved by calculating a coefficient specifically for the

sample temperature.

A.4.3 Leaching effects

As detailed in 7.5.4, this particular test technique accumulates data, generally requiring a

longer test duration than the recommended maximum of 15 min.

Because the test solution is deionised, it will aggressively seek out ions. There are many

different process steps involved in the manufacture of circuit assemblies, the majority of which

include ionic species.

There is always a risk of the leaching of ions from within the components, for example flame

retardants used in the printed circuit board dielectric, because of the de-ionised solution on

the test specimen. Many of these are required to ensure satisfactory performance of the

finished circuit assembly. It is therefore necessary to minimise the risk of a leaching effect

that will cause these ionic species to be "pulled" onto the circuit surface, even through the

laminate and solder resist.

For this reason, a maximum test duration of 15 min should be observed.

A.5 Conversion of conductivity to contamination

The formula to convert in μS to μg/cm is:

( c K v)

x=

2a+ b/ 100 / 100

((( ) ) )

where

x is the contamination (NaCl Equivalent) in µg/cm ;

c is the test solution ratio (eg. 50:50 or 75:25);

K is the conductivity in µS/cm;

𝑣𝑣 is the total tank volume in ml;

a is the surface area of the test specimen (single side) in mm ;

b is the surface area of the components in mm .

A.6 Calibration

Fill the test solution to the height specified by the equipment manufacturer and allow the

solution to settle. Place a calibrated hydrometer in the test solution until it comes to

equilibrium. Read the specific gravity at the lowest part of the solution meniscus. A solution of

75 % propan-2-ol should have a specific gravity of 0,858 5 ± 0,020 at 20 °C. A solution of 50 %

propan-2-ol should have a specific gravity of 0,921 ± 0,020 at 20 °C.

Insert a calibrated thermometer into the test solution and read the temperature to the nearest

0,5 °C.

Use the charts in Figure 5 or Figure 6 to determine if propan-2-ol or deionized water should

be added to the solution composition to bring it into compliance. If the measured specific

gravity is within the bands indicated in Figure 5 and Figure 6, no additions are necessary.

– 22 – IEC 61189-5-504:2020 IEC 2020

Annex B

(informative)

Measurement methods

B.1 Method 1

A sample of at least 10 printed circuit boards, electrical or electronic components or printed

circuit assemblies shall be taken out of the production line at the point where ionic

contamination is to be measured. Run the test and record the results. As with any statistical

measure, the more samples tested, the more accurate the Pass/Fail will be.

Once all of the tests are complete, calculate the average (mean) result by adding all the

results together and dividing by the number of results taken.

A worked example of this method can be found in Table B.1 and the text below that.

Pass/Fail = X + 3σ

Table B.1 – Pass/Fail value method 1 worked example

Board

Number 1 2 3 4 5 6 7 8 9 10

0,556 0,737 0,708 0,642 0,705 0,807 0,662 0,839 0,597 0,648

Average/mean:

(0,556 + 0,737 + 0,708 + 0,642 + 0,705 + 0,807 + 0,662 + 0,839 + 0,597 + 0,648) / 10 = 0,690

Standard deviation:

2 2 2 2 2

(0,556 – 0,690) + (0,737 – 0,690) + (0,708 – 0,690) + (0,642 – 0,690) + (0,705 – 0,690) +

2 2 2 2 2

(0,807 – 0,690) + (0,662 – 0,690) + (0,839 – 0,690) + (0,597 – 0,690) + (0,648 – 0,690) =

0,070 1

0,070 1 / (10 − 1) = 0,007 789

0,007 789 = 0,088 25

Pass/Fail = 0,690 + (0,088 25 × 3) = 0,955

Therefore, your Pass/Fail value for this production line should be 0,955 μg/cm ≡ NaCl.

Figure B.1 shows an example of a test pass, and Figure B.2 shows an example of a test fail.

Figure B.1 – Test pass

Figure B.2 – Test fail

– 24 – IEC 61189-5-504:2020 IEC 2020

B.2 Method 2

First characterize the board or assembly process using the SIR/ECM test method described in

IEC 61189-5-502, or IPC-TM-650 2.3.6.7, together with IPC 9202 and IPC 9203.

Once the assembly production process has been characterised, then a Pass/Fail value can be

determined by running this test on specimens that have completed SIR testing with

satisfactory results.

EXAMPLE SIR tested specimens yield 0,4 μg/cm ≡ NaCl using this test. The user may then impose a range

2 2

between 0,45 μg/cm ≡ NaCl and 0,35 μg/cm ≡ NaCl.

Both methods will produce a Pass/Fail value that can be used so

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...