IEC 61788-7:2006

(Main)Superconductivity - Part 7: Electronic characteristic measurements - Surface resistance of superconductors at microwave frequencies

Superconductivity - Part 7: Electronic characteristic measurements - Surface resistance of superconductors at microwave frequencies

IEC 61788-7:2006 describes measurement of the surface resistance of superconductors at microwave frequencies by the standard two-resonator method. The object of measurement is the temperature dependence of Rs at the resonant frequency. The applicable measurement range of surface resistances for this method is as follows:

- Frequency: 8 GHz - Measurement resolution: 0,01 milliohm at 10 GHz.

Supraconductivité - Partie 7 : Mesures des caractéristiques électroniques - Résistance superficielle des supraconducteurs à des hyperfréquences

L'IEC 61788-7:2006 décrit la mesure de la résistance de surface des supraconducteurs à des hyperfréquences au moyen de la méthode normalisée à deux résonateurs. La dépendance à la température de Rs à la fréquence résonante constitue l'objet de la mesure.

L'étendue de mesure applicable des résistances superficielles pour cette méthode est la suivante:

– Fréquence: 8 GHz – Résolution de mesure: 0,01 m à 10 GHz

Les données relatives à la résistance de surface à la fréquence mesurée, et à la fréquence établie à 10 GHz, en posant l'hypothèse de la règle de comparaison f 2, sont consignées dans le rapport d'essai.

General Information

- Status

- Published

- Publication Date

- 24-Oct-2006

- Technical Committee

- TC 90 - Superconductivity

- Drafting Committee

- WG 8 - TC 90/WG 8

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 20-Mar-2020

- Completion Date

- 30-Nov-2017

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61788-7:2006 - Superconductivity Part 7 - defines a standardized laboratory method to measure the surface resistance (Rs) of superconducting materials at microwave frequencies. The standard specifies the two‑resonator (dielectric resonator) technique to determine the temperature dependence of Rs at a resonant frequency, with practical measurement coverage in the microwave band and high sensitivity (example resolution: 0.01 milliohm at 10 GHz). The publication also updates recommendations for resonator designs (including closed‑type resonators) and includes guidance on sapphire dielectric rods commonly used for high‑precision measurements.

Key topics and technical requirements

- Measurement method: Standard two‑resonator dielectric resonator approach to extract Rs from resonator Q‑values and insertion loss.

- Temperature dependence: Procedures for measuring Rs(T) over cryogenic to elevated temperatures (cryocooler setups are illustrated).

- Apparatus and components:

- Dielectric resonators (sapphire rods recommended), resonator geometries (closed‑type favored for stability).

- Vector Network Analyzer (VNA) specifications and calibration/measurement procedures.

- Sample holders, specimen preparation and mounting to avoid measurement artifacts.

- Measurement procedure: Setup, reference‑level measurement, frequency response capture, and calculation steps to determine Rs and dielectric parameters (ε′ and tan δ of standard rods).

- Precision, accuracy and reporting: Uncertainty sources (temperature control, sample support, instrument specs), resolution limits, and required information for a compliant test report.

- Recommended measurement frequencies: Examples and design tables in the standard include microwave bands (the standard adds recommended frequencies such as 12 GHz, 18 GHz and 22 GHz in addition to specified microwave ranges).

Applications and who uses it

IEC 61788-7 is intended for:

- Materials scientists and thin‑film researchers characterizing high‑Tc and low‑Tc superconducting films.

- Microwave and RF engineers designing low‑loss filters, resonators, antennas and delay lines that use superconducting films.

- Test laboratories and QA/qualification teams requiring repeatable, traceable Rs measurements for production control.

- Component manufacturers and R&D organizations developing HTS-based telecom or sensing products.

Practical uses include material selection, process optimization for epitaxial films, component loss budgeting, and acceptance testing of superconducting microwave components.

Related standards

- Other parts of the IEC 61788 series covering critical current, residual resistance ratio, AC loss and mechanical tests (e.g., Parts 1–6, 8–13) - useful when a complete superconducting material characterization program is required.

Keywords: IEC 61788-7, surface resistance, superconductors, microwave measurements, dielectric resonator, sapphire resonator, two-resonator method, Rs(T), vector network analyzer, cryocooler.

Buy Documents

IEC 61788-7:2006 - Superconductivity - Part 7: Electronic characteristic measurements - Surface resistance of superconductors at microwave frequencies Released:10/25/2006

IEC 61788-7:2006 - Superconductivity - Part 7: Electronic characteristic measurements - Surface resistance of superconductors at microwave frequencies Released:7/23/2020

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61788-7:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Superconductivity - Part 7: Electronic characteristic measurements - Surface resistance of superconductors at microwave frequencies". This standard covers: IEC 61788-7:2006 describes measurement of the surface resistance of superconductors at microwave frequencies by the standard two-resonator method. The object of measurement is the temperature dependence of Rs at the resonant frequency. The applicable measurement range of surface resistances for this method is as follows: - Frequency: 8 GHz - Measurement resolution: 0,01 milliohm at 10 GHz.

IEC 61788-7:2006 describes measurement of the surface resistance of superconductors at microwave frequencies by the standard two-resonator method. The object of measurement is the temperature dependence of Rs at the resonant frequency. The applicable measurement range of surface resistances for this method is as follows: - Frequency: 8 GHz - Measurement resolution: 0,01 milliohm at 10 GHz.

IEC 61788-7:2006 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.050 - Superconductivity and conducting materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61788-7:2006 has the following relationships with other standards: It is inter standard links to IEC 61788-7:2020, IEC 61788-7:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61788-7:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61788-7

Second edition

2006-10

Superconductivity –

Part 7:

Electronic characteristic measurements –

Surface resistance of superconductors at

microwave frequencies

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61788-7

Second edition

2006-10

Superconductivity –

Part 7:

Electronic characteristic measurements –

Surface resistance of superconductors at

microwave frequencies

© IEC 2006 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale V

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61788-7 © IEC:2006(E)

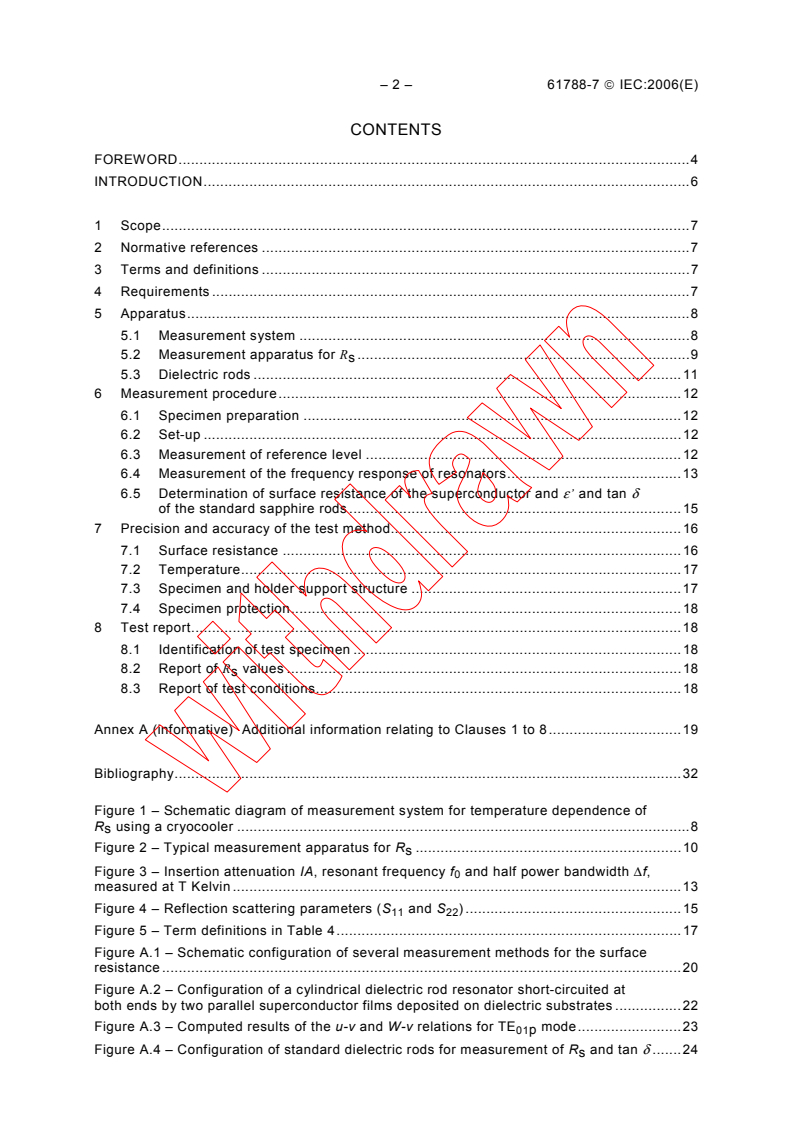

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terms and definitions .7

4 Requirements .7

5 Apparatus.8

5.1 Measurement system .8

5.2 Measurement apparatus for R .9

s

5.3 Dielectric rods .11

6 Measurement procedure.12

6.1 Specimen preparation .12

6.2 Set-up .12

6.3 Measurement of reference level .12

6.4 Measurement of the frequency response of resonators.13

6.5 Determination of surface resistance of the superconductor and ε’ and tan δ

of the standard sapphire rods .15

7 Precision and accuracy of the test method.16

7.1 Surface resistance .16

7.2 Temperature.17

7.3 Specimen and holder support structure .17

7.4 Specimen protection.18

8 Test report.18

8.1 Identification of test specimen .18

8.2 Report of R values .18

s

8.3 Report of test conditions.18

Annex A (informative) Additional information relating to Clauses 1 to 8.19

Bibliography.32

Figure 1 – Schematic diagram of measurement system for temperature dependence of

R using a cryocooler .8

s

Figure 2 – Typical measurement apparatus for R .10

s

Figure 3 – Insertion attenuation IA, resonant frequency f and half power bandwidth Δf,

measured at T Kelvin .13

Figure 4 – Reflection scattering parameters (S and S ) .15

11 22

Figure 5 – Term definitions in Table 4.17

Figure A.1 – Schematic configuration of several measurement methods for the surface

resistance .20

Figure A.2 – Configuration of a cylindrical dielectric rod resonator short-circuited at

both ends by two parallel superconductor films deposited on dielectric substrates .22

Figure A.3 – Computed results of the u-v and W-v relations for TE mode.23

01p

Figure A.4 – Configuration of standard dielectric rods for measurement of R and tan δ .24

s

61788-7 © IEC:2006(E) – 3 –

Figure A.5 – Three types of dielectric resonators .24

Figure A.6 – Mode chart to design TE resonator short-circuited at both ends by

parallel superconductor films [11] .27

Figure A.7 – Mode chart to design TE resonator short-circuited at both ends by

parallel superconductor films [11] .28

Figure A.8 – Mode chart for TE closed-type resonator.29

Figure A.9 – Mode chart for TE closed-type resonator.30

Table 1 – Typical dimensions of pairs of standard sapphire rods for 12 GHz, 18 GHz

and 22 GHz .11

Table 2 – Dimensions of superconductor film for 12 GHz, 18 GHz, and 22 GHz .12

Table 3 – Specifications on vector network analyzer .16

Table 4 – Specifications on sapphire rods.16

– 4 – 61788-7 © IEC:2006(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SUPERCONDUCTIVITY –

Part 7: Electronic characteristic measurements –

Surface resistance of superconductors

at microwave frequencies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61788-7 has been prepared by IEC technical committee 90:

Superconductivity.

This second edition cancels and replaces the first edition, published in 2002, of which it

constitutes a technical revision. Examples of technical changes made are: 1) closed type

resonators are recommended from the viewpoint of the stable measurements, 2) uniaxial-

anisotropic characteristics of sapphire rods are taken into consideration for designing the size

of the sapphire rods, and 3) recommended measurement frequency of 18 GHz and 22 GHz

are added to 12 GHz described in the first edition.

The text of this standard is based on the following documents:

FDIS Report on voting

90/193/FDIS 90/198/RVD

61788-7 © IEC:2006(E) – 5 –

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61788 consists of the following parts, under the general title Superconductivity:

Part 1: Critical current measurement – DC critical current of Cu/Nb-Ti composite super-

conductors

Part 2: Critical current measurement – DC critical current of Nb Sn composite super-

conductors

Part 3: Critical current measurement – DC critical current of Ag- and/or Ag alloy-sheathed

Bi-2212 and Bi-2223 oxide superconductors

Part 4: Residual resistance ratio measurement – Residual resistance ratio of Nb-Ti

composite superconductors

Part 5: Matrix to superconductor volume ratio measurement – Copper to superconductor

volume ratio of Cu/Nb-Ti composite superconductors

Part 6: Mechanical properties measurement – Room temperature tensile test of Cu/Nb-Ti

composite superconductors

Part 7: Electronic characteristic measurements – Surface resistance of superconductors at

microwave frequencies

Part 8: AC loss measurements – Total AC loss measurement of Cu/Nb-Ti composite

superconducting wires exposed to a transverse alternating magnetic field by a

pickup coil method

Part 9: Measurements for bulk high temperature superconductors – Trapped flux density of

large grain oxide superconductors

Part 10: Critical temperature measurement – Critical temperature of Nb-Ti, Nb Sn, and

Bi-system oxide composite superconductors by a resistance method

Part 11: Residual resistance ratio measurement – Residual resistance ratio of Nb Sn

composite superconductors

Part 12: Matrix to superconductor volume ratio measurement – Copper to non-copper

volume ratio of Nb Sn composite superconducting wires

Part 13: AC loss measurements – Magnetometer methods for hysteresis loss in Cu/Nb-Ti

multifilamentary composites

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 61788-7 © IEC:2006(E)

INTRODUCTION

Since the discovery of some Perovskite-type Cu-containing oxides, extensive research and

development (R & D) work on high-temperature oxide superconductors has been, and is being,

made worldwide, and its application to high-field magnet machines, low-loss power

transmission, electronics and many other technologies is in progress.

In various fields of electronics, especially in telecommunication fields, microwave passive

devices such as filters using oxide superconductors are being developed and are undergoing

1)

on-site testing [1,2] .

Superconductor materials for microwave resonators, filters, antenna and delay lines have the

advantage of very low loss characteristics. Knowledge of this parameter is of primary

importance for the development of new materials on the supplier side and for the design of

superconductor microwave components on the customer side. The parameters of

superconductor materials needed for the design of microwave low loss components are the

surface resistance R and the temperature dependence of the surface resistance.

s

Recent advances in high Tc superconductor (HTS) thin films with R several orders of

s

magnitude lower than that of normal metals have increased the need for a reliable

characterization technique to measure this property [3,4]. Traditionally, the R of Nb or any

s

other low temperature superconducting material was measured by first fabricating an entire

three dimensional resonant cavity and then measuring its Q-value. The R could be calculated

s

by solving the EM field distribution inside the cavity. Another technique involves placing a

small sample inside a larger cavity. This technique has many forms but usually involves the

uncertainty introduced by extracting the loss contribution due to the HTS films from the

experimentally measured total loss of the cavity.

The best HTS samples are epitaxial films grown on flat crystalline substrates and no high

quality films have been grown on any curved surface so far. What is needed is a technique

that: can use these small flat samples; requires no sample preparation; does not damage or

th

change the film; is highly repeatable; has great sensitivity (down to 1/1 000 the R of copper);

s

has great dynamic range (up to the R of copper); can reach high internal powers with only

s

modest input powers; and has broad temperature coverage (4,2 K to 150 K).

The dielectric resonator method is selected among several methods [5,6,7] to determine the

surface resistance at microwave frequencies because it is considered to be the most popular

and practical at present. Especially, the sapphire resonator is an excellent tool for measuring

the R of HTS materials [8,9].

s

The test method given in this standard can be also applied to other superconductor bulk

plates including low Tc material.

This standard is intended to provide an appropriate and agreeable technical base for the time

being to engineers working in the fields of electronics and superconductivity technology.

The test method covered in this standard is based on the VAMAS (Versailles Project on

Advanced Materials and Standards) pre-standardization work on the thin film properties of

superconductors.

___________

1)

Figures in square brackets refer to the Bibliography.

61788-7 © IEC:2006(E) – 7 –

SUPERCONDUCTIVITY –

Part 7: Electronic characteristic measurements –

Surface resistance of superconductors

at microwave frequencies

1 Scope

This part of IEC 61788 describes measurement of the surface resistance of superconductors

at microwave frequencies by the standard two-resonator method. The object of measurement

is the temperature dependence of R at the resonant frequency.

s

The applicable measurement range of surface resistances for this method is as follows:

– Frequency: 8 GHz < f < 30 GHz

– Measurement resolution: 0,01 mΩ at 10 GHz

The surface resistance data at the measured frequency, and that scaled to 10 GHz, assuming

the f rule for comparison, are reported.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-815, International Electrotechnical Vocabulary (IEV) – Part 815: Superconductivity

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-815 apply.

In general, surface impedance Z for conductors, including superconductors, is defined as the

s

ratio of the electric field E to the magnetic field H , tangential to a conductor surface:

t t

Z = E /H = R + jX

s t t s s

where R is the surface resistance and X is the surface reactance.

s s

4 Requirements

The surface resistance R of a superconductor film shall be measured by applying a

s

microwave signal to a dielectric resonator with the superconductor film specimen and then

measuring the attenuation of the resonator at each frequency. The frequency shall be swept

around the resonant frequency as the centre, and the attenuation–frequency characteristics

shall be recorded to obtain Q-value, which corresponds to the loss.

The target precision of this method is a coefficient of variation (standard deviation divided by

the average of the surface resistance determinations) that is less than 20 % for the

measurement temperature range from 30 K to 80 K.

– 8 – 61788-7 © IEC:2006(E)

It is the responsibility of the user of this standard to consult and establish appropriate safety

and health practices and to determine the applicability of regulatory limitations prior to use.

Hazards exist in this type of measurement. The use of a cryogenic system is essential to cool

the superconductors to allow transition into the superconducting state. Direct contact of skin

with cold apparatus components can cause immediate freezing, as can direct contact with a

spilled cryogen. The use of an r.f.-generator is also essential to measure high-frequency

properties of materials. If its power is too high, direct contact to human bodies can cause an

immediate burn.

5 Apparatus

5.1 Measurement system

Figure 1 shows a schematic diagram of the system required for the microwave measurement.

The system consists of a network analyzer system for transmission measurement, a

measurement apparatus, and a thermometer for monitoring the measuring temperature.

An incident power generated from a suitable microwave source such as a synthesized

sweeper is applied to the dielectric resonator fixed in the measurement apparatus. The

transmission characteristics are shown on the display of the network analyzer.

Vector network

analyser

Synthesized

sweeper

Thermometer

S-parameter

test set

Thermal sensor

Measurement apparatus

Cryocooler

IEC 004/02

Figure 1 – Schematic diagram of measurement system

for temperature dependence of R using a cryocooler

s

The measurement apparatus is fixed in a temperature-controlled cryocooler.

For the measurement of R for superconductor films, a vector network analyzer is recom-

s

mended. A vector network analyzer has better measurement accuracy than a scalar network

analyzer due to its wide dynamic range.

System interface

61788-7 © IEC:2006(E) – 9 –

5.2 Measurement apparatus for R

s

Figure 2 shows a schematic of a typical measurement apparatus (closed type resonator) for

the R of superconductor films deposited on a substrate with a flat surface. The upper

s

superconductor film is pressed down by a spring, which is made of phosphor bronze. The

plate type spring is recommended to be used for the improvement of measurement accuracy.

This type of spring reduces the friction between the spring and the other part of the apparatus,

and allows the smooth movement of superconductor films due to the thermal expansion of the

dielectric rod. In order to minimize the measurement error, the sapphire rod and the copper

ring shall be set in coaxial.

Two semi-rigid cables for measuring transmission characteristics of the resonator shall be

attached on both sides of the resonator in an axial symmetrical position (φ = 0 and π, where φ

is the rotational angle around the central axis of the sapphire rod). Each of the two semi-rigid

cables shall have a small loop at the ends. The plane of the loop shall be set parallel to that

of the superconductor films in order to suppress the unwanted TM modes. The coupling

mn0

loops shall be carefully checked for cracks in the spot weld joint that may have developed

upon repeated thermal cycling. These cables can move right and left to adjust the insertion

attenuation (IA). In this adjustment, coupling of unwanted cavity modes to the interested

dielectric resonance mode shall be suppressed. Unwanted, parasitic coupling to the other

modes reduces the high Q value of the TE mode resonator. For suppressing the parasitic

coupling, special attention shall be paid to designing high Q resonators. Two other types of

resonators along with the closed type shown in Figure 2 can be used. They are explained in

Clause A.4.

– 10 – 61788-7 © IEC:2006(E)

Screw Screws

Hexagonal

head bolt

Phosphor bronze

plate spring

Copper supports

Copper plate

Spot welding

Superconductor film

Copper ring

Small loop

Connector

Semi-rigid

Superconductor film

coaxial cable

Sapphire rod

Copper block

Screws to fix on

a cold stage

IEC 1733/06

Figure 2 – Typical measurement apparatus for R

s

61788-7 © IEC:2006(E) – 11 –

A reference line made of a semi-rigid cable shall be used to measure the full transmission

power level, i.e., the reference level. This cable has a length equal to the sum of the two

cables of the measurement apparatus. The semi-rigid cable with the outer diameter of

1,20 mm is recommended.

In order to minimize the measurement error, two superconductor films shall be set to be

parallel to each other. To ensure that the two superconductor films remain in tight contact with

the ends of the sapphire rod, without any air gap, both of the surfaces of the films and the

ends of the rod shall be cleaned carefully.

5.3 Dielectric rods

Two dielectric rods with the same relative permittivity, ε’, and loss factor, tan δ, preferably cut

from one cylindrical dielectric rod, are required. These two rods, standard dielectric rods, shall

have the same diameter but different heights: one has a height three times longer than the

other.

It is preferable to use standard dielectric rods with low tan δ to achieve the requisite

measurement accuracy on R . Recommended dielectric rods are sapphire rods with tan δ less

s

–6

than 10 at 77 K. Specifications on the sapphire rods are described in 7.1. In order to

minimize the measurement error in R of the superconductor films, both ends of the sapphire

s

rods shall be polished parallel to each other and perpendicular to the axis. Specifications for

the sapphire rods are described in Clause 7.

The diameter and the heights of the standard sapphire rods shall be carefully designed so

that the TE and TE modes do not couple to other TM, HE and EH modes, since the

011 013

coupling between TE mode and other modes causes the degradation of unloaded Q. A design

guideline for the standard sapphire rods is described in Clause A.5. Table 1 shows typical

examples of dimensions of the standard sapphire rods for 12 GHz, 18 GHz, and 22 GHz

resonance. At higher frequencies the unloaded Q value will be lower, which makes the

measurement easier, and the error will be lower.

Table 1 – Typical dimensions of pairs of standard sapphire rods for

12 GHz, 18 GHz and 22 GHz

Diameter Height

Frequency

d h

GHz

mm mm

Short rod (TEresonator) 11,4 5,7

Long rod (TE resonator) 11,4 17,1

Short rod (TEresonator) 7,6 3,8

Long rod (TE resonator) 7,6 11,4

Short rod (TEresonator) 6,2 3,1

Long rod (TE resonator) 6,2 9,3

– 12 – 61788-7 © IEC:2006(E)

6 Measurement procedure

6.1 Specimen preparation

From error estimation, the film diameter shall be about three times larger than that of the

sapphire rods. In this configuration, the reduction in precision of R due to the different

s

radiation losses between TE and TE mode can be considered negligible, given the

011 013

target precision of 20 %. The film thickness shall be about three times larger than the London

penetration depth value at each temperature. If the film thickness is much less than three

times the London penetration depth, the measured R should mean the effective surface

s

resistance.

Table 2 shows dimensions of the superconductor films recommended for the standard

sapphire rods of 12 GHz, 18 GHz, and 22 GHz.

Table 2 – Dimensions of superconductor film for 12 GHz, 18 GHz, and 22 GHz

Standard dielectric rod Superconductor film

Frequency Diameter Diameter Thickness

d

d′

GHz

μm

mm

mm

12 11,4 >35 ≅0,5

18 7,6 >25

≅0,5

22 6,2 >20 ≅0,5

In case of using closed type resonators, the dimensions of the superconductor films shall also

be designed taking into account the dimension of the copper cylinder between the

superconductor films. A design guideline for the dimension of the copper cylinder of the

closed type resonator is described in Clause A.6.

6.2 Set-up

Set up the measurement equipment as shown in Figure 1. All of the measurement apparatus,

standard sapphire rods, and superconductor films shall be kept in a clean and dry state as

high humidity may degrade the unloaded Q-value. The specimen and the measurement

apparatus shall be fixed in a temperature-controlled cryocooler. The specimen chamber shall

be generally evacuated. The temperatures of the superconductor films and standard sapphire

rods shall be measured by a diode thermometer, or a thermocouple. The temperatures of the

upper and lower superconductor films, and standard sapphire rods must be kept as close as

possible. This can be achieved by covering the measurement apparatus with aluminum foil, or

filling the specimen chamber with helium gas.

6.3 Measurement of reference level

The level of full transmission power (reference level) shall be measured first. Fix the output

power of the synthesized sweeper below 10 mW because the measurement accuracy

depends on the measuring signal level. Connect the reference line of semi-rigid cable

between the input and output connectors. Then, measure the transmission power level over

the entire measurement frequency and temperature range. The reference level can change

several decibels when temperature of the apparatus is changed from room temperature to the

lowest measurement temperature. Therefore, the temperature dependence of the reference

level must be taken into account.

61788-7 © IEC:2006(E) – 13 –

Reference level at T K

IA

f

3,01 dB

Δf

Frequency GHz

IEC 007/02

Figure 3 – Insertion attenuation IA, resonant frequency f

and half power bandwidth Δf, measured at T Kelvin

6.4 Measurement of the frequency response of resonators

The temperature dependence of the surface resistance R can be obtained through the

s

measurements of resonant frequency f and unloaded quality factor Q for TE and TE

0 u 011 013

resonators, which shall be measured as follows.

a) Connect the measurement apparatus between the input and output connectors (Figure 1).

Insert the standard short sapphire rod near the centre of the lower superconductor film

and fix the distance between the rod and each of the loops of the semi-rigid cables to be

equal to each other, so that this transmission-type resonator can be under-coupled

equally to both loops. Put down the upper superconductor film gently to touch the top face

of the rod. Be careful not to damage the surface of the superconductor films by excessive

pressure. Evacuate and cool down the specimen chamber below the critical temperature.

b) Find the TE mode resonance peak of this resonator at a frequency nearly equal to the

designed value of f .

c) Narrow the frequency span on the display so that only the resonance peak of TE mode

can be shown (Figure 3). Confirm that the insertion attenuation IA of this mode is larger

than 20 dB from the reference level, which depends strongly on the temperature.

d) Measure the temperature dependence of f and the half power band width Δf. The loaded

Q, Q , of the TE resonator is given by

L

f

Q = (1)

L

Δf

e) The unloaded Q-value, Q , shall be extracted from the Q by at least one of the two

u

L

techniques described below.

One technique for extracting the unloaded Q-value involves measuring the insertion

attenuation IA. The Q is given by

u

Q

− IA[]dB / 20

L

Q = , A = 10 (2)

u t

1 - A

t

Attenuation dB

– 14 – 61788-7 © IEC:2006(E)

This technique of using insertion attenuation assumes that the coupling on both sides of

the resonator is identical. The coupling loops are difficult to fabricate, the orientation of

the loop is difficult to control, and any movement of the sapphire rod during measurement

is not known. These assembly dependent effects are also temperature dependent. This

potential asymmetry in coupling can result in large errors in calculating the coupling factor

if the coupling is strong (IA <~ 10 dB). If the coupling is weak enough (IA > 20 dB),

asymmetry in the coupling becomes less important.

Another technique for extracting the unloaded Q-value involves measuring the reflection

scattering parameters at the resonant frequency of both sides of the resonator.

Q = Q (1+ β + β ) (3)

u L 1 2

1− | S |

β = (4)

| S | + | S |

11 22

1− | S |

β = (5)

| S | + | S |

11 22

In the above equations, S and S are the reflection scattering parameters as shown in

11 22

Figure 4, and are measured in linear units of power, not relative dB. β and β are the

1 2

coupling coefficients.

This technique of using the reflection scattering parameters has two advantages. It does

not require the additional step of calibration of the reference level and it gives a

measurement of the coupling values for both sides of the resonator. This also has two

disadvantages. It only works for a narrow band resonance (which is fortunately the case)

and is limited by the dynamic range of the network analyzer in measuring the reflection

coefficients.

A combination of the two techniques is an excellent “double” check and is therefore

recommended.

f) The f and Q measured for this short rod are denoted as f and Q . By slowly changing

0 u 01 u

the temperature of the cryocooler, the temperature dependence of f and Q shall be

01 u1

measured.

g) After the temperature dependence measurement of f and Q is finished, the

01 u1

measurement apparatus shall be heated up to room temperature.

h) Then, replace the TE resonator in the apparatus with the TE resonator at room

011 013

temperature, cool down the apparatus to a temperature lower than the critical temperature,

and measure the temperature dependence of f and Q of its TE resonance mode,

0 u 013

denoted as f and Q , in a similar way as the TE resonator case. When the length of

03 u 011

the sapphire rod of the TE resonator is precisely three times longer than that of the

TE resonator, the f of the TE resonator must coincide with f of the TE

011 03 013 01 011

resonator. If carefully designed, the difference between f and f is usually very small

01 03

(<~0,25%). We can treat as f = f = f in the calculations of 6.5.

0 01 03

61788-7 © IEC:2006(E) – 15 –

S or S

11 22

f

Frequency

IEC 008/02

Figure 4 – Reflection scattering parameters (S and S )

11 22

6.5 Determination of surface resistance of the superconductor and ε’ and tan δ of the

standard sapphire rods

Calculate the temperature dependence of the surface resistance R of the superconductor

s

films, and ε’ and tan δ of the standard sapphire rods using the temperature dependence of

f , Q , f , and Q from Equations (6), (7) and (8).

01 u1 03 u3

⎛ ⎞

2h ⎛ ⎞

30π ×3 ε'+W 1 1

⎜ ⎟

⎜ ⎟

R = − (6)

s

⎜ ⎟

⎜ ⎟

()3 −1 1+W Q Q

⎝ u1 u3⎠

λ0

⎝ ⎠

⎛ ⎞

λ

2 2

ε' = ⎜ ⎟()+ + 1 (7)

u v

⎜ ⎟

πd

⎝ ⎠

W

1+

⎛ ⎞

3 1

ε '

⎜ ⎟

tan δ = - (8)

⎜ ⎟

(3 - 1) Q Q

⎝ u3 u1⎠

c

where λ = (9)

f

2 2

J (u) K (v)K (v) −

K (v)

1 0 2 1

W = (10)

2 2

K (v) J (u) − J (u)J (u)

1 1 0 2

2⎡ ⎤

⎛ ⎞

λ

2 0

⎛ πd⎞

⎜ ⎟

= ⎢ -1⎥ (11)

⎜ ⎟

v

λ ⎜ ⎟

⎝ ⎠

2h

⎢ ⎥

⎝ 0⎠

⎣ ⎦

(u) (v)

J K

0 0

u = -v (12)

(u) (v)

J K

1 1

Reflection coefficient

– 16 – 61788-7 © IEC:2006(E)

In the equations, λ is the free space resonant wavelength, c is the velocity of light in a

vacuum (c = 2,9979 × 10 m/s), h is the height of the short standard dielectric rod. The value

2 2

u is given by the transcendental Equation (12) using the value of v , where J (u) is the

n

Bessel function of the first kind, and K (v) is the modified Bessel function of the second kind.

n

The derivations of the equations are described in Clause A.3.

Generally the thermal expansion coefficient of the rods must be known to determine the

temperature dependence of their sizes. However, the thermal expansion effect of the sapphire

rods can be neglected for the target precision of the R (20 %).

s

It is noted that the measured R means the effective surface resistance if the film thickness is

s

not much larger than the temperature-dependent penetration depth.

7 Precision and accuracy of the test method

7.1 Surface resistance

The surface resistance shall be determined from the Q-value measured with a dielectric

resonator technique.

A vector network analyzer as specified in Table 3 shall be used to record the frequency

dependence of attenuation. The resulting record shall allow the determination of Q to a

–2

relative uncertainty of 10 .

Table 3 – Specifications for vector network analyzer

Dynamic range of S above 60 dB

Frequency resolution below 1 Hz

Attenuation uncertainty below 0,1 dB

Input power limitation below 10 dBm

The dielectric resonators shall be provided with two dielectric rods with low tan δ of less than

–6

10 at 77 K and a radius less than 1/3 of the superconducting specimen’s radius. The best

candidate for the rods is sapphire as specified in Table 4. Term definitions in Table 4 are

shown in Figure 5.

Table 4 – Specifications for sapphire rods

Diameter ±0,05 mm

Height ±0,05 mm

Flatness below 0,005 mm

Surface roughness top and bottom surface: below 10 nm r.m.s.

cylindrical surface: below 0,001 mm r.m.s.

Perpendicularity within 0,1 degree

Axis parallel to c-axis within 0,3°

61788-7 © IEC:2006(E) – 17 –

Surface roughness Flatness

c-axis of

Cylinder axis

Perpendicularity

crystal

IEC 009/02

Figure 5 – Term definitions in Table 4

The technique as described assumes that single and triple height sapphire rods can be

fabricated with the same tan δ. However, the variation of the tan δ between nominally identical

rods, cut from the same boule and polished by the same technique, may be as large as two

orders of magnitude. To date, the smallest variation in tan δ between nominally identical

sapphire rods has been a factor of four[9]. Therefore, the uncertainty in the measured tan δ is

large. The variation of tan δ of the present sapphire rod causes an additional uncertainty up to

at least 10 % in the surface resistance measurement. This limits the target precision of the

present technique at 20 %. If reproducibility of sapphire rods is improved, or a selection

method for standard sapphire rods is established, a target precision can be improved.

7.2 Temperature

The measurement apparatus is cooled down to the specified temperature by any means

during testing. An easy choice would be to immerse the apparatus into a liquid cryogen. This

technique is quick and simple and yields a known and stable temperature. Unfortunately, most

HTS materials are damaged by the condensation of moisture that occurs when removing the

sample from the cryogen. In addition, uncertainties generated by the presence of a gas/liquid

mixture within the cavity, and the inability to measure R as a function of temperature support

s

the use of other cooling methods. These limitations can be circumvented by the immersion of

a vacuum can into a liquid cryogen. If the vacuum can is backfilled with gas, then rapid

cooling and uniform temperatures occur. If heaters are attached to the apparatus, then the

temperature dependence of the HTS material can be measured. A third and equally good

choice is the use of a cryocooler. In this case, the resonator is under vacuum and cooled by

conduction through the metallic package. Care must be taken to avoid temperature gradients

with the apparatus.

A cryostat shall be provided with the necessary environment for measuring R and the

s

specimen shall be measured while in a stable and isothermal state. The specimen

temperature is assumed to be the same as the sample holder temperature. The holder tem-

perature shall be reported to an accuracy of ±0,5 K, measured by means of an appropriate

temperature sensor.

The difference between the specimen temperature and the holder temperature shall be

minimized by using shields with good thermal conductivity.

7.3 Specimen and holder support structure

The support structure shall provide adequate support for the specimen. It is imperative that

the two films be parallel and mechanically stable throughout the measurement, especially in a

cryocooler and over a wide range of temperature.

– 18 – 61788-7 © IEC:2006(E)

7.4 Specimen protection

Condensation of moisture and scratching of the film deteriorate superconducting properties.

Some protection measures should be provided for the specimens. Polytetrafluoroethylene

(PTFE) or polymethylmethacrylate (PMMA) coating does not affect the measurements, thus

they can be used for protection. A coating material thickness of less than several micrometres

is recommended.

8 Test report

8.1 Identification of test specimen

The test specimen shall be identified, if possible, by the following:

a) name of the manufacturer of the specimen;

b) classification and/or symbol;

c) lot number;

d) chemical composition of the thin film and the substrate;

e) thickness and roughness of the thin film;

f) manufacturing process technique.

8.2 Report of R values

s

The R values, together with their corresponding f , f , Q , Q , IA and/or (β , β ), ε’ and

s 01 03 u1 u3 1 2

tan δ values, and their temperature dependence shall be reported.

8.3 Report of test conditions

The following test conditions shall be reported:

a) test frequency and resolution of frequency;

b) test maximum r.f. power;

c) test temperature, accuracy of temperature and temperature difference in two plates;

d) sample history with temperature variation.

61788-7 © IEC:2006(E) – 19 –

Annex A

(informative)

Additional information relating to Clauses 1 to 8

A.1 Scope

The establishment of the standard measurement method is needed to evaluate film quality of

high Tc superconductor (HTS) films having low surface resistance R values such as 0,1 mΩ

s

at 10 GHz. Several resonance methods as shown in Figure A.1 have been proposed so far to

measure them in microwave and millimetre wave range. These resonator structures are

grouped into the following six types:

2)

A.1.1 Cylindrical cavity method [1]

Figure A.1(a) shows a cavity structure using the TE mode, which is constructed from a

copper cylinder and two HTS films. In the microwave range below 30 GHz, the R

s

measurement precision of this

...

IEC 61788-7 ®

Edition 2.0 2006-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 7: Electronic characteristic measurements – Surface resistance of

superconductors at microwave frequencies

Supraconductivité –

Partie 7: Mesures des caractéristiques électroniques – Résistance de surface

des supraconducteurs à des hyperfréquences

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61788-7 ®

Edition 2.0 2006-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Superconductivity –

Part 7: Electronic characteristic measurements – Surface resistance of

superconductors at microwave frequencies

Supraconductivité –

Partie 7: Mesures des caractéristiques électroniques – Résistance de surface

des supraconducteurs à des hyperfréquences

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.20; 29.050 ISBN 978-2-8322-8658-6

– 2 – IEC 61788-7:2006 IEC 2006

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Requirements . 7

5 Apparatus . 8

5.1 Measurement system . 8

5.2 Measurement apparatus for R . 9

s

5.3 Dielectric rods . 11

6 Measurement procedure . 12

6.1 Specimen preparation . 12

6.2 Set-up . 12

6.3 Measurement of reference level . 12

6.4 Measurement of the frequency response of resonators . 13

6.5 Determination of surface resistance of the superconductor and ε’ and tan δ

of the standard sapphire rods . 15

7 Precision and accuracy of the test method. 16

7.1 Surface resistance . 16

7.2 Temperature . 17

7.3 Specimen and holder support structure . 17

7.4 Specimen protection . 18

8 Test report. 18

8.1 Identification of test specimen . 18

8.2 Report of R values . 18

s

8.3 Report of test conditions . 18

Annex A (informative) Additional information relating to Clauses 1 to 8 . 19

Bibliography . 32

Figure 1 – Schematic diagram of measurement system for temperature dependence of

R using a cryocooler . 8

s

Figure 2 – Typical measurement apparatus for R . 10

s

Figure 3 – Insertion attenuation IA, resonant frequency f and half power bandwidth ∆f,

measured at T Kelvin . 13

Figure 4 – Reflection scattering parameters (S and S ) . 15

11 22

Figure 5 – Term definitions in Table 4 . 17

Figure A.1 – Schematic configuration of several measurement methods for the surface

resistance . 20

Figure A.2 – Configuration of a cylindrical dielectric rod resonator short-circuited at

both ends by two parallel superconductor films deposited on dielectric substrates . 22

Figure A.3 – Computed results of the u-v and W-v relations for TE mode . 23

01p

Figure A.4 – Configuration of standard dielectric rods for measurement of R and tan δ . 24

s

Figure A.5 – Three types of dielectric resonators . 24

Figure A.6 – Mode chart to design TE resonator short-circuited at both ends by

parallel superconductor films [11] . 27

Figure A.7 – Mode chart to design TE resonator short-circuited at both ends by

parallel superconductor films [11] . 28

Figure A.8 – Mode chart for TE closed-type resonator . 29

Figure A.9 – Mode chart for TE closed-type resonator . 30

Table 1 – Typical dimensions of pairs of standard sapphire rods for 12 GHz, 18 GHz

and 22 GHz . 11

Table 2 – Dimensions of superconductor film for 12 GHz, 18 GHz, and 22 GHz . 12

Table 3 – Specifications on vector network analyzer . 16

Table 4 – Specifications on sapphire rods . 16

– 4 – IEC 61788-7:2006 IEC 2006

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SUPERCONDUCTIVITY –

Part 7: Electronic characteristic measurements –

Surface resistance of superconductors

at microwave frequencies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61788-7 has been prepared by IEC technical committee 90:

Superconductivity.

This bilingual version (2020-07) corresponds to the monolingual English version, published in

2006-10.

This second edition cancels and replaces the first edition, published in 2002, of which it

constitutes a technical revision. Examples of technical changes made are: 1) closed type

resonators are recommended from the viewpoint of the stable measurements, 2) uniaxial-

anisotropic characteristics of sapphire rods are taken into consideration for designing the size

of the sapphire rods, and 3) recommended measurement frequency of 18 GHz and 22 GHz

are added to 12 GHz described in the first edition.

The text of this standard is based on the following documents:

FDIS Report on voting

90/193/FDIS 90/198/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61788 consists of the following parts, under the general title Superconductivity:

Part 1: Critical current measurement – DC critical current of Cu/Nb-Ti composite super-

conductors

Part 2: Critical current measurement – DC critical current of Nb Sn composite super-

conductors

Part 3: Critical current measurement – DC critical current of Ag- and/or Ag alloy-sheathed

Bi-2212 and Bi-2223 oxide superconductors

Part 4: Residual resistance ratio measurement – Residual resistance ratio of Nb-Ti

composite superconductors

Part 5: Matrix to superconductor volume ratio measurement – Copper to superconductor

volume ratio of Cu/Nb-Ti composite superconductors

Part 6: Mechanical properties measurement – Room temperature tensile test of Cu/Nb-Ti

composite superconductors

Part 7: Electronic characteristic measurements – Surface resistance of superconductors at

microwave frequencies

Part 8: AC loss measurements – Total AC loss measurement of Cu/Nb-Ti composite

superconducting wires exposed to a transverse alternating magnetic field by a

pickup coil method

Part 9: Measurements for bulk high temperature superconductors – Trapped flux density of

large grain oxide superconductors

Part 10: Critical temperature measurement – Critical temperature of Nb-Ti, Nb Sn, and

Bi-system oxide composite superconductors by a resistance method

Part 11: Residual resistance ratio measurement – Residual resistance ratio of Nb Sn

composite superconductors

Part 12: Matrix to superconductor volume ratio measurement – Copper to non-copper

volume ratio of Nb Sn composite superconducting wires

Part 13: AC loss measurements – Magnetometer methods for hysteresis loss in Cu/Nb-Ti

multifilamentary composites

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61788-7:2006 IEC 2006

INTRODUCTION

Since the discovery of some Perovskite-type Cu-containing oxides, extensive research and

development (R & D) work on high-temperature oxide superconductors has been, and is being,

made worldwide, and its application to high-field magnet machines, low-loss power

transmission, electronics and many other technologies is in progress.

In various fields of electronics, especially in telecommunication fields, microwave passive

devices such as filters using oxide superconductors are being developed and are undergoing

1)

on-site testing [1,2] .

Superconductor materials for microwave resonators, filters, antenna and delay lines have the

advantage of very low loss characteristics. Knowledge of this parameter is of primary

importance for the development of new materials on the supplier side and for the design of

superconductor microwave components on the customer side. The parameters of

superconductor materials needed for the design of microwave low loss components are the

surface resistance R and the temperature dependence of the surface resistance.

s

Recent advances in high Tc superconductor (HTS) thin films with R several orders of

s

magnitude lower than that of normal metals have increased the need for a reliable

characterization technique to measure this property [3,4]. Traditionally, the R of Nb or any

s

other low temperature superconducting material was measured by first fabricating an entire

could be calculated

three dimensional resonant cavity and then measuring its Q-value. The R

s

by solving the EM field distribution inside the cavity. Another technique involves placing a

small sample inside a larger cavity. This technique has many forms but usually involves the

uncertainty introduced by extracting the loss contribution due to the HTS films from the

experimentally measured total loss of the cavity.

The best HTS samples are epitaxial films grown on flat crystalline substrates and no high

quality films have been grown on any curved surface so far. What is needed is a technique

that: can use these small flat samples; requires no sample preparation; does not damage or

th

change the film; is highly repeatable; has great sensitivity (down to 1/1 000 the R of copper);

s

has great dynamic range (up to the R of copper); can reach high internal powers with only

s

modest input powers; and has broad temperature coverage (4,2 K to 150 K).

The dielectric resonator method is selected among several methods [5,6,7] to determine the

surface resistance at microwave frequencies because it is considered to be the most popular

and practical at present. Especially, the sapphire resonator is an excellent tool for measuring

the R of HTS materials [8,9].

s

The test method given in this standard can be also applied to other superconductor bulk

plates including low Tc material.

This standard is intended to provide an appropriate and agreeable technical base for the time

being to engineers working in the fields of electronics and superconductivity technology.

The test method covered in this standard is based on the VAMAS (Versailles Project on

Advanced Materials and Standards) pre-standardization work on the thin film properties of

superconductors.

___________

1)

Figures in square brackets refer to the Bibliography.

SUPERCONDUCTIVITY –

Part 7: Electronic characteristic measurements –

Surface resistance of superconductors

at microwave frequencies

1 Scope

This part of IEC 61788 describes measurement of the surface resistance of superconductors

at microwave frequencies by the standard two-resonator method. The object of measurement

is the temperature dependence of R at the resonant frequency.

s

The applicable measurement range of surface resistances for this method is as follows:

– Frequency: 8 GHz < f < 30 GHz

– Measurement resolution: 0,01 mΩ at 10 GHz

The surface resistance data at the measured frequency, and that scaled to 10 GHz, assuming

the f rule for comparison, are reported.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-815, International Electrotechnical Vocabulary (IEV) – Part 815: Superconductivity

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-815 apply.

In general, surface impedance Z for conductors, including superconductors, is defined as the

s

ratio of the electric field E to the magnetic field H , tangential to a conductor surface:

t t

Z = E /H = R + jX

s t t s s

where R is the surface resistance and X is the surface reactance.

s s

4 Requirements

The surface resistance R of a superconductor film shall be measured by applying a

s

microwave signal to a dielectric resonator with the superconductor film specimen and then

measuring the attenuation of the resonator at each frequency. The frequency shall be swept

around the resonant frequency as the centre, and the attenuation–frequency characteristics

shall be recorded to obtain Q-value, which corresponds to the loss.

The target precision of this method is a coefficient of variation (standard deviation divided by

the average of the surface resistance determinations) that is less than 20 % for the

measurement temperature range from 30 K to 80 K.

– 8 – IEC 61788-7:2006 IEC 2006

It is the responsibility of the user of this standard to consult and establish appropriate safety

and health practices and to determine the applicability of regulatory limitations prior to use.

Hazards exist in this type of measurement. The use of a cryogenic system is essential to cool

the superconductors to allow transition into the superconducting state. Direct contact of skin

with cold apparatus components can cause immediate freezing, as can direct contact with a

spilled cryogen. The use of an r.f.-generator is also essential to measure high-frequency

properties of materials. If its power is too high, direct contact to human bodies can cause an

immediate burn.

5 Apparatus

5.1 Measurement system

Figure 1 shows a schematic diagram of the system required for the microwave measurement.

The system consists of a network analyzer system for transmission measurement, a

measurement apparatus, and a thermometer for monitoring the measuring temperature.

An incident power generated from a suitable microwave source such as a synthesized

sweeper is applied to the dielectric resonator fixed in the measurement apparatus. The

transmission characteristics are shown on the display of the network analyzer.

Vector network

analyser

Synthesized

sweeper

Thermometer

S-parameter

test set

Thermal sensor

Measurement apparatus

Cryocooler

IEC 004/02

Figure 1 – Schematic diagram of measurement system

for temperature dependence of R using a cryocooler

s

The measurement apparatus is fixed in a temperature-controlled cryocooler.

For the measurement of R for superconductor films, a vector network analyzer is recom-

s

mended. A vector network analyzer has better measurement accuracy than a scalar network

analyzer due to its wide dynamic range.

System interface

5.2 Measurement apparatus for R

s

Figure 2 shows a schematic of a typical measurement apparatus (closed type resonator) for

the R of superconductor films deposited on a substrate with a flat surface. The upper

s

superconductor film is pressed down by a spring, which is made of phosphor bronze. The

plate type spring is recommended to be used for the improvement of measurement accuracy.

This type of spring reduces the friction between the spring and the other part of the apparatus,

and allows the smooth movement of superconductor films due to the thermal expansion of the

dielectric rod. In order to minimize the measurement error, the sapphire rod and the copper

ring shall be set in coaxial.

Two semi-rigid cables for measuring transmission characteristics of the resonator shall be

attached on both sides of the resonator in an axial symmetrical position (φ = 0 and π, where φ

is the rotational angle around the central axis of the sapphire rod). Each of the two semi-rigid

cables shall have a small loop at the ends. The plane of the loop shall be set parallel to that

of the superconductor films in order to suppress the unwanted TM modes. The coupling

mn0

loops shall be carefully checked for cracks in the spot weld joint that may have developed

upon repeated thermal cycling. These cables can move right and left to adjust the insertion

attenuation (IA). In this adjustment, coupling of unwanted cavity modes to the interested

dielectric resonance mode shall be suppressed. Unwanted, parasitic coupling to the other

modes reduces the high Q value of the TE mode resonator. For suppressing the parasitic

coupling, special attention shall be paid to designing high Q resonators. Two other types of

resonators along with the closed type shown in Figure 2 can be used. They are explained in

Clause A.4.

– 10 – IEC 61788-7:2006 IEC 2006

Screws

Screw

Hexagonal

head bolt

Phosphor bronze

plate spring

Copper supports

Copper plate

Spot welding

Superconductor film

Copper ring

Small loop

Connector

Semi-rigid

Superconductor film

coaxial cable

Sapphire rod

Copper block

Screws to fix on

a cold stage

IEC 1733/06

Figure 2 – Typical measurement apparatus for R

s

A reference line made of a semi-rigid cable shall be used to measure the full transmission

power level, i.e., the reference level. This cable has a length equal to the sum of the two

cables of the measurement apparatus. The semi-rigid cable with the outer diameter of

1,20 mm is recommended.

In order to minimize the measurement error, two superconductor films shall be set to be

parallel to each other. To ensure that the two superconductor films remain in tight contact with

the ends of the sapphire rod, without any air gap, both of the surfaces of the films and the

ends of the rod shall be cleaned carefully.

5.3 Dielectric rods

Two dielectric rods with the same relative permittivity, ε’, and loss factor, tan δ, preferably cut

from one cylindrical dielectric rod, are required. These two rods, standard dielectric rods, shall

have the same diameter but different heights: one has a height three times longer than the

other.

It is preferable to use standard dielectric rods with low tan δ to achieve the requisite

measurement accuracy on R . Recommended dielectric rods are sapphire rods with tan δ less

s

–6

than 10 at 77 K. Specifications on the sapphire rods are described in 7.1. In order to

minimize the measurement error in R of the superconductor films, both ends of the sapphire

s

rods shall be polished parallel to each other and perpendicular to the axis. Specifications for

the sapphire rods are described in Clause 7.

The diameter and the heights of the standard sapphire rods shall be carefully designed so

that the TE and TE modes do not couple to other TM, HE and EH modes, since the

011 013

coupling between TE mode and other modes causes the degradation of unloaded Q. A design

guideline for the standard sapphire rods is described in Clause A.5. Table 1 shows typical