IEC 62969-3:2018

(Main)Semiconductor devices - Semiconductor interface for automotive vehicles - Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle sensors

Semiconductor devices - Semiconductor interface for automotive vehicles - Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle sensors

IEC 62969-3:2018 describes terms, definitions, symbols, configurations, and test methods that can be used to evaluate and determine the performance characteristics of mechanical shock driven piezoelectric energy harvesting devices for automotive vehicle sensor applications.

This document is also applicable to energy harvesting devices for motorbikes, automobiles, buses, trucks and their respective engineering subsystems applications without any limitations of device technology and size.

Dispositifs à semiconducteurs – Interface à semiconducteurs pour les véhicules automobiles – Partie 3 : Récupération de l’énergie piézoélectrique produite par les chocs pour les capteurs de véhicules automobiles

L’IEC 62969-3:2018 décrit les termes, définitions, symboles, configurations et les méthodes d’essai pouvant être utilisés pour apprécier et déterminer les caractéristiques de performance des dispositifs de récupération de l’énergie piézoélectrique produite par des chocs mécaniques pour des applications mettant en œuvre des capteurs de véhicules automobiles.

Le présent document est également applicable aux dispositifs de récupération d’énergie pour les motos, les automobiles, les bus, les camions ainsi que leurs applications d’ingénierie aux sous-systèmes, sans restriction concernant la technologie et la taille des dispositifs.

General Information

- Status

- Published

- Publication Date

- 06-May-2018

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 7 - TC 47/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-May-2018

- Completion Date

- 25-May-2018

Overview

IEC 62969-3:2018 is an international standard developed by the International Electrotechnical Commission (IEC) that defines the terminology, symbols, configurations, and test methods for evaluating shock-driven piezoelectric energy harvesting devices in automotive vehicle sensor applications. This standard specifically addresses the performance characteristics of mechanical shock-driven piezoelectric energy harvesters used to power sensors across a wide range of automotive vehicles including motorbikes, automobiles, buses, and trucks.

By providing clear guidelines and standardized testing methods, IEC 62969-3:2018 facilitates consistent development and assessment of innovative energy harvesting solutions that convert mechanical shocks into electrical energy, supporting sustainable and reliable sensor operations in harsh automotive environments.

Key Topics

Piezoelectric Energy Harvesting: The document focuses on mechanical shock-driven piezoelectric transducers that generate electrical energy from the physical shocks experienced by automotive sensors.

Terms and Definitions: Clear definitions for general terms, piezoelectric transducer parameters, and characteristic energy harvesting parameters are established to ensure uniform understanding.

Performance Parameters: Essential ratings and parameters such as capacitance, natural frequency, damping ratio, output voltage, current, power, and optimal load impedance are described and standardized for testing.

Test Methods: The standard provides comprehensive procedures for electrical and mechanical characterization of energy harvesters:

- Electrical testing includes output waveform measurement, power output, and load optimization.

- Mechanical testing addresses durability under temperature, humidity, and shock reliability conditions.

Configurations and Symbols: Reference layouts like cantilever piezoelectric film setups and equivalent electrical circuit representations are included to standardize evaluation framework.

Application Scope: Expands beyond cars to encompass the entire automotive ecosystem-motorbikes, trucks, buses-and their engineering subsystems without size or technology restrictions.

Applications

IEC 62969-3:2018 is invaluable for manufacturers, designers, testing laboratories, and automotive engineers focused on:

Automotive Sensor Systems: Ensuring sensor modules can harvest energy efficiently from vehicle dynamics, reducing reliance on batteries and external power sources.

Energy Harvesting Devices: Developing and benchmarking piezoelectric harvesters optimized for shock environments typical in automotive contexts.

Durability and Reliability Testing: Validating that energy harvesters maintain performance under rigorous mechanical shock, temperature fluctuations, and humidity stresses.

Motorcycles, Buses, and Trucks: Extending energy harvesting solutions to diverse vehicles with varying operational conditions and mechanical shock profiles.

Sustainable Automotive Design: Integrating energy harvesting technologies to support next-generation low-power, wireless vehicle sensors that enhance vehicle safety and efficiency.

Related Standards

IEC 62969 Series:

- Part 1: General requirements of power interfaces for automotive sensors.

- Part 2: Efficiency evaluation methods for wireless power transmission using resonance.

- Part 4: Evaluation method of data interfaces for automotive vehicle sensors.

Other Relevant IEC Standards: IEC standards covering semiconductor devices, automotive electronics, and sensor interfaces that collectively provide a comprehensive framework for automotive electronic systems integration.

Keywords: IEC 62969-3, shock driven piezoelectric energy harvesting, automotive vehicle sensors, energy harvester testing, piezoelectric transducer performance, automotive sensor power interface, semiconductor devices standard, mechanical shock energy harvesting, automotive electronics, sensor energy solutions.

Frequently Asked Questions

IEC 62969-3:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Semiconductor interface for automotive vehicles - Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle sensors". This standard covers: IEC 62969-3:2018 describes terms, definitions, symbols, configurations, and test methods that can be used to evaluate and determine the performance characteristics of mechanical shock driven piezoelectric energy harvesting devices for automotive vehicle sensor applications. This document is also applicable to energy harvesting devices for motorbikes, automobiles, buses, trucks and their respective engineering subsystems applications without any limitations of device technology and size.

IEC 62969-3:2018 describes terms, definitions, symbols, configurations, and test methods that can be used to evaluate and determine the performance characteristics of mechanical shock driven piezoelectric energy harvesting devices for automotive vehicle sensor applications. This document is also applicable to energy harvesting devices for motorbikes, automobiles, buses, trucks and their respective engineering subsystems applications without any limitations of device technology and size.

IEC 62969-3:2018 is classified under the following ICS (International Classification for Standards) categories: 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62969-3:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62969-3 ®

Edition 1.0 2018-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Semiconductor interface for automotive vehicles –

Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle

sensors

Dispositifs à semiconducteurs – Interface à semiconducteurs pour les véhicules

automobiles –

Partie 3: Récupération de l’énergie piézoélectrique produite par les chocs pour

les capteurs de véhicules automobiles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 62969-3 ®

Edition 1.0 2018-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Semiconductor interface for automotive vehicles –

Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle

sensors

Dispositifs à semiconducteurs – Interface à semiconducteurs pour les véhicules

automobiles –

Partie 3: Récupération de l’énergie piézoélectrique produite par les chocs pour

les capteurs de véhicules automobiles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.99 ISBN 978-2-8322-5685-5

– 2 – IEC 62969-3:2018 © IEC 2018

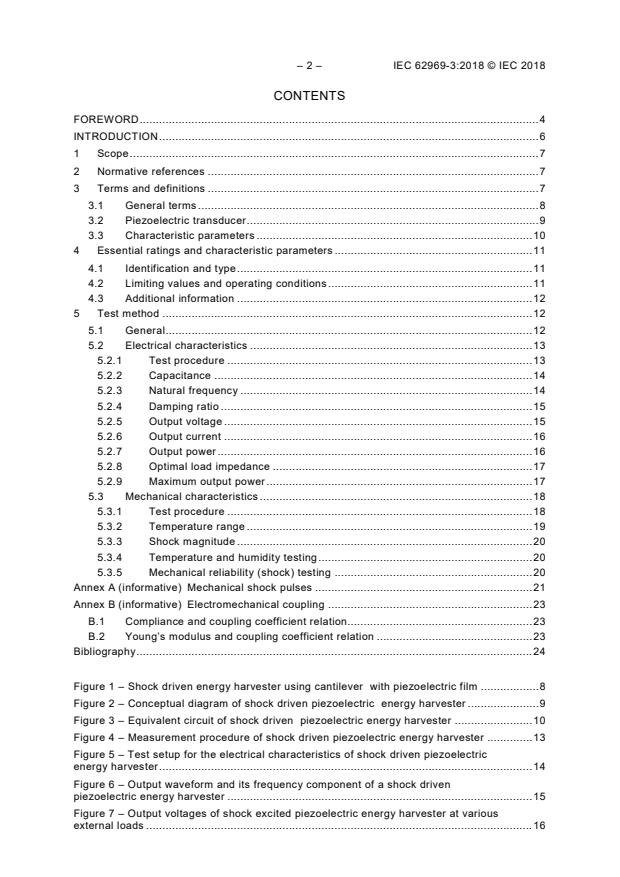

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

3.1 General terms . 8

3.2 Piezoelectric transducer . 9

3.3 Characteristic parameters . 10

4 Essential ratings and characteristic parameters . 11

4.1 Identification and type . 11

4.2 Limiting values and operating conditions . 11

4.3 Additional information . 12

5 Test method . 12

5.1 General . 12

5.2 Electrical characteristics . 13

5.2.1 Test procedure . 13

5.2.2 Capacitance . 14

5.2.3 Natural frequency . 14

5.2.4 Damping ratio . 15

5.2.5 Output voltage . 15

5.2.6 Output current . 16

5.2.7 Output power . 16

5.2.8 Optimal load impedance . 17

5.2.9 Maximum output power . 17

5.3 Mechanical characteristics . 18

5.3.1 Test procedure . 18

5.3.2 Temperature range . 19

5.3.3 Shock magnitude . 20

5.3.4 Temperature and humidity testing . 20

5.3.5 Mechanical reliability (shock) testing . 20

Annex A (informative) Mechanical shock pulses . 21

Annex B (informative) Electromechanical coupling . 23

B.1 Compliance and coupling coefficient relation. 23

B.2 Young’s modulus and coupling coefficient relation . 23

Bibliography . 24

Figure 1 – Shock driven energy harvester using cantilever with piezoelectric film . 8

Figure 2 – Conceptual diagram of shock driven piezoelectric energy harvester . 9

Figure 3 – Equivalent circuit of shock driven piezoelectric energy harvester . 10

Figure 4 – Measurement procedure of shock driven piezoelectric energy harvester . 13

Figure 5 – Test setup for the electrical characteristics of shock driven piezoelectric

energy harvester . 14

Figure 6 – Output waveform and its frequency component of a shock driven

piezoelectric energy harvester . 15

Figure 7 – Output voltages of shock excited piezoelectric energy harvester at various

external loads . 16

Figure 8 – Output currents of shock driven piezoelectric energy harvester at various

output voltages . 16

Figure 9 – Output power of shock driven piezoelectric energy harvester at various

external loads . 17

Figure 10 – Output power and voltage of shock driven piezoelectric energy harvester at

various shock amplitudes . 18

Figure 11 – Block diagram of a test setup for evaluating the reliability of shock driven

piezoelectric energy harvester . 19

Figure A.1 – Comparison of general shock patterns and shock pattern from automobile . 21

Figure A.2 – Impact (or shock) recorded by an electronic impact recorder . 22

Table 1 – Specification parameters for shock driven piezoelectric energy harvesters . 11

– 4 – IEC 62969-3:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

SEMICONDUCTOR INTERFACE FOR AUTOMOTIVE VEHICLES –

Part 3: Shock driven piezoelectric energy harvesting

for automotive vehicle sensors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62969-3 has been prepared by IEC technical committee 47:

Semiconductor devices.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47/2461/FDIS 47/2480/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62969 series, published under the general title Semiconductor

devices – Semiconductor interface for automotive vehicles, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62969-3:2018 © IEC 2018

INTRODUCTION

The IEC 62969 series is composed of four parts as follow:

• IEC 62969-1, Semiconductor devices – Semiconductor interface for automotive vehicles –

Part 1: General requirements of power interface for automotive vehicle sensors

• IEC 62969-2, Semiconductor devices – Semiconductor interface for automotive vehicles –

Part 2: Efficiency evaluation methods of wireless power transmission using resonance for

automotive vehicle sensors

• IEC 62969-3, Semiconductor devices – Semiconductor interface for automotive vehicles –

Part 3: Shock driven piezoelectric energy harvesting for automotive vehicle sensors

• IEC 62969-4 , Semiconductor devices – Semiconductor interface for automotive vehicles

– Part 4: Evaluation method of data interface for automotive vehicle sensors

The IEC 62969 series covers power and data interfaces for sensors in automotive vehicles.

The first part covers general requirements of test conditions such as temperature, humidity,

vibration, etc for automotive sensor power interface. This part also includes various electrical

performances of power interface such as voltage drop from power source to automotive

sensors, noises, voltage level, etc. The second part covers “Efficiency evaluation methods of

wireless power transmission using resonance for automotive vehicle sensors “. The third part

covers “Shock driven piezoelectric energy harvesting for automotive vehicle sensors”. The

fourth part covers “Evaluation methods of data interface for automotive vehicle sensors”.

___________

To be published

SEMICONDUCTOR DEVICES –

SEMICONDUCTOR INTERFACE FOR AUTOMOTIVE VEHICLES –

Part 3: Shock driven piezoelectric energy harvesting

for automotive vehicle sensors

1 Scope

This part of IEC 62969 describes terms, definitions, symbols, configurations, and test

methods that can be used to evaluate and determine the performance characteristics of

mechanical shock driven piezoelectric energy harvesting devices for automotive vehicle

sensor applications.

This document is also applicable to energy harvesting devices for motorbikes, automobiles,

buses, trucks and their respective engineering subsystems applications without any limitations

of device technology and size.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60749-5, Semiconductor devices – Mechanical and climatic test methods – Part 5:

Steady-state temperature humidity bias life test

IEC 60749-10, Semiconductor devices – Mechanical and climatic test methods – Part 10:

Mechanical shock

IEC 60749-12, Semiconductor devices – Mechanical and climatic test methods – Part 12:

Vibration, variable frequency

IEC 62830-1, Semiconductor devices – Semiconductor devices for energy harvesting and

generation – Part 1: Vibration based piezoelectric energy harvesting

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62830-1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 62969-3:2018 © IEC 2018

3.1 General terms

3.1.1

shock

sudden acceleration or deceleration resulting in transient physical excitation; characterized by

the peak acceleration, the duration, and the shape of the shock pulse (rectangular, half-sine,

sawtooth, etc.)

Note 1 to entry: The fundamental frequency of the automotive vehicle shock is varied from 0,5 Hz to 20 Hz.

Note 2 to entry: Mechanical shock pulses are sinusoidal, rectangular, half-sine, sawtooth, etc. waves. Detailed

explanation of mechanical shock pulses with an analysis of shock amplitude and duration/frequency of automobile

and conventional shaker have been included in Annex A (informative).

3.1.2

shock driven energy harvester

generator that responds to the applied mechanical shock, transforms shock into vibration

(mechanical oscillation), and converts the vibration to the electricity

Note 1 to entry: The generated power depends on the characteristics of applied shock and, mechanical and

electrical characteristics of the generator itself.

Note 2 to entry: Shock energy harvester to convert shock to electricity by using piezoelectric transducers is

comprised of inertial mass, spring, and piezoelectric transducer as shown in Figure 1. The piezoelectric transducer

contains two electrodes and a piezoelectric film. Vibration is induced in response to the applied shock that

introduces a reciprocating motion to the mass. The spring which suspends the mass is bended and the bending of

spring introduces tensile and compression of piezoelectric film. The top and bottom electrodes of piezoelectric film

harvest generated charges from the piezoelectric effect.

Note 3 to entry: Shock driven energy harvester is represented as shown in Figure 2. It is configured by mass,

spring, damping, and piezoelectric transducer. The piezoelectric transducer is generally viewed as damping.

Electrodes

Piezoelectric film

Output

R

Spring

Mass

Fixed base

Shock

IEC

Key

Configuration of energy harvester Components to operate a energy harvester

Mass Inertial mass to induce mechanical Shock Transient physical excitation supplied

oscillation responding to applied shock to vibrate the mass of energy

harvester

Spring To couple the induced vibration to the R External load

mass by suspending it

Piezoelectric Body layer of piezoelectric transducer for

film energy harvester

Figure 1 – Shock driven energy harvester using cantilever

with piezoelectric film

Spring

Piezoelectric

transducer

Mass

Damping

Shock

IEC

Key

Configuration of energy harvester Components to operate an energy harvester

Damping Reduction of the acceleration of Piezoelectric Power generator via piezoelectric

oscillation of mass transducer effect

Figure 2 – Conceptual diagram of shock driven piezoelectric

energy harvester

3.2 Piezoelectric transducer

3.2.1

piezoelectric effect

phenomenon in which a mechanical deformation produces an electric polarization of

piezoelectric material, and conversely an electric polarization produces a mechanical

deformation

[SOURCE: IEC 60050-121:1998, 121-12-86, modified]

3.2.2

piezoelectric charge constant

d

ij

polarization generated per unit of mechanical stress applied to a piezoelectric material

Note 1 to entry: The first subscript to d indicates the direction of polarization generated in the material when the

electric field, is zero or, alternatively, is the direction of the applied field strength. The second subscript is the

direction of the applied stress or the induced strain, respectively. d : induced strain in direction Z-axis per unit

electric field applied in direction Z-axis. d : induced strain in direction X-axis per unit electric field applied in

direction Z-axis.

3.2.3

electromechanical coupling coefficient

k

value to describe the conversion rate of electrical energy to mechanical form or vice versa

Note 1 to entry: The coefficient is a combination of elastic, dielectric and piezoelectric constants which appears

naturally in the expression of piezoelectric transducer as following

d

k= (1)

1/2

(sε)

– 10 – IEC 62969-3:2018 © IEC 2018

where

d is the piezoelectric charge constant

s is elastic compliance (inverse of Young's modulus) at constant electric field

ε is permittivity of the piezoelectric material at constant stress

Note 2 to entry: The relationship of electromechanical coupling coefficient with compliance and Young’s modulus

have been elaborated in Annex B (informative).

3.3 Characteristic parameters

3.3.1

equivalent circuit

arrangement of ideal circuit elements that has circuit parameters, electrically equivalent to

those of a shock driven piezoelectric energy harvester

Note 1 to entry: Shock driven piezoelectric energy harvester can be divided into mechanical and electrical parts

as shown in Figure 3. The mechanical part consists of series elements m, k , b , and transformer (coupling

sp m

element between mechanical and electrical parts)- where m, k , and b represent the effective mass, spring

sp m

constant of spring, damping, respectively; and piezoelectric effect to convert mechanically induced strain to

electrical charge density with coupling coefficient k. The electrical part is comprised of parallel connected C , R,

p

and transformer- where C and R represent the capacitance between two electrodes of piezoelectric transducer and

p

external load.

k b

m sp m

k

C

p

A(t) R

Mechanical part Electrical part

IEC

Key

Mechanical part Electrical part

m effective mass C capacitance of piezoelectric

p

transducer

k spring constant R external load

sp

b damping coefficient

m

A(t) induced vibration in response to the

applied shock

Figure 3 – Equivalent circuit of shock driven

piezoelectric energy harvester

[SOURCE: IEC 60050-521:2002, 521-05-35, modified]

3.3.2

natural frequency

ω

n

free vibration frequency of the mass-spring-damping system of the energy harvester to

generate largest output power

k

sp

ω = (2)

n

m

3.3.3

damped natural frequency

ω

d

frequency of free vibration of the mass-spring-damping system of the energy harvester

incorporating damping in response to the shock excitation

ω =ω 1−ζ (3)

d n

where ζ is the damping ratio determined by logarithmic decrement of output voltage waveform,

normalized from electrical and mechanical damping.

3.3.4

shock excitation amplitude

acceleration amplitude of the random applied shock to the energy harvester for maximum

duration as measured on the enclosure over which the energy harvester will not sustain

permanent damage though not necessarily functioning within the specified tolerances

4 Essential ratings and characteristic parameters

4.1 Identification and type

The shock driven energy harvester shall be clearly and durably marked in the order given

below:

a) year and week (or month) of manufacture;

b) manufacture’s name or trade mark;

c) terminal identification (optional);

d) serial number;

e) factory identification code (optional).

4.2 Limiting values and operating conditions

The characteristic parameters should be listed as shown in Table 1. The manufacturer shall

clearly announce the operating conditions and their limitation for energy harvesting. Limiting

value is the maximum induced vibration to ensure the operation of vibration energy harvester

for power generation without any damage.

Table 1 – Specification parameters for shock driven

piezoelectric energy harvesters

Measuring

Parameter Symbol Min. Max. Unit

conditions

Insert name of

characteristic

parameters

– 12 – IEC 62969-3:2018 © IEC 2018

4.3 Additional information

Some additional information should be given such as equivalent circuits (natural frequency,

internal impedance, output voltage and power, etc.), handling precautions, physical

information (outline dimension, terminals, accessories, installation guide, etc.), package

information, PCB interface and mounting information, and other information, etc.

5 Test method

5.1 General

Basically, general test procedures for shock driven energy harvester are performed as shown

in Figure 4. After the energy harvester is being mounted on a test fixture, it is measured by

using voltage, current, and LCR meters. Since the input impedances of these meters are

usually 10 MΩ, miniaturized or micro sized energy harvesters should not be characterized

accurately due to their large internal impedance. For measuring and characterizing these

devices accurately, the ultra-high-impedance meters should be used.

Before connecting the energy harvester to the test fixture, meter, cable, and vibration exciter

shall be calibrated. After calibration, connect test cable with mounted energy harvester test

fixture on shaker table (shock exciter). The reading of output voltage or current on display of

the meters is carefully taken with applied shock which is measured by the accelerometer.

NOTE Shock driven energy harvester can be measured as shown in Figure 4. After mounting the energy

harvester onto a shaker table, electrical characteristic are measured by using a meter or equivalent equipment. If

the measurements are satisfactory, reliability test for temperature range with thermal cycling and mechanical

failure with various shock and vibration, is performed for commercially use.

Start

Output voltage

Natural frequency

Output power

Damping ratio

Electrical characterization

Optimal load

Capacitance

Maximum output power

Temperature range

Shock excitation Mechanical characterization

Mean-time-to-failure

End

IEC

Key

Procedure Reference subclause Procedure Reference subclause

Start Optimal load 5.2.8

Electrical characterization Maximum output power 5.2.9

Natural frequency 3.3.2 and 5.2.3 Mechanical characterization

Damping ratio 3.3.3 and 5.2.4 Temperature range 5.3.2

Capacitance 5.2.2 Shock excitation 3.3.4 and 5.3.1

Output voltage 5.2.5 Mean-time-to-failure 5.3.3

Output power 5.2.7

Figure 4 – Measurement procedure of shock driven

piezoelectric energy harvester

5.2 Electrical characteristics

5.2.1 Test procedure

Figure 5 shows a test setup of the electrical characteristic of a shock driven piezoelectric

energy harvester. To measure the electrical characteristics of a shock driven piezoelectric

energy harvester, the device shall be attached on a shaker table as shown in Figure 5. When

a particular type of shock with specified acceleration amplitude is applied to the device, an

output voltage or current across an external load is measured.

The following test procedure is performed:

a) A specified shock is induced to the energy harvester.

b) The voltage or current across the external load which is connected to the terminals of the

energy harvester is measured using a voltage or current meter.

c) The voltage and current are measured with various acceleration amplitude of shock by

adjusting the amplifying ratio of power amplifier.

d) The maximum voltage and current are derived from various external loads to find the

optimal load.

– 14 – IEC 62969-3:2018 © IEC 2018

A

Vibration controller

DUT

V

Terminals

Electrodynam

ic Shaker External load

Power amplifier

IEC

Key

Component and meters to monitor Equipment and supplies

DUT: device A piece of energy harvester Vibration To produce and supply an initial

under test controller drive signal (specified type of shock)

to the power amplifier

Voltage meter (V) To detect a voltage across the Power To supply a specified level of

external load amplifier electrical power to the shock exciter

Ampere meter (A) To detect a current through the Electrodynamic To supply a specified level and type

external load Shaker of mechanical shock to a piece of

DUT

External load (R)

Figure 5 – Test setup for the electrical characteristics

of shock driven piezoelectric energy harvester

5.2.2 Capacitance

It is a capacitance measured between two terminals of energy harvesting device. A calibration

of a LCR meter shall be made in order to eliminate systematic errors occurred in the LCR

meter, cable, and connectors. When the device is connected to the LCR meter, its

capacitance will be displayed.

5.2.3 Natural frequency

It is the frequency, normally expressed in Hz, of the energy harvester at which its output

voltage/power is obtained. Figure 6 shows the typical output voltage waveform of a sock

excited energy harvester and its frequency component obtained by Fast Fourier Transform

(FFT).

Voltage

FFT

0 2

–5

–10

0 0,02 0,04 0,06 0,08 0,1 50 100 150 200 250 300 350 400 450

Time (s) Frequency (Hz)

IEC IEC

a) b)

Figure 6 – Output waveform and its frequency component

of a shock driven piezoelectric energy harvester

5.2.4 Damping ratio

It is a measure of how the output decays with time after a single shock impulse is applied to

the energy harvester. It is a dimensionless quantity that is calculated from the logarithmic

decrement of the output voltage response by using the following formula:

1 a

ζ= ln (4)

2π a

2

where a and a are the two consecutive peak amplitudes of the voltage waveform.

1 2

5.2.5 Output voltage

It is the peak-peak/rms voltage for specified duration measured across the terminals of energy

harvester with a specified external load in response to applied shock. Figure 7 shows the

graphical shape of measured output voltage versus external resistive load connected to the

terminal of energy harvester. The open circuit voltage is the measured peak-peak/rms voltage

for specified duration when there is no external load connected to the terminal of energy

harvester at a specific shock excitation.

Output voltage (V)

Amplitude (a.u.)

– 16 – IEC 62969-3:2018 © IEC 2018

1,5

0,5

0 1 2 3 4 5 6 7 8 9 10

External load (KΩ)

IEC

Figure 7 – Output voltages of shock excited piezoelectric

energy harvester at various external loads

5.2.6 Output current

It is the current measured through the specified external load connected to the terminal of

vibration energy harvester at the specified shock excitation. Figure 8 shows the graphical

shape of measured current versus output voltage of energy harvester. The short circuit

current from the terminal of the energy harvester is the measured current when the voltage

across the energy harvester is zero.

0,9

0,8

0,7

0,6

0,5

0,4

0,3

0,2

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 2

Output voltage (V)

IEC

Figure 8 – Output currents of shock driven piezoelectric

energy harvester at various output voltages

5.2.7 Output power

Output power (peak/average) is calculated from the measured output voltage and current for

specified duration of energy harvester with external load.

Output current (µA) Output voltage (V)

(5)

P= IV[W]

Figure 9 shows the graphical shape of measured output power (peak/average) versus external

load of energy harvester.

0,5

0,4

0,3

0,2

0,1

0 1 2 3 4 5 6 7 8 9 10

External load (KΩ)

IEC

Figure 9 – Output power of shock driven piezoelectric energy

harvester at various external loads

5.2.8 Optimal load impedance

Optimal load impedance is the specified value of the external load transferred the largest

electrical energy from energy harvester.

5.2.9 Maximum output power

It is a maximum value of output power (peak/average) measured from energy harvester at a

specified applied shock amplitude for specified duration. The applied shock amplitude is

defined in 5.3.3. Figure 10 shows the graphical shape of measured output power

(peak/average) and voltage (peak-peak/rms) for specified duration versus various applied

shock amplitudes.

Output power (µW)

– 18 – IEC 62969-3:2018 © IEC 2018

3 3

Voltage

2,5 2,5

Power

2 2

1,5 1,5

1 1

0,5 0,5

0 0

0 0,1 0,2 0,3 0,4 0,5

Input vibration (g)

IEC

Figure 10 – Output power and voltage of shock driven piezoelectric

energy harvester at various shock amplitudes

5.3 Mechanical characteristics

5.3.1 Test procedure

Figure 11 shows a test setup of the reliability of a shock driven piezoelectric energy harvester.

The harvesting device shall be repeatedly operated until the failure of device. When a specific

type of shock excitation is applied to the device, output voltage or current is measured

through an external load connected to the device.

To test the reliability, the following test procedure is performed:

a) A shock impulse is induced to the energy harvester.

b) The output voltage or current of energy harvester is measured by the meter.

c) The test is continuously performed for a few months.

Output voltage (V)

Output power (µW)

Temperature

controller

A

Vibration controller

DUT

V

Electrodyna

mic Shaker

Temperature controlled

Power amplifier

environmental chamber

IEC

Key

Component and meters to monitor Equipment and supplies

DUT: device under test A piece of energy Vibration controller To produce and supply an initial

harvester drive signal (specified type of

shock) to the power amplifier

Voltage meter (V) To detect a voltage Power amplifier To supply a specified level of

across the external load electrical power to the shock

exciter

Ampere meter (A) To detect a current Electrodynamic shaker To supply a specified level and

through the external load type of mechanical shock to a

piece of DUT

Temperature controlled To keep a specified temperature

environment chamber value of a piece of DUT

Figure 11 – Block diagram of a test setup for evaluating the reliability

of shock driven piezoelectric energy harvester

5.3.2 Temperature range

The objective of this test is to evaluate its reliability by low/high temperature cycling test. The

temperature range should be specified from the applications. First, the test is performed at the

temperature cycling test chamber, and second, by placing the finished energy harvester in an

oven. The performance characteristics are monitored by a meter.

– 20 – IEC 62969-3:2018 © IEC 2018

5.3.3 Shock magnitude

The objective of this test is to evaluate its reliability by high input acceleration for specified

duration. The operating range should be specified from the application. First, the test is

performed as repetitive test of shock excitation with various acceleration and duration.

Second, by placing the finished energy harvester on the shock exciter. The performance

characteristics are monitored by a meter.

IEC 60749-12 applies.

5.3.4 Temperature and humidity testing

IEC 60749-5 applies.

5.3.5 Mechanical reliability (shock) testing

IEC 60749-10 applies.

Annex A

(informative)

Mechanical shock pulses

Mechanical shock pulses are sinusoidal, rectangular, half-sine, sawtooth, etc. waves. The

damage potential of a shock pulse depends upon its peak amplitude, duration and waveform.

The peak amplitude is measured in units of “g” where g = 9,8m/s . The waveform is described

in three ways, namely frequency, duration, and velocity change (ΔV). Frequency describes

the time as compared to cycles per second and the unit of measurement is Hertz (Hz).

Duration describes the time as compared to seconds and the usual unit of measure is

milliseconds (ms). Velocity change (ΔV) is the area under the acceleration time graph of the

shock. It directly relates to the energy contained in the shock. The higher the velocity changes

the higher the energy content.

Subfigure A.1 a) shows a shock wave or an impact wave in time domain. The wave is a sine

curve with acceleration in g (g = 9,8m/s ) along the y-axis and time in ms along the x-axis.

The magnitude of shock pulse varies depending on the origin of shock in automobile and one

general shock pattern is shown in Subfigure A.1 b). This kind of shock can be reproducible

using conventional electrodynamic shaker.

An analysis of shock amplitude and duration/frequency of conventional shaker is shown in

Figure A.2. The following conditions when simultaneously reach damage a transformer of

electrodynamic shaker: (a) the peak acceleration exceeds the critical acceleration, and (b) the

duration of the peak half sine curve exceeds the critical shock duration, or the frequency is

lower than the critical frequency.

IEC

IEC

a) General shock patterns b) Shock pattern from automobile

Figure A.1 – Comparison of general shock patterns and shock pattern from automobile

– 22 – IEC 62969-3:2018 © IEC 2018

IEC

Figure A.2 – Impact (or shock) recorded by an electronic impact recorder

Annex B

(informative)

Electromechanical coupling

B.1 Compliance and coupling coefficient relation

The relation between elastic compliance and piezoelectric coupling coefficient is the following:

D E 2

s = s (1− k )

where

D

s is the compliance at constant dielectric field D (open circuit);

E

s is the compliance at constant field strength E (short circuit);

k is the piezoelectric coupling coefficient.

B.2 Young’s modulus and coupling coefficient relation

The relation between Young’s modulus and the piezoelectric coupling coefficient is the

following:

2 E

1 (1− k ) Y

D

= or Y =

D E 2

Y Y (1− k )

where

D

Y is the Young's modulus at open circuit;

E

Y is the Young's modulus at short circuit.

The piezoelectric material has two different Young's moduli, depending on the electrical

boundary conditions (short circuit or open circuit). Since k is always less than 1.0, the open

D E

circuit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...