EN 10216-2:2002

(Main)Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

This Part of EN 10216 specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel.

NOTE This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order.

Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 2: Rohre aus unlegierten und legierten Stählen mit festgelegten Eigenschaften bei erhöhten Temperaturen

Dieser Teil der EN 10216 enthält die technischen Lieferbedingungen für nahtlose Rohre mit kreisförmigem Querschnitt aus unlegiertem und legiertem Stahl mit festgelegten Eigenschaften bei erhöhten Temperaturen und legt dafür zwei Prüfkategorien fest.

ANMERKUNG Dieser Teil der EN 10216 kann auch für Rohre mit nichtkreisförmigem Querschnitt angewendet werden; notwendige Anpassungen sollten bei der Anfrage und Bestellung vereinbart werden.

Tubes sans soudure en acier pour service sous pression - Conditions techniques de livraison - Partie 2: Tubes en acier non allié et allié avec caractéristiques spécifiées à température élevée

La présente partie de la norme européenne spécifie les conditions techniques de livraison, selon deux catégories d'essai, pour les tubes sans soudure à section circulaire en acier non allié et allié, avec caractéristiques spécifiées à température élevée. Il est important que l'acheteur, lors de l'appel d'offres et de la commande, prenne en compte les exigences des règlementations nationales appropriées pour l'application visée.

Nevarjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 2. del: Nelegirane in legirane jeklene cevi s specificiranimi lastnostmi za delo pri povišanih temperaturah

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2002

- Withdrawal Date

- 07-Aug-2007

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 29/SC 1 - Tubes for pressure purposes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 08-Aug-2007

- Completion Date

- 08-Aug-2007

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 10216-2:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties". This standard covers: This Part of EN 10216 specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel. NOTE This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order.

This Part of EN 10216 specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel. NOTE This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order.

EN 10216-2:2002 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10216-2:2002 has the following relationships with other standards: It is inter standard links to EN 10216-2:2002+A2:2007, EN 1092-1:2007, EN 13480-2:2012, EN 10216-2:2002/A1:2004, EN 10216-2:2002/prA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10216-2:2002 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/005, M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10216-2:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 2: Rohre aus unlegierten und legierten Stählen mit festgelegten Eigenschaften bei erhöhten TemperaturenTubes sans soudure en acier pour service sous pression - Conditions techniques de livraison - Partie 2: Tubes en acier non allié et allié avec caractéristiques spécifiées a température élevéeSeamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 10216-2:2002SIST EN 10216-2:2003en01-april-2003SIST EN 10216-2:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10216-2May 2002ICS 23.040.10; 77.140.75English versionSeamless steel tubes for pressure purposes - Technical deliveryconditions - Part 2: Non-alloy and alloy steel tubes with specifiedelevated temperature propertiesTubes sans soudure en acier pour service sous pression -Conditions techniques de livraison - Partie 2: Tubes enacier non allié et allié avec caractéristiques spécifiées àtempérature élevéeNahtlose Stahlrohre für Druckbeanspruchungen -Technische Lieferbedingungen - Teil 2: Rohre ausunlegierten und legierten Stählen mit festgelegtenEigenschaften bei erhöhten TemperaturenThis European Standard was approved by CEN on 25 April 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10216-2:2002 ESIST EN 10216-2:2003

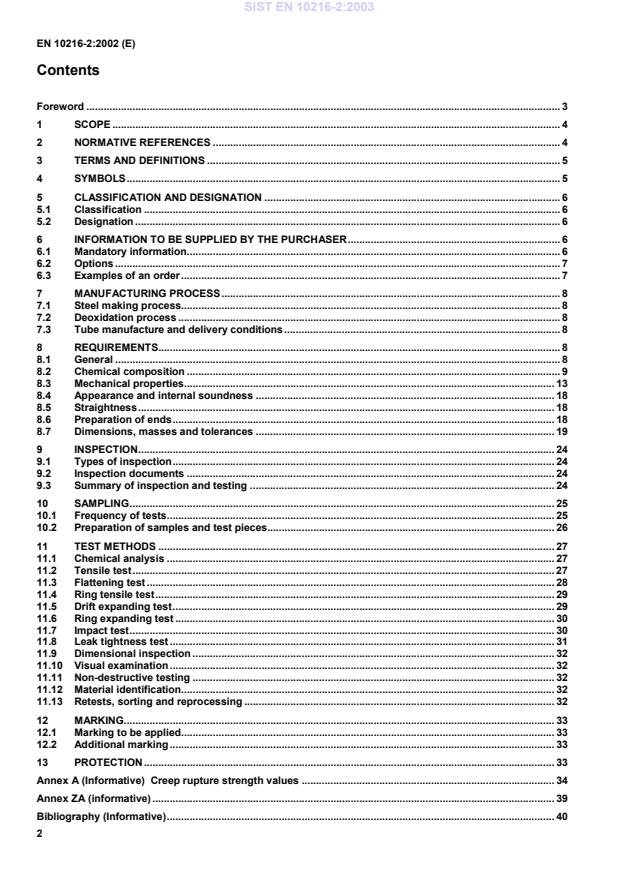

Creep rupture strength values.34Annex ZA (informative).39Bibliography (Informative).40SIST EN 10216-2:2003

of steel tubes Part 1 : Automatic electromagnetic testing of seamless andwelded (except submerged arc welded) ferromagnetic steel tubes for verification of hydraulic leak-tightness.EN 10246-5, Non-Destructive Testing

of steel tubes – Part 5: Automatic full peripheral magnetic transducer/fluxleakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for thedetection of longitudinal imperfections.EN 10246-6, Non-Destructive

Testing of steel tubes - Part 6: Automatic full peripheral ultrasonic testing ofseamless steel tubes for the detection of transverse imperfections.SIST EN 10216-2:2003

of steel tubes - Part 7 : Automatic full peripheral ultrasonic testing ofseamless and welded (except submerged arc welded) steel tubes for the detection of longitudinal imperfections.EN 10246-14, Non-Destructive Testing of steel tubes - Part 14:Automatic ultrasonic testing of seamless andwelded (except submerged arc welded) steel tubes for the detection of laminar imperfections.EN 10256, Non-Destructive Testing of steel tubes - Qualification and competence of level 1 and level 2 NDTpersonnel.EN ISO 377, Steel and steel products - Location and preparation of samples and test pieces for mechanicaltesting (ISO 377:1997)prEN 101681) , Iron and steel products - Inspection documents - List of information and description.prEN 102661), Steel tubes, fittings and structural hollow sections - Symbols and definition of terms for use inproduct standardsEN ISO 2566-1, Steel - Conversion of elongation values – Part 1: Carbon and low-alloy steels (ISO 2566-1:1984)ISO 14284, Steel and iron - Sampling and preparation of samples for the determination of chemical compositionCR 10260, Designation systems for steel - Additional symbolsCR 10261, ECISS Information Circular IC 11 - Iron and steel - Review of available methods of chemical analysis.3 TERMS AND DEFINITIONSFor the purposes of this Part of EN 10216, the terms and definitions given in EN 10020, EN 10021, EN 10052 andprEN 10266 and the following apply:3.1test categoryclassification that indicates the extent and level of inspection and testing3.2employerorganisation for which a person works on a regular basis.NOTEThe employer may be either the tube manufacturer or supplier or a third party organisation providing,

Non-Destructive Testing (NDT) services.4 SYMBOLSFor the purpose of this Part of EN 10216, the symbols given in prEN 10266 and the following apply: d

specified inside diameter; dminspecified minimum inside diameter; Tminspecified minimum wall thickness; Dccalculated outside diameter; dccalculated inside diameter;

1)In preparation; until this document is published as a European Standard, the corresponding nationalstandard(s) should be agreed at the time of enquiry and order.SIST EN 10216-2:2003

(see Table 4): the symbols GH for elevated temperature.5.2.3The steel name of alloy steel grades is designated by the chemical composition (see Table 2) and thesymbols for the heat treatment, where specified in column 3 and footnote 3 of Table 1.6 INFORMATION TO BE SUPPLIED BY THE PURCHASER6.1 Mandatory informationThe following information shall be supplied by the purchaser at the time of enquiry and order:a) the quantity (mass or total length or number);b) the term "tube";c) the dimensions (outside diameter

D and wall thickness T or a set of dimensions covered by Option 11) (seeTable 6);d) the designation of the steel grade in accordance with this Part of EN 10216 (see 5.2);e) the test category for non-alloy steel (see 9.3).SIST EN 10216-2:2003

for non-alloy steel

grades (see Table 4).6) Tensile testing at elevated temperature (see 8.3.2).7) Selection of leak-tightness test method (see 8.4.2.1).8) Non-Destructive Testing for test category 2 tubes for detection of transverse imperfections (see8.4.2.2).9) Non-Destructive Testing for test category 2 tubes for detection of laminar imperfections (see 8.4.2.2).10) Special ends preparation (see 8.6).11) Set of dimensions other than D and T (see 8.7.1).12) Exact lengths (see 8.7.3).13) The type of inspection document other than the standard document (see 9.2.1).14) Test pressure for hydrostatic leak-tightness test (see 11.8.1).15) Wall thickness measurement away from the ends (see 11.9).16) Non-Destructive Testing method (see 11.11.1).17) Additional marking (see 12.2).18) Protection (see 13).6.3 Examples of an order6.3.1 Example 1100 t of seamless tube with an outside diameter of 168,3 mm, a wall thickness of 4,5 mm, in accordance with EN10216-2,

made of steel grade P265GH, to test category 1 with a 3.1.C inspection certificate in accordance withEN 10204:100 t - Tube - 168,3 x 4,5 - EN 10216-2 - P265GH - TC1 - Option 13: 3.1.C6.3.2 Example 2100 m of seamless tube with a minimum inside diameter of 240 mm, a minimum wall thickness of 40 mm inaccordance with Part of EN 10216, made of steel grade 10CrMo9-10, with a 3.1.C inspection certificate inaccordance with EN 10204:100 m - Tube - dmin 240 x Tmin 40 - EN 10216-2 - 10CrMo9-10 - Option 13: 3.1.CSIST EN 10216-2:2003

= Tdoftoleranced22minmin(2)SIST EN 10216-2:2003

30 mm the carbon content may be increased by 0,02 % for cast and product analysis.f The upper carbon value of 0,23 % shall not be exceeded for product analysis.SIST EN 10216-2:2003

0,02 0,40

0,05Si 0,40

to

1,00

0,06 1,00

0,05Mn 1,00

to

1,50

0,10P 0,025+ 0,005 0,010+ 0,003S 0,010

0,020+ 0,005Al 0,060

0,005B 0,006

0,001 1,00

0,05 1,00

to

10,00

0,10Cr 10,00

to

12,50

0,15Cu 0,80

0,05 0,35

0,03Mo 0,35

to

1,20

0,04N 0,070

0,01Nb 0,10

0,005 0,35

0,05Ni 0,35

to

1,30

0,07Ti 0,060+ 0,010 0,10+ 0,01V 0,10

to

0,55

0,038.3 Mechanical properties8.3.1 Mechanical properties at and below room temperatureThe mechanical properties at and below room temperature of the tubes

shall conform to

the requirements inTable 4 and in clauses 11.3, 11.4, 11.5 and 11.6.8.3.2 Proof strength at elevated temperatureThe minimum proof strength Rp0,2 values at elevated temperature are given in Table 5.Option 6: Proof strength Rp0,2 shall be verified. The test temperature shall be specified at the time of enquiryand order.SIST EN 10216-2:2003

proof strengthReH or Rp0,2

for Wall Thickness Tmin.TensileStrengthRmElongationA min.%

aMinimum average absorbed

energy KVJat a temperature of°CT

T

T

T

100ltltMPa *MPa *MPa *MPa *MPa *200-10200P195GH1.0348195---320 to 4402725-40 c28 d-27 cP235GH1.0345235225215-360 to 5002523-40 c28 d-27 cP265GH1.0425265255245-410 to 5702321-40 c28 d-27 c20MnNb61.0471355345335-500 to 6502220.40 c--27 c16Mo31.5415280270260-450 to 600222040 c--27 c-8MoB5-41.5450400---540 to 690191740 c--27 c-14MoV6-31.7715320320310-460 to 610201840 c f--27 c-10CrMo5-51.7338275275265-410 to 560222040 c--27 c-13CrMo4-51.7335290290280-440 to 590222040 c--27 c-10CrMo9-101.7380280280270-480 to 630222040 c--27 c-11CrMo9-101.7383355355355-540 to 680201840 c--27 c-25CrMo41.7218345345345-540 to 690181540 c f--27 c-20CrMoV13-5-51.7779590590590-740 to 880161440 c f--27 c-15NiCuMoNb5-6-41.6368440440440440 e610 to 780191740 c f--27 c-SIST EN 10216-2:2003

proof strengthReH or Rp0,2

for Wall Thickness Tmin.TensileStrengthRmElongationA min.%

aMinimum average absorbed

energy KVJat a temperature of°CT

T

T

T

100ltltMPa *MPa *MPa *MPa *MPa *200-10200X11CrMo5+I1.7362+I175175175175430 to 580222040 c--27 c-X11CrMo5+NT11.7362+NT1280280280280480 to 640201840 c--27 c-X11CrMo5+NT21.7362+NT2390390390390570 to 740181640 c--27 c-X11CrMo9-1+I1.7386+I210210210-460 to 640201840 c--27 c-X11CrMo9-1+NT1.7386+NT390390390-590 to 740181640 c--27 c-X10CrMoVNb9-11.4903450450450450630 to 830191740 c f--27 c-X20CrMoV11-11.4922490490490490690 to 840171440 c f--27 cal = longitudinal

t = transverseb To be verified when options 4 and/or 5 are/is specified, unless footnote f) applies.c Option 4: Impact energy shall be verified.d Option 5: Longitudinal impact energy shall be verified.e For wall thickness 60 mm T

80 mm.f Impact test mandatory for wall thickness T

16 mm.* MPa = 1 N/mm2SIST EN 10216-2:20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...