IEC 60297-3-107:2012

(Main)Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-107: Dimensions of subracks and plug-in units, small form factor

Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-107: Dimensions of subracks and plug-in units, small form factor

IEC 60297-3-107:2012 defines the interface dimensions between subracks and associated plug-in units using connectors as defined in PICMG-MTCA.0 (Fixed board, see Figure 7) and IEC 61076-4-116 (Two part, see Figure 12) and other two part connectors, (see Figure 15). For mechanical and climatic tests refer to IEC 61587-1. For electromagnetic shielding performance tests refer to IEC 61587-3.

Structures mécaniques pour équipements électroniques - Dimensions des structures mécaniques de la série 482,6 mm (19 pouces) - Partie 3-107: Dimensions des bacs et blocs enfichables de petit facteur de forme

La CEI 60297-3-107:2012 définit les dimensions d'interface entre des bacs et des blocs enfichables associés à l'aide de connecteurs comme cela est défini dans la spécification PICMG-MTCA.0 (cartes fixes, voir Figure 7) et dans la CEI 61076-4-116 (en deux parties, voir Figure 12) et d'autres connecteurs en deux parties (voir Figure 15). Pour les essais mécaniques et climatiques, se rapporter à la CEI 61587-1. Pour les essais de performances du blindage électromagnétique, se reporter à la CEI 61587-3.

General Information

- Status

- Published

- Publication Date

- 09-Jan-2012

- Technical Committee

- SC 48D - Mechanical structures for electrical and electronic equipment

- Drafting Committee

- WG 4 - TC 48/SC 48D/WG 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Jan-2012

- Completion Date

- 15-Jan-2012

Overview

IEC 60297-3-107:2012 is an essential international standard issued by the International Electrotechnical Commission (IEC) that specifies the mechanical dimensions for subracks and plug-in units with a small form factor within the 482.6 mm (19 inch) series. This standard builds upon the traditional 19-inch rack concepts, addressing the increasing demand for more compact electronic equipment configurations used in modern applications.

This standard defines precise interface dimensions between subracks and plug-in units, with specific focus on connectors as standardized in PICMG-MTCA.0 (MicroTCA) and IEC 61076-4-116. It includes comprehensive mechanical dimensioning, ensuring interoperability and ease of integration within electronic equipment enclosures.

Key Topics

Subrack Dimensions

Detailed front, rear, side, and top mechanical dimensions for small form factor subracks ensure consistent physical compatibility across equipment from different manufacturers.Plug-in Units

Defines the form factor and mechanical dimensions of plug-in units that fit within the subracks, facilitating modular design and easy maintenance or upgrade of embedded electronic systems.Connector Interfaces

Specifies dimensions for connectors complying with PICMG-MTCA.0 (fixed board connector) and IEC 61076-4-116 two-part connectors. This ensures reliable electrical and mechanical connection while supporting the latest electronics interconnect technologies.Backplane Layouts

Provides backplane dimensioning tailored for the specified connectors to guarantee precise mechanical and electrical alignment within subracks.Electromagnetic Compatibility (EMC) and Electrostatic Discharge (ESD) Provisions

Includes mechanical design recommendations for electromagnetic shielding and ESD protection for both subracks and plug-in units. These provisions enhance equipment resilience and compliance with regulatory requirements.Additional Mechanical Features

Covers latch mechanisms for ruggedized applications and hot-swap functions, reflecting modern usability and reliability demands.

Applications

IEC 60297-3-107 applies broadly across industries requiring compact, modular electronic equipment such as:

Telecommunications Systems

Supporting MicroTCA architectures with small form factor plug-in boards.Data Centers and Server Racks

Enabling high-density equipment arrangement with precise mechanical compatibility.Industrial Automation

Facilitating modular control units that must fit within standard 19-inch racks but optimized for smaller footprints.Military and Aerospace Electronics

Where ruggedized and EMI/ESD compliant modular components in compact form factors are critical.Test and Measurement Equipment

Standardized rack dimensions streamline rack-mounted system design.

Using IEC 60297-3-107 supports interoperability, reduces customization costs, and simplifies maintenance in electronic equipment design.

Related Standards

IEC 60297 Series

Covers mechanical structures for electronic equipment in various sizes and configurations, including part 3-101 which describes standard plug-in units.PICMG MTCA.0 (MicroTCA Specification)

Defines connectors and backplane interfaces relevant to this standard.IEC 61076-4-116

Specifies two-part connectors used in small form factor board interconnections.IEC 61587-1 and IEC 61587-3

Give mechanical, climatic, and electromagnetic shielding test requirements complementing the designs specified in IEC 60297-3-107.

Keywords: IEC 60297-3-107, 19 inch rack, subrack dimensions, small form factor plug-in units, PICMG MicroTCA, IEC 61076-4-116, mechanical structures electronic equipment, electromagnetic compatibility, electrostatic discharge, modular electronic equipment, backplane dimensions, connector interfaces, IEC standards, electronic equipment design.

Frequently Asked Questions

IEC 60297-3-107:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-107: Dimensions of subracks and plug-in units, small form factor". This standard covers: IEC 60297-3-107:2012 defines the interface dimensions between subracks and associated plug-in units using connectors as defined in PICMG-MTCA.0 (Fixed board, see Figure 7) and IEC 61076-4-116 (Two part, see Figure 12) and other two part connectors, (see Figure 15). For mechanical and climatic tests refer to IEC 61587-1. For electromagnetic shielding performance tests refer to IEC 61587-3.

IEC 60297-3-107:2012 defines the interface dimensions between subracks and associated plug-in units using connectors as defined in PICMG-MTCA.0 (Fixed board, see Figure 7) and IEC 61076-4-116 (Two part, see Figure 12) and other two part connectors, (see Figure 15). For mechanical and climatic tests refer to IEC 61587-1. For electromagnetic shielding performance tests refer to IEC 61587-3.

IEC 60297-3-107:2012 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.240 - Mechanical structures for electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60297-3-107:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60297-3-107 ®

Edition 1.0 2012-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series –

Part 3-107: Dimensions of subracks and plug-in units, small form factor

Structures mécaniques pour équipements électroniques – Dimensions des

structures mécaniques de la série 482,6 mm (19 pouces) –

Partie 3-107: Dimensions des bacs et blocs enfichables de petit facteur de forme

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60297-3-107 ®

Edition 1.0 2012-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series –

Part 3-107: Dimensions of subracks and plug-in units, small form factor

Structures mécaniques pour équipements électroniques – Dimensions des

structures mécaniques de la série 482,6 mm (19 pouces) –

Partie 3-107: Dimensions des bacs et blocs enfichables de petit facteur de forme

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX V

ICS 31.240 ISBN 978-2-88912-844-0

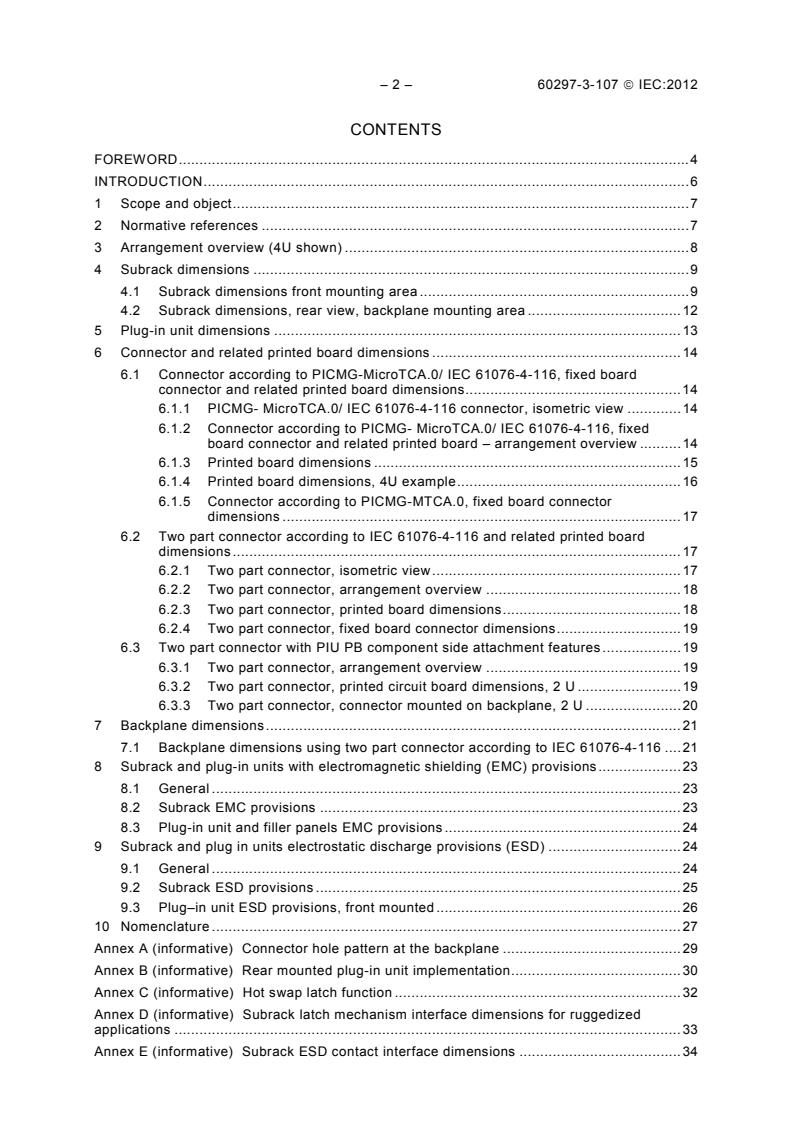

– 2 – 60297-3-107 IEC:2012

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope and object . 7

2 Normative references . 7

3 Arrangement overview (4U shown) . 8

4 Subrack dimensions . 9

4.1 Subrack dimensions front mounting area . 9

4.2 Subrack dimensions, rear view, backplane mounting area . 12

5 Plug-in unit dimensions . 13

6 Connector and related printed board dimensions . 14

6.1 Connector according to PICMG-MicroTCA.0/ IEC 61076-4-116, fixed board

connector and related printed board dimensions . 14

6.1.1 PICMG- MicroTCA.0/ IEC 61076-4-116 connector, isometric view . 14

6.1.2 Connector according to PICMG- MicroTCA.0/ IEC 61076-4-116, fixed

board connector and related printed board – arrangement overview . 14

6.1.3 Printed board dimensions . 15

6.1.4 Printed board dimensions, 4U example . 16

6.1.5 Connector according to PICMG-MTCA.0, fixed board connector

dimensions . 17

6.2 Two part connector according to IEC 61076-4-116 and related printed board

dimensions . 17

6.2.1 Two part connector, isometric view . 17

6.2.2 Two part connector, arrangement overview . 18

6.2.3 Two part connector, printed board dimensions . 18

6.2.4 Two part connector, fixed board connector dimensions . 19

6.3 Two part connector with PIU PB component side attachment features . 19

6.3.1 Two part connector, arrangement overview . 19

6.3.2 Two part connector, printed circuit board dimensions, 2 U . 19

6.3.3 Two part connector, connector mounted on backplane, 2 U . 20

7 Backplane dimensions . 21

7.1 Backplane dimensions using two part connector according to IEC 61076-4-116 . 21

8 Subrack and plug-in units with electromagnetic shielding (EMC) provisions . 23

8.1 General . 23

8.2 Subrack EMC provisions . 23

8.3 Plug-in unit and filler panels EMC provisions . 24

9 Subrack and plug in units electrostatic discharge provisions (ESD) . 24

9.1 General . 24

9.2 Subrack ESD provisions . 25

9.3 Plug–in unit ESD provisions, front mounted . 26

10 Nomenclature . 27

Annex A (informative) Connector hole pattern at the backplane . 29

Annex B (informative) Rear mounted plug-in unit implementation . 30

Annex C (informative) Hot swap latch function . 32

Annex D (informative) Subrack latch mechanism interface dimensions for ruggedized

applications . 33

Annex E (informative) Subrack ESD contact interface dimensions . 34

60297-3-107 IEC:2012 – 3 –

Figure 1 – Arrangement overview . 8

Figure 2 – Subrack dimensions, front view . 10

Figure 3 – Subrack dimensions, side view . 11

Figure 4 – Subrack dimensions, top view . 12

Figure 5 – Subrack dimensions, rear view . 12

Figure 6 – Plug-in unit dimensions . 13

Figure 7 – PICMG- MicroTCA.0/ IEC 61076-4-116 connector, isometric view . 14

Figure 8 – PICMG- MicroTCA.0/ IEC 61076-4-116 fixed board connector, arrangement

overview – Top view . 14

Figure 9 – Printed board dimensions . 15

Figure 10 – Printed board dimensions, 4U example . 16

Figure 11 – Connector according to PICMG- MTCA.0, fixed board connector

dimensions . 17

Figure 12 – Fixed board and free board connector – Isometric view . 17

Figure 13 – Two part connector, arrangement overview – Top view . 18

Figure 14 – Two part connector, printed board dimensions . 18

Figure 15 – Two part connector, arrangement overview – Top view . 19

Figure 16 – Two part connector, dimensions, 2 U . 19

Figure 17 – Two part connector, connector mounted on backplane dimensions, 2 U . 20

Figure 18 – Backplane dimensions. 22

Figure 19 – Subrack EMC dimensions . 23

Figure 20 – Plug-in unit EMC dimensions. 24

Figure 21 – Subrack ESD provision . 25

Figure 22 – Plug-in unit ESD provision . 26

Figure A.1 – Connector pin location according to IEC 61076-4-116, front view . 29

Figure B.1 – Depth dimension subrack type 1, side view . 30

Figure B.2 – Depth dimension subrack type 2, side view . 30

Figure B.3 – Depth dimension subrack type 3, side view . 31

Table 1 – Height dimensions . 26

Table 2 – Depth dimensions . 27

– 4 – 60297-3-107 IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STRUCTURES FOR ELECTRONIC EQUIPMENT –

DIMENSIONS OF MECHANICAL STRUCTURES

OF THE 482,6 mm (19 in) SERIES –

Part 3-107: Dimensions of subracks and

plug-in units, small form factor

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60297-3-107 has been prepared by subcommittee 48D:

Mechanical structures for electronic equipment, of IEC technical committee 48:

Electromechanical components and mechanical structures for electronic equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

48D/492/FDIS 48D/501/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

60297-3-107 IEC:2012 – 5 –

A list of all parts of IEC 60297 series, under the general title Mechanical structures for

electronic equipment – Dimensions of mechanical structures of the 482,6 mm (19 in) series,

can be found of the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60297-3-107 IEC:2012

INTRODUCTION

This standard provides for an alternative/smaller form factor of plug-in units as defined in

IEC 60297-3-101.

New technologies requiring smaller plug-in unit form factors used in 19 in equipment practice

are rapidly gaining acceptance.

Recognizing this development it became obvious that a generic interface standard would be

an advantage to the industry.

This standard is based upon and coordinated with the plug-in unit form factor as defined in

AMC.0 and MicroTCA developed by PICMG (PCI Industrial Computers Manufacturer Group).

By making critical interface dimensions available and permitting the use of alternative

connectors to the industry (beyond AMC.0 and MicroTCA) multiple product solutions may

make use of this technology and will increase the overall market acceptance, increase

availability, and reduce cost.

In order to meet the requirements of small form factor plug-in units within the subrack the

interface dimensions required differ from IEC 60297-3-101. This standard defines these small

form factor interface dimensions.

The small form factor generic dimensions are based on and coordinated with AMC.0 and

MicroTCA.

Since the AMC.0 and MicroTCA Specification defines only a limited range of connectors this

standard opens the possible use of other suitable connectors.

60297-3-107 IEC:2012 – 7 –

MECHANICAL STRUCTURES FOR ELECTRONIC EQUIPMENT –

DIMENSIONS OF MECHANICAL STRUCTURES

OF THE 482,6 mm (19 in) SERIES –

Part 3-107: Dimensions of subracks and

plug-in units, small form factor

1 Scope and object

This part of IEC 60297 defines the interface dimensions between subracks and associated

plug-in units using connectors as defined in PICMG-MTCA.0 (Fixed board, see Figure 7) and

IEC 61076-4-116 (Two part, see Figure 12) and other two part connectors, (see Figure 15).

For mechanical and climatic tests refer to IEC 61587-1.

For electromagnetic shielding performance tests refer to IEC 61587-3.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60297-3-100: Mechanical structures for electronic equipment - Dimensions of mechanical

structures of the 482,6 mm (19 in) series – Part 3-100: Basic dimensions of front panels,

subracks, chassis, racks and cabinets

IEC 61076-4-116: Connectors for electronic equipment – Product requirements – Printed

board connectors: Detail specification for a high-speed two-part connector with integrated

shielding function (to be published)

PICMG AMC.0: Advanced Mezzanine Card Specification

PICMG MicroTCA.0: Micro Telecommunications Computing Architecture

PICMG MicroTCA.1: Air Cooled Rugged MicroTCA Specification

– 8 – 60297-3-107 IEC:2012

3 Arrangement overview (4U shown)

Typical subrack

Left side of plug-in unit =

component side

4U plug-in unit with 4U plug-in unit with

4U power unit

PICMG-AMC.0 connector

two part connector (connector not shown)

according to

IEC 61076-4-116

IEC 2770/11

Figure 1 – Arrangement overview

60297-3-107 IEC:2012 – 9 –

4 Subrack dimensions

4.1 Subrack dimensions front mounting area

482,6 ± 0,4

≥ 428,08

D

C

Z 426,72

B

A

0,2 G

B

M2

Mounting positions M3;

L

front and rear

First possible guide

rail position (connector

See Figure 4 dependent)

A

A

G

0,2 D

Y

≥ 1,35

B See Figure 3

5,90

4,26 5,08

82 × = 416,56

mounting positions M3 and

First M3 mounting position possible guide rail mounting positions

and first possible

centreline of guide rail /

printed circuit board of

IEC 2771/11

plug-in unit

Figure 2a – Front area dimensions

H 7

H5

H6

H1

U

– 10 – 60297-3-107 IEC:2012

Detail “Z“

14,7 ± 1,2

Detail “Y“

M2

A

Both hole 4,26

types are

permitted

L 2,1 ± 0,1

G

The guide rail shall be

made of electrically

insulated material

5,08

10,3 ± 0,4

13,5 ± 0,4

IEC 2772/11

Figure 2b – Mounting holes and guide rail dimensions

Figure 2 – Subrack dimensions, front view

Cross Section B - B

≤ D2

≥ 16,8

Height separation plane

Back-

plane

X

L

Guide rail

Fixed board

Connector

R

See Figure 18

≤ D3

D1

E F

IEC 2773/11

Figure 3a – Guide rail dimensions

H1

H3 H2

H4

6,8 +0,5

6,8 +0,5

≤ 1,65

H6

U

60297-3-107 IEC:2012 – 11 –

E

Dimensions for ESD

provisions see Fig. 21 Other

application specific detail

may apply. Examples: PICMG-

AMC.0; PICMG-MTCA.0 and

PICMG-MTCA.1

≤ D2

Areas provided L Application specific detail may

apply.

for plug-in unit

features Examples: PICMG-AMC.0 and

PICMG-MTCA.0 and PICMG-

≤ D3

M3 MTCA.1

Guide rail

+10

10 to first thread

> 2,0 Threads

> 6,1

clearance

D1

Detail “X“

E

IEC 2774/11

Figure 3b – Mounting hole dimensions

Figure 3 – Subrack dimensions, side view

+0,3

Ø3,2

0,0

H 6

H5

≥ 3,1

– 12 – 60297-3-107 IEC:2012

Cross Section A – A (see Figure 2)

≤ 449 (incl.fixing hardware)

Detail „W“

F

Optional designs

Backplane

Sidepanel may exceed D1

attachment

(e.g. for EMC shielding )

plane

C

D

Typical

guide rail

W

⊕ 0,6 E

E E

A

Area provided for

Front

E

plug-in unit features

attachment plane

IEC 2775/11

Figure 4 – Subrack dimensions, top view

4.2 Subrack dimensions, rear view, backplane mounting area

426,72

M3 threaded holes shall

be applied for backplane

L

mounting

M2

C

D

≥ 1,35

4,26

5,90

5,08

82 × = 416,56

Backplane mounting points M3

First possible backplane

A

B

mounting position M3

IEC 2776/11

Figure 5 – Subrack dimensions, rear view

H 6

60297-3-107 IEC:2012 – 13 –

5 Plug-in unit dimensions

5,08

(n× -1,36) ± 0,2

12,30 ± 0,3

Plug-in unit

printed board

5,08

n×

V

Plug-in unit

front panel

L

G1

User specific

4,55

K

M

IEC 2777/11

Figure 6a – Front panel dimensions

M

Detail „V“

< 6,0 fastened

< 1,0 unfastened

K

M3

Retention device shall

allow a permanent

bottoming (J-J1=0) of

0,3 M

the edge board

connector and the

equivalent two part

connector as defined in

IEC 61076-4-116 at a

max. force of 5 N

IEC 2778/11

Figure 6b – Retention device dimensions

Figure 6 – Plug-in unit dimensions

H12

H9

H8

– 14 – 60297-3-107 IEC:2012

6 Connector and related printed board dimensions

NOTE The MTCA.0 fixed board connectors is identical with the fixed board connector of IEC 61076-4-116.

6.1 Connector according to PICMG-MicroTCA.0/ IEC 61076-4-116, fixed board

connector and related printed board dimensions

6.1.1 PICMG- MicroTCA.0/ IEC 61076-4-116 connector, isometric view

Printed board

Example for guide

of printed board

Fixed board

connector

Backplane

IEC 2779/11

Figure 7 – PICMG- MicroTCA.0/ IEC 61076-4-116 connector, isometric view

6.1.2 Connector according to PICMG- MicroTCA.0/ IEC 61076-4-116, fixed board

connector and related printed board – arrangement overview

J and J1

M and M1 and M2

Plug-in unit

PICMG-MTCA.0

Fixed Board Connector

Backplane

186,65

F1

K

IEC 2780/11

Figure 8 – PICMG- MicroTCA.0/ IEC 61076-4-116 fixed board connector,

arrangement overview – Top view

60297-3-107 IEC:2012 – 15 –

6.1.3 Printed board dimensions

≤ D6

S

Detail „U“

Both sides (top and bottom)

Card guide keep out

zones - both sides

Connector

component

keep out zones – Card edge

J

both sides

U

L

7,90

R1,0

45°

G1

R0,5

≤ D4

R0,5

D5

+2,8

10,7

0,0

J

K

IEC 2781/11

Figure 9a – Printed board dimensions, side view

View „S“

Detail „T“

J

K

0,4 ± 0,1

M

M

T

J

Card edge

45° ± 2°

IEC 2782/11

Figure 9b – Printed board dimensions, top view

Figure 9 – Printed board dimensions

1,6 ± 0,16

(PCB)

≥ 1,70

≥ 1,70

36,75

H13

H10

0,6

(4,25)

H13

H10

– 16 – 60297-3-107 IEC:2012

6.1.4 Printed board dimensions, 4U example

+2,8

10,7

0,0

7,3

6,7

Connector

component

Missing dimensions:

keep out zones –

see Figure 9:

both sides

Printed board dimensions

Zone X:

May be used for

additional connectors

not defined in this

standard. This (these)

additional connector(s)

may plug into a

common backplane.

Connector

component

keep out zones –

both sides

L

Card edge

G1

D5

J

K

IEC 2783/11

Figure 10 – Printed board dimensions, 4U example

36,75

≥ 42,50

≤107,50

H13

H10

60297-3-107 IEC:2012 – 17 –

6.1.5 Connector according to PICMG-MTCA.0, fixed board connector dimensions

J and J1

F

(10,60 max.)

M and M1

Optional PICMG-MTCA.0

Protrusion fixed board connector

L and L1 L and L1

Backplane

G1

(7,50 max.)

(7,10 max.)

Plug-in unit

(5,80 ± 0,10 )

IEC 2784/11

Figure 11 – Connector according to PICMG- MTCA.0, fixed board connector dimensions

6.2 Two part connector according to IEC 61076-4-116 and related printed board

dimensions

6.2.1 Two part connector, isometric view

Printed board

Example for guide

of printed board

Free board

connector

Fixed board

connector

Backplane

IEC 2785/11

Figure 12 – Fixed board and free board connector – Isometric view

(74,90 max )

– 18 – 60297-3-107 IEC:2012

6.2.2 Two part connector, arrangement overview

K

J and J1

M and M1 and M2

Backplane

Free board

Plug-in unit

connector

F1

Fixed board

connector

IEC 2786/11

Figure 13 – Two part connector, arrangement overview – Top view

6.2.3 Two part connector, printed board dimensions

≤ D6

Missing PCB dimensions:

Vendor specific

Card guide keep out

zones - both sides

Free board

connector

L and L1

G1

≤ D4

F1

D5

K

J and J1

M and M1 and M2

Backplane

Free board Fixed board

Plug-in unit

connector connector

IEC 2787/11

Figure 14 – Two part connector, printed board dimensions

≥ 1,70

≥ 1,70

(70,00 max.)

60297-3-107 IEC:2012 – 19 –

6.2.4 Two part connector, fixed board connector dimensions

See 6.1.5: Fixed board connector dimensions

6.3 Two part connector with PIU PB component side attachment features

NOTE Connectors typically attached to a PIU PB on one of the outer component surfaces are based on a PB

thickness of 1,6 mm nominal for the purpose of this standard. See Figure 15.

6.3.1 Two part connector, arrangement overview

F1

K

Fixed connector

mounted

on backplane

Component side

M and M2

Connector mounted

Backplane

on PIU

Power Unit

IEC 2788/11

Figure 15 – Two part connector, arrangement overview – Top view

6.3.2 Two part connector, printed circuit board dimensions, 2 U

1,5 × 45°

Module face plate

dimensions,

see 5.1

Free connector

dimensions: User

specific

L and L1

Missing printed

board dimensions

see 6.1.2

User specific

Backplane

F1

User specific

186,65

K

Free connector

M

IEC 2789/11

Figure 16 – Two part connector, dimensions, 2 U

1,6 ± 0,16

(PB)

– 20 – 60297-3-107 IEC:2012

6.3.3 Two part connector, connector mounted on backplane, 2 U

Fixed connector

dimensions user

specific

L and L1

Backplane

F1

M

IEC 2790/11

Figure 17 – Two part connector, connector mounted on backplane dimensions, 2 U

60297-3-107 IEC:2012 – 21 –

7 Backplane dimensions

7.1 Backplane dimensions using two part connector according to IEC 61076-4-116

Figure 18 illustrates the backplane heights and width dimensions as well as the first connector

position, using two part connector according to IEC 61076-4-116.

View R (see Figure 3)

< 426,72

< 4,26

+0,3

Ø3,2

0,0

M and M1

L and L1

First

possible

mounting

position

5,08

5,08

n ×

possible mounting positions

4,26

A

Fixed board connector

according to

IEC 61076-4-116

J1

F1

IEC 2791/11

Figure 18a – 3U backplane dimensions, for 2 U plug-in units

H11 = 84,00

User specific

47,5

H14 =95,00

– 22 – 60297-3-107 IEC:2012

< 426,72

< 4,26

+0,3

Ø3,2

0,0

First

possible

M and M1

mounting

position

L

L1

5,08

5,08

n ×

possible mounting positions

4,26

A

Fixed board connector

according to

IEC 61076-4-116

J1

F1

IEC 2792/11

Figure 18b – 4U Backplane dimensions

Figure 18 – Backplane dimensions

H11 = 159,00

User specific

47,5

H14 = 170,00

60297-3-107 IEC:2012 – 23 –

8 Subrack and plug-in units with electromagnetic shielding (EMC) provisions

8.1 General

The dimensional specifications of electromagnetic shielding provisions for subracks and

associated plug-in units are restricted to the subrack and plug-in unit interfaces. The basic

dimensions are in accordance with Clauses 4 and 5 of this standard. Only the extended

dimensions of the shielding interfaces are subject of this clause. Materials of the shielding

interfaces should be chosen for adequate contact properties.

8.2 Subrack EMC provisions

For corresponding plug-in unit dimensions, see 5.1.

F - F

EMC gasket

C

D D - D

Front view

C - C

F F

Conductive surface

E E

Conductive area

min. 12,0

C D

T

EMC gasket only

T

2,54

-0,5

E - E

E

Centerline EMC gasket

IEC 2793/11

Figure 19 – Subrack EMC dimensions

6,13 ± 0,5

≥ 10,5 ≥ 10,5

H5

max. 12,0

– 24 – 60297-3-107 IEC:2012

8.3 Plug-in unit and filler panels EMC provisions

The basic dimensions are in accordance with Clause 5 of this standard. Only the extended

dimensions of the shielding interface are shown.

EMC gasket:

Dimensions see Figure 19

Detail „T“

K

Conductive

surface

IEC 2794/11

Figure 20 – Plug-in unit EMC dimensions

9 Subrack and plug in units electrostatic discharge provisions (ESD)

9.1 General

This clause specifies the interface dimensions for an electrostatic discharge contact

implemented in the guide rail and the corresponding conductive strip on the plug-in unit

printed board.

The conductive strips on the printed board are shown for two application requirements: With

permanent connection along with the depth dimension of the board or with interruption before

the board is fully engaged in the connector.

6,1 ± 0,5

60297-3-107 IEC:2012 – 25 –

9.2 Subrack ESD provisions

The ESD contact shall be connected to the subrack horizontal member and spring load fixed

within the determined guide rail area. The ESD contact shall be able to connect the inserted

board on both sides.

S

F

E

IEC 2795/11

Figure 21a – Subrack ESD provision, overview

Detail S

Front, top, horizontal

Subrack member only

Top guide rail only

View „Q“

Q

ESD contact point

at this side only

45,0 –5,0

ESD contact point

E

IEC 2796/11

Figure 21b – Subrack ESD provision, guide rail

Figure 21 – Subrack ESD provision

H7

– 26 – 60297-3-107 IEC:2012

9.3 Plug–in unit ESD provisions, front mounted

Missing dimensions, see Figure 6.

K

> 17,0

J

Generic ESD contact area at this side only

IEC 2797/11

Figure 22 – Plug-in unit ESD provision

Table 1 – Height dimensions

Height units

3 U 4 U

a

H1 ± 0,4 132,55 177,00

H2 ± 0,4 57,15 101,60

37,70 37,70

H3 ± 0,4

H4 ± 0,4 - -

H5 ± 0,4 76,20 151,20

84,00 159,00

H6 ± 0,2

H7 ± 0,4 74,00 149,00

H8 ± 0,2 95,00 170,00

H9 ± 0,2 84,00 159,00

H10 ± 0,1 73,50 148,50

H11 ± 0,2 84,00 159,00

H12 ± 0,2 73,80 148,80

65,00 65,00

H13 ± 0,1

H14 0 / -1,0 95,00 170,00

a

The height dimension H 1 is used as

reference if the subrack design is intended to

fit into the available height of n × U. Smaller

height dimensions may be used as

appropriate for stability or special design

requirements ( H1min = H14 ).

1,30 max.

60297-3-107 IEC:2012 – 27 –

Table 2 – Depth dimensions

185,85

D 1 ± 0,3

D 2 162,00

D 3 156,80

D 4 ≤ 153,50

D 5 ± 0,4 180,85

157,75

D 6 ≤

RD 1 ± 0,3 185,85

10 Nomenclature

Height

U: Coordination height unit of 44,45 mm (1,75 in). See IEC 60297-3-100.

H1: Subrack heights (equal to dimension E of IEC 60297-3-100).

H2: Subrack to cabinet or rack mounting hole positions (equal to dimensions Y / Z of

IEC 60297-3-100).

H3: Subrack to cabinet or rack mounting hole positions (equal to dimensions A of

IEC 60297-3-100).

H4: Subrack to cabinet or rack mounting hole positions (equal to dimensions Y / Z of

IEC 60297-3-100).

H5: Subrack vertical aperture opening for plug-in units.

H6: Mounting centre distance for front plug-in units and panels, front and rear.

H7: Printed board guidance height.

H8: Plug-in unit panel height.

H9: Vertical plug-in unit panel mounting centre distance.

H10: Printed board height into subrack guidance height.

H11: Mounting centre distance for backplane.

H12: Front/rear panel body height dimension.

H13: Printed board height into connector guidance height.

H14: Backplane height dimension.

Width

HP: The subrack aperture is theoretically divided into N x horizontal pitches (HP) of 5,08

mm.

The plug-in unit front panel width is divided into N x 5,08 mm horizontal pitches.

Depth

D1: Subrack dimension between front attachment plane and backplane attachment plane.

D2: Dimension between backplane attachment plane and top guide rail unit.

D3: Dimension between backplane attachment plane and bottom guide rail unit.

D4: Dimension PB keep out zone – bottom side, utilizing card edge connector.

D5: Plug-in unit dimension between rear of face plate and utilizing card edge connector.

D6: Dimension PB keep out zone – top side, utilizing card edge connector.

RD1: Subrack dimension between rear attachment plane and rear backplane attachment

plane.

– 28 – 60297-3-107 IEC:2012

Reference plane (given in square boxes)

A: Subrack, first pitch line

B: Subrack, last pitch line

C: Subrack, left inside wall

D: Subrack, right inside wall

E: Subrack, front attachment plane

F: Subrack, backplane attachment plane

F1: Bottom of connector touches F on backplane

G: Guide rail, interface surface to PB

G1: Module PB, interface surface to guide rail

J: Plug-in unit, PB leading edge

J1: Bottoming position of module PB or free board connector within fixed board connector

J2: Bottoming position of module PB within free board connector

J3: Free board connector, leading edge

K: Plug-in unit, rear of face plate

L: Centre line module PB and subrack

L1: Centre line of connector

M: Centre line of module PB thickness

M1: Centre line of connector cavity

M2: Centre line of guide rail

N: Subrack, rear attachment plane

O: Subrack, rear backplane attachment plane

60297-3-107 IEC:2012 – 29 –

Annex A

(informative)

Connector hole pattern at the backplane

M

L

Pin 01

Pin 170 IEC 2798/11

Figure A.1 – Connector pin location according to IEC 61076-4-116, front view

– 30 – 60297-3-107 IEC:2012

Annex B

(informative)

Rear mounted plug-in unit implementation

B.1 Subrack depth dimensions

B.1.1 Subrack type 1

Back-

plane

L

N

E

D1 RD1

F = O

IEC 2799/11

Figure B.1 – Depth dimension subrack type 1, side view

B.1.2 Subrack type 2

O

F

Back-

plane

L

D1

RD1

E N

Backplane thickness

IEC 2800/11

Figure B.2 – Depth dimension subrack type 2, side view

60297-3-107 IEC:2012 – 31 –

B.1.3 Subrack type 3

O

F

Distance between

datum “O“ and datum “F” ±0,2

Distance between

Backplane 1 and backplane 2

Backplane 1 Backplane 2

L

D1

RD1

E N

Thickness backplane 1

Thickness backplane 2

IEC 2801/11

Figure B.3 – Depth dimension subrack type 3, side view

– 32 – 60297-3-107 IEC:2012

Annex C

(informative)

Hot swap latch function

For detailed information, see PICMG-AMC.0 and PICMG-MTCA.0.

60297-3-107 IEC:2012 – 33 –

Annex D

(informative)

Subrack latch mechanism interface dimensions

for ruggedized applications

For detailed information, see PICMG-MTCA.1 section 2.5.2.2: Mandatory subrack latch

mechanism.

– 34 – 60297-3-107 IEC:2012

Annex E

(informative)

Subrack ESD contact interface dimensions

For detailed information, see PICMG-MTCA.0, Figure 2-42; view Y.

_____________

– 36 – 60297-3-107 CEI:2012

SOMMAIRE

AVANT-PROPOS . 38

INTRODUCTION . 40

1 Domaine d’application et objet . 41

2 Références normatives . 41

3 Vue d'ensemble de disposition (4U représentés) . 42

4 Dimensions des bacs . 43

4.1 Dimensions des bacs, zone de montage avant . 43

4.2 Dimensions des bacs, vue de derrière, zone de montage des fonds de panier . 46

5 Dimensions des blocs enfichables . 47

6 Connecteur et dimensions de carte imprimée associée . 48

6.1 Connecteur conforme à la spécification PICMG-MicroTCA.0/CEI 61076-4-116,

connecteur pour carte fixe et dimensions de carte imprimée associée . 48

6.1.1 Connecteur PICMG- MicroTCA.0/CEI 61076-4-116, vue isométrique . 48

6.1.2 Connecteur conforme à la spécification PICMG-MicroTCA.0/

CEI 61076-4-116, connecteur pour carte fixe et carte imprimée

associée – vue d'ensemble de disposition . 48

6.1.3 Dimensions de carte imprimée . 49

6.1.4 Dimensions de carte imprimée, exemple 4U . 50

6.1.5 Connecteur conforme à la spécification PICMG-MTCA.0, dimensions

de connecteur pour carte fixe . 51

6.2 Connecteur en deux parties conforme à la CEI 61076-4-116 et dimensions

de carte imprimée associée . 52

6.2.1 Connecteur en deux parties, vue isométrique . 52

6.2.2 Connecteur en deux parties, vue d'ensemble de disposition . 53

6.2.3 Connecteur en deux parties, dimensions de carte imprimée . 53

6.2.4 Connecteur en deux parties, dimensions de connecteur pour carte fixe . 54

6.3 Connecteur en deux parties avec fixations latérales pour composant sur

carte imprimée PIU . 54

6.3.1 Connecteur en deux parties, vue d'ensemble de disposition . 54

6.3.2 Connecteur en deux parties, dimensions de carte imprimée, 2 U . 54

6.3.3 Connecteur en deux parties, connecteur installé dans un fond de

panier, 2 U . 55

7 Dimensions des fonds de panier .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...