IEC TR 63357:2022

(Main)Semiconductor devices - Standardization roadmap of fault test method for automotive vehicles

Semiconductor devices - Standardization roadmap of fault test method for automotive vehicles

IEC TR 63357:2022(E) describes standardization roadmap of fault test methods for integrated circuits used in automotive vehicles. Since automotive vehicles are exposed in harsh environment such as very low or high temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment. There are several fault test methods and related issues to be standardized.

Semiconductor devices used in automotive vehicles are exposed in harsh environment of very high or very low temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment Evaluation results following this fault test methods will provide robustness of the semiconductor device.

General Information

- Status

- Published

- Publication Date

- 10-Oct-2022

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 6 - TC 47/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Oct-2022

- Completion Date

- 03-Nov-2022

Overview - IEC TR 63357:2022 (Fault test method roadmap for automotive semiconductor devices)

IEC TR 63357:2022 is a Technical Report that provides a standardization roadmap of fault test methods for integrated circuits (ICs) used in automotive vehicles. It focuses on fault detection and testability for semiconductors exposed to harsh automotive environments - extreme temperatures, vibration, electromagnetic and high‑frequency signals (e.g., automotive RADAR and V2X). The report summarizes background, key technologies (JTAG, DFT, DFM, scan test, ATPG), terminology (fault, failure, transient vs. permanent, fault coverage) and identifies standardization priorities and actions.

Key topics and technical requirements

- Scope and motivation: Addresses why automotive semiconductors need dedicated fault test methods because of environmental stresses and increasing RF/vehicle‑to‑everything (V2X) use.

- Terminology and metrics: Defines critical terms used in testability and dependability such as fault, failure, error, fault coverage, test coverage, and fault models.

- Fault test technologies:

- JTAG / IEEE 1149.x (boundary scan) for interconnect and board-level testing.

- Design for Testability (DFT) and Design for Manufacturability (DFM) techniques that embed test features into ICs.

- Scan test, scan chains/cells, and automatic test pattern generation (ATPG) to create and apply test vectors and measure fault coverage.

- Fault simulation methods for evaluating test set quality.

- Environmental & RF considerations: Discusses interaction with automotive RADAR bands (e.g., 24 GHz and 77–81 GHz ranges) and wireless/V2X frequency allocations, highlighting the need to consider RF immunity and high‑frequency test conditions.

- Roadmap deliverables: A table of standardization actions (technology areas, gaps, and priorities) to guide future standards work for automotive fault testing.

Applications - who uses this standard

- Semiconductor designers and test engineers building automotive ICs and SoCs

- Automotive OEMs and Tier‑1 suppliers validating component robustness

- Test equipment vendors implementing ATPG, scan, and JTAG capabilities

- Certification bodies and standards committees aligning test methods for automotive safety and reliability

- System integrators and maintenance teams assessing field failures and diagnostics

Related standards and references

- IEC 60050‑192 (dependability vocabulary)

- IEEE 1149.1 (JTAG / boundary‑scan)

- Regional V2X and RADAR regulatory standards (ETSI, IEEE, ARIB et al.) referenced in the report

IEC TR 63357:2022 is a practical roadmap for harmonizing fault test methods in automotive semiconductors - improving robustness, fault coverage, and interoperability across design, manufacturing, and in‑vehicle testing workflows. Keywords: IEC TR 63357:2022, fault test method, automotive semiconductor, JTAG, DFT, scan test, ATPG, V2X, automotive RADAR.

Frequently Asked Questions

IEC TR 63357:2022 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Standardization roadmap of fault test method for automotive vehicles". This standard covers: IEC TR 63357:2022(E) describes standardization roadmap of fault test methods for integrated circuits used in automotive vehicles. Since automotive vehicles are exposed in harsh environment such as very low or high temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment. There are several fault test methods and related issues to be standardized. Semiconductor devices used in automotive vehicles are exposed in harsh environment of very high or very low temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment Evaluation results following this fault test methods will provide robustness of the semiconductor device.

IEC TR 63357:2022(E) describes standardization roadmap of fault test methods for integrated circuits used in automotive vehicles. Since automotive vehicles are exposed in harsh environment such as very low or high temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment. There are several fault test methods and related issues to be standardized. Semiconductor devices used in automotive vehicles are exposed in harsh environment of very high or very low temperature, vibration, high frequency signals, etc. Therefore, they are tested for possible faults which can be caused by harsh environment Evaluation results following this fault test methods will provide robustness of the semiconductor device.

IEC TR 63357:2022 is classified under the following ICS (International Classification for Standards) categories: 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 63357:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 63357 ®

Edition 1.0 2022-10

TECHNICAL

REPORT

colour

inside

Semiconductor devices – Standardization roadmap of fault test method for

automotive vehicles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 63357 ®

Edition 1.0 2022-10

TECHNICAL

REPORT

colour

inside

Semiconductor devices – Standardization roadmap of fault test method for

automotive vehicles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.99 ISBN 978-2-8322-5766-1

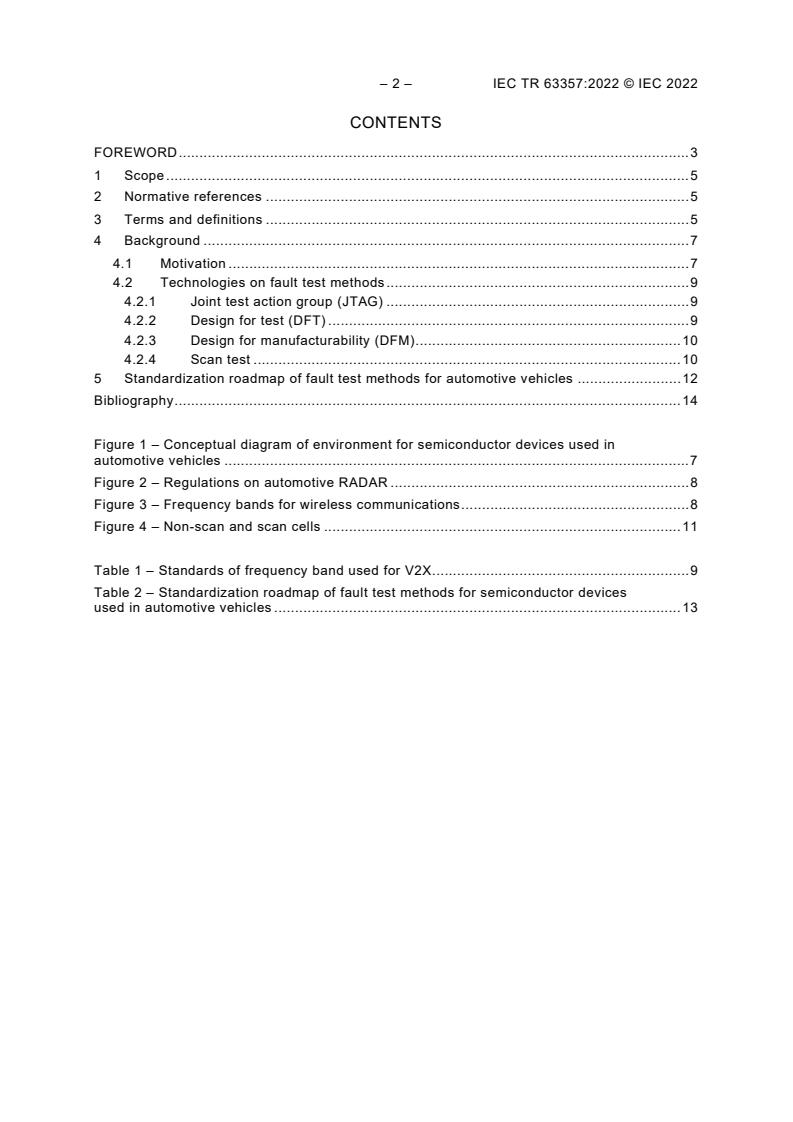

– 2 – IEC TR 63357:2022 © IEC 2022

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Background . 7

4.1 Motivation . 7

4.2 Technologies on fault test methods . 9

4.2.1 Joint test action group (JTAG) . 9

4.2.2 Design for test (DFT) . 9

4.2.3 Design for manufacturability (DFM) . 10

4.2.4 Scan test . 10

5 Standardization roadmap of fault test methods for automotive vehicles . 12

Bibliography . 14

Figure 1 – Conceptual diagram of environment for semiconductor devices used in

automotive vehicles . 7

Figure 2 – Regulations on automotive RADAR . 8

Figure 3 – Frequency bands for wireless communications . 8

Figure 4 – Non-scan and scan cells . 11

Table 1 – Standards of frequency band used for V2X . 9

Table 2 – Standardization roadmap of fault test methods for semiconductor devices

used in automotive vehicles . 13

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES – STANDARDIZATION ROADMAP

OF FAULT TEST METHOD FOR AUTOMOTIVE VEHICLES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TR 63357 has been prepared by the IEC technical committee 47: Semiconductor devices.

It is a Technical Report.

The text of this Technical Report is based on the following documents:

Draft Report on voting

47/2677/DTR 47/2714/RVDTR

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Report is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

– 4 – IEC TR 63357:2022 © IEC 2022

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

SEMICONDUCTOR DEVICES – STANDARDIZATION ROADMAP

OF FAULT TEST METHOD FOR AUTOMOTIVE VEHICLES

1 Scope

This Technical Report describes standardization roadmap of fault test methods for integrated

circuits used in automotive vehicles. Since automotive vehicles are exposed in harsh

environment such as very low or high temperature, vibration, high frequency signals, etc.

Therefore, they are tested for possible faults which can be caused by harsh environment. There

are several fault test methods and related issues to be standardized.

Semiconductor devices used in automotive vehicles are exposed in harsh environment of very

high or very low temperature, vibration, high frequency signals, etc. Therefore, they are tested

for possible faults which can be caused by harsh environment Evaluation results following this

fault test methods will provide robustness of the semiconductor device.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-192, International Electrotechnical Vocabulary (IEV) – Part 192: Dependability

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-192 apply, as

well as the following.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

automatic test pattern generation

ATPG

method/technology used to find an input (or test) sequence that, when applied to a digital circuit,

enables automatic test equipment to distinguish between the correct circuit behavior and the

faulty circuit behavior caused by defects

Note 1 to entry: The generated patterns are used to test semiconductor devices after manufacture, or to assist with

determining the cause of failure. The effectiveness of ATPG is measured by the number of modeled defects, or fault

models, detectable and by the number of generated patterns. These metrics generally indicate test quality (higher

with more fault detections) and test application time (higher with more patterns).

3.2

error

discrepancy between an observed or measured value or condition, and the true, specified or

theoretically correct value or condition

– 6 – IEC TR 63357:2022 © IEC 2022

[IEC 60050-192:2015, 192-03-02, modified – The words "a computed, observed or measured"

have been replaced by "an observed or measured" and the notes to entry have been removed.]

3.3

failure

loss of ability to perform as required

[IEC 60050-192:2015, 192-03-01, modified – The specific use as well as the three

existing notes have been removed.]

3.4

fault

inability to perform as required, due to an internal state

[IEC 60050-192:2015, 192-04-01, modified – The specific use has been deleted,

as well as the four existing notes.]

3.5

fault coverage

proportion of faults that can be detected, under given conditions

[IEC 60050-192:2015, 192-07-24]

3.6

fault detection

event by which the presence of a fault becomes apparent

[IEC 60050-192:2015, 192-06-18, modified – The note has been removed.]

3.7

fault model

definition of a possible fault type which gives incorrect values at any speed or at-speed, and

sensitized by performing only one operation or multiple operations sequentially

3.8

fault simulation

simulation of DUT in the presence of faults to evaluate the quality of a test set, usually in terms

of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...