IEC 62047-25:2016

(Main)Semiconductor devices - Micro-electromechanical devices - Part 25: Silicon based MEMS fabrication technology - Measurement method of pull-press and shearing strength of micro bonding area

Semiconductor devices - Micro-electromechanical devices - Part 25: Silicon based MEMS fabrication technology - Measurement method of pull-press and shearing strength of micro bonding area

IEC 62047-25:2016 specifies the in-situ testing method to measure the bonding strength of micro bonding area which is fabricated by micromachining technologies used in silicon-based micro-electromechanical system (MEMS). This document is applicable to the in-situ pull-press and shearing strength measurement of the micro bonding area fabricated by microelectronic technology process and other micromachining technology.

Dispositifs à semiconducteurs - Dispositifs microélectromécaniques - Partie 25: Technologie de fabrication de MEMS à base de silicium - Méthode de mesure de la résistance à la traction-compression et au cisaillement d'une micro zone de brasure

L'IEC 62047-25:2016 spécifie la méthode d'essai in situ pour mesurer la résistance de brasure d'une microzone de brasure fabriquée par des technologies de micro-usinage utilisées dans un système microélectromécanique (MEMS) à base de silicium. Le présent document s'applique à la mesure in situ de la résistance à la traction-compression et de la résistance au cisaillement d'une microzone de brasure fabriquée par un processus microélectronique et d'autres technologies de micro-usinage.

General Information

- Status

- Published

- Publication Date

- 28-Aug-2016

- Technical Committee

- SC 47F - Micro-electromechanical systems

- Drafting Committee

- WG 1 - TC 47/SC 47F/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Aug-2016

- Completion Date

- 15-Oct-2016

Overview

IEC 62047-25:2016 is an international standard developed by the International Electrotechnical Commission (IEC) that defines the measurement methods for pull-press and shearing strength of micro bonding areas in silicon-based micro-electromechanical systems (MEMS). The standard targets semiconductor devices fabricated using micromachining technologies, specifically focusing on the in-situ testing of bonding strength in MEMS components. This ensures the mechanical reliability and durability of micro bonding areas that connect functional elements in MEMS devices.

The standard addresses challenges caused by defects, contamination, and thermal mismatch stress, which can degrade bonding strength as device scales shrink. By providing a patterned, straightforward testing approach, IEC 62047-25 eliminates the need for specialized instruments such as scanning probe microscopy or nanoindenters, making it accessible for foundries and designers to implement during fabrication.

Key Topics

Scope and Purpose

Specifies the in-situ pull-press and shearing strength measurement methods for micro bonding areas fabricated using microelectronic and micromachining technologies in silicon-based MEMS.Testing Structure Design and Fabrication Requirements

Details the design parameters for specialized testing structures integrated onto MEMS substrates to facilitate reliable strength measurements.Testing Environment Conditions

Defines environmental factors and conditions under which bond strength tests should be performed to ensure accurate and repeatable results.Pull-Press Testing Method

Describes how to impose loading force and measure the pull-press strength by applying tensile and compressive forces to the bonding area.Shearing Testing Method

Outlines the process for applying lateral forces to determine the bonding area's resistance to shearing stress.Result Processing and Interpretation

Provides guidance on analyzing measurement data for pull-press and shearing tests, including strength value calculations.Appendices with Dimensional Data

Includes comprehensive tables and figures offering dimensions for testing structures and typical tensile/compressive strength values across different bonding area sizes, from 10 µm × 10 µm up to 150 µm × 150 µm.

Applications

IEC 62047-25:2016 is critical for multiple stakeholders across the semiconductor and MEMS device development ecosystem, including:

MEMS Fabrication Foundries

Can implement the standardized testing structures directly into production wafers to enable ongoing quality assessment of bonding strength during manufacturing.Design Engineers

Access quantitative metrics on bonding integrity that inform device design decisions, enhancing reliability and lifetime of MEMS components.Quality Control and Reliability Testing Teams

Utilize this standard to conduct non-destructive, repeatable, and in-situ tests that help identify bond weaknesses caused by contamination, defects, or thermal stresses.Research & Development

Benchmark new bonding materials and techniques for MEMS packaging, ensuring compatibility and mechanical robustness.Microelectronics Manufacturing

Apply the methods as part of broader process control strategies for silicon-based microfabrication technologies, improving overall device yield.

Related Standards

IEC 62047-25:2016 is part of the IEC 62047 series on Micro-electromechanical devices and silicon-based MEMS fabrication technology. Related standards include:

- IEC 62047-1 – General requirements and test methods for MEMS devices.

- IEC 62047-xx – Other parts covering specific fabrication methods, packaging, or performance testing of semiconductor MEMS devices.

- ISO/IEC Directives – Guidelines followed in drafting and maintaining IEC standards ensuring global applicability and consistency.

- Industry-specific standards on semiconductor device manufacturing and reliability, which complement MEMS-specific testing procedures by addressing broader microfabrication process controls.

By adhering to IEC 62047-25:2016, semiconductor manufacturers and MEMS developers benefit from a robust, standardized approach to assessing micro bonding strength, enhancing product quality and enabling more reliable, high-performance MEMS technologies across various applications. Keywords: MEMS fabrication technology, silicon-based MEMS, micro bonding area, pull-press measurement, shearing strength testing, microelectromechanical devices, bond strength measurement, microfabrication process, semiconductor device reliability.

Buy Documents

IEC 62047-25:2016 - Semiconductor devices - Micro-electromechanical devices - Part 25: Silicon based MEMS fabrication technology - Measurement method of pull-press and shearing strength of micro bonding area

Frequently Asked Questions

IEC 62047-25:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Micro-electromechanical devices - Part 25: Silicon based MEMS fabrication technology - Measurement method of pull-press and shearing strength of micro bonding area". This standard covers: IEC 62047-25:2016 specifies the in-situ testing method to measure the bonding strength of micro bonding area which is fabricated by micromachining technologies used in silicon-based micro-electromechanical system (MEMS). This document is applicable to the in-situ pull-press and shearing strength measurement of the micro bonding area fabricated by microelectronic technology process and other micromachining technology.

IEC 62047-25:2016 specifies the in-situ testing method to measure the bonding strength of micro bonding area which is fabricated by micromachining technologies used in silicon-based micro-electromechanical system (MEMS). This document is applicable to the in-situ pull-press and shearing strength measurement of the micro bonding area fabricated by microelectronic technology process and other micromachining technology.

IEC 62047-25:2016 is classified under the following ICS (International Classification for Standards) categories: 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62047-25:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62047-25 ®

Edition 1.0 2016-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Micro-electromechanical devices –

Part 25: Silicon based MEMS fabrication technology – Measurement method of

pull-press and shearing strength of micro bonding area

Dispositifs à semiconducteurs – Dispositifs microélectromécaniques –

Partie 25: Technologie de fabrication de MEMS à base de silicium – Méthode de

mesure de la résistance à la traction-compression et au cisaillement d'une

micro zone de brasure

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62047-25 ®

Edition 1.0 2016-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Micro-electromechanical devices –

Part 25: Silicon based MEMS fabrication technology – Measurement method of

pull-press and shearing strength of micro bonding area

Dispositifs à semiconducteurs – Dispositifs microélectromécaniques –

Partie 25: Technologie de fabrication de MEMS à base de silicium – Méthode de

mesure de la résistance à la traction-compression et au cisaillement d'une

micro zone de brasure

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.99 ISBN 978-2-8322-3609-3

– 2 – IEC 62047-25:2016 © IEC 2016

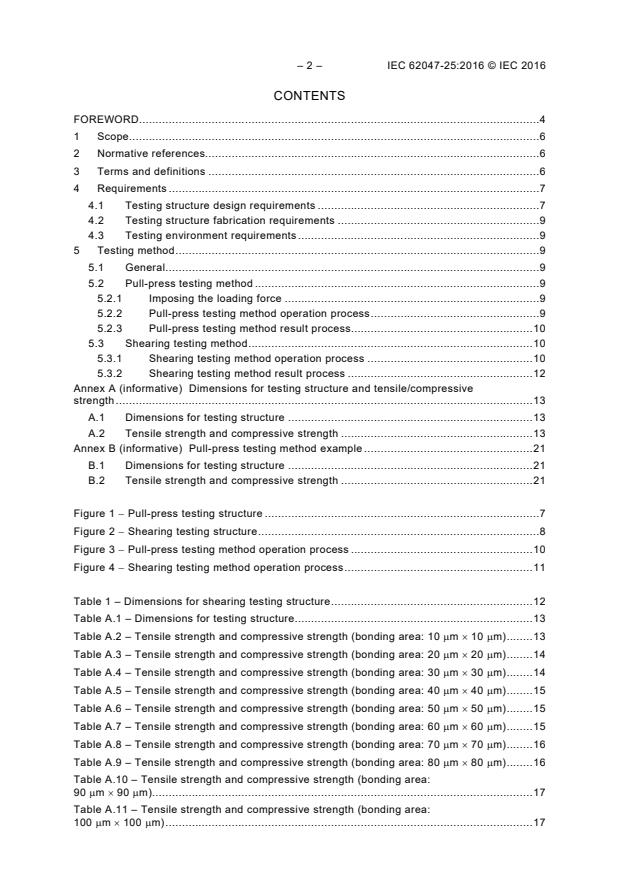

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references. 6

3 Terms and definitions . 6

4 Requirements . 7

4.1 Testing structure design requirements . 7

4.2 Testing structure fabrication requirements . 9

4.3 Testing environment requirements . 9

5 Testing method . 9

5.1 General . 9

5.2 Pull-press testing method . 9

5.2.1 Imposing the loading force . 9

5.2.2 Pull-press testing method operation process . 9

5.2.3 Pull-press testing method result process . 10

5.3 Shearing testing method . 10

5.3.1 Shearing testing method operation process . 10

5.3.2 Shearing testing method result process . 12

Annex A (informative) Dimensions for testing structure and tensile/compressive

strength . 13

A.1 Dimensions for testing structure . 13

A.2 Tensile strength and compressive strength . 13

Annex B (informative) Pull-press testing method example . 21

B.1 Dimensions for testing structure . 21

B.2 Tensile strength and compressive strength . 21

Figure 1 − Pull-press testing structure . 7

Figure 2 − Shearing testing structure . 8

Figure 3 − Pull-press testing method operation process . 10

Figure 4 − Shearing testing method operation process . 11

Table 1 – Dimensions for shearing testing structure . 12

Table A.1 – Dimensions for testing structure . 13

Table A.2 – Tensile strength and compressive strength (bonding area: 10 µm × 10 µm) . 13

Table A.3 – Tensile strength and compressive strength (bonding area: 20 µm × 20 µm) . 14

Table A.4 – Tensile strength and compressive strength (bonding area: 30 µm × 30 µm) . 14

Table A.5 – Tensile strength and compressive strength (bonding area: 40 µm × 40 µm) . 15

Table A.6 – Tensile strength and compressive strength (bonding area: 50 µm × 50 µm) . 15

Table A.7 – Tensile strength and compressive strength (bonding area: 60 µm × 60 µm) . 15

Table A.8 – Tensile strength and compressive strength (bonding area: 70 µm × 70 µm) . 16

Table A.9 – Tensile strength and compressive strength (bonding area: 80 µm × 80 µm) . 16

Table A.10 – Tensile strength and compressive strength (bonding area:

90 µm × 90 µm) . 17

Table A.11 – Tensile strength and compressive strength (bonding area:

100 µm × 100 µm) . 17

Table A.12 – Tensile strength and compressive strength (bonding area:

110 µm × 110 µm) . 18

Table A.13 – Tensile strength and compressive strength (bonding area:

120 µm × 120 µm) . 18

Table A.14 – Tensile strength and compressive strength (bonding area:

130 µm × 130 µm) . 19

Table A.15 – Tensile strength and compressive strength (bonding area:

140 µm × 140 µm) . 19

Table A.16 – Tensile strength and compressive strength (bonding area:

150 µm × 150 µm) . 20

Table B.1 – Dimensions for testing structure . 21

Table B.2 – Tensile strength and compressive strength (bonding area:

110 µm × 110 µm) . 21

– 4 – IEC 62047-25:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MICRO-ELECTROMECHANICAL DEVICES –

Part 25: Silicon based MEMS fabrication technology – Measurement

method of pull-press and shearing strength of micro bonding area

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62047-25 has been prepared by subcommittee 47F: Micro-

electromechanical systems, of IEC technical committee 47: Semiconductor devices.

The text of this standard is based on the following documents:

FDIS Report on voting

47F/249/FDIS 47F/252/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62047-25:2016 © IEC 2016

SEMICONDUCTOR DEVICES –

MICRO-ELECTROMECHANICAL DEVICES –

Part 25: Silicon based MEMS fabrication technology – Measurement

method of pull-press and shearing strength of micro bonding area

1 Scope

This part of IEC 62047 specifies the in-situ testing method to measure the bonding strength of

micro bonding area which is fabricated by micromachining technologies used in silicon-based

micro-electromechanical system (MEMS).

This document is applicable to the in-situ pull-press and shearing strength measurement of

the micro bonding area fabricated by microelectronic technology process and other

micromachining technology.

Micro anchor, fixed on the substrate through the micro bonding area, provides mechanical

support of the movable sensing/actuating functional components in MEMS devices. With the

devices scaling, the bonding strength degradation, induced by defects, contaminations and

thermal mismatch stress on bonding surface, becomes severer. This standard specifies an in-

situ testing method of the pull-press and shearing strength based on a patterned technique.

This document does not need intricate instruments (such as scanning probe microscopy and

nanoindenter) and to prepare the test specimen specially.

Since the testing structure in this standard can be implanted in device fabrication as a

standard detection pattern, this document can provide a bridge, by which the fabrication

foundry can give some quantitative reference for the designer.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 62047-1, Semiconductor devices – Micro-electromechanical devices – Part 1: Terms and

definitions

ISO 10012, Measurement management systems – Requirements for measurement processes

and measuring equipment

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62047-1 and

ISO 10012 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

anchor

silicon-glass bonding area which supports the MEMS function structure

4 Requirements

4.1 Testing structure design requirements

The schemes of testing structures are shown in Figure 1 and Figure 2.

IEC

a) The scheme of the pull-press testing structure

IEC

b) The three-view drawing of the pull-press testing structure

Key

h thickness of the testing structure arm

h height of the anchor beam in the bonding area

a side length of the bonding area

l length of the testing structure arm, this parameter should be designed with sequential values

w width of the testing structure arm

d dimension of the loading point

Figure 1 − Pull-press testing structure

– 8 – IEC 62047-25:2016 © IEC 2016

IEC

a) The scheme of the shearing testing structure

IEC

b) The three-view drawing of the shearing testing structure

Key

h thickness of the testing structure arm

h height of the anchor beam in the bonding area

a side length of the bonding area

l length of the testing structure arm

w width of the testing structure arm

d dimension of the loading point

δ resolution of the rotation ruler

Figure 2 − Shearing testing structure

The design of the testing structure should be as follows:

a) To prevent the testing structure arm from breaking earlier than the bonding area, the

strength of the arm should be designed high enough. For instance, if the arm thickness is

limited by design rule, a wider arm design is recommended.

b) The arm length of pull-press strength testing structure should be designed with sequential

values. The common difference, the length interval, should satisfy the requirement of the

testing resolution. The consumed area by the testing structure should be also taken into

consideration.

c) The design of the ruler within the shearing strength testing structure should satisfy the

resolution requirement. The ruler should be clearly monitored by the optical microscopy.

d) The testing structure should be designed to be robust enough to withstand the dimension

deviation induced by fabrication process. The roughness of the structure surface caused

by the wet or dry etching process, isotropic or anisotropic etching process should be also

taken in consideration in design work.

4.2 Testing structure fabrication requirements

Requirements for bulk silicon testing structures with micro bonding area(s) are the following:

a) The fabrication of testing structures should meet the requirements of bulk silicon

processes.

b) The testing structure material is bulk silicon, so the physical and chemical characteristics

should refer to the silicon wafer used in the practical fabrication processes.

c) It is highly recommended to use RIE process to etch the anchor of the testing structure to

ensure the anchor formation.

In case of strength testing of micro bonding area other than silicon based MEMS, similar

structures may be prepared by using different materials, and other requirements shall be

proposed.

4.3 Testing environment requirements

Testing environment requirements are the following:

a) A kind of violent air flow is prohibited during the testing operation. The testing bench

should be stabilized.

b) Environmental contaminations caused by the dusts and fragments from the fracture of the

testing structure should be taken into consideration in testing operation processes.

5 Testing method

5.1 General

During the testing operation process, the testing structure is placed on the probe station. The

deformation or fracture of the structure is monitored by microscopy and the bonding strength

can be calculated utilizing the testing structure parameters.

5.2 Pull-press testing method

5.2.1 Imposing the loading force

During the testing operation with pull-press testing method, the loading force is imposed

vertically at the loading point on the structure arm.

5.2.2 Pull-press testing method operation process

The pull-press testing method operation process is as follows:

a) During the operation process, the chip with testing structure is fixed on the probe station.

The loading force is imposed vertically at the loading point on the structure arm by the

station needle (A) until the arm is deformed to contact with the bottom surface and the

bonding area (B or C) is monitored by the microscopy, see Figure 3. The bonding strength

is defined to be higher than σ (or σ ) while the fracture occurs in the structure with arm

li,T li,C

length of l (l >l ) and does not occur in the structure with arm length of l , where σ

i+1 i i+1 i li,T

and σ are tensile strength and compressive strength respectively, namely the maximum

li,C

stress value at the bonding area when the corresponding testing structure arm deforms to

contact with the bottom surface, acquired by finite element analysis. And subscript T and

subscript C represent tensile and compressive stress respectively.

– 10 – IEC 62047-25:2016 © IEC 2016

Loading

Probe

point A

Testing structure

Compressive fracture

Compressive fracture

point B (not broken)

point B (not broken)

Probe Probe

Tensile fracture

Tensile fracture

point C (broken)

point C (not broken)

IEC

Figure 3 − Pull-press testing method operation process

b) The loading should be perpendicular to the bottom surface and the loading process should

be slow and stable. The needle and whole testing structure should be present in the field

of views under an optical microscopy. When the arm contacts with the bottom surface (or

the fracture occurs in the testing structure), the loading process should be stopped and

the needle should be raised slowly until it is separated from the testing structure.

5.2.3 Pull-press testing method result process

During the testing structure arm design process, a table, about the maximum compressive

and tensile stress value at the bonding area when every testing structure arm in the design

deforms to contact with the bottom surface, should be built. After the testing operation, the

bonding strength can be referred to the table according to the arm length with which the

anchor is broken.

In case that the stress cannot be obtained, the testing structure parameters in Annex A can

be used. And the reference stress tables are listed from Table A.2 to Table A.16.

If the arm length is not listed in the reference tables, the relative stress can be interpolated

from the table content.

If the fracture occurs in the bulk silicon structure first, the bonding strength can be known as

bigger than the bulk silicon strength.

5.3 Shearing testing method

5.3.1 Shearing testing method operation process

The shearing testing method operation process is as follows:

a) During the operation process, the chip with testing structure is fixed on the probe station.

The loading force is imposed laterally at the loading point on the structure arm by the

station needle (A) and the deformation is monitored by the microscopy, see Figure 4. The

rotation deflection can be read out from the ruler located at the end of the arm.

Loading

point A

Deflection ruler

Rotation

Testing structure

Probe

IEC

a) Before probe loading

Deflection ruler

d

Rotation

Testing structure

Probe

IEC

b) Dimension of the rotation deflection at a monitoring length by the deflection ruler

Figure 4 − Shearing testing method operation process

b) The loading should be parallel with the bottom surface and the loading process should be

slow and stable. The needle and whole testing structure should be present in the field of

views under the optical microscopy. When the fracture occurs in the testing structure or at

the bonding area, the loading process should be stopped and the needle should be

retracted slowly until it is separated with the testing structure.

c) According to various bonding areas, the recommended testing structure dimensions are

calculated in order to get a reasonable resolution and operation needle pressure, as listed

in Table 1.

– 12 – IEC 62047-25:2016 © IEC 2016

Table 1 – Dimensions for shearing testing structure

a × a (µm ) w × h (µm ) l (µm)

13 × 13 33 × 80

17 × 17 37 × 80 241

20 × 20 40 × 80 240

25 × 25 45 × 80

30 × 30 50 × 80 240

40 × 40 100 × 80 565

50 × 50 150 × 80

60 × 60 200 × 80

70 × 70 250 × 80 605

80 × 80 250 × 80

1 456

90 × 90 300 × 80

100 × 100 400 × 80 1 423

1 444

110 × 110 400 × 80

1 449

120 × 120 400 × 80

5.3.2 Shearing testing method result process

The shearing stress τ can be calculated as:

max

h w

τ = 0,14 × d

max

3 2

a l

where

h thickness of the testing structure arm

a side length of the bonding area

l length of the testing structure arm

w width of the testing structure arm

d rotation deflection

If the fracture occurs in the bulk silicon structure first, the bonding strength can be known as

bigger than the bulk silicon strength.

Annex A

(informative)

Dimensions for testing structure and tensile/compressive strength

A.1 Dimensions for testing structure

Ranges of dimensions for testing structure are described as Table A.1.

Table A.1 – Dimensions for testing structure

Dimensions in µm

l a h w h d

2 1

20 (a <= 70) 80 (a <= 70)

300 to 2 000 10 to 150 200 100

70 (a > 70) 80 (a > 70)

A.2 Tensile strength and compressive strength

Tensile strength σ and compressive strength σ are described in the following tables, from

L,T L,C

Table A.2 to Table A.16.

Table A.2 – Tensile strength and compressive strength (bonding area: 10 µm × 10 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 1 072,1 -1 135,8

850 1 008,3 -1 067,9

900 951,6 -1 007,6

950 900,7 -953,5

1 000 855,1 -905,0

1 050 813,7 -861,0

1 100 776,0 -821,0

1 150 741,6 -784,4

1 200 710,0 -750,9

1 250 680,9 -720,0

1 300 654,2 -691,7

1 350 629,3 -665,3

1 400 606,2 -640,8

– 14 – IEC 62047-25:2016 © IEC 2016

Table A.3 – Tensile strength and compressive strength (bonding area: 20 µm × 20 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 1 883,4 -1 751,9

850 1 699,4 -1 576,6

900 1 541,1 -1 426,5

950 1 403,8 -1 296,7

1 000 1 284,2 -1 184,1

1 050 1 179,4 -1 085,5

1 100 1 086,5 -998,6

1 150 1 004,5 -921,9

1 200 931,5 -853,8

1 250 866,0 -792,8

1 300 807,4 -738,3

1 350 754,4 -689,1

1 400 706,4 -644,7

Table A.4 – Tensile strength and compressive strength (bonding area: 30 µm × 30 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 1 558,3 -1 598,8

850 1 416,3 -1 496,4

900 1 296,4 -1 328,1

950 1 188,5 -1 253,9

1 000 1 096,4 -1 121,7

1 050 1 012,2 -1 066,7

1 100 939,8 -960,5

1 150 874,0 -892,8

1 200 814,9 -832,1

1 250 760,7 -800,3

1 300 712,7 -749,5

1 350 669,1 -703,4

1 400 629,4 -661,5

Table A.5 – Tensile strength and compressive strength (bonding area: 40 µm × 40 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

500 2 036,2 -2 142,1

550 1 736,4 -1 882,0

600 1 499,2 -1 569,7

650 1 306,9 -1 365,9

700 1 149,8 -1 199,7

750 1 019,3 -1 062,1

800 910,0 -947,1

850 817,4 -849,8

900 738,4 -766,9

950 670,2 -695,5

1 000 611,1 -633,7

Table A.6 – Tensile strength and compressive strength (bonding area: 50 µm × 50 µm)

σ (MPa) σ (MPa)

l (µm)

L,T L,C

500 1 241,9 -1 294,9

550 1 046,0 -1 087,1

600 893,4 -926,1

650 770,9 -797,9

700 672,6 -694,8

750 592,3 -610,3

800 525,2 -540,4

850 469,0 -481,9

900 421,0 -432,5

950 380,3 -390,2

1 000 345,2 -353,8

Table A.7 – Tensile strength and compressive strength (bonding area: 60 µm × 60 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

300 1 690,1 -1 813,2

320 1 505,5 -1 608,7

340 1 351,1 -1 438,6

360 1 219,2 -1 294,1

380 1 104,3 -1 168,7

400 1 005,9 -1 061,9

420 920,1 -969,0

440 844,3 -887,2

460 777,9 -815,8

480 719,0 -752,7

500 666,0 -696,0

– 16 – IEC 62047-25:2016 © IEC 2016

Table A.8 – Tensile strength and compressive strength (bonding area: 70 µm × 70 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

300 1 136,0 -1 206,6

320 1 008,2 -1 065,9

340 901,6 -949,4

360 811,3 -851,0

380 733,0 -766,3

400 665,9 -694,1

420 607,9 -631,8

440 556,6 -577,1

460 511,9 -529,4

480 472,3 -487,4

500 436,7 -449,8

Table A.9 – Tensile strength and compressive strength (bonding area: 80 µm × 80 µm)

σ (MPa) σ (MPa)

l (µm)

L,T L,C

800 2 547,6 -2 633,9

900 2 128,7 -2 189,6

1 000 1 804,8 -1 850,6

1 100 1 547,9 -1 585,4

1 200 1 346,3 -1 374,1

1 300 1 080,1 -1 202,3

1 400 1 043,2 -1 061,2

1 500 929,0 -943,7

1 600 831,5 -844,9

1 700 750,7 -761,0

1 800 680,3 -688,9

1 900 618,5 -626,7

2 000 566,4 -572,6

Table A.10 – Tensile strength and compressive strength (bonding area: 90 µm × 90 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 2 170,8 -2 257,1

900 1 791,2 -1 854,4

1 000 1 503,7 -1 551,3

1 100 1 280,5 -1 317,2

1 200 1 103,7 -1 132,6

1 300 961,1 -984,2

1 400 844,6 -863,4

1 500 748,1 -763,5

1 600 667,3 -680,1

1 700 598,9 -609,7

1 800 540,5 -549,7

1 900 490,3 -498,1

2 000 446,8 -453,5

Table A.11 – Tensile strength and compressive strength

(bonding area: 100 µm × 100 µm)

σ (MPa) σ (MPa)

l (µm)

L,T L,C

800 1 883,4 -1 751,9

850 1 699,4 -1 576,6

900 1 541,1 -1 426,5

950 1 403,8 -1 296,7

1 000 1 284,2 -1 184,1

1 050 1 179,4 -1 085,5

1 100 1 086,5 -998,6

1 150 1 004,5 -921,9

1 200 931,5 -853,8

1 250 866,0 -792,8

1 300 807,4 -738,3

1 350 754,4 -689,1

1 400 706,4 -644,7

– 18 – IEC 62047-25:2016 © IEC 2016

Table A.12 – Tensile strength and compressive strength

(bonding area: 110 µm × 110 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 1 411,3 -1 413,9

850 1 268,7 -1 267,7

900 1 147,4 -1 143,4

950 1 042,2 -1 036,3

1 000 950,9 -943,6

1 050 871,3 -862,8

1 100 801,0 -791,9

1 150 739,1 -729,5

1 200 684,0 -674,2

1 250 634,9 -624,9

1 300 590,8 -580,8

1 350 551,2 -541,3

1 400 515,5 -505,6

Table A.13 – Tensile strength and compressive strength

(bonding area: 120 µm × 120 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

700 1 355,1 -1 309,5

750 1 199,5 -1 154,3

800 1 069,4 -1 025,5

850 959,3 -917,1

900 865,5 -824,9

950 784,2 -745,8

1 000 714,4 -677,7

1 050 653,3 -618,5

1 100 599,8 -566,7

1 150 552,6 -521,2

1 200 510,7 -480,9

1 250 473,4 -445,2

1 300 439,9 -413,1

Table A.14 – Tensile strength and compressive strength

(bonding area: 130 µm × 130 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

600 1 636,1 -1 466,8

625 1 522,9 -1 361,1

650 1 419,7 -1 265,5

675 1 327,5 -1 180,3

700 1 244,1 -1 103,4

725 1 167,7 -1 033,4

750 1 098,6 -970,1

775 1 035,7 -912,8

800 977,7 -860,0

825 924,0 -811,4

850 875,2 -767,2

875 830,2 -726,6

900 788,5 -689,1

Table A.15 – Tensile strength and compressive strength

(bonding area: 140 µm × 140 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

600 1 340,4 -1 356,2

625 1 246,0 -1 256,6

650 1 160,9 -1 167,2

675 1 084,3 -1 087,3

700 1 014,9 -1 015,1

725 952,1 -949,7

750 894,9 -890,5

775 842,8 -836,9

800 795,1 -787,8

825 751,1 -742,8

850 710,9 -701,7

875 673,7 -663,8

900 639,3 -629,1

– 20 – IEC 62047-25:2016 © IEC 2016

Table A.16 – Tensile strength and compressive strength

(bonding area: 150 µm × 150 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

500 1 652,7 -1 538,9

525 1 515,2 -1 449,6

550 1 393,7 -1 285,5

575 1 286,8 -1 220,4

600 1 191,6 -1 125,8

625 1 106,8 -1 009,3

650 1 030,2 -966,7

675 961,6 -871,3

700 899,4 -812,6

725 843,0 -784,1

750 791,9 -734,8

775 745,3 -668,3

800 702,7 -628,6

825 663,5 -592,1

850 627,5 -577,0

875 594,4 -545,6

900 563,9 -500,5

Annex B

(informative)

Pull-press testing method example

B.1 Dimensions for testing structure

To test the bonding strength of a silicon-glass-bonding sample with 110 µm × 110 µm bonding

area, the dimension parameters are listed in Table B.1. The arm sequence is designed from

800 µm to 1 400 µm, with an interval of 50 µm.

Table B.1 – Dimensions for testing structure

Dimensions in µm

l a h w h d

2 1

800 to 1 400 10 to 150 70 200 80 100

B.2 Tensile strength and compressive strength

The testing begins with the longest arm structure. The test should be carried out as given in

5.2.1 a). If no fracture occurs, raise the needle slowly, and continue to compress the next

testing structure with shorter length.

Repeat the above operation. The bonding area does not fracture with 1 050 µm length arm but

fractures with 1 000 µm length arm. The bonding strength is 950,9 MPa referred to the data of

Table B.2.

Table B.2 – Tensile strength and compressive strength (bonding area: 110 µm × 110 µm)

l (µm) σ (MPa) σ (MPa)

L,T L,C

800 1 411,3 -1 413,9

850 1 268,7 -1 267,7

900 1 147,4 -1 143,4

950 1 042,2 -1 036,3

1 000 950,9 -943,6

1 050 871,3 -862,8

1 100 801,0 -791,9

1 150 739,1 -729,5

1 200 684,0 -674,2

1 250 634,9 -624,9

1 300 590,8 -580,8

1 350 551,2 -541,3

1 400 515,5 -505,6

– 22 – IEC 62047-25:2016 © IEC 2016

The higher resolution can be achieved when the smaller arm length interval is employed.

If the fracture occurs in the bulk silicon structure first, the bonding strength can be known as

bigger than the bulk silicon strength.

___________

– 24 – IEC 62047-25:2016 © IEC 2016

SOMMAIRE

AVANT-PROPOS . 26

1 Domaine d’application. 28

2 Références normatives . 28

3 Termes et définitions . 29

4 Exigences . 29

4.1 Exigences de conception d'une structure d'essai . 29

4.2 Exigences de fabrication d'une structure d'essai . 32

4.3 Exigences de l'environnement d'essai . 32

5 Méthode d'essais . 32

5.1 Généralités . 32

5.2 Méthode d'essai de traction-compression. 32

5.2.1 Application de la force de la charge . 32

5.2.2 Processus de fonctionnement de la méthode d'essai de traction-

compression . 32

5.2.3 Traitement des résultats de la méthode d'essai de traction-compression . 33

5.3 Méthode d'essai de cisaillement . 34

5.3.1 Processus de fonctionnement de la méthode d'essai de cisaillement . 34

5.3.2 Traitement des résultats de la méthode d'essai de cisaillement . 35

Annexe A (informative) Dimensions de la structure d'essai et résistance à la

traction/compression . 36

A.1 Dimensions de la structure d'essai . 36

A.2 Résistance à la traction et à la compression . 36

Annexe B (informative) Exemple de méthode d'essai de traction-compression . 44

B.1 Dimensions de la structure d'essai . 44

B.2 Résistance à la traction et à la compression . 44

Figure 1 – Structure d'essai traction-compression . 30

Figure 2 – Structure d'essai de cisaillement . 31

Figure 3 – Processus de fonctionnement de la méthode d'essai de traction-

compression . 33

Figure 4 – Processus de fonctionnement de la méthode d'essai de cisaillement . 34

Tableau 1 – Dimensions pour la structure d'essai de cisaillement . 35

Tableau A.1 – Dimensions de la structure d'essai . 36

Tableau A.2 – Résistance à la traction et à la compression (zone de brasure: 10 µm ×

10 µm) . 36

Tableau A.3 – Résistance à la traction et à la compression (zone de brasure: 20 µm ×

20 µm) . 37

Tableau A.4 – Résistance à la traction et à la compression (zone de brasure:

30 µm × 30 µm) . 37

Tableau A.5 – Résistance à la traction et à la compression (zone de brasure:

40 µm × 40 µm) . 38

Tableau A.6 – Résistance à la traction et à la compression (zone de brasure:

50 µm × 50 µm) . 38

Tableau A.7 – Résistance à la traction et à la compression (zone de brasure:

60 µm × 60 µm) . 38

Tableau A.8 – Résistance à la traction et à la compression (zone de brasure:

70 µm × 70 µm) . 39

Tableau A.9 – Résistance à la traction et à la compression (zone de brasure:

80 µm × 80 µm) . 39

Tableau A.10 – Résistance à la traction et à la compression (zone de brasure:

90 µm × 90 µm) . 40

Tableau A.11 – Résistance à la traction et à la compression (zone de brasure:

100 µm × 100 µm) . 40

Tableau A.12 – Résistance à la traction et à la compression (zone de brasure:

110 µm × 110 µm) . 41

Tableau A.13 – Résistance à la traction et à la com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...