IEC 61010-2-201:2024

(Main)Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-201: Particular requirements for control equipment

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-201: Particular requirements for control equipment

IEC 61010-2-201:2024 supplements or modifies the corresponding clauses in IEC 61010-1 so as to convert that publication into the IEC standard: Particular requirements for control equipment. This document is to be used in conjunction with IEC 61010-1:2010, and IEC 61010 1:2010/AMD1:2016. Where a particular subclause of IEC 61010-1 is not mentioned in this document, that subclause applies as far as is reasonable. Where this document states "addition", "modification", "replacement", or "deletion", the relevant requirement, test specification or note in IEC 61010 1 should be adapted accordingly.

This edition includes the following significant technical changes with respect to the previous edition:

a) 1.1.1: the related equipment included in the Scope has been clarified;

b) 4.3.2.101: the optical fibre module has been deleted;

c) 5.4.3: equipment installation has been clarified;

d) 6.7.1.1: revision of the figure representing insulation between separate circuits has been included;

e) 6.7.101: the subclause relating to insulation for FIELD WIRING TERMINALS of OVERVOLTAGE CATEGORY ll with a nominal voltage up to 1 000 V has been deleted;

f) 6.7.1.101: a new subclause relating to insulation for SELV/PELV CIRCUITS has been included;

g) 6.8.3: specification of voltage tester has been added;

h) 6.9.3: an additional exception relating to colour coding has been included;

i) 6.9.101: a new subclause relating to wiring for secondary circuits e.g. SELV/PELV has been included;

j) 8.2.2.101: additional requirements for glass displays have been included;

k) 8.3: the subclause relating to the drop test has been removed;

l) 9.3.2: additional requirements for material of connectors and insulating material have been included;

m) The particular requirements for non-metallic material have been clarified;

n) Clause 11: the particular requirements for protection against HAZARDS from fluid and solid foreign objects have been removed;

o) 12.4: an additional subclause relating to microwave radiation has been included;

p) 14.102: the description of switching devices has been clarified;

Exigences de securité pour appareils électriques de mesurage, de régulation et de laboratoire - Partie 2-201: Exigences particulières pour les équipements de commande

L'IEC 61010-2-201:2024 complète ou modifie les articles correspondants de l'IEC 61010-1, de façon à transformer cette publication en norme IEC: Exigences particulières pour les équipements de commande. Le présent document doit être utilisé conjointement avec l'IEC 61010-1:2010 et l'IEC 61010 1:2010/AMD1:2016. Lorsqu'un paragraphe particulier de l'IEC 61010-1 n'est pas mentionné dans le présent document, ce paragraphe s'applique pour autant que cela soit raisonnable. Lorsque le présent document mentionne "addition", "modification", "remplacement" ou "suppression", il convient d'adapter l'exigence, la spécification d'essai ou la note correspondante de l'IEC 61010 1 en conséquence.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) 1.1.1: clarification concernant les équipements inclus dans le domaine d'application;

b) 4.3.2.101: suppression du module à fibre optique;

c) 5.4.3: clarification de l'installation de l'équipement;

d) 6.7.1.1: révision de la figure représentant l'isolation entre des circuits séparés;

e) 6.7.101: suppression du paragraphe concernant l'isolation des BORNES A CABLER SUR PLACE de CATEGORIE DE SURTENSION ll avec une tension nominale maximale de 1 000 V;

f) 6.7.1.101: ajout d'un nouveau paragraphe concernant l'isolation des CIRCUITS TBTS/TBTP;

g) 6.8.3: ajout d'une spécification pour le contrôleur de tension;

h) 6.9.3: ajout d'une exception supplémentaire pour le codage des couleurs;

i) 6.9.101: ajout d'un nouveau paragraphe concernant le câblage des circuits secondaires, par exemple TBTS/TBTP;

j) 8.2.2.101: ajout d'exigences supplémentaires pour les écrans en verre;

k) 8.3: suppression du paragraphe concernant l'essai de chute;

l) 9.3.2: ajout d'exigences supplémentaires pour les matériaux des connecteurs et les matériaux isolants;

m) clarification des exigences particulières relatives aux matériaux non métalliques;

n) Article 11: suppression des exigences particulières concernant la protection contre les DANGERS des fluides et des corps solides étrangers;

o) 12.4: ajout d'un paragraphe supplémentaire concernant le rayonnement hyperfréquence;

p) 14.102: clarification concernant la description des appareils de commutation.

General Information

- Status

- Published

- Publication Date

- 23-Oct-2024

- Technical Committee

- TC 65 - Industrial-process measurement, control and automation

- Drafting Committee

- JWG 13 - TC 65/JWG 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Oct-2024

- Completion Date

- 18-Oct-2024

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61010-2-201:2024 is the latest International Electrotechnical Commission (IEC) standard specifying safety requirements for electrical equipment used in measurement, control, and laboratory environments, focusing particularly on control equipment. This third edition updates and supplements IEC 61010-1 to address specific risks associated with control equipment, ensuring protection against electrical shock, mechanical hazards, fire, radiation, and environmental factors. It is designed to be used in conjunction with IEC 61010-1:2010 and its amendment IEC 61010-1:2010/AMD1:2016.

The standard reflects significant technical changes compared to previous editions, clarifying scope, insulation requirements, installation procedures, component specifications, and additional protections against hazards such as microwave radiation. It is an essential document for manufacturers, designers, and safety professionals to ensure compliance and safe operation of control equipment in industrial and laboratory applications.

Keywords: IEC 61010-2-201, electrical equipment safety, control equipment standard, measurement and control safety, laboratory electrical equipment, electrical hazard protection

Key Topics

Scope and Application: Defines requirements supplementing IEC 61010-1 for control equipment used in measurement and laboratory settings, clarifying equipment categories and specific protections.

Electric Shock Protection: Detailed insulation requirements, including revisions on reinforced and basic insulation, protection for SELV/PELV circuits, and specifications for field wiring terminals.

Mechanical Hazards: Protection against potential injury from moving parts, with standards for panel-mounted equipment and installation criteria to prevent mechanical risks.

Fire and Heat Resistance: Standards for materials, temperature limits, and fire spread control, including updated requirements for non-metallic materials and magnesium alloy fire enclosures.

Radiation and Environmental Hazards: Includes safety measures against microwave radiation, laser sources, sonic and ultrasonic pressure, plus guidelines for protection from fluids and foreign objects.

Components and Interlocks: Specifications on connectors, insulating materials, and switching devices, alongside interlock systems to prevent unsafe operation.

Marking and Documentation: Requirements for clear labeling and comprehensive documentation to support safe use, maintenance, and risk assessment processes.

Testing Procedures: Normative tests for insulation strength, temperature endurance, mechanical stress resistance, and routine safety verifications.

Applications

IEC 61010-2-201:2024 plays a critical role in ensuring the safe design, manufacturing, installation, and operation of control equipment used in:

Industrial Automation: Protecting control panels, programmable logic controllers (PLCs), and interface equipment from electrical and mechanical hazards.

Laboratory Instruments: Safeguarding control systems in analytical and research environments where precise measurement control and user safety are paramount.

Process Control Systems: Providing guidelines for control units in chemical, pharmaceutical, and food processing plants where equipment interfacing and environment pose unique safety risks.

Instrumentation and Monitoring Devices: Ensuring that control equipment meets electrical safety standards to prevent hazards during monitoring and measurement tasks.

The standard supports risk management by detailing rigorous testing and inspection criteria, offering manufacturers a clear framework to achieve compliance and user confidence.

Related Standards

IEC 61010-1: General safety requirements for electrical equipment for measurement, control, and laboratory use. IEC 61010-2-201 serves as a supplement for control equipment specifics.

IEC 61010-1:2010 / AMD1:2016: The amendment to the general standard, providing baseline safety concepts referenced by IEC 61010-2-201.

IEC 60664-1: Insulation coordination for equipment within low-voltage systems, which complements insulation requirements in IEC 61010-2-201.

IEC 60204 Series: Safety of machinery – electrical equipment of machines, applicable to control systems in industrial machines.

ISO/IEC Guide 51: Safety aspects related to risk assessment and risk reduction, supporting the risk assessment clauses in IEC 61010-2-201.

By aligning with these and other IEC standards, IEC 61010-2-201 ensures a harmonized approach to electrical safety for control equipment, facilitating international compliance and market acceptance.

Summary: IEC 61010-2-201:2024 is a comprehensive safety standard for control equipment used in measurement, control, and laboratory applications. It builds upon the general standard IEC 61010-1 by addressing particular safety requirements including electric shock prevention, mechanical hazard protection, fire resistance, and radiation safeguards. Adhering to this standard ensures manufacturers deliver safe, reliable control equipment complying with global electrical safety norms.

Buy Documents

IEC 61010-2-201:2024 EXV - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-201: Particular requirements for control equipment/24/2024

IEC 61010-2-201:2024 - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-201: Particular requirements for control equipment Released:10/24/2024

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

IEC 61010-2-201:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-201: Particular requirements for control equipment". This standard covers: IEC 61010-2-201:2024 supplements or modifies the corresponding clauses in IEC 61010-1 so as to convert that publication into the IEC standard: Particular requirements for control equipment. This document is to be used in conjunction with IEC 61010-1:2010, and IEC 61010 1:2010/AMD1:2016. Where a particular subclause of IEC 61010-1 is not mentioned in this document, that subclause applies as far as is reasonable. Where this document states "addition", "modification", "replacement", or "deletion", the relevant requirement, test specification or note in IEC 61010 1 should be adapted accordingly. This edition includes the following significant technical changes with respect to the previous edition: a) 1.1.1: the related equipment included in the Scope has been clarified; b) 4.3.2.101: the optical fibre module has been deleted; c) 5.4.3: equipment installation has been clarified; d) 6.7.1.1: revision of the figure representing insulation between separate circuits has been included; e) 6.7.101: the subclause relating to insulation for FIELD WIRING TERMINALS of OVERVOLTAGE CATEGORY ll with a nominal voltage up to 1 000 V has been deleted; f) 6.7.1.101: a new subclause relating to insulation for SELV/PELV CIRCUITS has been included; g) 6.8.3: specification of voltage tester has been added; h) 6.9.3: an additional exception relating to colour coding has been included; i) 6.9.101: a new subclause relating to wiring for secondary circuits e.g. SELV/PELV has been included; j) 8.2.2.101: additional requirements for glass displays have been included; k) 8.3: the subclause relating to the drop test has been removed; l) 9.3.2: additional requirements for material of connectors and insulating material have been included; m) The particular requirements for non-metallic material have been clarified; n) Clause 11: the particular requirements for protection against HAZARDS from fluid and solid foreign objects have been removed; o) 12.4: an additional subclause relating to microwave radiation has been included; p) 14.102: the description of switching devices has been clarified;

IEC 61010-2-201:2024 supplements or modifies the corresponding clauses in IEC 61010-1 so as to convert that publication into the IEC standard: Particular requirements for control equipment. This document is to be used in conjunction with IEC 61010-1:2010, and IEC 61010 1:2010/AMD1:2016. Where a particular subclause of IEC 61010-1 is not mentioned in this document, that subclause applies as far as is reasonable. Where this document states "addition", "modification", "replacement", or "deletion", the relevant requirement, test specification or note in IEC 61010 1 should be adapted accordingly. This edition includes the following significant technical changes with respect to the previous edition: a) 1.1.1: the related equipment included in the Scope has been clarified; b) 4.3.2.101: the optical fibre module has been deleted; c) 5.4.3: equipment installation has been clarified; d) 6.7.1.1: revision of the figure representing insulation between separate circuits has been included; e) 6.7.101: the subclause relating to insulation for FIELD WIRING TERMINALS of OVERVOLTAGE CATEGORY ll with a nominal voltage up to 1 000 V has been deleted; f) 6.7.1.101: a new subclause relating to insulation for SELV/PELV CIRCUITS has been included; g) 6.8.3: specification of voltage tester has been added; h) 6.9.3: an additional exception relating to colour coding has been included; i) 6.9.101: a new subclause relating to wiring for secondary circuits e.g. SELV/PELV has been included; j) 8.2.2.101: additional requirements for glass displays have been included; k) 8.3: the subclause relating to the drop test has been removed; l) 9.3.2: additional requirements for material of connectors and insulating material have been included; m) The particular requirements for non-metallic material have been clarified; n) Clause 11: the particular requirements for protection against HAZARDS from fluid and solid foreign objects have been removed; o) 12.4: an additional subclause relating to microwave radiation has been included; p) 14.102: the description of switching devices has been clarified;

IEC 61010-2-201:2024 is classified under the following ICS (International Classification for Standards) categories: 17.020 - Metrology and measurement in general; 19.020 - Test conditions and procedures in general; 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61010-2-201:2024 has the following relationships with other standards: It is inter standard links to IEC 61010-2-201:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61010-2-201:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61010-2-201 ®

Edition 3.0 2024-10

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This full version of IEC 61010-2-201:2024 includes the content of the references made to

IEC 61010-1:2010+AMD1:2016 CSV

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-201: Particular requirements for control equipment

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61010-2-201 ®

Edition 3.0 2024-10

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This full version of IEC 61010-2-201:2024 includes the content of the references made to

IEC 61010-1:2010+AMD1:2016 CSV

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-201: Particular requirements for control equipment

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.020, 19.020, 25.040.40 ISBN 978-2-8322-9966-1

TC 66/Publication 61010-1 (2010), Third edition/I-SH 01

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 1: General requirements

INTERPRETATION SHEET 1

This interpretation sheet has been prepared by IEC technical committee 66: Safety of

measuring, control and laboratory equipment.

The text of this interpretation sheet is based on the following documents:

ISH Report on voting

66/497A/ISH 66/505/RVD

Full information on the voting for the approval of this interpretation sheet can be found in the

report on voting indicated in the above table.

___________

IEC 61010-1:2010 contains a requirement in 6.8.3.1 pertaining to voltage testers for type tests

as follows:

“The generator shall be able to supply a power of at least 500 VA.”

This has given rise to the following questions:

How does one interpret the requirement for voltage testers in 6.8.3.1 of IEC 61010-1:2010?

Specifically, this subclause requires that “The generator shall be able to supply a power of at

least 500 VA.” Does this requirement apply throughout the rated output range of the voltage

tester? What is meant by the word “generator”? Is the “generator” the power supply within the

voltage tester, or the voltage tester output, or something else?

Interpretation:

“A voltage tester used for type tests must be able to deliver at least 500 VA at its full-rated

output voltage. It does not necessarily need to deliver 500 VA if set for lower voltages.

For example, a voltage tester that can deliver 100 mA at any test output voltage up to 5 000 V

(and a current corresponding to 500 VA above 5 000 V) would meet the requirement.

The requirements for voltage testers used for routine (production line) tests are included in

Annex F. The requirements of 6.8.3.1 do not apply to these voltage testers.”

February 2013 ICS 19.080, 71.040.10 French text overleaf

– 2 – IEC 61010-2-201:2024 EXV © IEC 2024

CONTENTS

FOREWORD . 9

INTRODUCTION to IEC 61010-1:2010 . 12

INTRODUCTION IEC 61010-2-201:2024 . 12

1 Scope and object . 13

1.1 Scope . 13

1.2 Object . 14

1.3 Verification . 15

1.4 Environmental conditions . 15

2 Normative references . 16

3 Terms and definitions . 18

3.1 Equipment and states of equipment . 18

3.2 Parts and accessories . 19

3.3 Quantities . 20

3.4 Tests . 20

3.5 Safety terms . 20

3.6 Insulation . 22

4 Tests . 25

4.1 General . 25

4.2 Sequence of tests . 26

4.3 Reference test conditions . 26

4.4 Testing in SINGLE FAULT CONDITION . 28

5 Marking and documentation . 32

5.1 Marking . 32

5.2 Warning markings . 37

5.3 Durability of markings . 38

5.4 Documentation . 38

6 Protection against electric shock . 42

6.1 General . 42

6.2 Determination of ACCESSIBLE parts . 42

6.3 Limit values for ACCESSIBLE parts. 47

6.4 Primary means of protection . 51

6.5 Additional means of protection in case of SINGLE FAULT CONDITIONS . 51

6.6 Connections to external circuits . 59

6.7 Insulation requirements . 60

6.8 Procedure for voltage tests . 75

6.9 Constructional requirements for protection against electric shock . 78

6.10 Connection to the MAINS supply source and connections between parts of

equipment . 79

6.11 Disconnection from supply source . 82

7 Protection against mechanical HAZARDS . 82

7.1 General . 82

7.2 Sharp edges . 83

7.3 Moving parts . 83

7.4 Stability . 85

7.5 Provisions for lifting and carrying. 86

7.6 Wall mounting . 87

7.7 Expelled parts . 87

8 Resistance to mechanical stresses . 87

8.1 General . 87

8.2 ENCLOSURE rigidity tests . 89

8.3 Drop test . 91

9 Protection against the spread of fire . 92

9.1 General . 92

9.2 Eliminating or reducing the sources of ignition within the equipment . 94

9.3 Containment of fire within the equipment, should it occur . 94

9.4 Limited-energy circuit . 99

9.5 Requirements for equipment containing or using flammable liquids . 100

9.6 Overcurrent protection . 100

10 Equipment temperature limits and resistance to heat . 101

10.1 Surface temperature limits for protection against burns . 101

10.2 Temperatures of windings . 102

10.3 Other temperature measurements . 103

10.4 Conduct of temperature tests . 103

10.5 Resistance to heat . 108

11 Protection against HAZARDS from fluids and solid foreign objects . 109

11.1 General . 109

11.2 Cleaning . 110

11.3 Spillage . 110

11.4 Overflow . 110

11.5 Battery electrolyte . 111

11.6 Equipment RATED with a degree of ingress protection (IP code) . 111

11.7 Fluid pressure and leakage . 112

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 115

12.1 General . 115

12.2 Equipment producing ionizing radiation . 115

12.3 Optical radiation . 116

12.4 Microwave radiation . 117

12.5 Sonic and ultrasonic pressure . 117

12.6 Laser sources. 118

13 Protection against liberated gases and substances, explosion and implosion . 119

13.1 Poisonous and injurious gases and substances . 119

13.2 Explosion and implosion . 119

14 Components and subassemblies . 120

14.1 General . 120

14.2 Motors . 121

14.3 Overtemperature protection devices . 122

14.4 Fuse holders . 122

14.5 MAINS voltage selection devices . 122

14.6 MAINS transformers tested outside equipment . 122

14.7 Printed wiring boards. 123

14.8 Circuits used to limit TRANSIENT OVERVOLTAGES . 123

14.101 Components bridging insulation . 123

14.102 Switching devices . 124

– 4 – IEC 61010-2-201:2024 EXV © IEC 2024

15 Protection by interlocks . 127

16 HAZARDS resulting from application . 127

16.1 REASONABLY FORESEEABLE MISUSE . 127

16.2 Ergonomic aspects . 128

17 RISK assessment . 128

Annex A (normative) Measuring circuits for touch current (see 6.3) . 129

A.1 Measuring circuit for a.c. with frequencies up to 1 MHz and for d.c. 129

A.2 Measuring circuits for sinusoidal a.c. with frequencies up to 100 Hz and for

d.c. . 130

A.3 Current measuring circuit for electrical burns at high frequencies . 130

A.4 Current measuring circuit for WET LOCATION . 131

Annex B (normative) Standard test fingers (see 6.2) . 132

Annex C (normative) Measurement of CLEARANCES and CREEPAGE DISTANCES . 134

Annex D (normative) Parts between which insulation requirements are specified (see

6.4 and 6.5.3) . 138

Annex E (informative) Guideline for reduction of POLLUTION DEGREES . 141

Annex F (normative) ROUTINE TESTS . 143

F.1 General . 143

F.2 Protective earth . 143

F.3 MAINS CIRCUITS . 143

F.4 Floating circuits . 144

F.101 Supply circuits other than MAINS and floating circuits . 144

Annex G (informative) Leakage and rupture from fluids under pressure . 146

G.1 General . 146

G.2 Pressures above 2 MPa and a product pressure and volume greater than

200 kPa⋅l . 146

G.3 Pressures between 50 kPa and 2 MPa, and pressure times volume above

200 kPa⋅l . 149

G.4 Pressures below 50 kPa, or pressure times volume below 200 kPa⋅l . 149

G.5 Overpressure safety devices . 150

Annex H (normative) Qualification of conformal coatings for protection against

POLLUTION . 151

H.1 General . 151

H.2 Technical properties . 151

H.3 Qualification of coatings . 151

Annex I (informative) Line-to-neutral voltages for common MAINS supply systems . 154

Annex J (informative) RISK assessment . 156

J.1 RISK assessment procedure . 156

J.2 Achieving TOLERABLE RISK . 157

J.3 An application of RISK assessment procedures . 158

Annex K (normative) Insulation requirements not covered by 6.7 . 159

K.1 Insulation for MAINS CIRCUITS . 159

K.2 Insulation in secondary circuits . 166

K.3 Insulation in circuits not addressed in 6.7, Clause K.1 or Clause K.2 . 173

K.4 Reduction of TRANSIENT OVERVOLTAGES by the use of overvoltage limiting

devices . 179

Annex L (informative) Index of defined terms . 180

Annex AA (informative) General approach to safety for control equipment . 181

AA.1 Personnel . 181

AA.2 Operating access areas . 182

AA.3 Service access areas . 182

AA.4 Equipment types. 182

Annex BB (informative) System drawing of isolation boundaries . 184

BB.1 General . 184

BB.2 Installation environment of OPEN control equipment . 184

BB.3 Control equipment electrical safety drawing. 186

BB.4 Applying IEC 61010-2-201 to the control equipment electrical safety drawing . 187

BB.5 Conclusion . 194

Annex CC (informative) Historical techniques for secondary circuits . 195

CC.1 Secondary circuits background . 195

CC.2 Secondary circuits without RISK of electrical shock . 195

CC.3 Secondary circuits without RISK of spread of fire . 197

Annex DD (normative) Flammability test for magnesium alloy fire ENCLOSURES or flame

barriers (see 9.3.2) . 199

DD.1 General . 199

DD.2 Samples . 199

DD.3 Mounting of samples . 199

DD.4 Test flame . 199

DD.5 Test procedure . 199

Annex EE (informative) Information and documentation and correlation to their uses . 200

Annex FF (informative) Measurement of CLEARANCES and CREEPAGE DISTANCES . 202

Bibliography . 204

Figure 1 – Measurements through openings in ENCLOSURES . 44

Figure 101 – Typical INTERFACE/PORT of control equipment . 46

Figure 2 – Maximum duration of short-term ACCESSIBLE voltages in SINGLE FAULT

CONDITION (see 6.3.2 a)) . 49

Figure 3 – Capacitance level versus voltage in NORMAL CONDITION and SINGLE FAULT

CONDITION (see 6.3.1 c) and 6.3.2 c)) . 50

Figure 4 – Acceptable arrangement of protective means against electric shock . 52

Figure 5 – Examples of binding screw assemblies . 56

Figure 102 – Examples of insulation between separate circuits and between circuits

and ACCESSIBLE conductive parts . 61

Figure 6 – Distance between conductors on an interface between two layers . 67

Figure 7 – Distance between adjacent conductors along an interface of two inner

layers . 67

Figure 8 – Distance between adjacent conductors located between the same two

layers . 68

Figure 9 – Detachable MAINS supply cords and connections . 80

Figure 103 – Mechanical HAZARDS, with regard to PANEL MOUNTED EQUIPMENT . 83

Figure 10 – Impact test using a sphere . 90

Figure 11 – Flow chart to explain the requirements for protection against

the spread of fire . 93

Figure 104 – Spread of fire HAZARDS, with regard to PANEL MOUNTED EQUIPMENT . 95

Figure 12 – Baffle . 97

– 6 – IEC 61010-2-201:2024 EXV © IEC 2024

Figure 13 – Area of the bottom of an ENCLOSURE to be constructed as specified in

9.3.2 c) 1) . 98

Figure 105 – General temperature test environment . 104

Figure 106 – Vented equipment . 105

Figure 107 – Non-vented equipment . 106

Figure 108 – PANEL MOUNTED EQUIPMENT extending through the wall of the end location

ENCLOSURE . 107

Figure 14 – Ball-pressure test apparatus . 109

Figure 16 – Ratio between test pressure and maximum working pressure . 114

Figure 15 – Flow chart for conformity options 14.1 a), b), c) and d) . 121

Figure A.1 – Measuring circuit for a.c. with frequencies up to 1 MHz and for d.c. . 129

Figure A.2 – Measuring circuits for sinusoidal a.c. with frequencies up to 100 Hz and

for d.c. . 130

Figure A.3 – Current measuring circuit for electrical burns . 131

Figure A.4 – Current measuring circuit for wet contact . 131

Figure B.1 – Rigid test finger . 132

Figure B.2 – Jointed test finger . 133

Figure C.1 – Examples of methods of measuring CLEARANCES and CREEPAGE DISTANCES . 137

Figures D.1a) to d) – Protection between HAZARDOUS LIVE circuits and ACCESSIBLE

parts . 139

Figures D.1e) to h) – Protection between HAZARDOUS LIVE circuits and circuits with

ACCESSIBLE external TERMINALS . 139

Figures D.2 a) and D.2 b) – Protection between a HAZARDOUS LIVE internal circuit and

an ACCESSIBLE part which is not bonded to other ACCESSIBLE parts . 140

Figures D.2 c) and D.2 d) – Protection between a HAZARDOUS LIVE primary circuit and

circuits which have ACCESSIBLE external TERMINALS . 140

Figure D.3 – Protection of external ACCESSIBLE TERMINALS of two HAZARDOUS LIVE

circuits . 140

Figure G.1 – Conformity verification process (see G.2) . 147

Figure H.1 – Test sequence and conformity . 153

Figure J.1 – Iterative process of RISK assessment and RISK reduction . 156

Figure J.2 – RISK reduction . 157

Figure K.1 – Distance between conductors on an interface between two layers . 163

Figure K.2 – Distance between adjacent conductors along an interface of an inner

layer . 164

Figure K.3 – Distance between adjacent conductors located between the same two

layers . 165

Figure K.4 – Example of recurring peak voltage . 177

Figure AA.1 – Control equipment access and safety concerns . 181

Figure BB.1 – Typical system ENCLOSURE layout . 185

Figure BB.2 – Simplified system schematic . 186

Figure BB.3 – HAZARD situation of the control equipment . 187

Figure BB.4 – Application of IEC 61010-2-201 to the control equipment safety drawing . 188

Figure BB.5 – Application of 6.7.1.5 items a) and b) to the control equipment safety

drawing . 188

Figure BB.6 – Application of 6.7.1.5 items a), b), c) and d) to the control equipment

safety drawing . 189

Figure BB.7 – REINFORCED INSULATION . 190

Figure BB.8 – BASIC INSULATION . 191

Figure BB.9 – REINFORCED INSULATION, BASIC INSULATION and impedance . 192

Figure BB.10 – REINFORCED INSULATION from external power supplies . 193

Figure BB.11 – BASIC INSULATION from external power supplies . 194

Figure EE.1 – Information and documentation for component products . 200

Figure EE.2 – Information and documentation accumulation and segregation tree for

an example installation . 201

Figure FF.1 – Path of a component mounted to a PWB (side view) . 203

Figure FF.2 – Path of a component mounted to a PWB (side view) . 203

Table 1 – Symbols . 35

Table 101 – INTERFACES, PORTS AND TERMINALS considered as OPERATOR ACCESSIBLE for

OPEN and ENCLOSED EQUIPMENT . 45

Table 2 – Tightening torque for binding screw assemblies . 56

Table 3 – Multiplication factors for CLEARANCES of equipment RATED for operation at

altitudes up to 5 000 m . 62

Table 4 – CLEARANCE and CREEPAGE DISTANCES for MAINS CIRCUITS of OVERVOLTAGE

CATEGORY II up to 300 V . 65

Table 5 – Test voltages for solid insulation between MAINS and between MAINS and

secondary circuits OVERVOLTAGE CATEGORY II up to 300 V . 66

Table 6 – CLEARANCES and test voltages for secondary circuits derived from MAINS

CIRCUITS of OVERVOLTAGE CATEGORY II up to 300 V . 70

Table 7 – CREEPAGE DISTANCES for secondary circuits . 72

Table 8 − Minimum values for distance or thickness (see 6.7.3.4.2 to 6.7.3.4.4) . 74

Table 9 – Distances between TERMINALS and foil . 75

Table 10 – Correction factors according to test site altitude for test voltages for

CLEARANCES . 76

Table 11 – Values for physical tests on cord anchorages . 81

Table 12 – Protective measures against mechanical HAZARDS to body parts. 85

Table 15 – Impact energy levels, test height and corresponding IK codes . 90

Table 16 – Acceptable perforation of the bottom of an ENCLOSURE . 97

Table 17 – Limits of maximum available current . 99

Table 18 – Values for overcurrent protection devices . 100

Table 19 – Surface temperature limits, under NORMAL CONDITION . 102

Table 20 – Maximum temperatures for insulation material of windings . 103

Table 22 – Lamp or lamp systems considered photobiologically safe . 117

Table 23 – Lamp or lamp systems considered photobiologically safe under certain

conditions . 117

Table 21 – Impulse voltages for OVERVOLTAGECATEGORY II . 123

Table 102 – Overload and endurance test voltages . 125

Table 103 – Overload test circuit values . 126

Table 104 – Endurance test circuit values . 127

Table C.1 – Dimensions of X. 134

– 8 – IEC 61010-2-201:2024 EXV © IEC 2024

Table E.1 – Environmental situations . 141

Table E.2 – Reduction of POLLUTION DEGREES (PD) . 142

Table F.1 – Test voltages for ROUTINE TESTS of MAINS CIRCUITS . 144

Table G.1 – Test pressures for equipment with pressures above 14 Mpa . 149

Table H.1 – Test parameters, test conditions and test procedures . 152

Table I.1 – Line-to-neutral voltages for common MAINS supply systems . 154

Table J.1 – Severity of harm . 158

Table J.2 – Probability of harm . 158

Table J.3 – RISK category . 158

Table K.1 – Multiplication factors for CLEARANCES for equipment RATED for operation at

altitudes up to 5 000 m . 160

Table K.2 – CLEARANCES and CREEPAGE DISTANCES for MAINS CIRCUITS of OVERVOLTAGE

CATEGORY II above 300 V . 160

Table K.3 – CLEARANCES and CREEPAGE DISTANCES for MAINS CIRCUITS of OVERVOLTAGE

CATEGORY III . 161

Table K.4 – CLEARANCES and CREEPAGE DISTANCES for MAINS CIRCUITS of OVERVOLTAGE

CATEGORY IV . 161

Table K.5 – Test voltages for solid insulation in MAINS CIRCUITS of OVERVOLTAGE

CATEGORY II above 300 V . 162

Table K.6 – Test voltages for solid insulation in MAINS CIRCUITS of OVERVOLTAGE

CATEGORY III . 162

Table K.7 – Test voltages for solid insulation in MAINS CIRCUITS of OVERVOLTAGE

CATEGORY IV . 162

Table K.8 – Test voltages for testing long-term stress of solid insulation in MAINS

CIRCUITS . 163

Table K.9 – Minimum values for distance or thickness of solid insulation . 164

Table K.10 – CLEARANCES and test voltages for secondary circuits derived from MAINS

CIRCUITS of OVERVOLTAGE CATEGORY II above 300 V . 167

Table K.11 – CLEARANCES and test voltages for secondary circuits derived from MAINS

CIRCUITS of OVERVOLTAGE CATEGORY III . 168

Table K.12 – CLEARANCES and test voltages for secondary circuits derived from MAINS

of OVERVOLTAGE CATEGORY IV . 169

CIRCUITS

Table K.13 – CREEPAGE DISTANCES for secondary circuits . 170

Table K.14 – Minimum values for distance or thickness (see K.2.4.2 to K.2.4.4) . 172

Table K.15 – CLEARANCE values for the calculation of K.3.2 . 175

Table K.16 – Test voltages based on CLEARANCES . 176

Table K.17 – CLEARANCES for BASIC INSULATION in circuits having recurring peak

voltages or WORKING VOLTAGES with frequencies above 30 kHz . 178

Table CC.1 – Limits of output current and output power for inherently limited power

sources . 198

Table CC.2 – Limits of output current, output power and RATINGS for over-current

protective devices for non-inherently limited power sources . 198

Table FF.1 – Dimensions of X . 202

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-201: Particular requirements for control equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to p

...

IEC 61010-2-201 ®

Edition 3.0 2024-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-201: Particular requirements for control equipment

Exigences de securité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-201: Exigences particulières pour les équipements de commande

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61010-2-201 ®

Edition 3.0 2024-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-201: Particular requirements for control equipment

Exigences de securité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-201: Exigences particulières pour les équipements de commande

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.020, 19.020, 25.040.40 ISBN 978-2-8322-9783-4

– 2 – IEC 61010-2-201:2024 © IEC 2024

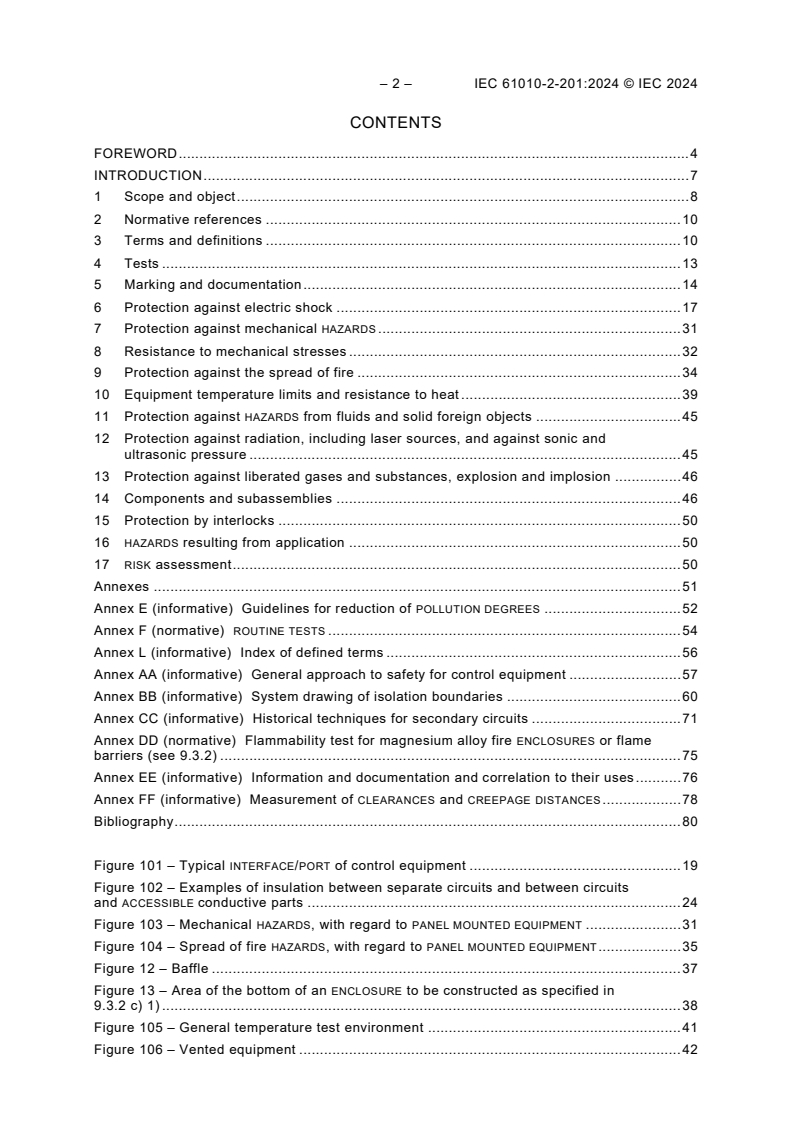

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope and object . 8

2 Normative references . 10

3 Terms and definitions . 10

4 Tests . 13

5 Marking and documentation . 14

6 Protection against electric shock . 17

7 Protection against mechanical HAZARDS . 31

8 Resistance to mechanical stresses . 32

9 Protection against the spread of fire . 34

10 Equipment temperature limits and resistance to heat . 39

11 Protection against HAZARDS from fluids and solid foreign objects . 45

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 45

13 Protection against liberated gases and substances, explosion and implosion . 46

14 Components and subassemblies . 46

15 Protection by interlocks . 50

16 HAZARDS resulting from application . 50

17 RISK assessment . 50

Annexes . 51

Annex E (informative) Guidelines for reduction of POLLUTION DEGREES . 52

Annex F (normative) ROUTINE TESTS . 54

Annex L (informative) Index of defined terms . 56

Annex AA (informative) General approach to safety for control equipment . 57

Annex BB (informative) System drawing of isolation boundaries . 60

Annex CC (informative) Historical techniques for secondary circuits . 71

Annex DD (normative) Flammability test for magnesium alloy fire ENCLOSURES or flame

barriers (see 9.3.2) . 75

Annex EE (informative) Information and documentation and correlation to their uses . 76

Annex FF (informative) Measurement of CLEARANCES and CREEPAGE DISTANCES . 78

Bibliography . 80

Figure 101 – Typical INTERFACE/PORT of control equipment . 19

Figure 102 – Examples of insulation between separate circuits and between circuits

and ACCESSIBLE conductive parts . 24

Figure 103 – Mechanical HAZARDS, with regard to PANEL MOUNTED EQUIPMENT . 31

Figure 104 – Spread of fire HAZARDS, with regard to PANEL MOUNTED EQUIPMENT . 35

Figure 12 – Baffle . 37

Figure 13 – Area of the bottom of an ENCLOSURE to be constructed as specified in

9.3.2 c) 1) . 38

Figure 105 – General temperature test environment . 41

Figure 106 – Vented equipment . 42

Figure 107 – Non-vented equipment . 43

Figure 108 – PANEL MOUNTED EQUIPMENT extending through the wall of the end location

ENCLOSURE . 44

Figure AA.1 – Control equipment access and safety concerns . 57

Figure BB.1 – Typical system ENCLOSURE layout . 60

Figure BB.2 – Simplified system schematic . 62

Figure BB.3 – HAZARD situation of the control equipment . 63

Figure BB.4 – Application of IEC 61010-2-201 to the control equipment safety drawing . 64

Figure BB.5 – Application of 6.7.1.5 items a) and b) to the control equipment safety

drawing . 64

Figure BB.6 – Application of 6.7.1.5 items a), b), c) and d) to the control equipment

safety drawing . 65

Figure BB.7 – REINFORCED INSULATION . 66

Figure BB.8 – BASIC INSULATION . 67

Figure BB.9 – REINFORCED INSULATION, BASIC INSULATION and impedance . 68

Figure BB.10 – REINFORCED INSULATION from external power supplies . 69

Figure BB.11 – BASIC INSULATION from external power supplies . 70

Figure EE.1 – Information and documentation for component products . 76

Figure EE.2 – Information and documentation accumulation and segregation tree for

an example installation . 77

Figure FF.1 – Path of a component mounted to a PWB (side view) . 79

Figure FF.2 – Path of a component mounted to a PWB (side view) . 79

Table 101 – INTERFACES, PORTS AND TERMINALS considered as OPERATOR ACCESSIBLE for

OPEN and ENCLOSED EQUIPMENT . 18

Table 3 – Multiplication factors for clearances of equipment rated for operation at

altitudes up to 5 000 m . 25

Table 4 – CLEARANCE and CREEPAGE DISTANCES for MAINS CIRCUITS of OVERVOLTAGE

CATEGORY II up to 300 V. 27

Table 5 – Test voltages for solid insulation between MAINS and between MAINS and

secondary circuits OVERVOLTAGE CATEGORY II up to 300 V . 28

Table 6 – CLEARANCES and test voltages for secondary circuits derived from MAINS

CIRCUITS of OVERVOLTAGE CATEGORY II up to 300 V . 29

Table 16 – Acceptable perforation of the bottom of an ENCLOSURE . 36

Table 19 – Surface temperature limits, under NORMAL CONDITION . 39

Table 102 – Overload and endurance test voltages . 47

Table 103 – Overload test circuit values . 49

Table 104 – Endurance test circuit values . 50

Table E.1 – Environmental situations . 52

Table E.2 – Reduction of POLLUTION DEGREES (PD) . 53

Table CC.1 – Limits of output current and output power for inherently limited power

sources . 74

Table CC.2 – Limits of output current, output power and RATINGS for over-current

protective devices for non-inherently limited power sources . 74

Table FF.1 – Dimensions of X . 78

– 4 – IEC 61010-2-201:2024 © IEC 2024

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-201: Particular requirements for control equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 61010-2-201 has been prepared by IEC technical committee 65: Industrial-process

measurement, control and automation. It is an International Standard.

This third edition cancels and replaces the second edition published in 2017. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) 1.1.1: the related equipment included in the Scope has been clarified;

b) 4.3.2.101: the optical fibre module has been deleted;

c) 5.4.3: equipment installation has been clarified;

d) 6.7.1.1: revision of the figure representing insulation between separate circuits has been

included;

e) 6.7.101: the subclause relating to insulation for FIELD WIRING TERMINALS of OVERVOLTAGE

ll with a nominal voltage up to 1 000 V has been deleted;

CATEGORY

f) 6.7.1.101: a new subclause relating to insulation for SELV/PELV CIRCUITS has been included;

g) 6.8.3: specification of voltage tester has been added;

h) 6.9.3: an additional exception relating to colour coding has been included;

i) 6.9.101: a new subclause relating to wiring for secondary circuits e.g. SELV/PELV has been

included;

j) 8.2.2.101: additional requirements for glass displays have been included;

k) 8.3: the subclause relating to the drop test has been removed;

l) 9.3.2: additional requirements for material of connectors and insulating material have been

included;

m) The particular requirements for non-metallic material have been clarified;

n) Clause 11: the particular requirements for protection against HAZARDS from fluid and solid

foreign objects have been removed;

o) 12.4: an additional subclause relating to microwave radiation has been included;

p) 14.102: the description of switching devices has been clarified;

The text of this International Standard is based on the following documents:

Draft Report on voting

65/1049/FDIS 65/1095/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61010 series, published under the general title Safety requirements

for electrical equipment for measurement, control, and laboratory use, can be found on the IEC

website.

This document is to be used in conjunction with IEC 61010-1:2010, and

IEC 61010-1:2010/AMD1:2016.

This document supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for control equipment.

Where a particular subclause of IEC 61010-1 is not mentioned in this document, that subclause

applies as far as is reasonable. Where this document states "addition", "modification",

"replacement", or "deletion", the relevant requirement, test specification or note in IEC 61010-1

should be adapted accordingly.

– 6 – IEC 61010-2-201:2024 © IEC 2024

In this document,

a) the following print types are used:

– requirements and definitions: in roman type;

NOTES: in smaller roman type;

–

– conformity and tests: in italic type;

– terms used throughout this document which have been defined in Clause 3: SMALL ROMAN

CAPITALS.

b) subclauses, figures, tables and notes which are additional to those in IEC 61010-1 are

numbered starting from 101. Additional annexes are lettered starting from AA and additional

list items are lettered from aa).

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

IEC 61010-2-2xx documents are a series of standards on the safety of industrial-process

measurement, control and automation equipment.

This document specifies the complete safety related requirements and related tests for control

equipment (e.g. programmable controller (PLC), the components of distributed control systems

(DCS), I/O devices, human machine interface (HMI)).

Safety terms of general use are defined in IEC 61010-1. More specific terms are defined in each

relevant part of the IEC 61010 series.

– 8 – IEC 61010-2-201:2024 © IEC 2024

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-201: Particular requirements for control equipment

1 Scope and object

IEC 61010-1:2010, Clause 1 and IEC 61010-1:2010/AMD1:2016, Clause 1 apply, except as

follows:

1.1.1 Equipment included in scope

Replacement:

Replace the existing text with the following:

This part of IEC 61010 specifies safety requirements and related verification tests for control

equipment or their associated peripherals, or both.

Some equipment examples are:

• programmable logic controller (PLC);

• programmable automation controller (PAC);

• distributed control systems (DCS);

• industrial PC (computers) and panel PC;

• programming and debugging tools (PADTs);

• displays and human-machine interfaces (HMI);

• any product performing the function of control equipment or their associated peripherals, or

both;

• positioners; and

• control equipment which have as their intended use the command and control of machines,

automated manufacturing and industrial processes, for example discrete and continuous

control.

Components of the above named equipment and within the scope of this document are, for

example:

• (auxiliary) stand-alone power supplies;

• peripherals such as digital and analogue I/O,

• remote-I/O;

• industrial network equipment, embedded or stand-alone (e.g. switches, routers, wireless

base station).

Control equipment and their associated peripherals are intended to be used in an industrial

environment. This document considers equipment designed as OPEN or ENCLOSED EQUIPMENT.

NOTE 1 Control equipment intended also for use in other environments or for other purposes (example: for use in

building installations to control light or other electrical installations, or for use on cars, trains or ships) can have

additional conformity requirements defined by the safety standard(s) for these applications. These requirements can

involve for example: insulation, spacings and power restrictions.

NOTE 2 Computing devices and similar equipment within the scope of the IEC 60950 series or the IEC 62368 series

and conforming to their requirements are considered to be suitable for use with control equipment within the scope

of this document. However, some of the requirements of the IEC 60950 series for resistance to moisture and liquids

are less stringent, IEC 61010-1:2010, 5.4.4, second paragraph takes this aspect into account.

Control equipment covered in this document is typically intended for use in OVERVOLTAGE

CATEGORY II (IEC 60664-1) in low-voltage installations, where the RATED equipment supply

voltage does not exceed 1 000 V a.c. RMS (50/60 Hz), or 1 000 V d.c.

Where control equipment is intended for installation to supply systems with OVERVOLTAGE

CATEGORY III or IV, additional requirements are identified in Annex K.

The requirements of ISO/IEC Guide 51 and IEC Guide 104, as they relate to this part of

IEC 61010, are incorporated herein.

1.1.2 Equipment excluded from scope

Replacement:

Replace the existing text with the following:

This document does not deal with aspects of the overall automated system, for example a

complete assembly line. Control equipment (e.g. DCS and PLC), their application programme

and their associated peripherals are considered as components (components in this context are

items which perform no useful function by themselves) of an overall automated system.

Since control equipment (e.g. DCS and PLC) are component devices, safety considerations for

the overall automated system including installation and application are beyond the scope of this

document. Refer to the IEC 60364 series or applicable national and local regulations for

electrical installation and guidelines.

1.2.1 Aspects included in scope

Replace the first sentence with the following:

The purpose of the requirements of this document is to ensure that all HAZARDs to the OPERATOR,

SERVICE PERSONNEL and the surrounding area are reduced to a tolerable level.

NOTE By using the terms "OPERATOR" and "SERVICE PERSONNEL" this document considers the perception of HAZARDS

depending on training and skills. Annex AA provides a general approach in this regard.

1.2.2 Aspects excluded from scope

Replacement:

Replace the existing text with the following:

This document does not cover:

a) reliability, functionality, performance, or other properties of the control equipment not related

to safety;

b) mechanical or climatic requirements for operation, transport or storage;

c) EMC requirements (see e.g. the IEC 61326 series or IEC 61131-2);

d) protective measures for explosive atmospheres (see e.g. the IEC 60079 series);

e) functional safety (see e.g. the IEC 61508 series, IEC 61131-6).

– 10 – IEC 61010-2-201:2024 © IEC 2024

2 Normative references

IEC 61010-1:2010, Clause 2 and IEC 61010-1:2010/AMD1:2016, Clause 2 apply, except as

follows:

Addition:

Add the following new references:

IEC 60384-14, Fixed capacitors for use in electronic equipment – Part 14: Sectional

specification – Fixed capacitors for electromagnetic interference suppression and connection

to the supply mains

IEC 60695-2-11, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end products (GWEPT)

IEC 60695-11-3, Fire hazard testing – Part 11-3: Test flames – 500 W flames – Apparatus and

confirmational test methods

IEC 60695-11-20, Fire hazard testing – Part 11-20: Test flames – 500 W flame test method

IEC 60947-4-1, Low-voltage switchgear and controlgear – Part 4-1: Contactors and motor-

starters – Electromechanical contactors and motor-starters

IEC 60947-4-2, Low-voltage switchgear and controlgear – Part 4-2: Contactors and motor-

starters – Semiconductor motor controllers, starters and soft-starters

IEC 60947-5-1:2016, Low-voltage switchgear and controlgear – Part 5-1: Control circuit devices

and switching elements – Electromechanical control circuit devices

IEC 61010-1:2010, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

IEC 61010-1:2010/AMD1:2016

IEC 61010-2-030, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 2-030: Particular requirements for equipment having testing or measuring

circuits

IEC 61810-1:2015, Electromechanical elementary relays – Part 1: General and safety

requirements

3 Terms and definitions

IEC 61010-1:2010, Clause 3 applies, except as follows:

3.1.3

PORTABLE EQUIPMENT

Modification:

Replace the definition with the following:

equipment intended to be carried by hand and not fixed during NORMAL USE

3.2.3

PROTECTIVE CONDUCTOR TERMINAL

Modification:

Replace the term "PROTECTIVE CONDUCTOR TERMINAL" with "PROTECTIVE EARTH TERMINAL" and

add the following Note to entry:

Note 1 to entry: PROTECTIVE EARTH TERMINAL is most familiar to industrial users, manufacturers, etc. Therefore

since this document is targeted towards industrial use, the most familiar term is utilized.

3.2.4

ENCLOSURE

Replacement:

Replace the definition and NOTE with the following:

housing affording the type and degree of protection suitable for the intended application

[SOURCE: IEC 60050-151:2001, 151-13-08]

Add the following new terms and definitions:

3.101

AMBIENT TEMPERATURE

temperature, determined under specified conditions, of the air surrounding the equipment

3.102

ENCLOSED EQUIPMENT

equipment which includes an ENCLOSURE, having safety capability, or a combination of an

ENCLOSURE, having safety capability, and installation provisions enclosing on all sides, with the

possible exception of its mounting surface, to prevent personnel from accidentally touching

HAZARDOUS LIVE, hot or moving parts contained therein and meeting requirements of mechanical

strength, flammability, and stability (where applicable)

EXAMPLE HAND-HELD EQUIPMENT.

Note 1 to entry: This definition is related to IEC 60050-441:1984, 441-12-02.

3.103

FIELD WIRING

wiring of the control equipment, which is not installed in the control equipment manufacturer's

facility

EXAMPLE MAINS supply wiring.

3.104

INTERFACE

shared boundary between one control equipment and another control equipment, or between

parts of a control equipment, through which information or electrical energy is conveyed

[SOURCE: IEC 61131-2:2017, 3.1.21]

– 12 – IEC 61010-2-201:2024 © IEC 2024

3.105

MODULAR EQUIPMENT

equipment consisting of different modules such as a Rack, CPU, different I/O-modules, network

modules

Note 1 to entry: MODULAR EQUIPMENT can:

a) be OPEN EQUIPMENT or ENCLOSED EQUIPMENT;

b) consist of modules that cannot operate alone or of a basic module that is operational alone and can be enhanced

in function by additional modules;

c) vary in size and functionality depending on the combination and the number of modules;

d) be combined with operational equipment or enhanced in function by the addition of modules by the customer.

3.106

OPEN EQUIPMENT

equipment which does not protect personnel from accidentally touching HAZARDOUS LIVE or

moving parts contained therein nor meet requirements of mechanical strength, flammability and

stability (where applicable)

Note 1 to entry: See Annex AA.

3.107

PANEL MOUNTED EQUIPMENT

equipment where a portion of the equipment may form part of the ENCLOSURE

Note 1 to entry: See Figure 103.

3.108

PORT

access to a device or network where electromagnetic energy or signals may be supplied or

received or where the device or network variables may be observed or measured

Note 1 to entry: PORT is most commonly used with respect to EMC.

3.109

PROTECTIVE EXTRA-LOW VOLTAGE CIRCUIT

PELV CIRCUIT

protective earth referenced electrical circuit in which the voltage cannot exceed the following:

NORMAL CONDITION and SINGLE FAULT CONDITION: The a.c. voltage levels are 30 V RMS, 42,4 V

peak and the d.c. voltage level is 60 V. For equipment intended for use in WET LOCATIONS, the

a.c. voltage levels are 16 V RMS, 22,6 V peak and the d.c. voltage level is 35 V

Note 1 to entry: Transients are not taken into consideration in PELV CIRCUITS.

[SOURCE: IEC 60050-195:2021, 195-06-29, modified – In the preferred term, "system" has

been replaced with "circuit", a full description and clarifications have been added and the Note

to entry has been replaced with a new Note to entry.]

3.110

SAFETY EXTRA-LOW VOLTAGE CIRCUIT

SELV CIRCUIT

non-protective earth referenced electrical circuit in which the voltage cannot exceed the

following:

NORMAL CONDITION and SINGLE FAULT CONDITION: The a.c. voltage levels are 30 V RMS, 42,4 V

peak and the d.c. voltage level is 60 V. For equipment intended for use in WET LOCATIONS, the

a.c. voltage levels are 16 V RMS, 22,6 V peak and the d.c. voltage level is 35 V

Note 1 to entry: Transients are not taken into consideration in SELV CIRCUITS.

[SOURCE: IEC 60050-195:2021, 195-06-28, modified – In the preferred term, "system" has

been replaced with "circuit", a full description and clarifications have been added and the Note

to entry has been replaced with a new Note to entry.]

3.111

SERVICE PERSONNEL

person who is installing, changing or repairing the control equipment, with the appropriate

technical training, experience and awareness of HAZARDS and of measures to minimize danger

to themselves, other persons or to the control equipment, in an industrial environment

Note 1 to entry: SERVICE PERSONNEL are persons having the appropriate technical training and experience

necessary to be aware of HAZARDS – e.g. electrical HAZARDS, temperature HAZARDS, fire HAZARDS – to which they are

exposed in performing a task and of measures to minimize danger to themselves or to other persons or to the control

equipment, in an industrial environment.

Note 2 to entry: SERVICE PERSONNEL change or repair control equipment e.g. hardware configuration or installation

of software updates provided by the manufacturer.

Note 3 to entry: See AA.1.3 for more detail.

4 Tests

IEC 61010-1:2010, Clause 4 and IEC 61010-1:2010/AMD1:2016, Clause 4 apply, except as

follows:

4.1 General

Add the following three paragraphs of requirements after the third paragraph of requirements,

before the first conformity statement:

The product is verified in accordance with this document in a documented test configuration,

which represents the least favourable configuration. See 4.3.

It is likely or possible that there are different test configurations which yield least favourable

test conditions. For example there can be a least favourable configuration for the temperature

test, and a different least favourable test configuration for the voltage test. If this is the case

then the appropriate least favourable test configuration(s) shall be used with regard to 4.3.2

and 4.4.

These least favourable test configurations and test conditions shall be practical and useful for

the intended applications.

Add the following conformity statement at the end of the list of conformity statements:

Conformity verification: The selected test configuration(s) and test conditions shall be

documented with the rationale in the test report.

4.4.1 General

Add the following note to item a):

NOTE A fault condition can include open or short circuit of components, as well as disabling or bridging one means

or layer of protection.

– 14 – IEC 61010-2-201:2024 © IEC 2024

4.4.4.3 Spread of fire

Add the following to the conformity statement:

Optionally, for OPEN EQUIPMENT:

The equipment may be placed inside a wire mesh cage covered with cheesecloth. The wire

mesh cage shall be maximum 1,5 times the size (length, width, height) of the device or

representative system including the device, to simulate the intended ENCLOSURE during the

single fault condition testing. See 10.4.1.101 for representative system methodology.with a

tolerance of

The wire mesh cage shall be a metal screen with a mesh 25 mm × 25 mm with a tolerance of

5 mm, centre to centre with a wire diameter of 0,8 mm ± 0,3 mm.

NOTE 1 The wire mesh used is commonly known as chicken wire, 25 mm hexagonal mesh weave made of 0,81

gauge wire.

Cheesecloth is a bleached cotton cloth of approximately 40 g/m containing no flame retardants.

NOTE 2 Cheesecloth is a coarse, loosely woven cotton gauze, originally used for wrapping cheese.

NOTE 3 Panel mounted equipment can combine the two methods.

5 Marking and documentation

IEC 61010-1:2010, Clause 5 and IEC 61010-1:2010/AMD1:2016, Clause 5 apply, except as

follows:

5.1.3 MAINS supply

Replace line 14 of Table 1 with the following:

5.1.5.2 TERMINALS

Modification:

Replace item a) as follows:

UNCTIONAL EARTH TERMINALS (i.e. used for non-safety purposes such as interference

a) F

immunity improvement) shall be marked with one of the following symbols:

IEC 60417-5018 (2011-07) or

IEC 61010-1:2010, symbol 5 of Table 1, IEC 60417-5017 (2006-08).

Where a TERMINAL serves both as the PROTECTIVE CONDUCTOR TERMINAL and as a FUNCTIONAL

EARTH TERMINAL, symbol 6 of Table 1 and other requirements for PROTECTIVE CONDUCTOR

TERMINAL shall be applied. Where a TERMINAL serves both as an earth (ground) TERMINAL

and FUNCTIONAL EARTH TERMINAL, symbol 5 of Table 1 and other requirements for earth

TERMINALS shall be applied.

Addition:

Add the following new item after d):