IEC 61967-4:2021

(Main)Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method

Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method

IEC 61967-4:2021 specifies a method to measure the conducted electromagnetic emission (EME) of integrated circuits by direct radio frequency (RF) current measurement with a 1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network. These methods ensure a high degree of reproducibility and correlation of EME measurement results. This edition includes the following significant technical changes with respect to the previous edition:

- frequency range of 150 kHz to 1 GHz has been deleted from the title;

- recommended frequency range for 1 Ω method has been reduced to 30 MHz;

- Annex G with recommendations and guidelines for frequency range extension beyond 1 GHz has been added.

Circuits intégrés - Mesure des émissions électromagnétiques - Partie 4: Mesure des émissions conduites - Méthode par couplage direct 1 ohm/150 ohms

L’IEC 61967-4:2021 spécifie une méthode de mesure de l’émission électromagnétique (EME) conduite des circuits intégrés par mesure directe des courants RF avec une sonde résistive de 1 Ω et mesure des tensions RF en utilisant un réseau de couplage de 150 Ω. Ces méthodes assurent un degré élevé de reproductibilité, ainsi que la corrélation des résultats des mesures EME. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- la gamme de fréquences de 150 kHz à 1 GHz a été supprimée du titre;

- la gamme de fréquences recommandée pour la méthode à 1 Ω a été réduite à 30 MHz;

- l’Annexe G avec les recommandations et les lignes directrices pour l’extension de gamme de fréquences au-dessus de 1 GHz a été ajoutée.

General Information

- Status

- Published

- Publication Date

- 15-Mar-2021

- Technical Committee

- SC 47A - Integrated circuits

- Drafting Committee

- WG 9 - TC 47/SC 47A/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Mar-2021

- Completion Date

- 15-Apr-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61967-4:2021 - Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method - defines a standardized laboratory method to measure conducted electromagnetic emissions (EME) from integrated circuits (ICs). The standard prescribes direct RF current measurement using a 1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network to ensure reproducible, comparable results between test labs and designers.

This edition (2021) introduces notable changes:

- the phrasing "150 kHz to 1 GHz" was removed from the title;

- the recommended frequency range for the 1 Ω method has been reduced to 30 MHz;

- Annex G adds guidance for extending measurements beyond 1 GHz.

Key topics and requirements

- Measurement principles: direct RF current injection and RF voltage coupling to characterize conducted emissions at IC pins and return paths.

- Test equipment and probes: specifications and verification procedures for the 1 Ω RF current probe, RF measuring instruments and the 150 Ω impedance matching network.

- Test setup and PCB considerations: recommended printed circuit test board layouts, connector/jumper arrangements and examples of EMC main/IC test boards (Annex E).

- Test procedure and reporting: step‑by‑step measurement methods, probe calibration checks (Annex A), and required test report content to support reproducibility.

- Assessment and classification: informative annexes provide emission level classification (Annex B) and example reference levels for specific sectors (Annex C - automotive).

- Special topics: common‑mode coupling network designs for differential ICs (Annex F) and guidelines for frequency range extension above 1 GHz (Annex G).

Practical applications and users

Who will use IEC 61967-4:2021:

- IC designers and EMC engineers validating on‑die and package-level conducted emissions early in development.

- Test laboratories and compliance houses seeking standardized, repeatable procedures for IC‑level EME measurements.

- Automotive semiconductor suppliers and system integrators using the standard’s reference levels and test board examples.

- R&D teams investigating sources of conducted disturbances and grounding/return‑path mitigation.

Benefits:

- Improved reproducibility and correlation of IC emission measurements across labs.

- Clear guidance for selecting probes, coupling networks and PCB layouts to reduce measurement variability.

- Practical annexes that accelerate adoption for automotive and high‑speed differential interfaces.

Related standards

- IEC 61000‑4‑6 (referenced matching network concepts) and other IEC IC/EMC measurement standards can be used in conjunction with IEC 61967‑4:2021 for broader immunity and emission testing programs.

Keywords: IEC 61967-4:2021, integrated circuits, conducted emissions, electromagnetic emissions, 1 ohm probe, 150 ohm coupling, RF current measurement, EMC testing, probe calibration, high-frequency extension.

REDLINE IEC 61967-4:2021 - Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method Released:3/16/2021 Isbn:9782832295908

IEC 61967-4:2021 - Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method

Frequently Asked Questions

IEC 61967-4:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Integrated circuits - Measurement of electromagnetic emissions - Part 4: Measurement of conducted emissions - 1 ohm/150 ohm direct coupling method". This standard covers: IEC 61967-4:2021 specifies a method to measure the conducted electromagnetic emission (EME) of integrated circuits by direct radio frequency (RF) current measurement with a 1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network. These methods ensure a high degree of reproducibility and correlation of EME measurement results. This edition includes the following significant technical changes with respect to the previous edition: - frequency range of 150 kHz to 1 GHz has been deleted from the title; - recommended frequency range for 1 Ω method has been reduced to 30 MHz; - Annex G with recommendations and guidelines for frequency range extension beyond 1 GHz has been added.

IEC 61967-4:2021 specifies a method to measure the conducted electromagnetic emission (EME) of integrated circuits by direct radio frequency (RF) current measurement with a 1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network. These methods ensure a high degree of reproducibility and correlation of EME measurement results. This edition includes the following significant technical changes with respect to the previous edition: - frequency range of 150 kHz to 1 GHz has been deleted from the title; - recommended frequency range for 1 Ω method has been reduced to 30 MHz; - Annex G with recommendations and guidelines for frequency range extension beyond 1 GHz has been added.

IEC 61967-4:2021 is classified under the following ICS (International Classification for Standards) categories: 31.200 - Integrated circuits. Microelectronics. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61967-4:2021 has the following relationships with other standards: It is inter standard links to IEC 61967-4:2002/COR1:2017, IEC 61967-4:2002/AMD1:2006, IEC 61967-4:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61967-4:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61967-4 ®

Edition 2.0 2021-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Integrated circuits – Measurement of electromagnetic emissions, 150 kHz to 1

Ghz –

Part 4: Measurement of conducted emissions – 1 Ω/150 Ω direct coupling

method

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61967-4 ®

Edition 2.0 2021-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Integrated circuits – Measurement of electromagnetic emissions, 150 kHz to 1

Ghz –

Part 4: Measurement of conducted emissions – 1 Ω/150 Ω direct coupling

method

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.200 ISBN 978-2-8322-9590-8

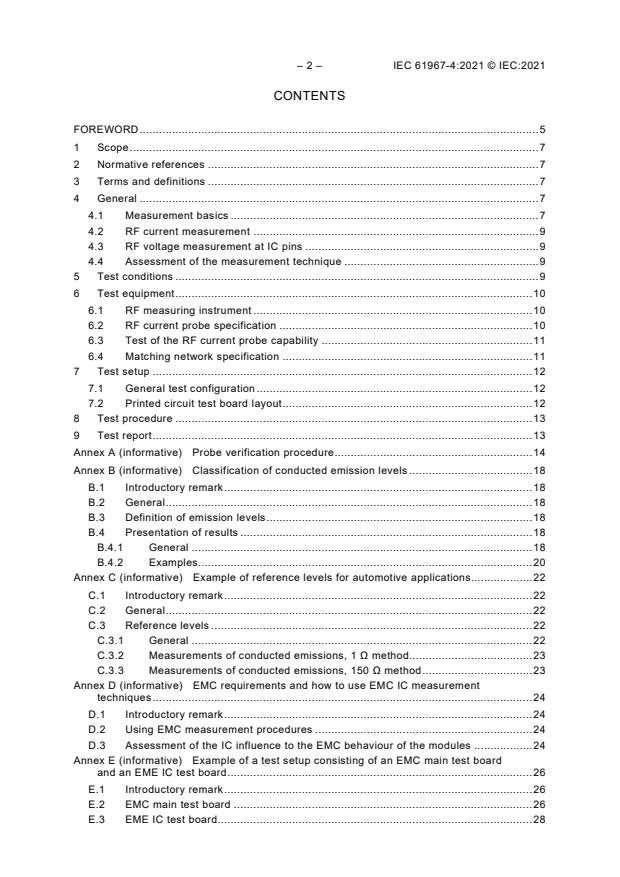

– 2 – IEC 61967-4:2021 RLV © IEC:2021

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General . 8

4.1 Measurement basics . 8

4.2 RF current measurement . 9

4.3 RF voltage measurement at IC pins . 9

4.4 Assessment of the measurement technique . 10

5 Test conditions . 10

6 Test equipment . 10

6.1 Test receiver specification RF measuring instrument . 10

6.2 RF current probe specification . 10

6.3 Test of the RF current probe capability . 11

6.4 Matching network specification . 11

7 Test setup . 12

7.1 General test configuration . 12

7.2 Printed circuit test board layout . 12

8 Test procedure . 13

9 Test report . 13

Annex A (normative informative) Probe calibration verification procedure . 15

Annex B (informative) Classification of conducted emission levels . 19

B.1 Introductory remark . 19

B.2 General . 19

B.3 Definition of emission levels . 19

B.4 Presentation of results . 19

B.4.1 General . 19

B.4.2 Examples. 21

Annex C (informative) Example of reference levels for automotive applications. 23

C.1 Introductory remark . 23

C.2 General . 23

C.3 Reference levels . 23

C.3.1 General . 23

C.3.2 Measurements of conducted emissions, 1 Ω method . 24

C.3.3 Measurements of conducted emissions, 150 Ω method . 24

Annex D (informative) EMC requirements and how to use EMC IC measurement

techniques . 25

D.1 Introduction Introductory remark . 25

D.2 Using EMC measurement procedures . 25

D.3 Assessment of the IC influence to the EMC behaviour of the modules . 25

Annex E (informative) Example of a test setup consisting of an EMC main test board

and an EME IC test board . 27

E.1 Introductory remark . 27

E.2 EMC main test board . 27

E.3 EME IC test board. 29

E.3.1 General explanation of the test board . 29

E.3.2 How to build the test system . 29

E.3.3 PCB layout and component positioning . 31

Annex F (informative) 150 Ω direct coupling networks for common mode emission

measurements of differential mode data transfer ICs and similar circuits . 33

F.1 Basic direct coupling network . 33

F.2 Example of a common-mode coupling network alternative for high speed

CAN or LVDS or RS485 or similar systems . 34

F.3 Example of a common-mode coupling network alternative for differential IC

outputs to resistive loads (e.g. airbag ignition driver) . 35

F.4 Example of a common-mode coupling network for fault tolerant CAN

systems . 35

Annex G (informative) Measurement of conducted emissions in extended frequency

range . 37

G.1 General . 37

G.2 Guidelines . 37

G.2.1 Measurement network . 37

G.2.2 Network components . 38

G.2.3 Network layout . 40

G.2.4 Network verification . 40

G.2.5 Test board . 41

G.3 Application area . 43

Bibliography . 45

Figure 1 – Example of two emitting loops returning to the IC via common ground . 8

Figure 2 – Example of IC with two ground pins, a small I/O loop and two emitting loops . 9

Figure 3 – Construction of the1 Ω RF current probe . 10

Figure 4 – Impedance matching network corresponding with IEC 61000-4-6 . 12

Figure 5 – General test configuration . 12

Figure A.1 – Test circuit . 15

Figure A.2 – Insertion loss of the 1 Ω probe . 16

Figure A.3 – Layout of the calibration verification test circuit . 17

Figure A.4 – Connection of the calibration verification test circuit . 17

Figure A.5 – Minimum decoupling limit versus frequency . 18

Figure A.6 – Example of 1 Ω probe input impedance characteristic . 18

Figure B.1 – Emission level scheme. 20

Figure B.2 – Example of the maximum emission level G8f . 21

Figure C.1 – 1 Ω method − Examples of reference levels for conducted disturbances

from semiconductors (peak detector) . 24

Figure C.2 – 150 Ω method − Examples of reference levels for conducted disturbances

from semiconductors (peak detector) . 24

Figure E.1 – EMC main test board . 28

Figure E.2 – Jumper field . 28

Figure E.3 – EME IC test board (contact areas for the spring connector pins of the

main test board) . 29

Figure E.4 – Example of an EME IC test system . 30

Figure E.5 – Component side of the EME IC test board . 31

– 4 – IEC 61967-4:2021 RLV © IEC:2021

Figure E.6 – Bottom side of the EME IC test board . 32

Figure F.1 – Basic direct coupling for common mode EMC measurements . 33

Figure F.2 – Measurement setup for the S21 measurement of the common-mode

coupling . 34

Figure F.3 – Using split load termination as coupling for measuring equipment . 34

Figure F.4 – Using split load termination as coupling for measuring equipment . 35

Figure F.5 – Example of an acceptable adaptation for special network requirements

(e.g. for fault tolerant CAN systems) . 35

Figure G.1 – Example of a 150 Ω measurement network . 38

Figure G.2 – Example of RF characteristic of network components . 39

Figure G.3 – Examples of S21 characteristic by simulation . 41

Figure G.4 – Examples of test board section . 42

Figure G.5 – Examples of unwanted cross coupling between measurement network

and traces on test PCB . 42

Figure G.6 – Examples of unwanted signal line cross coupling on S21 transfer

characteristic of RF measurement network . 42

Figure G.7 – Examples of test board with additional signal line connected to IC pin . 43

Figure G.8 – Examples of stub lines length effects on S21 transfer characteristic of

RF measurement network . 43

Table 1 – Specification of the RF current probe . 11

Table 2 – Characteristics of the impedance matching network . 12

Table B.1 – Emission levels . 22

Table D.1 – Examples in which the measurement procedure can be reduced . 25

Table D.2 – System- and module-related ambient parameters . 26

Table D.3 – Changes at the IC which influence the EMC. 26

Table G.1 – Draft selection table for conducted emission measurements at pins above

1 GHz . 44

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS,

150 kHz TO 1 GHz –

Part 4: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 61967-4:2002+AMD1:2006 CSV. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in strikethrough

red text.

– 6 – IEC 61967-4:2021 RLV © IEC:2021

IEC 61967-4 has been prepared by subcommittee 47A: Integrated circuits, of IEC technical

committee 47: Semiconductor devices. It is an International Standard.

This second edition cancels and replaces the first edition published in 2002 and

Amendment 1:2006. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) frequency range of 150 kHz to 1 GHz has been deleted from the title;

b) recommended frequency range for 1 Ω method has been reduced to 30 MHz;

c) Annex G with recommendations and guidelines for frequency range extension beyond

1 GHz has been added.

The text of this International Standard is based on the following documents:

Draft Report on voting

47A/1101/CDV 47A/1107/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 61967 series, under the general title Integrated circuits –

Measurement of electromagnetic emissions can be found on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS,

150 kHz TO 1 GHz –

Part 4: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method

1 Scope

This part of IEC 61967 specifies a method to measure the conducted electromagnetic emission

(EME) of integrated circuits by direct radio frequency (RF) current measurement with a

1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network. These

methods guarantee ensure a high degree of repeatability reproducibility and correlation of EME

measurements measurement results.

IEC 61967-1 specifies general conditions and definitions of the test methods.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61000-4-6, Electromagnetic compatibility (EMC) – Part 4-6: Testing and measurement

techniques – Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61967-1, Integrated circuits – Measurement of electromagnetic emissions, 150 kHz to

1 GHz – Part 1: General conditions and definitions

CISPR 16-1-1, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1-1: Radio disturbance and immunity measuring apparatus – Measuring

apparatus

CISPR 16-1-2, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1-2: Radio disturbance and immunity measuring apparatus – Ancillary

equipment – Conducted disturbances

CISPR 16-1-3, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1-3: Radio disturbance and immunity measuring apparatus – Ancillary

equipment – Disturbance power

CISPR 16-1-4, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1-4: Radio disturbance and immunity measuring apparatus – Ancillary

equipment – Radiated disturbances

CISPR 16-1-5, Specification for radio disturbance and immunity measuring apparatus and

methods – Part 1-5: Radio disturbance and immunity measuring apparatus – Antenna

calibration test sites for 30 MHz to 1 000 MHz

3 Terms and definitions

For the purposes of this document, the terms and definitions of IEC 61967-1 apply.

– 8 – IEC 61967-4:2021 RLV © IEC:2021

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General

4.1 Measurement basics

The maximum tolerated emission level from an integrated circuit (IC) depends on the permitted

maximum emission level of the electronic system, which includes the IC, and also on the

immunity level of other parts of the electronic system itself (so called inherent EMC). The value

of this emission level is dependent on system and application specific (ambient) parameters.

To characterise ICs, i.e. to provide typical EME values for a data sheet, a simple measurement

procedure and non-resonant measurement setup are required to guarantee a high degree of

repeatability reproducibility. Subclause 4.1 describes the basis of this test procedure.

Figure 1 – Example of two emitting loops returning to the IC via common ground

The emission of an IC is generated by sufficiently fast changes of voltages and currents inside

the IC. These changes drive RF currents inside and outside the IC. The RF currents cause

conducted EME, which is mainly distributed via the IC pins conductor loops in the printed circuit

board (PCB) and the cabling. These loops are regarded as the emitting loop antennas. In

comparison to the dimension of these loops, the loops in the internal IC structure are considered

to be small.

The RF currents that accompany ICs action are different in amplitude, phase and spectral

content. Any RF current has its own loop that returns to the IC. All loops return mostly via the

ground or supply connection back to the IC. In Figure 1, this is shown for two loops returning

via ground. Loop 1 represents the supply wiring harness for the IC while loop 2 represents the

routing of an output signal. The common return path via ground is a suitable location to measure

the conducted EME as the measurement of the common RF sum current of the ground pin. This

test is named the “RF current measurement”.

If the IC under test has only one ground pin and all other pins are suspected to contribute

essentially to the EME, then the RF sum current is measured between the ground pin of the IC

under test and the ground (see i + i in Figure 1).

1 2

Figure 2 – Example of IC with two ground pins,

a small I/O loop and two emitting loops

If the IC under test has more than one ground pin or some of the pins are not suspected to

contribute much to the whole EME, then the IC under test gets its own ground plane as shown

in Figure 2. This ground plane is named “IC ground”. It is kept separately from the other ground,

that is named “RF-shield and peripheral ground”. The RF current is measured between the IC

ground and the peripheral ground.

ICs are often used in different configurations based on the application. For instance, a

microcontroller could be used as a single chip controller, with the I/O ports directly connected

to the external cabling system. In order to understand the influence of a single I/O pin on the

emission level of the IC, an additional measurement procedure, using the same equipment, is

provided. This measurement is named “single pin RF voltage measurement at IC pins” (see

also 4.3). In addition to the RF sum current measurement, the RF current measurement of a

single supply pin may can be of interest in the analysis of an IC. This can also be attained with

application of the RF current measurement probe. For example, the RF current probe can be

applied to any of the multiple ground or supply pins in order to quantify the contribution of the

measured pin to the whole emission.

4.2 RF current measurement

In the test procedure, this measurement shall be made by measuring the voltage across the

1 Ω resistance of a RF current probe using a test measurement receiver. The measurement

shall be made at the location shown in Figure 1 and Figure 2. The construction of the RF current

probe is specified in 6.2. The RF voltage level measured by the receiver is the voltage resulting

from all of RF currents returning to the IC through the probe impedance. The voltage

measurement can be converted to current by dividing the voltage by the probe impedance, if

the probe impedance is determined for the applicable frequency range e.g. in a verification

report.

NOTE 1 The probe impedance can be frequency dependant, caused by stray inductances of the probe, and thus

the usable frequency range can be limited.

NOTE 2 The probe impedance causes, depending on the IC current consumption, a voltage drop that can affect the

proper operation of the IC and limit the application of this method.

4.3 RF voltage measurement at IC pins

This measurement is used to identify the contribution of a single pin or a group of pins to the

EME of the IC under test. This measurement is only applied to those pins of the IC under test

that are intended to be connected directly to long (longer than 10 cm) PCB traces or wiring

harnesses (e.g. I/O, supply). These pins are loaded by a typical antenna common mode

impedance of 150 Ω, as specified in IEC 61000-4-6. In order to connect the test measurement

receiver, that has an input-impedance of 50 Ω, the load has to be built as an impedance

matching network. This matching network is defined in 6.4.

Other I/O-pins of an IC may be loaded as specified in the general part of IEC 61967-1.

– 10 – IEC 61967-4:2021 RLV © IEC:2021

4.4 Assessment of the measurement technique

The above techniques have the following properties:

– high measurement reproducibility, because few parameters influence the result;

– capability to compare different IC configurations (e.g. packages);

– single pin EME measurements of the various I/O pins are dependent on their importance for

the emission in a specific application;

– assessment of the EME contribution of the IC using current sum measurement;

– linear transfer function with constant frequency response as the measurement is made using

resistive impedance;

– simple calibration verification of the measurement impedance using insertion loss

measurement;

– measurement is also possible at very low frequencies.

With these characteristics, it is possible to measure the EME of ICs with a high degree of

reproducibility and therefore this technique offers a good method for comparison.

Annex D gives an example of how the measurement techniques may can be used for the

assessment of ICs.

5 Test conditions

All test conditions needed required in this document are specified in IEC 61967-1.

6 Test equipment

6.1 Test receiver specification RF measuring instrument

The measurement equipment has to shall fulfil the requirements described in IEC 61967-1.

6.2 RF current probe specification

Figure 3 shows the basic construction of the 1 Ω RF current probe.

Figure 3 – Construction of the 1 Ω RF current probe

Table 1 presents a detailed specification of the RF current probe.

To prevent the measurement equipment from being damaged by DC voltage, the use of a DC

block is recommended. This shall have an attenuation of <0,5 dB at the lowest frequency to be

measured.

___________

To prevent the measurement equipment from being damaged by DC voltage, the use of a DC block is

recommended. This shall have an attenuation of <0,5 dB at the lowest frequency to be measured.

Table 1 – Specification of the RF current probe

Frequency range DC – 1 GHz

DC to 30 MHz

The applicable frequency range of the used probe shall be

evaluated e.g. in a S-parameter measurement and

documented in the test report.

Current probes available on the market have proved to be

usable e.g. only up to 30 MHz. Therefore bandwidth and

impedance over frequency of the used probe shall be verified

and documented in a diagram. The same applies to on-board

probes with SMD components.

In future, for enhanced RF probes, the usable frequency range

may change.

a)

Measurement resistor

RF resistor (low inductance) 1 Ω (±1 %).

The measurement resistor can also consist of resistors in

parallel, which increases the maximum permissible current

through the probe (e.g. 2 Ω//2 Ω) and reduce the stray

inductance.

Matching resistor 49 Ω (±1 %)

Maximum current < 0,5 A

Output impedance Z

40 Ω to 60 Ω

o

Insertion loss in calibration verification circuit 34 dB ± 2 dB

Decoupling in calibration verification circuit See Figure A.1 and Figure A.5.

Cable connection

Flexible, double shielded coaxial cable with 50 Ω ± 2 Ω line

impedance. The RF connector shall be mounted with low

reflection. The insertion loss includes the cable and the probe.

Changes to the cable length will result in additional attenuation

to be considered with the measurement results.

Construction Coaxial probe or comparable construction, which can be

connected to a 4 mm coaxial socket. The measurement

resistor shall be as close as possible to the probe tip. It shall

be built in such a way that no mechanical damage is possible.

The connection of the probe cable shall be coaxial; the probe

tips should be replaceable, but nevertheless firmly connected

to the cable.

a)

The series impedance caused by the parasitic inductance should be lower than the resistor in the used

measurement range.

6.3 Test of the RF current probe capability

The current probe shall be tested for qualification and calibration functionally verified in a test

circuit shown and described in detail in Annex A.

6.4 Matching network specification

Based on IEC 61000-4-6, a cabling network can be represented in most cases by an antenna

with an impedance of about 150 Ω. In order to get accurate measurement results over the full

frequency range, a termination network of 150 145 Ω ± 20 Ω shall be used. Usual measurement

equipment provides an input impedance of 50 Ω so that the matching network shall match the

signal line impedance to the equipment impedance. The circuitry is shown in Figure 4, and the

characteristics of the impedance matching network used are shown in Table 2. Additional

information of matching networks for differential pin measurements are provided in Annex F

and recommendations.

– 12 – IEC 61967-4:2021 RLV © IEC:2021

Figure 4 – Impedance matching network corresponding with IEC 61000-4-6

Table 2 – Characteristics of the impedance matching network

Frequency range B 150 kHz – 1 GHz

f

Input impedance with 50 Ω termination Z 145 Ω ± 20 Ω

i

0,258 6 (−11,75 dB ± 2 dB)

Insertion loss within a 50 Ω system

Voltage ratio V / V 0,173 8 (−15,20 dB ± 2 dB)

out in

7 Test setup

7.1 General test configuration

The test set-up shall be in accordance with figure 5. A general test configuration is shown in

Figure 5. This general test configuration can be built up in the form of a special test

configuration (an example is described in Clause E.2) or in any other configuration, e.g. also in

a real application.

Figure 5 – General test configuration

7.2 Printed circuit test board layout

In order to obtain a high degree of repeatability of measurements reproducibility of

measurement results and be able to make a valid comparison between different printed circuit

test boards, the following guidance is given.

The test board should be built using PCB material of epoxy type (thickness 0,6 mm to 3 mm,

dielectric constant about 4,7). The top side and the bottom side are covered with a minimal

35 µm copper layer.

The bottom layer should be used as ground plane.

If peripheral ground and IC ground are used for the 1 Ω method, these two grounds are isolated

by an isolation gap. This isolation gap should be between 0,5 mm and 0,6 mm. If needed, the

IC ground shall be located underneath the DUT. The maximum size of this area should not

exceed the size of the package minimum footprint by more than 3 mm on each side.

To obtain the necessary accuracy for higher frequencies, parasitic coupling capacitance

between IC ground and peripheral ground shall be controlled. This parasitic coupling

capacitance between IC ground and peripheral ground shall be lower than 30 pF.

The IC ground is solely connected to the peripheral ground via the 1 Ω probe. A socket for the

In case of external RF current probe, a socket should be used. The shield of the RF current

probe tip should be connected to the RF peripheral ground by the socket, while the IC ground

or the IC ground pin is connected to the current probe tip. The connection between the IC

ground and the probe tip shall be as short as possible. In any case, the trace length shall not

exceed 15 mm. The trace should be connected to the IC ground at the shortest distance to the

centre point of the DUT.

If the above-mentioned directives guidelines are not applicable, the transfer characteristic of

modified design shall be determined and documented in the test report.

The DUT and all components needed to operate the DUT should be mounted onto the top side

of the test board. As much wiring as possible should be routed in the top layer. The device

under test DUT should be placed in the centre of the PCB, while the needed matching networks

should be placed around this centre. The wiring between the IC pins and the matching network

should be designed to have a line impedance of 150 Ω. In case the 150 Ω line impedance is

difficult to implement, the line must shall be of the maximum reasonable impedance but short

enough, in order to comply with the requirements of Table 2.

The wiring of the outputs of the matching networks should be designed to have a line impedance

of 50 Ω. An example of a PCB layout can be found in Annex E.

The supply shall be connected with a single wire directly to the capacitor C5. C5 could be a

surface mount device, of electrolytic type and having a value of at least 10 µF. The capacitor

C5 shall be positioned near the probe socket.

The test board may have any rectangular or circular shape.

Additional information and guidelines for extended frequency applications are described in

Annex G.

8 Test procedure

The requirements for the test procedure are described in IEC 61967-1.

9 Test report

The requirements for the test report are described in IEC 61967-1.

Emission measurement results may be presented using classification or reference levels. An

example of a classification scheme for emission levels is presented in Annex B. In addition,

– 14 – IEC 61967-4:2021 RLV © IEC:2021

Annex C shows how this classification scheme may be applied to set up reference levels for

ICs used in the automotive industry.

Annex A

(normative informative)

Probe calibration verification procedure

The test circuit shown in Figure A.1 is recommended for the probe calibration verification. It

consists of a PCB laid out using microstrip techniques (see Figure A.3). The PCB has an input

port to which the RF generator is connected. The RF current probe to be calibrated verified is

connected to the output port. The RF current probe output is connected to a test receiver (see

Figure A.4). This calibration verification procedure measures the isolation provided by the test

circuit in a 50 Ω system (see also CISPR 16-1-2 [1] ) and the insertion loss of the RF current

probe.

Two separate measurements are required recommended. The first measurement is performed

with the test circuit configured as shown in Figure A.1, circuit diagram A. Note that clamp A is

not inserted. While sweeping the RF generator over the required frequency range, measure the

voltage appearing at the output of the RF current probe.

Figure A.1 – Test circuit

The second measurement is performed identically to the first one but with clamp A installed to

shunt the RF generator to the probe input as shown in Figure A.1, circuit diagram B. This

measurement results in the RF current probe insertion loss which indicates its sensitivity.

Figure A.2 shows a result of such a measurement.

___________

Numbers in square brackets refer to the Bibliography.

– 16 – IEC 61967-4:2021 RLV © IEC:2021

Figure A.2 – Insertion loss of the 1 Ω probe

The calculated difference of both measurements is called the “decoupling”. The decoupling shall

should be above the limit shown in Figure A.5. The decoupling is equal to the measurement

dynamics in relation to the signal source. The decoupling does include the quality

characteristics, the sensitivity and the shielding of the probe.

Dimensions in millimetres

Key

1 coupling area

2 reference ground

Figure A.3 – Layout of the calibration verification test circuit

Figure A.4 – Connection of the calibration verification test circuit

– 18 – IEC 61967-4:2021 RLV © IEC:2021

Figure A.5 – Minimum decoupling limit versus frequency

In order to evaluate the performance and the applicable frequency range of the used 1 Ω probe,

it is recommended to characterize the probe input impedance characteristic. This can be done

with a scattering parameter measurement using a vector network analyser. For the

measurements, the vector network analyser should be calibrated including all connectors, cable

and traces to exclude all setup parasites from the result. An example of a 1 Ω probe input

impedance characteristic is shown in Figure A.6.

Figure A.6 – Example of 1 Ω probe input impedance characteristic

Annex B

(informative)

Classification of conducted emission levels

B.1 Introductory remark

The purpose of this Annex B is to provide a method of classifying the conducted emissions

levels of integrated circuits by application of the test conditions described in this specification.

B.2 General

This annex is not intended to specify or imply conducted emissions limits for ICs. However, by

careful application and agreement between manufacturer and user, it is possible to develop a

device specification that specifies the maximum conducted EME allowable for a specific

integrated circuit in a specific application when tested in accordance with the procedures in this

...

IEC 61967-4 ®

Edition 2.0 2021-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Integrated circuits – Measurement of electromagnetic emissions –

Part 4: Measurement of conducted emissions – 1 Ω/150 Ω direct coupling

method

Circuits intégrés – Mesure des émissions électromagnétiques –

Partie 4: Mesure des émissions conduites – Méthode par couplage direct

1 Ω/150 Ω

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61967-4 ®

Edition 2.0 2021-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Integrated circuits – Measurement of electromagnetic emissions –

Part 4: Measurement of conducted emissions – 1 Ω/150 Ω direct coupling

method

Circuits intégrés – Mesure des émissions électromagnétiques –

Partie 4: Mesure des émissions conduites – Méthode par couplage direct

1 Ω/150 Ω

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.200 ISBN 978-2-8322-9568-7

– 2 – IEC 61967-4:2021 © IEC:2021

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General . 7

4.1 Measurement basics . 7

4.2 RF current measurement . 9

4.3 RF voltage measurement at IC pins . 9

4.4 Assessment of the measurement technique . 9

5 Test conditions . 9

6 Test equipment . 10

6.1 RF measuring instrument . 10

6.2 RF current probe specification . 10

6.3 Test of the RF current probe capability . 11

6.4 Matching network specification . 11

7 Test setup . 12

7.1 General test configuration . 12

7.2 Printed circuit test board layout . 12

8 Test procedure . 13

9 Test report . 13

Annex A (informative) Probe verification procedure . 14

Annex B (informative) Classification of conducted emission levels . 18

B.1 Introductory remark . 18

B.2 General . 18

B.3 Definition of emission levels . 18

B.4 Presentation of results . 18

B.4.1 General . 18

B.4.2 Examples. 20

Annex C (informative) Example of reference levels for automotive applications. 22

C.1 Introductory remark . 22

C.2 General . 22

C.3 Reference levels . 22

C.3.1 General . 22

C.3.2 Measurements of conducted emissions, 1 Ω method . 23

C.3.3 Measurements of conducted emissions, 150 Ω method . 23

Annex D (informative) EMC requirements and how to use EMC IC measurement

techniques . 24

D.1 Introductory remark . 24

D.2 Using EMC measurement procedures . 24

D.3 Assessment of the IC influence to the EMC behaviour of the modules . 24

Annex E (informative) Example of a test setup consisting of an EMC main test board

and an EME IC test board . 26

E.1 Introductory remark . 26

E.2 EMC main test board . 26

E.3 EME IC test board. 28

E.3.1 General explanation of the test board . 28

E.3.2 How to build the test system . 28

E.3.3 PCB layout and component positioning . 30

Annex F (informative) 150 Ω direct coupling networks for common mode emission

measurements of differential mode data transfer ICs and similar circuits . 32

F.1 Basic direct coupling network . 32

F.2 Example of a common-mode coupling network alternative for LVDS or

RS485 or similar systems . 33

F.3 Example of a common-mode coupling network alternative for differential IC

outputs to resistive loads (e.g. airbag ignition driver) . 34

F.4 Example of a common-mode coupling network for CAN systems . 34

Annex G (informative) Measurement of conducted emissions in extended frequency

range . 35

G.1 General . 35

G.2 Guidelines . 35

G.2.1 Measurement network . 35

G.2.2 Network components . 36

G.2.3 Network layout . 38

G.2.4 Network verification . 38

G.2.5 Test board . 39

G.3 Application area . 41

Bibliography . 43

Figure 1 – Example of two emitting loops returning to the IC via common ground . 8

Figure 2 – Example of IC with two ground pins, a small I/O loop and two emitting loops . 8

Figure 3 – Construction of the 1 Ω RF current probe . 10

Figure 4 – Impedance matching network corresponding with IEC 61000-4-6 . 12

Figure 5 – General test configuration . 12

Figure A.1 – Test circuit . 14

Figure A.2 – Insertion loss of the 1 Ω probe . 14

Figure A.3 – Layout of the verification test circuit . 15

Figure A.4 – Connection of the verification test circuit . 16

Figure A.5 – Minimum decoupling limit versus frequency . 16

Figure A.6 – Example of 1 Ω probe input impedance characteristic . 17

Figure B.1 – Emission level scheme. 19

Figure B.2 – Example of the maximum emission level G8f . 20

Figure C.1 – 1 Ω method − Examples of reference levels for conducted disturbances

from semiconductors (peak detector) . 23

Figure C.2 – 150 Ω method − Examples of reference levels for conducted disturbances

from semiconductors (peak detector) . 23

Figure E.1 – EMC main test board . 27

Figure E.2 – Jumper field . 27

Figure E.3 – EME IC test board (contact areas for the spring connector pins of the

main test board) . 28

Figure E.4 – Example of an EME IC test system . 29

Figure E.5 – Component side of the EME IC test board . 30

Figure E.6 – Bottom side of the EME IC test board . 31

– 4 – IEC 61967-4:2021 © IEC:2021

Figure F.1 – Basic direct coupling for common mode EMC measurements . 32

Figure F.2 – Measurement setup for the S21 measurement of the common-mode

coupling . 33

Figure F.3 – Using split load termination as coupling for measuring equipment . 33

Figure F.4 – Using split load termination as coupling for measuring equipment . 34

Figure F.5 – Example of an acceptable adaptation for special network requirements

(e.g. for CAN systems) . 34

Figure G.1 – Example of a 150 Ω measurement network . 36

Figure G.2 – Example of RF characteristic of network components . 37

Figure G.3 – Examples of S21 characteristic by simulation . 39

Figure G.4 – Examples of test board section . 40

Figure G.5 – Examples of unwanted cross coupling between measurement network

and traces on test PCB . 40

Figure G.6 – Examples of unwanted signal line cross coupling on S21 transfer

characteristic of RF measurement network . 40

Figure G.7 – Examples of test board with additional signal line connected to IC pin . 41

Figure G.8 – Examples of stub lines length effects on S21 transfer characteristic of

RF measurement network . 41

Table 1 – Specification of the RF current probe . 11

Table 2 – Characteristics of the impedance matching network . 12

Table B.1 – Emission levels . 21

Table D.1 – Examples in which the measurement procedure can be reduced . 24

Table D.2 – System- and module-related ambient parameters . 25

Table D.3 – Changes at the IC which influence the EMC. 25

Table G.1 – Draft selection table for conducted emission measurements at pins above

1 GHz . 42

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS –

Part 4: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61967-4 has been prepared by subcommittee 47A: Integrated circuits, of IEC technical

committee 47: Semiconductor devices. It is an International Standard.

This second edition cancels and replaces the first edition published in 2002 and

Amendment 1:2006. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) frequency range of 150 kHz to 1 GHz has been deleted from the title;

b) recommended frequency range for 1 Ω method has been reduced to 30 MHz;

c) Annex G with recommendations and guidelines for frequency range extension beyond

1 GHz has been added.

– 6 – IEC 61967-4:2021 © IEC:2021

The text of this International Standard is based on the following documents:

Draft Report on voting

47A/1101/CDV 47A/1107/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 61967 series, under the general title Integrated circuits –

Measurement of electromagnetic emissions can be found on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTEGRATED CIRCUITS –

MEASUREMENT OF ELECTROMAGNETIC EMISSIONS –

Part 4: Measurement of conducted emissions –

1 Ω/150 Ω direct coupling method

1 Scope

This part of IEC 61967 specifies a method to measure the conducted electromagnetic emission

(EME) of integrated circuits by direct radio frequency (RF) current measurement with a

1 Ω resistive probe and RF voltage measurement using a 150 Ω coupling network. These

methods ensure a high degree of reproducibility and correlation of EME measurement results.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61000-4-6, Electromagnetic compatibility (EMC) – Part 4-6: Testing and measurement

techniques – Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61967-1, Integrated circuits – Measurement of electromagnetic emissions – Part 1: General

conditions and definitions

3 Terms and definitions

For the purposes of this document, the terms and definitions of IEC 61967-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General

4.1 Measurement basics

The maximum tolerated emission level from an integrated circuit (IC) depends on the permitted

maximum emission level of the electronic system, which includes the IC, and also on the

immunity level of other parts of the electronic system itself (so called inherent EMC). The value

of this emission level is dependent on system and application specific (ambient) parameters.

To characterise ICs, i.e. to provide typical EME values for a data sheet, a simple measurement

procedure and non-resonant measurement setup are required to guarantee a high degree of

reproducibility. Subclause 4.1 describes the basis of this test procedure.

– 8 – IEC 61967-4:2021 © IEC:2021

Figure 1 – Example of two emitting loops returning to the IC via common ground

The emission of an IC is generated by sufficiently fast changes of voltages and currents inside

the IC. These changes drive RF currents inside and outside the IC. The RF currents cause

conducted EME, which is mainly distributed via the IC pins conductor loops in the printed circuit

board (PCB) and the cabling. These loops are regarded as the emitting loop antennas. In

comparison to the dimension of these loops, the loops in the internal IC structure are considered

to be small.

The RF currents that accompany ICs action are different in amplitude, phase and spectral

content. Any RF current has its own loop that returns to the IC. All loops return mostly via the

ground or supply connection back to the IC. In Figure 1, this is shown for two loops returning

via ground. Loop 1 represents the supply wiring harness for the IC while loop 2 represents the

routing of an output signal. The common return path via ground is a suitable location to measure

the conducted EME as the measurement of the common RF sum current of the ground pin. This

test is named the “RF current measurement”.

If the IC under test has only one ground pin and all other pins are suspected to contribute

essentially to the EME, then the RF sum current is measured between the ground pin of the IC

under test and the ground (see i + i in Figure 1).

1 2

Figure 2 – Example of IC with two ground pins,

a small I/O loop and two emitting loops

If the IC under test has more than one ground pin or some of the pins are not suspected to

contribute much to the whole EME, then the IC under test gets its own ground plane as shown

in Figure 2. This ground plane is named “IC ground”. It is kept separately from the other ground,

that is named “RF-shield and peripheral ground”. The RF current is measured between the IC

ground and the peripheral ground.

ICs are often used in different configurations based on the application. For instance, a

microcontroller could be used as a single chip controller, with the I/O ports directly connected

to the external cabling system. In order to understand the influence of a single I/O pin on the

emission level of the IC, an additional measurement procedure, using the same equipment, is

provided. This measurement is named “single pin RF voltage measurement at IC pins” (see

also 4.3). In addition to the RF sum current measurement, the RF current measurement of a

single supply pin can be of interest in the analysis of an IC. This can also be attained with

application of the RF current measurement probe. For example, the RF current probe can be

applied to any of the multiple ground or supply pins in order to quantify the contribution of the

measured pin to the whole emission.

4.2 RF current measurement

In the test procedure, this measurement shall be made by measuring the voltage across the

1 Ω resistance of a RF current probe using a measurement receiver. The measurement shall

be made at the location shown in Figure 1 and Figure 2. The construction of the RF current

probe is specified in 6.2. The RF voltage level measured by the receiver is the voltage resulting

from all of RF currents returning to the IC through the probe impedance. The voltage

measurement can be converted to current by dividing the voltage by the probe impedance, if

the probe impedance is determined for the applicable frequency range e.g. in a verification

report.

NOTE 1 The probe impedance can be frequency dependant, caused by stray inductances of the probe, and thus

the usable frequency range can be limited.

NOTE 2 The probe impedance causes, depending on the IC current consumption, a voltage drop that can affect the

proper operation of the IC and limit the application of this method.

4.3 RF voltage measurement at IC pins

This measurement is used to identify the contribution of a single pin or a group of pins to the

EME of the IC under test. This measurement is only applied to those pins of the IC under test

that are intended to be connected directly to long (longer than 10 cm) PCB traces or wiring

harnesses (e.g. I/O, supply). These pins are loaded by a typical common mode impedance of

150 Ω, as specified in IEC 61000-4-6. In order to connect the measurement receiver, that has

an input-impedance of 50 Ω, the load has to be built as an impedance matching network. This

matching network is defined in 6.4.

Other I/O-pins of an IC may be loaded as specified in the general part of IEC 61967-1.

4.4 Assessment of the measurement technique

The above techniques have the following properties:

– high measurement reproducibility, because few parameters influence the result;

– capability to compare different IC configurations (e.g. packages);

– single pin EME measurements of the various I/O pins are dependent on their importance for

the emission in a specific application;

– assessment of the EME contribution of the IC using current sum measurement;

– simple verification of the measurement impedance using insertion loss measurement;

– measurement is also possible at very low frequencies.

With these characteristics, it is possible to measure the EME of ICs with a high degree of

reproducibility and therefore this technique offers a good method for comparison.

Annex D gives an example of how the measurement techniques can be used for the assessment

of ICs.

5 Test conditions

All test conditions required in this document are specified in IEC 61967-1.

– 10 – IEC 61967-4:2021 © IEC:2021

6 Test equipment

6.1 RF measuring instrument

The measurement equipment shall fulfil the requirements described in IEC 61967-1.

6.2 RF current probe specification

Figure 3 shows the basic construction of the 1 Ω RF current probe.

Figure 3 – Construction of the 1 Ω RF current probe

Table 1 presents a detailed specification of the RF current probe.

To prevent the measurement equipment from being damaged by DC voltage, the use of a DC

block is recommended. This shall have an attenuation of <0,5 dB at the lowest frequency to be

measured.

Table 1 – Specification of the RF current probe

Frequency range DC to 30 MHz

The applicable frequency range of the used probe shall be

evaluated e.g. in a S-parameter measurement and

documented in the test report.

Current probes available on the market have proved to be

usable e.g. only up to 30 MHz. Therefore bandwidth and

impedance over frequency of the used probe shall be verified

and documented in a diagram. The same applies to on-board

probes with SMD components.

In future, for enhanced RF probes, the usable frequency range

may change.

a)

Measurement resistor

RF resistor (low inductance) 1 Ω (±1 %).

The measurement resistor can also consist of resistors in

parallel, which increases the maximum permissible current

through the probe (e.g. 2 Ω//2 Ω) and reduce the stray

inductance.

Matching resistor 49 Ω (±1 %)

Maximum current < 0,5 A

Output impedance Z

40 Ω to 60 Ω

o

Insertion loss in verification circuit 34 dB ± 2 dB

Decoupling in verification circuit See Figure A.1 and Figure A.5.

Cable connection Flexible, double shielded coaxial cable with 50 Ω ± 2 Ω line

impedance. The RF connector shall be mounted with low

reflection. The insertion loss includes the cable and the probe.

Changes to the cable length will result in additional attenuation

to be considered with the measurement results.

Construction Coaxial probe or comparable construction, which can be

connected to a 4 mm coaxial socket. The measurement

resistor shall be as close as possible to the probe tip. It shall

be built in such a way that no mechanical damage is possible.

The connection of the probe cable shall be coaxial; the probe

tips should be replaceable, but nevertheless firmly connected

to the cable.

a)

The series impedance caused by the parasitic inductance should be lower than the resistor in the used

measurement range.

6.3 Test of the RF current probe capability

The current probe shall be functionally verified in a test circuit shown and described in detail in

Annex A.

6.4 Matching network specification

Based on IEC 61000-4-6, a cabling network can be represented in most cases by an antenna

with an impedance of about 150 Ω. In order to get accurate measurement results over the full

frequency range, a termination network of 145 Ω ± 20 Ω shall be used. Usual measurement

equipment provides an input impedance of 50 Ω so that the matching network shall match the

signal line impedance to the equipment impedance. The circuitry is shown in Figure 4, and the

characteristics of the impedance matching network used are shown in Table 2. Additional

information of matching networks for differential pin measurements are provided in Annex F

and recommendations.

– 12 – IEC 61967-4:2021 © IEC:2021

Figure 4 – Impedance matching network corresponding with IEC 61000-4-6

Table 2 – Characteristics of the impedance matching network

Frequency range 150 kHz – 1 GHz

Input impedance with 50 Ω termination Z 145 Ω ± 20 Ω

i

0,258 6 (−11,75 dB ± 2 dB)

Insertion loss within a 50 Ω system

Voltage ratio V / V 0,173 8 (−15,20 dB ± 2 dB)

out in

7 Test setup

7.1 General test configuration

A general test configuration is shown in Figure 5. This general test configuration can be built

up in the form of a special test configuration (an example is described in Clause E.2) or in any

other configuration, e.g. also in a real application.

Figure 5 – General test configuration

7.2 Printed circuit test board layout

In order to obtain a high degree of reproducibility of measurement results and be able to make

a valid comparison between different printed circuit test boards, the following guidance is given.

The test board should be built using PCB material of epoxy type (thickness 0,6 mm to 3 mm,

dielectric constant about 4,7). The top side and the bottom side are covered with a minimal

35 µm copper layer.

The bottom layer should be used as ground plane.

If peripheral ground and IC ground are used for the 1 Ω method, these two grounds are isolated

by an isolation gap. This isolation gap should be between 0,5 mm and 0,6 mm. If needed, the

IC ground shall be located underneath the DUT. The maximum size of this area should not

exceed the size of the package minimum footprint by more than 3 mm on each side.

To obtain the necessary accuracy for higher frequencies, parasitic coupling capacitance

between IC ground and peripheral ground shall be controlled. This parasitic coupling

capacitance between IC ground and peripheral ground shall be lower than 30 pF.

The IC ground is solely connected to the peripheral ground via the 1 Ω probe. In case of external

RF current probe, a socket should be used. The shield of the RF current probe tip should be

connected to the RF peripheral ground by the socket, while the IC ground or the IC ground pin

is connected to the current probe tip. The connection between the IC ground and the probe tip

shall be as short as possible. In any case, the trace length shall not exceed 15 mm. The trace

should be connected to the IC ground at the shortest distance to the centre point of the DUT.

If the above-mentioned guidelines are not applicable, the transfer characteristic of modified

design shall be determined and documented in the test report.

The DUT and all components needed to operate the DUT should be mounted onto the top side

of the test board. As much wiring as possible should be routed in the top layer. The DUT should

be placed in the centre of the PCB, while the needed matching networks should be placed