IEC 60599:2022

(Main)Mineral oil-filled electrical equipment in service - Guidance on the interpretation of dissolved and free gases analysis

Mineral oil-filled electrical equipment in service - Guidance on the interpretation of dissolved and free gases analysis

IEC 60599:2022 describes how the concentrations of dissolved gases or free gases can be interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest future action. This document is applicable to electrical equipment filled with mineral insulating oil and insulated with cellulosic paper or pressboard-based solid insulation. Information about specific types of equipment such as transformers (power, instrument, industrial, railways, distribution), reactors, bushings, switchgear and oil-filled cables is given only as an indication in the application notes. This document can be applied, but only with caution, to other liquid-solid insulating systems. In any case, the indications obtained are given only as guidance with resulting action undertaken only with proper engineering judgment.

Matériels électriques remplis d'huile minérale en service - Recommandations relatives à l'interprétation de l'analyse des gaz dissous et des gaz libres

IEC 60599:2022 décrit la façon dont les concentrations de gaz dissous ou de gaz libres peuvent être interprétées pour diagnostiquer l'état des matériels électriques remplis d'huile en service et pour proposer une intervention ultérieure. Le présent document s'applique aux matériels électriques remplis d'huile minérale isolante et isolés par des isolants solides constitués de papier ou de carton cellulosiques. Des informations relatives aux types spécifiques de matériels tels que les transformateurs (de puissance, de mesure, industriels, ferroviaires, de distribution), les réactances, les traversées, les appareillages de connexion et les câbles à huile fluide sont données, à titre informatif seulement, dans les notes d'application. Le présent document peut être appliqué, mais uniquement avec prudence, à d'autres systèmes d'isolation liquide-solide. Dans tous les cas, les indications obtenues sont données uniquement à titre de recommandations et toute action qui en résulte n'est à entreprendre qu'après une appréciation technique convenable.

General Information

- Status

- Published

- Publication Date

- 24-May-2022

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- MT 20 - TC 10/MT 20

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-May-2022

- Completion Date

- 17-Jun-2022

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60599:2022 (Edition 4.0) provides guidance for interpreting dissolved gas analysis (DGA) and free gas analysis results from mineral oil-filled electrical equipment. The standard explains how concentrations of dissolved or free gases can indicate the condition of oil-filled assets and suggests appropriate follow-up actions. It applies to equipment insulated with mineral insulating oil and cellulosic paper or pressboard, including transformers (power, instrument, industrial, distribution, railways), reactors, bushings, switchgear and oil‑filled cables. Interpretations are intended as guidance only and should be used with proper engineering judgment.

Key topics and technical requirements

- Mechanisms of gas formation - decomposition of oil, decomposition of cellulosic insulation, stray gassing and other gas sources.

- Identification of faults - guidance on linking gas species and mixtures to fault types (thermal, electrical, arcing, partial discharge).

- Gas ratios and diagnostic methods - basic gas ratios, CO/CO2, O2/N2, hydrocarbon ratios and use of graphical tools such as Duval’s triangle for fault classification.

- Conditions for calculation - how to examine DGA values, handle uncertainties and calculate meaningful gas ratios.

- Free gases in gas relays - specific considerations when interpreting free gas measurements.

- Probability and alarm levels - methods for assessing probability of failure, typical concentration values, alarm thresholds and rates of gas increase.

- Reporting and documentation - recommended content for DGA reports and equipment-specific application notes (Annex A).

- Graphical representations and tools - flow charts, interpretation tables (Table 1, Table 2) and multiple graphical representations (Annex B, Duval triangles).

- Supporting data - tables such as Ostwald solubility coefficients and typical concentration/rate ranges for different equipment types.

Applications and users

IEC 60599 is practical for:

- Asset managers and utilities performing transformer and substation condition monitoring.

- Maintenance and reliability engineers using DGA to plan interventions and maintenance priorities.

- Test laboratories and service companies that analyze oil samples and prepare DGA reports.

- Transformer manufacturers and commissioning teams for post‑installation monitoring.

- Consultants and safety engineers assessing risk and failure probability.

Use cases include routine condition monitoring, fault diagnosis, trending and alarm setting, and prioritizing corrective action based on DGA and free gas trends.

Related guidance

IEC 60599 complements other IEC guidance on insulating oils, transformer testing and condition assessment. It provides interpretative methods, equipment application notes and graphical tools but emphasizes that results must be combined with site knowledge and engineering judgment for final decisions.

Keywords: IEC 60599, dissolved gas analysis, DGA, free gas analysis, mineral oil-filled equipment, transformer diagnostics, Duval’s triangle, gas ratios.

Buy Documents

REDLINE IEC 60599:2022 CMV - Mineral oil-filled electrical equipment in service - Guidance on the interpretation of dissolved and free gases analysis Released:5/25/2022

IEC 60599:2022 - Mineral oil-filled electrical equipment in service - Guidance on the interpretation of dissolved and free gases analysis Released:5/25/2022

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60599:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mineral oil-filled electrical equipment in service - Guidance on the interpretation of dissolved and free gases analysis". This standard covers: IEC 60599:2022 describes how the concentrations of dissolved gases or free gases can be interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest future action. This document is applicable to electrical equipment filled with mineral insulating oil and insulated with cellulosic paper or pressboard-based solid insulation. Information about specific types of equipment such as transformers (power, instrument, industrial, railways, distribution), reactors, bushings, switchgear and oil-filled cables is given only as an indication in the application notes. This document can be applied, but only with caution, to other liquid-solid insulating systems. In any case, the indications obtained are given only as guidance with resulting action undertaken only with proper engineering judgment.

IEC 60599:2022 describes how the concentrations of dissolved gases or free gases can be interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest future action. This document is applicable to electrical equipment filled with mineral insulating oil and insulated with cellulosic paper or pressboard-based solid insulation. Information about specific types of equipment such as transformers (power, instrument, industrial, railways, distribution), reactors, bushings, switchgear and oil-filled cables is given only as an indication in the application notes. This document can be applied, but only with caution, to other liquid-solid insulating systems. In any case, the indications obtained are given only as guidance with resulting action undertaken only with proper engineering judgment.

IEC 60599:2022 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.040.10 - Insulating oils; 29.180 - Transformers. Reactors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60599:2022 has the following relationships with other standards: It is inter standard links to IEC 60599:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60599:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60599 ®

Edition 4.0 2022-05

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Mineral oil-filled electrical equipment in service – Guidance on the interpretation

of dissolved and free gases analysis

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a

Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60599 ®

Edition 4.0 2022-05

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Mineral oil-filled electrical equipment in service – Guidance on the interpretation

of dissolved and free gases analysis

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.99; 29.040.10; 29.180 ISBN 978-2-8322-3798-4

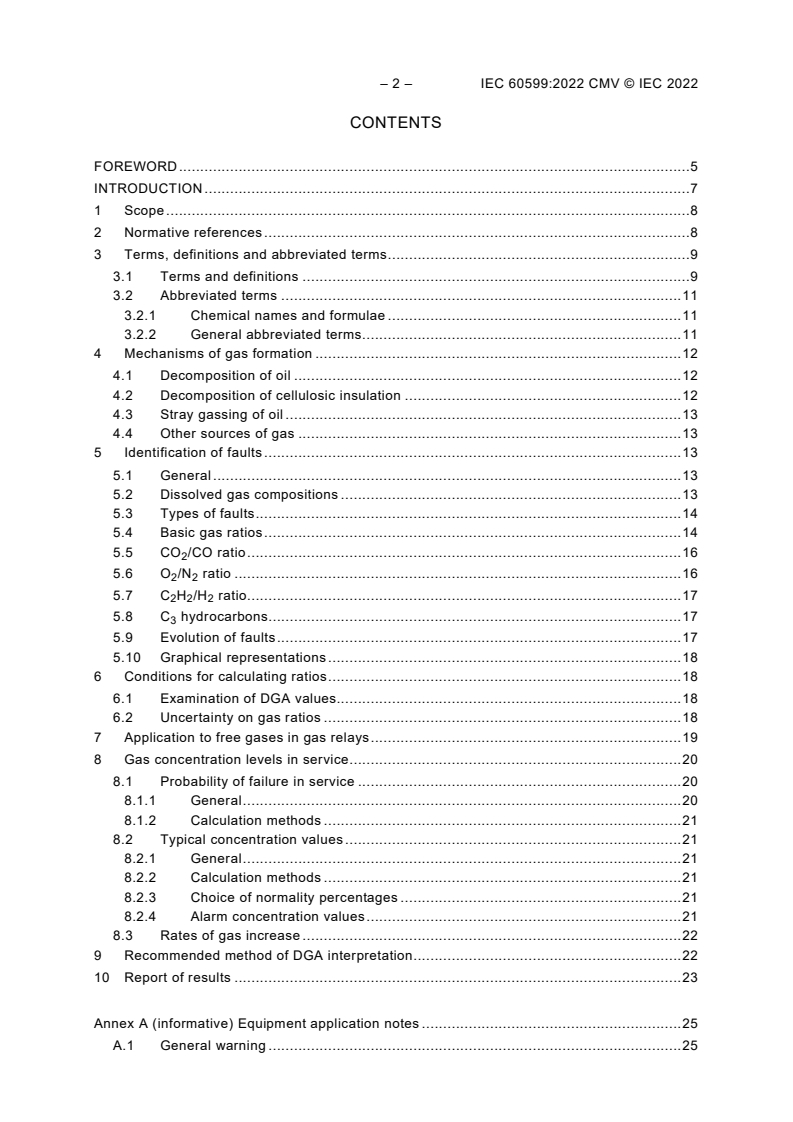

– 2 – IEC 60599:2022 CMV © IEC 2022

CONTENTS

FOREWORD .5

INTRODUCTION .7

1 Scope .8

2 Normative references .8

3 Terms, definitions and abbreviated terms .9

3.1 Terms and definitions .9

3.2 Abbreviated terms . 11

3.2.1 Chemical names and formulae . 11

3.2.2 General abbreviated terms . 11

4 Mechanisms of gas formation . 12

4.1 Decomposition of oil . 12

4.2 Decomposition of cellulosic insulation . 12

4.3 Stray gassing of oil . 13

4.4 Other sources of gas . 13

5 Identification of faults . 13

5.1 General . 13

5.2 Dissolved gas compositions . 13

5.3 Types of faults . 14

5.4 Basic gas ratios . 14

5.5 CO /CO ratio . 16

5.6 O /N ratio . 16

2 2

5.7 C H /H ratio. 17

2 2 2

5.8 C hydrocarbons . 17

5.9 Evolution of faults . 17

5.10 Graphical representations . 18

6 Conditions for calculating ratios . 18

6.1 Examination of DGA values . 18

6.2 Uncertainty on gas ratios . 18

7 Application to free gases in gas relays . 19

8 Gas concentration levels in service . 20

8.1 Probability of failure in service . 20

8.1.1 General . 20

8.1.2 Calculation methods . 21

8.2 Typical concentration values . 21

8.2.1 General . 21

8.2.2 Calculation methods . 21

8.2.3 Choice of normality percentages . 21

8.2.4 Alarm concentration values . 21

8.3 Rates of gas increase . 22

9 Recommended method of DGA interpretation . 22

10 Report of results . 23

Annex A (informative) Equipment application notes . 25

A.1 General warning . 25

A.2 Power transformers . 25

A.2.1 Specific subtypes . 25

A.2.2 Typical faults . 25

A.2.3 Identification of faults by DGA . 26

A.2.4 Typical concentration values . 26

A.2.5 Typical rates of gas increase . 27

A.2.6 Specific information to be added to the DGA report. 28

A.3 Industrial and special transformers . 28

A.3.1 Specific subtypes . 28

A.3.2 Typical faults . 28

A.3.3 Identification of faults by DGA . 29

A.3.4 Typical concentration values . 29

A.4 Instrument transformers . 30

A.4.1 Specific subtypes . 30

A.4.2 Typical faults . 30

A.4.3 Identification of faults by DGA . 31

A.4.4 Typical concentration values . 31

A.5 Oil-impregnated paper bushings . 32

A.5.1 Specific subtypes . 32

A.5.2 Typical faults . 32

A.5.3 Identification of faults by DGA . 32

A.5.4 Typical concentration values . 33

A.6 Oil-filled cables . 34

A.6.1 Typical faults . 34

A.6.2 Identification of faults by DGA . 34

A.6.3 Typical concentration values . 34

A.7 Switching equipment . 35

A.7.1 Specific subtypes . 35

A.7.2 Normal operation . 35

A.7.3 Typical faults . 35

A.7.4 Identification of faults by DGA . 35

A.8 Equipment filled with non-mineral fluids . 36

Annex B (informative) Graphical representations of gas ratios . 37

Bibliography . 41

List of comments . 42

Figure 1 – Flow chart . 24

Figure B.1 – Graphical representation 1 of gas ratios (see [3]) . 37

Figure B.2 – Graphical representation 2 of gas ratios . 38

Figure B.3 – Graphical representation 3 of gas ratios – Duval's triangle 1 for

transformers, bushings and cables (see [4]) . 39

Figure B.4 – Graphical representation 4 of gas ratios – Duval's triangle 2 for OLTCs

(see A.7.2) . 40

Table 1 – DGA interpretation table . 15

Table 2 – Simplified scheme of interpretation . 15

Table 3 – Ostwald solubility coefficients for various gases in mineral insulating oils . 20

Table A.1 – Typical faults in power transformers . 26

– 4 – IEC 60599:2022 CMV © IEC 2022

Table A.2 – Ranges of 90 % typical gas concentration values observed in power

transformers, in µl/l . 27

Table A.3 – Ranges of 90 % typical rates of gas increase observed in power

transformers (all types), in µl/l . 27

Table A.4 – Examples of 90 % typical concentration values observed on individual

networks . 29

Table A.5 – Ranges of 90 % typical concentration values observed in WTTs . 30

Table A.6 – Typical faults in instrument transformers. 31

Table A.7 – Ranges of 90 % typical concentration values observed in instrument

transformers . 31

Table A.8 – Maximum admissible values for sealed instrument transformers . 32

Table A.9 – Typical faults in bushings . 32

Table A.10 – Simplified interpretation scheme for bushings . 33

Table A.10 – 95 % typical concentration values in bushings.

Table A.11 – Ranges of 90 % typical concentration values in bushings . 33

Table A.12 – Ranges of 95 % typical concentration values observed on cables . 34

Table A.13 – Typical faults in switching equipment . 35

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINERAL OIL-FILLED ELECTRICAL EQUIPMENT IN SERVICE –

GUIDANCE ON THE INTERPRETATION OF DISSOLVED AND

FREE GASES ANALYSIS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 60599:2022 edition 4.0 allows

the user to identify the changes made to the previous IEC 60599:2015 edition 3.0.

Futhermore, comments from IEC TC 10 experts are provided to explain the reasons of the

most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in

green text, deletions are in strikethrough red text. Experts' comments are identified by a

blue-background number. Mouse over a number to display a pop-up note with the

comment.

This publication contains the CMV and the official standard. The full list of comments is

available at the end of the CMV.

– 6 – IEC 60599:2022 CMV © IEC 2022

IEC 60599 has been prepared by IEC technical committee 10: Fluids for electrotechnical

applications. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) revision of Clause A.5 on bushings, at the request of IEC subcommittee 36A, in order to

transfer to IEC 60599 the corresponding contents of IEC TR 61464 [1] relating to DGA in

bushings and include the new information on DGA in bushings available in CIGRE Technical

Brochure 771 (2019) [2];

b) revision of Clause A.3 on wind turbine transformers, in order to include in IEC 60599 the

new information on DGA in wind turbine transformers available in CIGRE Technical

Brochure 771 (2019) [2].

The text of this International Standard is based on the following documents:

Draft Report on voting

10/1164/FDIS 10/1174/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

___________

Numbers in square brackets refer to the Bibliography.

INTRODUCTION

Dissolved and free gas analysis (DGA) is one of the most widely used diagnostic tools for

detecting and evaluating faults in electrical equipment filled with insulating liquid. However,

interpretation of DGA results is often complex and should always be done with care, involving

experienced insulation maintenance personnel.

This document gives information for facilitating this interpretation. The first edition, published

in 1978, has served the industry well, but had its limitations, such as the absence of a diagnosis

in some cases, the absence of concentration levels and the fact that it was based mainly on

experience gained from power transformers. The second edition (2015) attempted to address

some of these shortcomings. Interpretation schemes were based on observations made after

inspection of a large number of faulty oil-filled equipment in service and concentrations levels

deduced from analyses collected worldwide.

– 8 – IEC 60599:2022 CMV © IEC 2022

MINERAL OIL-FILLED ELECTRICAL EQUIPMENT IN SERVICE –

GUIDANCE ON THE INTERPRETATION OF DISSOLVED AND

FREE GASES ANALYSIS

1 Scope

This document describes how the concentrations of dissolved gases or free gases may can be

interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest

future action.

This document is applicable to electrical equipment filled with mineral insulating oil and

insulated with cellulosic paper or pressboard-based solid insulation. Information about specific

types of equipment such as transformers (power, instrument, industrial, railways, distribution),

reactors, bushings, switchgear and oil-filled cables is given only as an indication in the

application notes (see Annex A).

This document may can be applied, but only with caution, to other liquid-solid insulating systems.

In any case, the indications obtained should be viewed are given only as guidance and any with

resulting action should be undertaken only with proper engineering judgment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-191:1990, International Electrotechnical Vocabulary – Chapter 191: Dependability

and quality of service (available at http://www.electropedia.org)

IEC 60050-192:2015, International Electrotechnical Vocabulary – Part 192: Dependability

(available at http://www.electropedia.org)

IEC 60050-212:2010, International Electrotechnical Vocabulary – Part 212: Electrical insulating

solids, liquids and gases (available at http://www.electropedia.org)

IEC 60050-604:1987, International Electrotechnical Vocabulary – Chapter 604: Generation,

transmission and distribution of electricity – Operation (available at http://www.electropedia.org)

IEC 60475, Method of sampling insulating liquids

IEC 60567:2011, Oil-filled electrical equipment – Sampling of gases and analysis of free and

dissolved gases – Guidance

IEC 61198, Mineral insulating oils – Methods for the determination of 2-furfural and related

compounds

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions, some of which are based

on IEC 60050-191, IEC 60050-192, IEC 60050-212 and IEC 60050-604, apply.

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

fault

unplanned occurrence or defect in an item which may result in one or more failures of the item

itself or of other associated equipment

[SOURCE: IEC 60050-604:1987, 604-02-01]

3.1.2

non-damage fault

fault which does not involve repair or replacement action at the point of the fault

Note 1 to entry: Typical examples are self-extinguishing arcs in switching equipment or general overheating without

paper carbonization or stray gassing of oil.

[SOURCE: IEC 60050-604:1987, 604-02-09]

3.1.3

damage fault

fault that involves repair or replacement action at the point of the fault

[SOURCE: IEC 60050-604:1987, 604-02-08]

3.1.4

incident

event of external or internal origin, affecting equipment or the supply system and which disturbs

its normal operation

Note 1 to entry: For the purposes of this document "incidents" are related to internal faults.

Note 2 to entry: For the purposes of this document typical examples of "incidents" are gas alarms, equipment

tripping or equipment leakage.

[SOURCE: IEC 60050-604:1987, 604-02-03]

3.1.5

failure

loss of ability to perform as required

Note 1 to entry: In electrical equipment, failure will result from a damage fault or incident necessitating outage,

repair or replacement of the equipment, such as internal breakdown, rupture of tank, fire or explosion.

[SOURCE: IEC 60050-192:2015, 192-03-01]

– 10 – IEC 60599:2022 CMV © IEC 2022

3.1.6

electrical fault

partial or disruptive discharge through the insulation

3.1.7

partial discharge

electric discharge that only partially bridges the insulation between conductors

Note 1 to entry: A partial discharge may occur inside the insulation or adjacent to a conductor.

Note 2 to entry: Scintillations of low energy on the surface of insulating materials are often described as partial

discharges but should rather be considered as disruptive discharges of low energy, since they are the result of local

dielectric breakdowns of high ionization density, or small arcs, according to the conventions of physics.

Note 3 to entry: For the purposes of this document the following consideration may can also be added:

– Corona is a form of partial discharge that occurs in gaseous media around conductors that are remote from solid

or liquid insulation. This term shall not be used as a general term for all forms of partial discharges.

– As a result of corona discharges, X-wax, a solid material consisting of polymerized fragments of the molecules

of the original liquid, can be formed.

[SOURCE: IEC 60050-212:2010, 212-11-39]

3.1.8

discharge (disruptive) discharge

passage of an arc following the breakdown

Note 1 to entry: The term "sparkover" (in French: "amorçage") is used when a disruptive discharge occurs in a

gaseous or liquid dielectric.

The term "flashover" (in French: "contournement") is used when a disruptive discharge occurs over the surface of a

solid dielectric surrounded by a gaseous or liquid medium.

The term "puncture" (in French: "perforation") is used when a disruptive discharge occurs through a solid dielectric.

Note 2 to entry: Discharges are often described as arcing, breakdown or short circuits. The following other specific

terms are also used in some countries:

– tracking (the progressive degradation of the surface of solid insulation by local discharges to form conducting or

partially conducting paths);

– sparking discharges that, in the conventions of physics, are local dielectric breakdowns of high ionization density

or small arcs.

[SOURCE: IEC 60050-604:1987, 604-03-38]

3.1.9

thermal fault

excessive temperature rise in the insulation

Note 1 to entry: Typical causes are

– insufficient cooling;

– excessive currents circulating in adjacent metal parts (as a result of bad contacts, eddy currents, stray losses or

leakage flux);

– excessive currents circulating through the insulation (as a result of high dielectric losses), leading to a thermal

runaway;

– overheating of internal winding or bushing connection lead;

– overloading.

3.1.10

typical values of gas concentrations

gas concentrations normally found in the equipment in service that have no symptoms of failure,

and that are exceeded by only an arbitrary percentage of higher gas contents (for example 10%)

Note 1 to entry: See 8.2.1.

Note 2 to entry: Typical values will differ in different types of equipment and in different networks, depending on

operating practices (load levels, climate, etc.).

Note 3 to entry: Typical values, in many countries and by many users, are quoted as "normal values", but this term

has not been used in this document to avoid possible misinterpretations.

3.2 Abbreviated terms

3.2.1 Chemical names and formulae

Name Formula

Nitrogen N

Oxygen O

Hydrogen H

Carbon monoxide CO

Carbon dioxide CO

Methane CH

Ethane C H

2 6

Ethylene C H

2 4

Acetylene C H

2 2

NOTE Acetylene and ethyne are both used for C H ; ethylene and ethene are both used for C H .

2 2 2 4

3.2.2 General abbreviated terms

CT current transformer

CTCV combined transformer (current-voltage)

CIVT cascade (inductive) voltage transformer

CVT capacitor voltage transformer

MVT magnetic voltage transformer

VT voltage transformer

ONAN oil natural air natural

OFAF oil forced air forced

DDB dodecylbenzene

WTT wind turbine transformer

D1 discharges of low energy

D2 discharges of high energy

DGA dissolved gas analysis

CIGRE Conseil International des Grands Réseaux Électriques

PD corona partial discharges

S analytical detection limit

T1 thermal fault, t < 300 °C

T2 thermal fault, 300 °C < t < 700 °C

T3 thermal fault, t > 700 °C

T thermal fault

D electrical fault

TP thermal fault in paper

– 12 – IEC 60599:2022 CMV © IEC 2022

ppm parts per million by volume of gas in oil, equivalent to µl (of gas)/l (of oil). See

IEC 60567:2011, 8.7, Note 1.

OLTC on-load tap-changer

4 Mechanisms of gas formation

4.1 Decomposition of oil

Mineral insulating oils are made of a blend of different hydrocarbon molecules containing CH ,

CH and CH chemical groups linked together by carbon-carbon molecular bonds.

Scission of some of the C-H and C-C bonds may can occur as a result of electrical and thermal

faults, with the formation of small unstable fragments, in radical or ionic form, such as

• •

• • •

H , CH , CH , CH or C (among many other more complex forms), which recombine rapidly,

3 2

through complex reactions, into gas molecules such as hydrogen (H-H), methane (CH -H),

ethane (CH -CH ), ethylene (CH = CH ) or acetylene (CH ≡ CH). C and C hydrocarbon

3 3 2 2 3 4

gases, as well as solid particles of carbon and hydrocarbon polymers (X-wax), are other

possible recombination products. The gases formed dissolve in oil, or accumulate as free gases

if produced rapidly in large quantities, and may can be analysed by DGA according to IEC 60567.

Low-energy faults, such as partial discharges of the cold plasma type (corona discharges),

favour the scission of the weakest C-H bonds (338 kJ/mol) through ionization reactions and the

accumulation of hydrogen as the main recombination gas. More and more energy and/or higher

temperatures are needed necessary for the scission of the C-C bonds and their recombination

into gases with a C-C single bond (607 kJ/mol), C=C double bond (720 kJ/mol) or C≡C triple

bond (960 kJ/mol), following processes bearing some similarities with those observed in the

petroleum oil-cracking industry.

Ethylene is thus favoured over ethane and methane above temperatures of approximately

500 °C (although still present in lower quantities below these temperatures). Acetylene requires

temperatures of at least 800 °C to 1 200 °C, and a rapid quenching to lower temperatures, in

order to accumulate as a stable recombination product. Acetylene is thus formed in significant

quantities mainly in arcs, where the conductive ionized channel is at several thousands of

degrees Celsius, and the interface with the surrounding liquid oil necessarily below 400 °C

(above which oil vaporizes completely), with a layer of oil vapour and/or decomposition gases

in between. Acetylene may can still be formed at lower temperatures (< 800 °C), but in very

minor quantities. Carbon particles form at 500 °C to 800 °C and are indeed observed after

arcing in oil or around very hot spots.

Oil may can oxidize with the formation of small quantities of CO and CO , which can accumulate

over long periods of time into more substantial amounts.

4.2 Decomposition of cellulosic insulation

The polymeric chains of solid cellulosic insulation (paper, pressboard, wood blocks) contain a

large number of anhydroglucose rings, and weak C-O molecular bonds and glycosidic bonds

which are thermally less stable than the hydrocarbon bonds in oil, and which decompose at

lower temperatures. Significant rates of polymer chain scission occur at temperatures higher

than 105 °C, with complete decomposition and carbonization above 300 °C (damage fault).

Carbon monoxide and dioxide, as well as water, is formed, together with minor amounts of

hydrocarbon gases, furanic and other compounds. Furanic compounds are analysed according

to IEC 61198, and used to complement DGA interpretation and confirm whether or not cellulosic

insulation is involved in a fault. CO and CO formation increases not only with temperature but

also with the oxygen content of oil and the moisture content of paper.

4.3 Stray gassing of oil

Stray gassing of oil has been defined by CIGRE [3] as the formation of gases in oil heated to

moderate temperatures (< 200 °C). H , CH and C H may can be formed in all equipment at

2 4 2 6

such temperatures or as a result of oil oxidation, depending on oil chemical structure. Stray

gassing is a non-damage fault. It can be evaluated using methods described in references [3]

and [4].

NOTE Stray gassing of oil has been observed in some cases to be enhanced by the presence in oil of a metal

passivator or other additives.

4.4 Other sources of gas

Gases may can be generated in some cases not as a result of faults in the equipment, but

through rusting corrosion or other chemical reactions involving steel, uncoated surfaces or

protective paints.

Hydrogen may can be produced by reaction of steel and galvanized steel with water, as long

as oxygen is available from the oil nearby. Large quantities of hydrogen have thus been reported

in some transformers that had never been energized. Hydrogen may can also be formed by

reaction of free water with special coatings on metal surfaces, or by catalytic reaction of some

types of stainless steel with oil, in particular oil containing dissolved oxygen at elevated

temperatures. Hydrogen, acetylene and other gases may can also be formed in new stainless

steel, absorbed during its manufacturing process, or produced by welding, and released slowly

into the oil. Internal transformer paints, such as alkyd resins and modified polyurethanes

containing fatty acids in their formulation, may can also form gases.

Gases may can also be produced, and oxygen consumed, by exposure of oil to sunlight.

These occurrences, however, are very unusual, and can be detected by performing DGA

analyses on new equipment which has never been energized, and by material compatibility

tests. The presence of hydrogen with the total absence of other hydrocarbon gases, for example,

may can be an indication of such a problem.

NOTE The case of gases formed at a previous fault and remnant in the transformer is dealt with in 5.4.

5 Identification of faults

5.1 General

Any gas formation in service, be it minimal, results from a stress of some kind, even if it is a

very mild one, like normal temperature ageing. However, as long as gas concentration is below

typical values and not significantly increasing, it should not be considered as an indication of a

"fault", but rather as the result of typical gas formation (see Figure 1). Typical values are specific

for each kind of equipment.

5.2 Dissolved gas compositions

Although the formation of some gases is favoured, depending on the temperature reached or

the energy contained in a fault (see 4.1), in practice mixtures of gases are almost always

obtained. One reason is thermodynamic: although not favoured, secondary gases are still

formed, albeit in minor quantities. Existing thermodynamic models derived from the petroleum

industry, however, cannot predict accurately the gas compositions formed, because they

correspond to ideal gas and/or temperature equilibria that do not exist in actual faults. Large

temperature gradients also occur in practice, for instance as a result of oil flow or vaporization

along a hot surface. This is particularly true in the case of arcs with power follow-through, which

transfer a lot of heat to the oil vapour and/or decomposition gas layer between the arc and the

oil, probably explaining the increasing formation of ethylene observed in addition to acetylene.

In addition, existing thermodynamic models do not apply to paper that turns irreversibly to

carbon above 300 °C.

– 14 – IEC 60599:2022 CMV © IEC 2022

5.3 Types of faults

Internal inspection of hundreds of faulty equipment has led to the following broad classes of

visually detectable faults:

– partial discharges (PD) of the cold plasma (corona) type, resulting in possible X-wax

deposition on paper insulation;

– discharges of low energy (D1), in oil and/or paper, evidenced by larger carbonized

perforations through paper (punctures), carbonization of the paper surface (tracking) or

carbon particles in oil (as in tap changer diverter operation); also, partial discharges of the

sparking type, inducing pinhole, carbonized perforations (punctures) in paper, which,

however, may be difficult to find;

– discharges of high energy (D2), in oil and/or paper, with power follow-through, evidenced

by extensive destruction and carbonization of paper, metal fusion at the discharge

extremities, extensive carbonization in oil and, in some cases, tripping of the equipment,

confirming the large current follow-through;

– thermal faults, in oil and/or paper, below 300 °C if the paper has turned brownish (T1), and

above 300 °C if it has carbonized (T2);

– thermal faults of temperatures above 700 °C (T3) if there is strong evidence of carbonization

of the oil, metal coloration (800 °C) or metal fusion (> 1 000 °C).

5.4 Basic gas ratios

Each of the six broad classes of faults leads to a characteristic pattern of hydrocarbon gas

composition, which can be translated into a DGA interpretation table, such as the one

recommended in Table 1 and based on the use of three basic gas ratios:

C H CH C H

2 2 4 2 4

C H H C H

2 4 2 2 6

Table 1 applies to all types of equipment, with a few differences in gas ratio limits depending

on the specific type of equipment.

Table 1 – DGA interpretation table

Case Characteristic fault

C H CH C H

2 2 4 2 4

C H H C H

2 4 2 2 6

a

PD Partial discharges (see Notes 3 and 4) < 0,1 < 0,2

NS

D1 Discharges of low energy > 1 0,1 to 0,5 > 1

D2 Discharges of high energy 0,6 to 2,5 0,1 to 1 > 2

a a

T1 < 1

Thermal fault t < 300 °C

NS > 1 but NS

T2 Thermal fault 300 °C < t < 700 °C < 0,1 > 1 1 to 4

b

T3 Thermal fault t > 700 °C > 1 > 4

< 0,2

NOTE 1 In some countries, the ratio C H /C H is used, rather than the ratio CH /H . Also in some countries,

2 2 2 6 4 2

slightly different ratio limits are used.

NOTE 2 Conditions for calculating gas ratios are indicated in 6.1 c).

NOTE 3 CH /H < 0,2 for partial discharges in instrument transformers. CH /H < 0,07 for partial discharges in

4 2 4 2

bushings.

NOTE 4 Gas decomposition patterns similar to partial discharges have been reported as a result of stray gassing

of oil (see 4.3).

a

NS = Non-significant whatever the value.

b

An increasing value of the amount of C H may can indicate that the hot spot temperature is higher than

2 2

1 000 °C.

Typical examples of faults in the various types of equipment (power transformers, instrument

transformers, etc.), corresponding to the six cases of Table 1, may can be found in Table A.1,

Table A.5, Table A.8 and Table A.12.

Some overlap between faults D1 and D2 is apparent in Table 1, meaning that a dual attribution

of D1 or D2 must should be given in some cases of DGA results. The distinction between D1

and D2 has been kept, however, as the amount of energy in the discharge may can significantly

increase the potential damage to the equipment and necessitate different preventive measures.

Table 1 applies to transformers. For switching equipment see Clause A.7 and reference [5] in

the bibliography.

NOTE Combinations of gas ratios that fall outside the range limits of Table 1 and do not correspond to a

characteristic fault of this table can be considered a mixture of faults, or new faults that combine with a high

background gas level (see 6.1).

In such a case, Table 1 cannot provide a diagnosis, but the graphical representations given in Annex B can be used

to visualize which characteristic fault of Table 1 is closest to the case.

The less detailed scheme of Table 2 can also be used in such a case in order to get at least a rough distinction

between partial discharges (PD), discharges (D) and thermal fault (T), rather than no diagnosis at all.

Table 2 – Simplified scheme of interpretation

Case

C H CH C H

2 2 4 2 4

C H H C H

2 4 2 2 6

PD < 0,2

D > 0,2

T < 0,2

– 16 – IEC 60599:2022 CMV © IEC 2022

5.5 CO /CO ratio

The formation of CO and CO from oil-impregnated paper insulation increases rapidly with

temperature. High values of CO (e.g. 1 000 ppm) and CO /CO ratios less than 3 are generally

considered as an indication of probable paper involvement in a fault, with possible carbonization,

in the presence of other fault gases.

However, in some recent transformers of the

...

IEC 60599 ®

Edition 4.0 2022-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mineral oil-filled electrical equipment in service – Guidance on the interpretation

of dissolved and free gases analysis

Matériels électriques remplis d'huile minérale en service – Recommandations

relatives à l'interprétation de l'analyse des gaz dissous et des gaz libres

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 300 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

19 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60599 ®

Edition 4.0 2022-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mineral oil-filled electrical equipment in service – Guidance on the interpretation

of dissolved and free gases analysis

Matériels électriques remplis d'huile minérale en service – Recommandations

relatives à l'interprétation de l'analyse des gaz dissous et des gaz libres

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.99; 29.040.10; 29.180 ISBN 978-2-8322-3696-3

– 2 – IEC 60599:2022 © IEC 2022

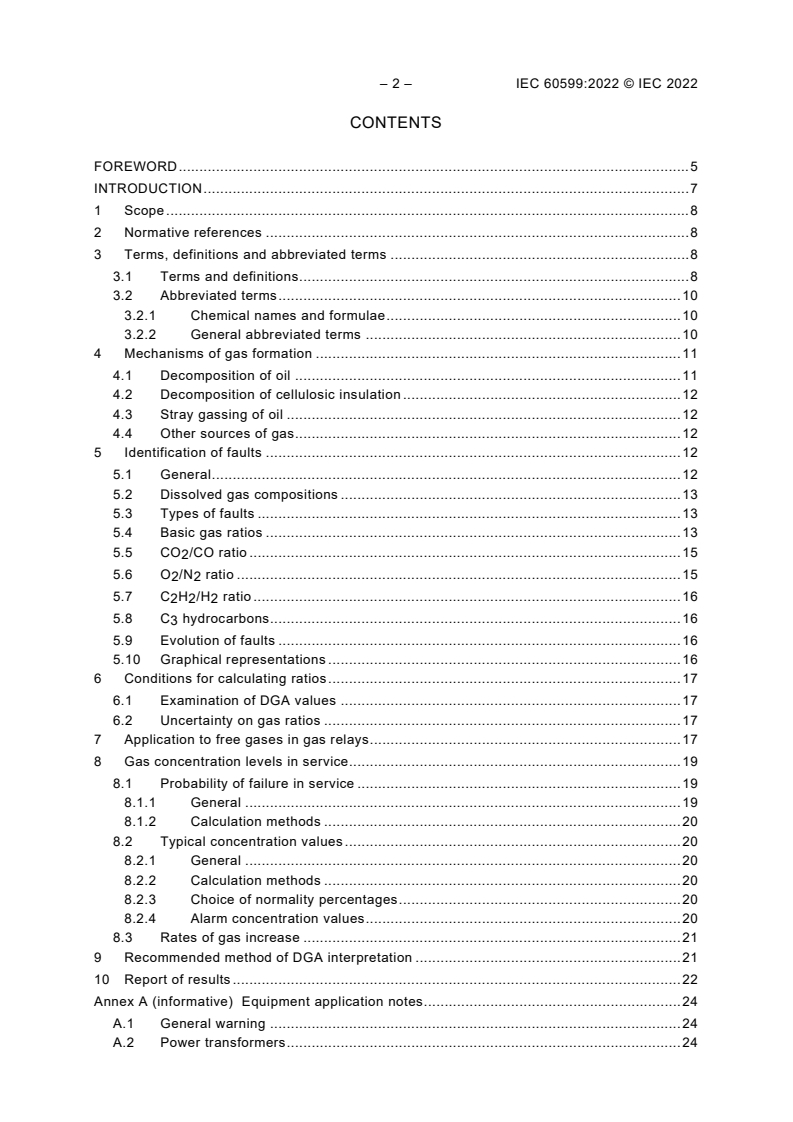

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Abbreviated terms . 10

3.2.1 Chemical names and formulae . 10

3.2.2 General abbreviated terms . 10

4 Mechanisms of gas formation . 11

4.1 Decomposition of oil . 11

4.2 Decomposition of cellulosic insulation . 12

4.3 Stray gassing of oil . 12

4.4 Other sources of gas . 12

5 Identification of faults . 12

5.1 General . 12

5.2 Dissolved gas compositions . 13

5.3 Types of faults . 13

5.4 Basic gas ratios . 13

5.5 CO /CO ratio . 15

5.6 O /N ratio . 15

2 2

5.7 C H /H ratio . 16

2 2 2

5.8 C hydrocarbons . 16

5.9 Evolution of faults . 16

5.10 Graphical representations . 16

6 Conditions for calculating ratios . 17

6.1 Examination of DGA values . 17

6.2 Uncertainty on gas ratios . 17

7 Application to free gases in gas relays . 17

8 Gas concentration levels in service . 19

8.1 Probability of failure in service . 19

8.1.1 General . 19

8.1.2 Calculation methods . 20

8.2 Typical concentration values . 20

8.2.1 General . 20

8.2.2 Calculation methods . 20

8.2.3 Choice of normality percentages . 20

8.2.4 Alarm concentration values . 20

8.3 Rates of gas increase . 21

9 Recommended method of DGA interpretation . 21

10 Report of results . 22

Annex A (informative) Equipment application notes . 24

A.1 General warning . 24

A.2 Power transformers . 24

A.2.1 Specific subtypes. 24

A.2.2 Typical faults . 24

A.2.3 Identification of faults by DGA . 25

A.2.4 Typical concentration values . 25

A.2.5 Typical rates of gas increase . 26

A.2.6 Specific information to be added to the DGA report . 27

A.3 Industrial and special transformers . 27

A.3.1 Specific subtypes. 27

A.3.2 Typical faults . 27

A.3.3 Identification of faults by DGA . 28

A.3.4 Typical concentration values . 28

A.4 Instrument transformers . 29

A.4.1 Specific subtypes. 29

A.4.2 Typical faults . 29

A.4.3 Identification of faults by DGA . 29

A.4.4 Typical concentration values . 30

A.5 Oil-impregnated paper bushings . 30

A.5.1 Specific subtypes. 30

A.5.2 Typical faults . 30

A.5.3 Identification of faults by DGA . 31

A.5.4 Typical concentration values . 31

A.6 Oil-filled cables . 32

A.6.1 Typical faults . 32

A.6.2 Identification of faults by DGA . 32

A.6.3 Typical concentration values . 32

A.7 Switching equipment . 33

A.7.1 Specific subtypes. 33

A.7.2 Normal operation . 33

A.7.3 Typical faults . 33

A.7.4 Identification of faults by DGA . 33

A.8 Equipment filled with non-mineral fluids . 34

Annex B (informative) Graphical representations of gas ratios . 35

Bibliography . 39

Figure 1 – Flow chart . 23

Figure B.1 – Graphical representation 1 of gas ratios . 35

Figure B.2 – Graphical representation 2 of gas ratios . 36

Figure B.3 – Graphical representation 3 of gas ratios – Duval's triangle 1 for

transformers, bushings and cables . 37

Figure B.4 – Graphical representation 4 of gas ratios – Duval's triangle 2 for OLTCs

(see A.7.2) . 38

Table 1 – DGA interpretation table . 14

Table 2 – Simplified scheme of interpretation . 14

Table 3 – Ostwald solubility coefficients for various gases in mineral insulating oils . 19

Table A.1 – Typical faults in power transformers . 25

Table A.2 – Ranges of 90 % typical gas concentration values observed in power

transformers . 26

– 4 – IEC 60599:2022 © IEC 2022

Table A.3 – Ranges of 90 % typical rates of gas increase observed in power

transformers (all types) . 26

Table A.4 – Examples of 90 % typical concentration values observed on individual

networks . 28

Table A.5 – Ranges of 90 % typical concentration values observed in WTTs . 28

Table A.6 – Typical faults in instrument transformers . 29

Table A.7 – Ranges of 90 % typical concentration values observed in instrument

transformers . 30

Table A.8 – Maximum admissible values for sealed instrument transformers. 30

Table A.9 – Typical faults in bushings . 31

Table A.10 – Simplified interpretation scheme for bushings . 31

Table A.11 – Ranges of 90 % typical concentration values in bushings . 32

Table A.12 – Ranges of 95 % typical concentration values observed on cables . 33

Table A.13 – Typical faults in switching equipment . 33

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MINERAL OIL-FILLED ELECTRICAL EQUIPMENT

IN SERVICE – GUIDANCE ON THE INTERPRETATION

OF DISSOLVED AND FREE GASES ANALYSIS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60599 has been prepared by IEC technical committee 10: Fluids for electrotechnical

applications. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) revision of Clause A.5 on bushings, at the request of IEC subcommittee 36A, in order to

transfer to IEC 60599 the corresponding contents of IEC TR 61464 [1] relating to DGA in

bushings and include the new information on DGA in bushings available in CIGRE Technical

Brochure 771 (2019) [2];

___________

Numbers in square brackets refer to the Bibliography.

– 6 – IEC 60599:2022 © IEC 2022

b) revision of Clause A.3 on wind turbine transformers, in order to include in IEC 60599 the

new information on DGA in wind turbine transformers available in CIGRE Technical

Brochure 771 (2019) [2].

The text of this International Standard is based on the following documents:

Draft Report on voting

10/1164/FDIS 10/1174/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

Dissolved and free gas analysis (DGA) is one of the most widely used diagnostic tools for

detecting and evaluating faults in electrical equipment filled with insulating liquid. However,

interpretation of DGA results is often complex and should always be done with care, involving

experienced insulation maintenance personnel.

This document gives information for facilitating this interpretation. The first edition, published

in 1978, has served the industry well, but had its limitations, such as the absence of a diagnosis

in some cases, the absence of concentration levels and the fact that it was based mainly on

experience gained from power transformers. The second edition (2015) attempted to address

some of these shortcomings. Interpretation schemes were based on observations made after

inspection of a large number of faulty oil-filled equipment in service and concentrations levels

deduced from analyses collected worldwide.

– 8 – IEC 60599:2022 © IEC 2022

MINERAL OIL-FILLED ELECTRICAL EQUIPMENT

IN SERVICE – GUIDANCE ON THE INTERPRETATION

OF DISSOLVED AND FREE GASES ANALYSIS

1 Scope

This document describes how the concentrations of dissolved gases or free gases can be

interpreted to diagnose the condition of oil-filled electrical equipment in service and suggest

future action.

This document is applicable to electrical equipment filled with mineral insulating oil and

insulated with cellulosic paper or pressboard-based solid insulation. Information about specific

types of equipment such as transformers (power, instrument, industrial, railways, distribution),

reactors, bushings, switchgear and oil-filled cables is given only as an indication in the

application notes.

This document can be applied, but only with caution, to other liquid-solid insulating systems.

In any case, the indications obtained are given only as guidance with resulting action

undertaken only with proper engineering judgment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60475, Method of sampling insulating liquids

IEC 60567:2011, Oil-filled electrical equipment – Sampling of gases and analysis of free and

dissolved gases – Guidance

IEC 61198, Mineral insulating oils – Methods for the determination of 2-furfural and related

compounds

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

fault

unplanned occurrence or defect in an item which may result in one or more failures of the item

itself or of other associated equipment

3.1.2

non-damage fault

fault which does not involve repair or replacement action at the point of the fault

Note 1 to entry: Typical examples are self-extinguishing arcs in switching equipment or general overheating without

paper carbonization or stray gassing of oil.

3.1.3

damage fault

fault that involves repair or replacement action at the point of the fault

3.1.4

incident

event of external or internal origin, affecting equipment or the supply system and which disturbs

its normal operation

Note 1 to entry: For the purposes of this document "incidents" are related to internal faults.

Note 2 to entry: For the purposes of this document typical examples of "incidents" are gas alarms, equipment

tripping or equipment leakage.

3.1.5

failure

loss of ability to perform as required

Note 1 to entry: In electrical equipment, failure will result from a damage fault or incident necessitating outage,

repair or replacement of the equipment, such as internal breakdown, rupture of tank, fire or explosion.

3.1.6

electrical fault

partial or disruptive discharge through the insulation

3.1.7

partial discharge

electric discharge that only partially bridges the insulation between conductors

Note 1 to entry: A partial discharge may occur inside the insulation or adjacent to a conductor.

Note 2 to entry: Scintillations of low energy on the surface of insulating materials are often described as partial

discharges but should rather be considered as disruptive discharges of low energy, since they are the result of local

dielectric breakdowns of high ionization density, or small arcs, according to the conventions of physics.

Note 3 to entry: For the purposes of this document the following consideration can also be added:

– Corona is a form of partial discharge that occurs in gaseous media around conductors that are remote from solid

or liquid insulation. This term shall not be used as a general term for all forms of partial discharges.

– As a result of corona discharges, X-wax, a solid material consisting of polymerized fragments of the molecules

of the original liquid, can be formed.

3.1.8

disruptive discharge

passage of an arc following the breakdown

Note 1 to entry: The term "sparkover" (in French: "amorçage") is used when a disruptive discharge occurs in a

gaseous or liquid dielectric.

The term "flashover" (in French: "contournement") is used when a disruptive discharge occurs over the surface of a

solid dielectric surrounded by a gaseous or liquid medium.

The term "puncture" (in French: "perforation") is used when a disruptive discharge occurs through a solid dielectric.

Note 2 to entry: Discharges are often described as arcing, breakdown or short circuits. The following other specific

terms are also used in some countries:

– tracking (the progressive degradation of the surface of solid insulation by local discharges to form conducting or

partially conducting paths);

– 10 – IEC 60599:2022 © IEC 2022

– sparking discharges that, in the conventions of physics, are local dielectric breakdowns of high ionization density

or small arcs.

3.1.9

thermal fault

excessive temperature rise in the insulation

Note 1 to entry: Typical causes are

– insufficient cooling;

– excessive currents circulating in adjacent metal parts (as a result of bad contacts, eddy currents, stray losses or

leakage flux);

– excessive currents circulating through the insulation (as a result of high dielectric losses), leading to a thermal

runaway;

– overheating of internal winding or bushing connection lead;

– overloading.

3.1.10

typical values of gas concentrations

gas concentrations normally found in the equipment in service that have no symptoms of failure,

and that are exceeded by only an arbitrary percentage of higher gas contents (for example

10 %)

Note 1 to entry: See 8.2.1.

Note 2 to entry: Typical values will differ in different types of equipment and in different networks, depending on

operating practices (load levels, climate, etc.).

Note 3 to entry: Typical values, in many countries and by many users, are quoted as "normal values", but this term

has not been used in this document to avoid possible misinterpretations.

3.2 Abbreviated terms

3.2.1 Chemical names and formulae

Name Formula

Nitrogen N

Oxygen O

Hydrogen H

Carbon monoxide CO

Carbon dioxide CO

Methane CH

Ethane C H

2 6

Ethylene C H

2 4

Acetylene C H

2 2

NOTE Acetylene and ethyne are both used for C H ; ethylene and ethene are both used for C H .

2 2 2 4

3.2.2 General abbreviated terms

CT current transformer

CTCV combined transformer (current-voltage)

CIVT cascade (inductive) voltage transformer

CVT capacitor voltage transformer

MVT magnetic voltage transformer

VT voltage transformer

ONAN oil natural air natural

OFAF oil forced air forced

DDB dodecylbenzene

WTT wind turbine transformer

D1 discharges of low energy

D2 discharges of high energy

DGA dissolved gas analysis

CIGRE Conseil International des Grands Réseaux Électriques

PD corona partial discharges

S analytical detection limit

T1 thermal fault, t < 300 °C

T2 thermal fault, 300 °C < t < 700 °C

T3 thermal fault, t > 700 °C

T thermal fault

D electrical fault

TP thermal fault in paper

ppm parts per million by volume of gas in oil, equivalent to µl (of gas)/l (of oil). See

IEC 60567:2011, 8.7, Note 1.

OLTC on-load tap-changer

4 Mechanisms of gas formation

4.1 Decomposition of oil

Mineral insulating oils are made of a blend of different hydrocarbon molecules containing CH ,

CH and CH chemical groups linked together by carbon-carbon molecular bonds.

Scission of some of the C-H and C-C bonds can occur as a result of electrical and thermal faults,

with the formation of small unstable fragments, in radical or ionic form, such as

• •

• • •

H , CH , CH , CH or C (among many other more complex forms), which recombine rapidly,

3 2

through complex reactions, into gas molecules such as hydrogen (H-H), methane (CH -H),

ethane (CH -CH ), ethylene (CH = CH ) or acetylene (CH ≡ CH). C and C hydrocarbon

3 3 2 2 3 4

gases, as well as solid particles of carbon and hydrocarbon polymers (X-wax), are other

possible recombination products. The gases formed dissolve in oil, or accumulate as free gases

if produced rapidly in large quantities, and can be analysed by DGA according to IEC 60567.

Low-energy faults, such as partial discharges of the cold plasma type (corona discharges),

favour the scission of the weakest C-H bonds (338 kJ/mol) through ionization reactions and the

accumulation of hydrogen as the main recombination gas. More and more energy and/or higher

temperatures are necessary for the scission of the C-C bonds and their recombination into

gases with a C-C single bond (607 kJ/mol), C=C double bond (720 kJ/mol) or C≡C triple bond

(960 kJ/mol), following processes bearing some similarities with those observed in the

petroleum oil-cracking industry.

Ethylene is thus favoured over ethane and methane above temperatures of approximately

500 °C (although still present in lower quantities below these temperatures). Acetylene requires

temperatures of at least 800 °C to 1 200 °C, and a rapid quenching to lower temperatures, in

order to accumulate as a stable recombination product. Acetylene is thus formed in significant

quantities mainly in arcs, where the conductive ionized channel is at several thousands of

degrees Celsius, and the interface with the surrounding liquid oil necessarily below 400 °C

(above which oil vaporizes completely), with a layer of oil vapour and/or decomposition gases

in between. Acetylene can still be formed at lower temperatures (< 800 °C), but in very minor

– 12 – IEC 60599:2022 © IEC 2022

quantities. Carbon particles form at 500 °C to 800 °C and are indeed observed after arcing in

oil or around very hot spots.

Oil can oxidize with the formation of small quantities of CO and CO , which can accumulate

over long periods of time into more substantial amounts.

4.2 Decomposition of cellulosic insulation

The polymeric chains of solid cellulosic insulation (paper, pressboard, wood blocks) contain a

large number of anhydroglucose rings, and weak C-O molecular bonds and glycosidic bonds

which are thermally less stable than the hydrocarbon bonds in oil, and which decompose at

lower temperatures. Significant rates of polymer chain scission occur at temperatures higher

than 105 °C, with complete decomposition and carbonization above 300 °C (damage fault).

Carbon monoxide and dioxide, as well as water, is formed, together with minor amounts of

hydrocarbon gases, furanic and other compounds. Furanic compounds are analysed according

to IEC 61198, and used to complement DGA interpretation and confirm whether or not cellulosic

insulation is involved in a fault. CO and CO formation increases not only with temperature but

also with the oxygen content of oil and the moisture content of paper.

4.3 Stray gassing of oil

Stray gassing of oil has been defined by CIGRE [3] as the formation of gases in oil heated to

moderate temperatures (< 200 °C). H , CH and C H can be formed in all equipment at such

2 4 2 6

temperatures or as a result of oil oxidation, depending on oil chemical structure. Stray gassing

is a non-damage fault. It can be evaluated using methods described in references [3] and [4].

NOTE Stray gassing of oil has been observed in some cases to be enhanced by the presence in oil of a metal

passivator or other additives.

4.4 Other sources of gas

Gases can be generated in some cases not as a result of faults in the equipment, but through

corrosion or other chemical reactions involving steel, uncoated surfaces or protective paints.

Hydrogen can be produced by reaction of steel and galvanized steel with water, as long as

oxygen is available from the oil nearby. Large quantities of hydrogen have thus been reported

in some transformers that had never been energized. Hydrogen can also be formed by reaction

of free water with special coatings on metal surfaces, or by catalytic reaction of some types of

stainless steel with oil, in particular oil containing dissolved oxygen at elevated temperatures.

Hydrogen, acetylene and other gases can also be formed in new stainless steel, absorbed

during its manufacturing process, or produced by welding, and released slowly into the oil.

Internal transformer paints, such as alkyd resins and modified polyurethanes containing fatty

acids in their formulation, can also form gases.

Gases can also be produced, and oxygen consumed, by exposure of oil to sunlight.

These occurrences, however, are very unusual, and can be detected by performing DGA

analyses on new equipment which has never been energized, and by material compatibility

tests. The presence of hydrogen with the total absence of other hydrocarbon gases, for example,

can be an indication of such a problem.

NOTE The case of gases formed at a previous fault and remnant in the transformer is dealt with in 5.4.

5 Identification of faults

5.1 General

Any gas formation in service, be it minimal, results from a stress of some kind, even if it is a