IEC 61892-6:1999

(Main)Mobile and fixed offshore units - Electrical installations - Part 6: Installation

Mobile and fixed offshore units - Electrical installations - Part 6: Installation

This part of IEC 61892 contains provisions for the installation of electrical equipment in mobile and fixed units, including pipelines, pumping or "pigging" stations, compressor stations and exposed location single-buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

General Information

- Status

- Published

- Publication Date

- 09-Feb-1999

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 21-Nov-2007

- Completion Date

- 13-Feb-2026

Relations

- Revised

IEC 61892-6:2007 - Mobile and fixed offshore units - Electrical installations - Part 6: Installation - Effective Date

- 05-Sep-2023

Overview

IEC 61892-6:1999 - "Mobile and fixed offshore units - Electrical installations - Part 6: Installation" is an international installation standard that sets out provisions for installing electrical equipment on mobile and fixed offshore petroleum units. It covers installations on platforms, pipelines, pumping/"pigging" stations, compressor stations and exposed single-buoy moorings used for drilling, production, processing and storage. Part 6 is one element of the IEC 61892 series, which provides a complete framework for offshore electrical safety, system design, equipment, cables, hazardous areas and mobile units.

Key topics and requirements

This installation-focused part addresses practical and safety-critical aspects of offshore electrical work, including:

- Earthing and bonding - general earthing principles, equipotential bonding, bonding connections and corrosion protection.

- Cables and wiring - installation practices, mechanical protection, cable trays and ducting interfaces with HVAC and vessels.

- Rotating and static plant - installation and location requirements for generators, motors and transformers (winding isolation, mounting and placement).

- Switchgear and controlgear - siting, clearances, insulating mats and access/egress passageway requirements.

- Semiconductor converters - installation considerations for power electronics.

- Secondary cells and batteries - location, access, ventilation, corrosion protection, supports and circuit protection.

- Luminaires and emergency lighting - protection levels, discharge lighting and emergency illumination.

- Heating, cooking and trace heating systems - guarding combustible materials, trace heating installation, marking and mechanical protection.

- Control & instrumentation - layout, compatibility, labeling, protection against leakage/condensation and interference.

- Communications and lightning protection - primary and secondary damage protection, air terminals and down conductors.

- Testing, inspection and documentation - types of completion tests, insulation resistance checks, functional testing (generators, switchgear, safety/emergency systems) and required documentation for operation and maintenance.

Applications and users

IEC 61892-6 is used by:

- Offshore electrical engineers and system designers implementing installations on platforms and subsea-related facilities.

- Installation contractors and commissioning teams responsible for wiring, earthing, and equipment placement.

- Asset owners, operators and maintenance teams managing lifecycle safety and documentation.

- Classification societies, regulatory bodies and safety auditors assessing compliance with offshore electrical installation best practice.

Related standards

- Other parts of the IEC 61892 series (Parts 1–7) for general requirements, system design, equipment, cables, mobile units and hazardous areas.

- International Maritime Organization (IMO) conventions and SOLAS provisions as applicable; IEC 61892 aims to coordinate with maritime safety requirements.

Keywords: IEC 61892-6, offshore electrical installations, earthing and bonding, cables and wiring, offshore platform electrical installation, lightning protection, testing and documentation.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 61892-6:1999 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mobile and fixed offshore units - Electrical installations - Part 6: Installation". This standard covers: This part of IEC 61892 contains provisions for the installation of electrical equipment in mobile and fixed units, including pipelines, pumping or "pigging" stations, compressor stations and exposed location single-buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

This part of IEC 61892 contains provisions for the installation of electrical equipment in mobile and fixed units, including pipelines, pumping or "pigging" stations, compressor stations and exposed location single-buoy moorings, used in the offshore petroleum industry for drilling, production, processing and for storage purposes.

IEC 61892-6:1999 is classified under the following ICS (International Classification for Standards) categories: 29.260.99 - Other electrical equipment for working in special conditions; 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61892-6:1999 has the following relationships with other standards: It is inter standard links to IEC 61892-6:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61892-6:1999 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL

IEC

STANDARD

61892-6

First edition

1999-02

Mobile and fixed offshore units –

Electrical installations –

Part 6:

Installation

Unités mobiles et fixes en mer –

Installations électriques –

Partie 6:

Installation

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken by

the technical committee which has prepared this publication, as well as the list of

publications issued, is to be found at the following IEC sources:

• IEC web site*

• Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International Electro-

technical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL

IEC

STANDARD

61892-6

First edition

1999-02

Mobile and fixed offshore units –

Electrical installations –

Part 6:

Installation

Unités mobiles et fixes en mer –

Installations électriques –

Partie 6:

Installation

IEC 1999 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

U

International Electrotechnical Commission

For price, see current catalogue

– 2 – 61892-6 © IEC:1999(E)

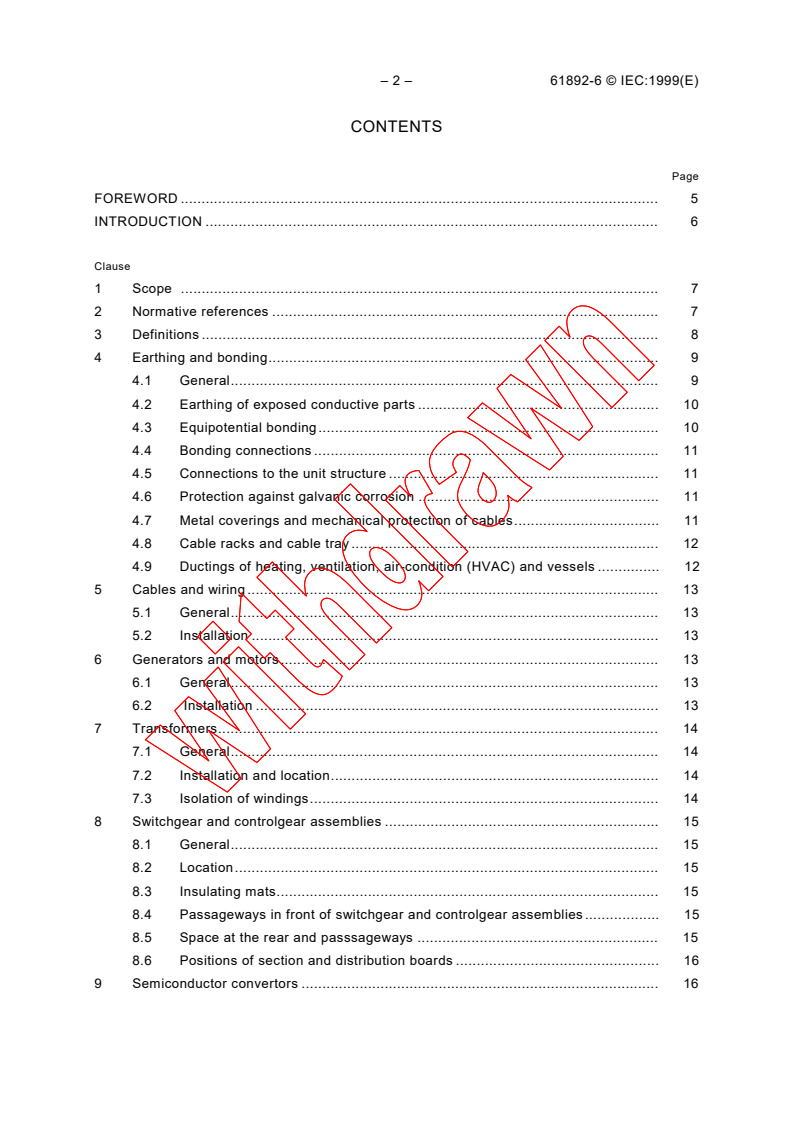

CONTENTS

Page

FOREWORD . 5

INTRODUCTION . 6

Clause

1 Scope. 7

2 Normative references. 7

3 Definitions. 8

4 Earthing and bonding. 9

4.1 General. 9

4.2 Earthing of exposed conductive parts . 10

4.3 Equipotential bonding. 10

4.4 Bonding connections. 11

4.5 Connections to the unit structure . 11

4.6 Protection against galvanic corrosion . 11

4.7 Metal coverings and mechanical protection of cables. 11

4.8 Cable racks and cable tray . 12

4.9 Ductings of heating, ventilation, air-condition (HVAC) and vessels . 12

5 Cables and wiring . 13

5.1 General. 13

5.2 Installation. 13

6 Generators and motors. 13

6.1 General. 13

6.2 Installation . 13

7 Transformers. 14

7.1 General. 14

7.2 Installation and location. 14

7.3 Isolation of windings. 14

8 Switchgear and controlgear assemblies . 15

8.1 General. 15

8.2 Location. 15

8.3 Insulating mats. 15

8.4 Passageways in front of switchgear and controlgear assemblies. 15

8.5 Space at the rear and passsageways . 15

8.6 Positions of section and distribution boards . 16

9 Semiconductor convertors. 16

61892-6 © IEC:1999(E) – 3 –

Clause Page

10 Secondary cells and batteries . 16

10.1 General. 16

10.2 Location. 16

10.3 Access. 17

10.4 Electrical installation in secondary battery compartments. 17

10.5 Protection against corrosion . 17

10.6 Fixing and supports. 18

10.7 Protection of circuits from secondary batteries. 18

11 Luminaires. 18

11.1 General. 18

11.2 Degree of protection and safety requirements. 18

11.3 Discharge lighting of voltage above 250 V . 18

11.4 Emergency lighting. 19

12 Heating and cooking appliances. 19

12.1 Guarding of combustible materials . 19

12.2 Position of controlgear and switchgear . 19

12.3 Mounting of space-heating appliances . 19

13 Trace and surface heating . 19

13.1 General. 19

13.2 Trace heating cables. 19

13.3 Marking. 20

13.4 Protection. 20

13.5 Mechanical protection. 20

13.6 Junction boxes. 20

14 Control and instrumentation. 20

14.1 General. 20

14.2 Layout. 20

14.3 Compatibility. 20

14.4 Labelling. 20

14.5 Labels. 21

14.6 Display colours. 21

14.7 Illumination. 21

14.8 Protection against fluid leakage. 21

14.9 Isolation of control rooms . 21

14.10 Protection from condensation . 21

14.11 Protection during installation period. 22

14.12 External cables and wiring. 22

14.13 Interference . 22

14.14 Sensors. 22

14.15 Measurements and indications . 22

– 4 – 61892-6 © IEC:1999(E)

Clause Page

14.16 Controls. 23

14.17 Alarm system. 23

15 Communication. 24

16 Lightning protection. 24

16.1 General. 24

16.2 Protection against primary structural damage . 24

16.3 Air terminals. 25

16.4 Down conductors. 25

16.5 Protection against secondary damage . 25

17 Test of completed installation . 26

17.1 General. 26

17.2 Inspections and tests . 26

17.3 Insulation-testing instruments. 26

17.4 Insulation resistance. 27

17.5 Generators. 27

17.6 Switchgear. 27

17.7 Lighting, heating and galley equipment . 28

17.8 Communication systems. 28

17.9 Emergency and safety systems . 28

17.10 Earthing. 28

17.11 Voltage drop. 28

17.12 Requirements of International Convention on Safety of Life at Sea (SOLAS) 28

18 Documentation. 28

18.1 General. 28

18.2 Equipment. 29

18.3 Testing. 29

18.4 Maintenance. 29

Annex A (informative) Bibliography . 30

61892-6 © IEC:1999(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

MOBILE AND FIXED OFFSHORE UNITS –

ELECTRICAL INSTALLATIONS –

Part 6: Installation

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61892-6 has been prepared by IEC technical committee 18:

Electrical installations of ships and of mobile and fixed offshore units.

The text of this standard is based on the following documents:

FDIS Report on voting

18/854/FDIS 18/861/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annex A is for information only.

A bilingual version of this standard may be issued at a later date.

IEC 61892 consists of the following parts, under the general title: Mobile and fixed offshore

units – Electrical installations.

Part 1: General requirements and conditions

Part 2: System design

Part 3: Equipment

Part 4: Cables

Part 5: Mobile units

Part 6: Installation

Part 7: Hazardous areas

– 6 – 61892-6 © IEC:1999(E)

INTRODUCTION

IEC 61892 forms a series of International Standards intended to ensure safety in the design,

selection, installation, maintenance and use of electrical equipment for the generation, storage,

distribution and utilization of electrical energy for all purposes in offshore units which are used

for the exploration or exploitation of petroleum resources.

This part of IEC 61892 also incorporates and co-ordinates, as far as possible, existing rules

and forms a code of interpretation, where applicable, of the requirements laid down by the

International Maritime Organization, and constitutes a guide for future regulations which may

be prepared and a statement of practice for offshore unit owners, constructors and appropriate

organizations.

This standard is based on equipment and practices which are in current use, but it is not

intended in any way to impede development of new or improved techniques.

The ultimate aim has been to produce a set of International Standards exclusively for the

offshore petroleum industry.

In this part of IEC 61892, references are made to other parts of the standard, which are still in

preparation. Footnotes are attached to such references. A footnote indicates which current

standard should be used until the part in preparation is published.

61892-6 © IEC:1999(E) – 7 –

MOBILE AND FIXED OFFSHORE UNITS –

ELECTRICAL INSTALLATIONS –

Part 6: Installation

1 Scope

This part of IEC 61892 contains provisions for the installation of electrical equipment in mobile

and fixed units, including pipelines, pumping or "pigging" stations, compressor stations and

exposed location single-buoy moorings, used in the offshore petroleum industry for drilling,

production, processing and for storage purposes.

This standard applies to equipment in all installations, whether permanent, temporary,

transportable or hand-held, to a.c. installations up to and including 15 000 V, and d.c. instal-

lations up to and including 1 000 V.

This standard does not apply to electrical installations in rooms used for medical purposes, or

in tankers.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 61892. At the time of publication, the editions indicated

were valid. All normative documents are subject to revision, and parties to agreements based

on this part of IEC 61892 are encouraged to investigate the possibility of applying the most

recent editions of the normative documents indicated below. Members of IEC and ISO maintain

registers of currently valid International Standards.

IEC 60092-101:1994, Electrical installations in ships – Part 101: Definitions and general

requirements

IEC 60092-201:1994, Electrical installations in ships – Part 201: System design – General

IEC 60092-203:1985, Electrical installations in ships – Part 203: System design – Acoustic and

optical signals

IEC 60092-301:1980, Electrical installations in ships – Part 301: Equipment – Generators and

motors

IEC 60092-350:1988, Electrical installations in ships – Part 350: Low-voltage shipboard power

cables – General construction and test requirements

IEC 60092-352:1997, Electrical installations in ships – Part 352: Choice and installation of

cables for low-voltage power systems

IEC 60092-401:1980, Electrical installations in ships – Part 401: Installation and test of

completed installation

Amendment 1 (1987)

IEC 60447:1993, Man-machine interface (MMI) – Actuating principles

IEC 60825-1:1993, Safety of laser products – Part 1: Equipment classification, requirements

and user's guide

IEC 61892-3: – Mobile and fixed offshore units – Electrical installations – Part 3: Equipment

(to be published)

ISO 8468:1990, Ship's bridge layout and associated equipment – Requirements and guidelines

– 8 – 61892-6 © IEC:1999(E)

3 Definitions

For the purpose of this part of IEC 61892, the following definitions apply.

3.1

bond

connection of non-current-carrying parts to ensure continuity of electrical connection, or to

equalize the potential between parts

3.2

earth

general mass of the structure or hull of a unit

NOTE – In the USA and Canada "ground" is used instead of "earth".

3.3

earthed

connected to the general mass of the structure or hull of a unit in such a manner as will ensure

at all times an immediate discharge of electrical energy without danger

3.4

electric surface heating

heat generated in the surface layer of a body to be heated by electrical means in order to raise

or maintain its temperature

3.5

electric surface heating system

system of electric surface heating devices together with any controls, thermal insulation and

protective cladding designed to meet a specified electric surface heating requirement

3.6

emergency switchboard

switchgear and controlgear assembly which is normally supplied by the main switchboard but,

in the event of failure of the main electrical power supply system, is directly supplied by the

emergency source of electrical power or the transitional source of emergency power and is

intended to distribute and control electrical energy to the emergency services for all electrical

consumers essential for the safety of the crew and the unit under emergency conditions

3.7

equipotential bonding

electrical connection putting various exposed conductive parts and extraneous conductive parts

at a substantially equal potential

3.8

exposed conductive part

conductive part which can readily be touched and which is not normally alive, but which may

become alive under fault conditions

NOTE – Typical exposed conductive parts are walls of enclosures, operating handles, etc.

3.9

extraneous conductive part

conductive part not forming a part of the electrical installation and liable to propagate a

potential, including earth potential

61892-6 © IEC:1999(E) – 9 –

3.10

main switchboard

switchgear and controlgear assembly which is directly supplied by the main source of electrical

power and is intended to distribute and control electrical energy to the unit's services

3.11

primary structural damage

damage which can result from lightning strike to units which do not provide a path of low

resistance to earth for the passage of lightning currents, for example units of non-metallic

construction or those having substantial non-metallic members

3.12

safety voltage (extra low voltage)

voltage which does not exceed 50 V a.c. r.m.s. between conductors, or between any conductor

and earth, in a circuit isolated from the supply by means such as a safety isolating transformer,

or convertor with separate windings; a voltage which does not exceed 50 V d.c. between

conductors, or between any conductor and earth, in a circuit which is isolated from higher

voltage circuits

NOTE 1 – Consideration should be given to the use of equipment operating at less than 50 V under certain

conditions, such as wet surroundings, exposure to heavy seas or powerful water jets where direct contact with live

parts is involved.

NOTE 2 – The voltage limit should not be exceeded either at full load or no-load but it is assumed, for the purpose

of this definition, that any transformer or convertor is operated at its rated supply voltage.

3.13

secondary damage

damage to units or to their electrical installations which can result as an indirect consequence

of a lightning strike to a unit or to its immediate vicinity. A path to earth of low resistance may

not prevent secondary damage which may occur as a result of high values of induced or

resistance drop voltages produced by the passage of lightning currents

3.14

secondary battery Syn. (rechargeable) battery; storage battery (USA)

two or more secondary cells connected together and used as a source of electric energy.

4 Equipment earthing and bonding

4.1 General

4.1.1 This clause 4, Equipment earthing and bonding contains mainly provisions for earthing

of exposed conductive parts and bonding of extraneous conductive parts, various other

bonding connections and a table for sizes of earth-continuity conductors and earthing

connections.

4.1.2 All metallic parts of a unit, that are not normally current-carrying parts, shall be

designated as either an exposed conductive part or an extraneous conductive part.

a) Exposed conductive parts shall be connected to earth under the specific conditions for each

type of system earthing:

– for TT- and IT-systems, the exposed conductive parts shall be connected directly to

earth;

– for TN-S systems, the exposed conductive parts shall be connected to the protective

conductor, which is connected to earth at the neutral point of the distribution system.

NOTE 1 – For the definition of TT-, IT- and TN-S-systems, see IEC 60364-3.

NOTE 2 – Earth or an equipotential bonding system may be the steel structure or the hull of a unit.

– 10 – 61892-6 © IEC:1999(E)

b) Extraneous conductive parts shall be connected to an equipotential bonding system.

For units that have separate modules and/or concrete structures, equipotential bonding

shall be installed between extraneous conductive parts.

It shall be ensured that there is no detrimental mutual influence between the different

protective measures applied in the same installation or in part of an installation.

1)

NOTE 1 – For earthing requirements of system neutral points, see IEC 61892-2

NOTE 2 – For earthing and bonding requirements in hazardous areas, see IEC 61892-7.

4.2 Earthing of exposed conductive parts

4.2.1 Unless specifically included in the following exemptions, all exposed conductive parts

shall be earthed:

– lamp caps;

– shades, reflectors and guards, supported on lampholders or luminaires constructed of, or

shrouded in, non-conducting material;

– metal parts on, or screws in or through, non-conducting material, which are separated by

such material from current-carrying parts, and from earthed non-current-carrying parts in

such a way that in normal use they cannot become live or come into contact with earthed

parts;

2)

– portable appliances which have a double and/or reinforced insulation (see lEC 61892-1 )

provided that the appliances conform with recognized safety requirements;

– bearing housings which are insulated in order to prevent the circulation of current in the

bearings;

– clips for fluorescent lighting tubes;

– equipment supplied at extra-low voltage (safety voltage);

– cable clips;

– equipment of "all-insulated" construction in which the insulation enclosing the equipment is

durable and continuous;

– fixed equipment or parts of equipment which, although not shrouded in insulation material,

are nevertheless protected in such a way that they cannot be touched and cannot come into

contact with exposed metal;

– equipment located in special earth-free rooms.

4.2.2 Metal parts of portable appliances, other than current-carrying parts and parts exempted

in 4.2.1, shall be connected to earth by means of a conductor in the flexible cable or cord,

which complies with table 1 and which is connected, for example, through the associated plug

and socket-outlet.

4.2.3 Secondary windings of instrument transformers shall be earthed.

4.2.4 The bonding shall be such as to give a substantially equal potential and a sufficiently

low earth-fault loop impedance to ensure correct operation of protective devices.

4.3 Equipotential bonding

4.3.1 Extraneous conductive parts shall be connected to the equipotential bonding system as

described in 4.4.

___________

1)

In preparation. Before IEC 61892-2 is published, see IEC 60092-201.

2)

In preparation. Before IEC 61892-1 is published, see IEC 60092-101.

61892-6 © IEC:1999(E) – 11 –

4.3.2 Metal frames or enclosures of equipment mounted in direct metallic contact with the unit

structure need no supplementary bonding, provided that the surfaces in contact are clean and

free from rust, scale or paint when installed and are firmly bolted together. Alternatively, they

may be connected to the unit structure by a connection complying with 4.4.

4.3.3 Removable gland plates shall be separately bonded to the parent equipment, unless the

connection between the gland plate and the parent equipment complies with the requirement of

4.3.2.

4.4 Bonding connections

4.4.1 Every bonding connection to earth shall be of copper or other corrosion-resistant

material and shall be securely installed and protected where necessary against damage and

also against galvanic corrosion. Connections shall be secured against becoming loose due to

vibration.

4.4.2 The nominal cross-sectional area of every copper bonding connection shall be not less

than required in table 1. Every other bonding connection shall have a conductance not less

than that specified for a copper bonding connection.

4.4.3 Equipotential bonding connections for extraneous conductive parts shall have a cross-

sectional area of at least 6 mm .

4.5 Connections to the unit structure

4.5.1 The bonding shall be achieved by means of a separate bonding conductor unless the

parts under consideration are installed in accordance with 4.3.2.

4.5.2 Every connection of an earth conductor or a bonding conductor to the unit structure or

hull shall be made in an accessible position, and shall be secured by a screw of brass or other

corrosion resistant material, which shall be used for this purpose only. In all cases, care shall

be taken to ensure clean metallic surfaces free from rust at the contact areas immediately

before the screw is tightened.

4.5.3 Any electrical or instrumentation equipment attached, but not welded, to the structure

steelwork, for example to hand rails, ladders and stairways, shall be bonded to the nearest

structural steelwork.

4.5.4 To minimize shock from high-frequency voltage induced by the radio transmitter,

handles, handrails, etc., made of metal on the bridge or upper decks shall be in good electrical

connection with the hull or superstructure.

NOTE – See IEC 60533.

4.6 Protection against galvanic corrosion

Methods of securing dissimilar materials, for example aluminium to the structure or steel hull of

a unit, often include insulation to prevent galvanic corrosion between the materials. In such

cases, a separate bonding connection shall be provided between, for example, an aluminium

superstructure and structure or hull, which shall be made in such a manner that galvanic

corrosion is avoided and the points of connection may be readily inspected.

4.7 Metal coverings and mechanical protection of cables

4.7.1 All metal coverings of cables shall be earthed at both ends, except in so far as the

provisions given for single-core cables for a.c wiring apply (see clause 5). Single-point earthing

is admitted for final subcircuits (at the supply end) and in those installations (control and

instrumentation cables, mineral-insulated cables, intrinsically safe circuits, control circuits, etc.)

where it is required for technical or security reasons, if any.

– 12 – 61892-6 © IEC:1999(E)

4.7.2 Earthing connections shall be carried out with conductors that have cross-sectional

areas (see table 1) related to the current rating of the cables, or by equivalent means, such as

metal clamps gripping the metal covering of the cable and connected to earth.

The metal covering of cables may be earthed by means of glands intended for that purpose

and so designed as to ensure an effective earth connection.

The glands shall be firmly attached to, and in effective contact with, a metal structure earthed

in accordance with this standard.

4.7.3 The electrical continuity of all-metal coverings throughout the length of the cables,

particularly at joints and tappings, shall be ensured.

4.7.4 Metal casings, pipes and conduits or trunking shall be effectively earthed.

4.7.5 Conduits may be earthed by being screwed into a metal enclosure, or by nuts on both

sides of the wall of a metal enclosure, provided the surfaces in contact are clean and free from

rust, scale or paint and that the enclosure is in accordance with these provisions on earthing.

The connections shall be painted immediately after assembly in order to prevent corrosion.

4.7.6 Cable sheaths and armour, and conduits, may be earthed by means of clamps or clips

of corrosion-resistant and galvanically compatible metal, making effective contact with sheath

or armour and earthed metal.

4.7.7 All joints in metal conduits and ducts and in metallic sheaths of cables used for earth

continuity shall be soundly made and protected, where necessary, against corrosion.

4.7.8 Instrument cables without armour shall normally have screens earthed at the control

equipment.

4.7.9 Instrument cables with armour shall have screen and armour insulated from each other

with the screen earthed at the control equipment only and the armour earthed at both ends,

unless it is required for functional reasons to be earthed at one end only, in which case it shall

normally be earthed at the equipment or, in the case of intrinsically safe circuits, in accordance

with 4.7.10.

4.7.10 Intrinsically safe (IS) cables shall normally have a screen connected to the IS earth

bar.

4.7.11 Spare cores of glanded multi-core or multi-pair electrical and instrumentation cables

shall be connected to terminal blocks and be collectively earthed.

NOTE – Due to the lack of international provisions covering the use of cable armours, metal sheaths or shields as

protective earthing conductors for connected equipment, reference is made to national codes.

4.8 Cable racks and cable tray

4.8.1 Electrical continuity shall be maintained at splices between sections of cable ladder,

rack or tray by the use of splice plates. Additional bonding is not required.

4.9 Ductings of heating, ventilation, air-condition (HVAC) and vessels

4.9.1 Vessels and equipment skids which are not seam-welded to the structural steel shall be

bonded to earth using the integral earthing bosses supplied with the equipment.

4.9.2 Electrical continuity shall be maintained between HVAC ducting sections and between

ducting and the main structure.

61892-6 © IEC:1999(E) – 13 –

Table 1 – Sizes of protective-earthing (PE) conductors and earthing connections

Type of earthing Cross-sectional Minimum cross-sectional area

connection area of associated of copper earthing connection

current-carrying

conductor

1. PE conductor in Any Same as current-carrying conductor up to and including 16 mm², or

flexible cable or one-half above 16 mm² but at least 16 mm²

flexible cord

2. PE conductor Up to and including Same as current-carrying conductor up to and including 16 mm² but

incorporated in 16 mm² at least 1,5 mm²

fixed cable

a) insulated PE Over 16 mm² 50 % of the current-carrying conductor but at least 16 mm²

conductor

b) bare PE conductor 1 mm² to 2,5 mm² 1 mm²

in contact with

4 mm² to 6 mm² 1,5 mm²

metallic covering

3. Separate fixed Not exceeding 3 mm² Same as current-carrying conductor subject to minimum of 1,5 mm²

earthing conductor for stranded earth conductor, or 3 mm² for solid earth conductor

Exceeding 3 mm² One-half of the cross-sectional area of the current-carrying

but not exceeding conductor, subject to a minimum of 3 mm²

125 mm²

Exceeding 125 mm² 64 mm²

5 Cables and wiring

5.1 General

This clause contains provisions for the installation of cables and wiring, while IEC 61892-4

(under consideration) contains provisions for the construction, rating and selection of cables.

5.2 Installation

Low-voltage cables and their accessories shall be installed in accordance with the

requirements given in IEC 60092-401, Section Nine and Amendment 1, except for clause 36,

and IEC 60092-352.

6 Generators and motors

6.1 General

This clause contains provisions for the installation of all types of electrical rotating machines on

1)

offshore units. Regarding location of generators, see IEC 61892-2 .

6.2 Installation

6.2.1 Generators and motors shall, where practicable, be installed to minimise the effect of

motion of the unit.

NOTE – Regarding requirements for lubrication, see IEC 61892-3.

___________

1)

In preparation. Before future IEC 61892-2 is published, see IEC 60092-201.

– 14 – 61892-6 © IEC:1999(E)

6.2.2 Generators shall be located in well-ventilated spaces where combustible gases cannot

accumulate.

NOTE – This requirement does not preclude the installation of generators and prime movers in zone 2, provided

sufficient precautions are taken with regard to ventilation and to explosion protection of equipment. For additional

requirements for installations in hazardous areas, see IEC 61892-7.

7 Transformers

7.1 General

This clause contains provisions for the installation of all types of transformers used for power

and lighting on offshore units.

7.2 Installation and location

7.2.1 Transformers shall be installed in well-ventilated compartments, accessible only to

authorized personnel. The one exception to this rule is that air-cooled transformers provided

with means of protection against accidental contact with live parts need not be installed in

special compartments.

7.2.2 Liquid-immersed transformers shall be installed in an area with provisions for

containment and drainage of liquid leakage. When flammable liquid such as oil is used,

consideration shall be given to the need for fire extinguishing equipment, taking into account

other equipment that may be installed within the same space.

7.2.3 Suitable arrangements shall be provided for cooling and containing all the liquid which

might escape from a damaged tank. Contamination of bilges shall be avoided by the provision

of suitable drip-trays or save-alls.

7.2.4 Transformers and their connections shall be protected against such mechanical

damage, condensation and corrosion as may reasonably be expected.

7.2.5 Where liquid cooling is used, consideration shall be given to the provision of a device

capable of detecting leakage into the enclosure and provision of an alarm signal in either

primary or secondary cooling circuit, as relevant. In addition, the flow of coolant shall be

monitored in order to operate an alarm in the event of a loss of flow.

7.2.6 Where provision is made for breathing, a suitable desiccator shall be provided.

7.2.7 Where forced cooling is used, it shall be possible to operate the transformer at reduced

power on failure of a pump or fan. Consideration shall be given to the provision of a suitable

temperature indicator and alarm facilities.

7.3 Isolation of windings

7.3.1 Means shall be provided for the isolation of secondary windings which can be connected

to a source of voltage.

7.3.2 Where transformers are arranged to operate in parallel, means shall be provided for the

isolation of the primary and secondary windings.

7.3.3 A suitable warning label indicating the points of isolation shall be provided near the point

of access.

61892-6 © IEC:1999(E) – 15 –

8 Switchgear and controlgear assemblies

8.1 General

This clause contains provisions for the installation of low-voltage switchgear and controlgear

assemblies.

8.2 Location

Switchgear and controlgear assemblies shall, in so far as practically possible, be

8.2.1

installed in easily accessible and well-ventilated locations where combustible gases, acid

vapours or similar do not occur, and shall be located well clear of heat sources such as boilers,

heated oil tanks, steam exhaust pipes or other heated pipes.

1)

In addition to complying with the appropriate requirements of IEC 61892-1 , all switchgear and

controlgear assemblies shall be so installed that no pipes or tanks are above them within the

same space or at their rear. Where this is unavoidable, pipes shall be continuous and without

openings in such locations.

8.2.2 Where switchgear and controlgear assemblies are located in dedicated rooms, pipes or

conduits for water, steam, gas, oil, etc., which are not related to the electrical equipment, are

not permitted.

8.3 Insulating mats

When the voltage exceeds the extra-low voltage (safety voltage) as defined in clause 3, an

insulating mat or grating shall be provided in front of switchgear and controlgear assemblies

and also at the rear, if access from the rear is required. The insulating mat or grating shall be

oil-resistant and non-slip.

NOTE 1 – If an assembly contains withdrawable equipment, the insulating mat or grating should be provided in

front of and on both sides of the equipment in its fully withdrawn position.

NOTE 2 – Removable mats for use only during repair and maintenance should be considered.

NOTE 3 – See IEC 61111.

NOTE 4 – This requirement does not apply when the floor is made of an insulating layer.

8.4 Passageways in front of switchgear and controlgear assemblies

8.4.1 An unobstructed passageway extending not less than 1 m wide from the furthest

projection shall be provided in front of any assemblies.

8.4.2 When an assembly contains withdrawable equipment, for example circuit-breaker and

starter chassis, the unobstructed passageway shall not be less than 0,4 m wide with this

equipment in its fully withdrawn position.

8.4.3 For small units, the unobstructed passageway may be reduced subject to agreement by

the appropriate authority.

8.5 Space at the rear and passsageways

When a space is provided at the rear of switchgear and controlgear assemblies, it shall be

ample to permit maintenance and in general shall be not less than 0,6 m in the clear, except

that the width may be reduced to 0,5 m where there are stiffeners and frames.

NOTE – For nominal voltages exceeding 600 V, it is recommended to increase this space.

___________

1)

In preparation. Before IEC 61892-1 is published, see IEC 60092-101.

– 16 – 61892-6 © IEC:1999(E)

Passageways behind main and emergency switchboards with open rear shall be of ample

height and shall, where practicable, be provided at each end with an access door fitted with an

external lock which can at all times be opened from the interior. The access doors shall carry a

permanent and prominent indication of the maximum voltage.

8.6 Positions of section and distribution boards

In accommodation spaces where open-type assemb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...