EN 13480-2:2012

(Main)Metallic industrial piping - Part 2: Materials

Metallic industrial piping - Part 2: Materials

This part of EN 13480 covers the requirements for materials (including clad materials) for industrial piping and supports covered by EN 13480-1 constructed of metallic materials and is currently limited to steels with sufficient ductility below the creep range. It specifies the assessment of compliance for these materials. It also provides rules for the establishment of technical delivery conditions for materials for industrial piping.

Metallische industrielle Rohrleitungen - Teil 2: Werkstoffe

Dieser Teil der EN 13480 legt die Anforderungen an Werkstoffe (einschließlich Plattierungswerkstoffe) für Rohrleitungen nach der EN 13480-1 aus metallischen Werkstoffen fest; sie ist zur Zeit auf Stähle ausreichender Duktilität begrenzt. Dieser Teil gilt nicht im Zeitstandbereich. Die Norm legt das für diese Werkstoffe anzuwendende Konformitätsbewertungsverfahren fest. Ferner enthält sie Regeln für die Festlegung von technischen Lieferbedingungen für Werkstoffe für Rohrleitungen.

Tuyauteries industrielles métalliques - Partie 2: Matériaux

La présente partie de la présente norme européenne spécifie les exigences relatives aux matériaux (y compris les matériaux métalliques plaqués) pour tuyauteries industrielles et supports fabriqués à partir de matériaux métalliques et couverts par prEN 13480-1. Elle est limitée actuellement aux aciers ayant une ductilité suffisante. La norme ne s'applique pas dans le domaine du fluage.

NOTE D'autres matériaux seront ajoutés ultérieurement par amendements.

Elle spécifie les exigences relatives au choix, à l'inspection, au contrôle et au marquage des matériaux métalliques destinés à la fabrication des tuyauteries industrielles.

Kovinski industrijski cevovodi - 2. del: Materiali

Ta del tega evropskega standarda določa zahteve za materiale (vključno s kovinskimi materiali za prevleke) za industrijske cevovode in nosilce iz standarda EN 13480-1, ki so izdelani iz kovinskih materialov. Trenutno je omejen na jekla z ustrezno duktilnostjo. Ta del tega evropskega standarda se ne uporablja za materiale v območju tečenja.

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jun-2012

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 267 - Industrial piping and pipelines

- Drafting Committee

- CEN/TC 267/WG 8 - Maintenance of EN 13480 series

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Jun-2017

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 04-Jul-2012

- Effective Date

- 13-Jun-2012

- Effective Date

- 06-Jun-2012

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13480-2:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metallic industrial piping - Part 2: Materials". This standard covers: This part of EN 13480 covers the requirements for materials (including clad materials) for industrial piping and supports covered by EN 13480-1 constructed of metallic materials and is currently limited to steels with sufficient ductility below the creep range. It specifies the assessment of compliance for these materials. It also provides rules for the establishment of technical delivery conditions for materials for industrial piping.

This part of EN 13480 covers the requirements for materials (including clad materials) for industrial piping and supports covered by EN 13480-1 constructed of metallic materials and is currently limited to steels with sufficient ductility below the creep range. It specifies the assessment of compliance for these materials. It also provides rules for the establishment of technical delivery conditions for materials for industrial piping.

EN 13480-2:2012 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13480-2:2012 has the following relationships with other standards: It is inter standard links to EN 13480-2:2002/A1:2010, EN 13480-2:2002, EN 13480-2:2002/A2:2010, EN 13480-2:2017, EN 10222-4:1998, EN 10216-2:2002, EN 10216-2:2002/A1:2004, EN 10028-1:2007+A1:2009, EN 10028-5:2009, EN 10216-4:2002/A1:2004, EN 10217-6:2002/A1:2005, EN 10164:2004, EN 10028-6:2009, EN 10028-4:2009, EN 10217-7:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13480-2:2012 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13480-2:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kovinski industrijski cevovodi - 2. del: MaterialiMetallische industrielle Rohrleitungen - Teil 2: WerkstoffeTuyauteries industrielles métalliques - Partie 2: MatériauxMetallic industrial piping - Part 2: Materials77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific useICS:Ta slovenski standard je istoveten z:EN 13480-2:2012SIST EN 13480-2:2012en,fr,de01-oktober-2012SIST EN 13480-2:2012SLOVENSKI

STANDARDSIST EN 13480-2:2002/A2:2011SIST EN 13480-2:2002/A1:2011SIST EN 13480-2:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13480-2

June 2012 ICS 23.040.01 Supersedes EN 13480-2:2002English Version

Metallic industrial piping - Part 2: Materials

Tuyauteries industrielles métalliques - Partie 2: Matériaux Metallische industrielle Rohrleitungen - Teil 2: Werkstoffe This European Standard was approved by CEN on 8 May 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13480-2:2012: ESIST EN 13480-2:2012

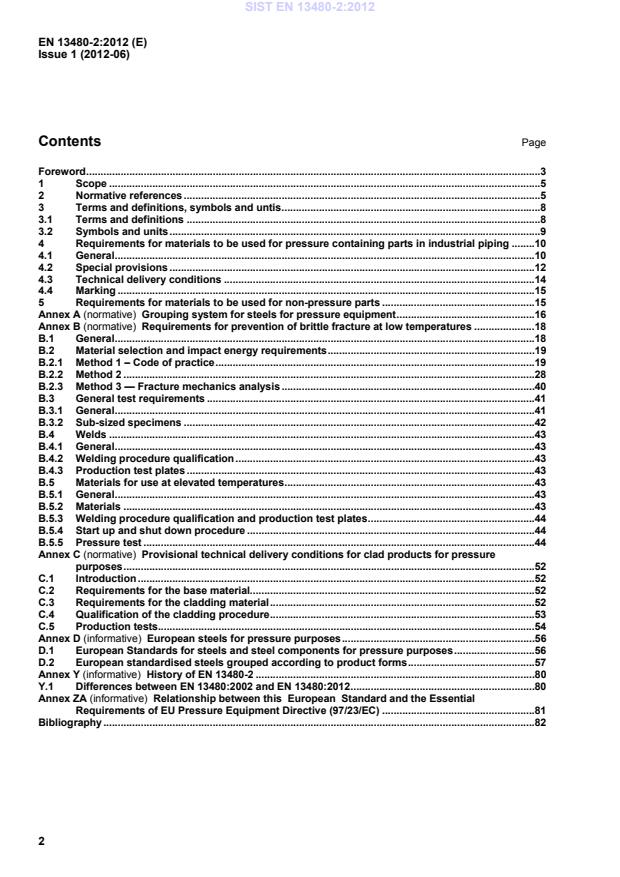

Grouping system for steels for pressure equipment .16 Annex B (normative)

Requirements for prevention of brittle fracture at low temperatures .18 B.1 General .18 B.2 Material selection and impact energy requirements .19 B.2.1 Method 1 – Code of practice .19 B.2.2 Method 2 .28 B.2.3 Method 3 — Fracture mechanics analysis .40 B.3 General test requirements .41 B.3.1 General .41 B.3.2 Sub-sized specimens .42 B.4 Welds .43 B.4.1 General .43 B.4.2 Welding procedure qualification .43 B.4.3 Production test plates .43 B.5 Materials for use at elevated temperatures .43 B.5.1 General .43 B.5.2 Materials .43 B.5.3 Welding procedure qualification and production test plates .44 B.5.4 Start up and shut down procedure .44 B.5.5 Pressure test .44 Annex C (normative)

Provisional technical delivery conditions for clad products for pressure purposes .52 C.1 Introduction .52 C.2 Requirements for the base material.52 C.3 Requirements for the cladding material .52 C.4 Qualification of the cladding procedure .53 C.5 Production tests .54 Annex D (informative)

European steels for pressure purposes .56 D.1 European Standards for steels and steel components for pressure purposes .56 D.2 European standardised steels grouped according to product forms .57 Annex Y (informative)

History of EN 13480-2 .80 Y.1 Differences between EN 13480:2002 and EN 13480:2012 .80 Annex ZA (informative)

Relationship between this

European

Standard and the Essential Requirements of EU Pressure Equipment Directive (97/23/EC) .81 Bibliography .82

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

This European Standard EN 13480 for metallic industrial piping consists of eight interdependent and not dissociable Parts which are:

Part 1: General; Part 2: Materials; Part 3: Design and calculation; Part 4: Fabrication and installation; Part 5: Inspection and testing; Part 6: Additional requirements for buried piping; CEN/TR 13480-7: Guidance on the use of conformity assessment procedures; Part 8: Additional requirements for aluminium and aluminium alloy piping. Although these Parts may be obtained separately, it should be recognised that the Parts are interdependent. As such the manufacture of metallic industrial piping requires the application of all the relevant Parts in order for the requirements of the Standard to be satisfactorily fulfilled. This European Standard will be maintained by a Maintenance MHD working group whose scope of working is limited to corrections and interpretations related to EN 13480.

The contact to submit queries can be found at http://portailgroupe.afnor.fr/public_espacenormalisation/CENTC267WG8/index.htm. A form for submitting questions can be downloaded from the link to the MHD website. After subject experts have agreed an answer, the answer will be communicated to the questioner. Corrected pages will be given specific issue number and issued by CEN according to CEN Rules. Interpretation sheets will be posted on the website of the MHD.

Amendments to this new edition may be issued from time to time and then used immediately as alternatives to rules contained herein. It is intended to deliver a new Issue of EN 13480:2012 each year, consolidating these Amendments and including other identified corrections.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

NOTE Other materials will be added later by amendments. It specifies the requirements for the selection, inspection, testing and marking of metallic materials for the fabrication of industrial piping. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 764-3:2002, Pressure equipment — Terminology Part 3: Definition of parties involved EN 1092-1:2007, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN designated — Part 1: Steel flanges EN 10028-1:2007+A1:2009+AC:2009, Flat products made of steels for pressure purposes — Part 1: General requirements EN 10028-2:2009, Flat products made of steels for pressure purposes — Part 2: Non-alloy and alloy steels with specified elevated temperature properties EN 10028-3:2009, Flat products made of steels for pressure purposes — Part 3: Weldable fine grain steels, normalized EN 10028-4:2009, Flat products made of steels for pressure purposes — Part 4: Nickel alloyed steels with specified low temperature properties EN 10028-5:2009, Flat products made of steels for pressure purposes — Part 5: Weldable fine grain steels, thermomechanically rolled EN 10028-6:2009, Flat products made of steels for pressure purposes — Part 6: Weldable fine grain steels, quenched and tempered EN 10028-7:2007, Flat products made of steels for pressure purposes — Part 7: Stainless steels EN 10164:2004, Steel products with improved deformation properties perpendicular to the surface of the product — Technical delivery conditions EN 10204:2004, Metallic products — Types of inspection documents EN 10213:2007, Steel castings for pressure purposes EN 10216-1:2002+A1:2004, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 1: Non-alloy steel tubes with specified room temperature properties

temperature properties EN 12074:1999, Welding consumables — Quality requirements for manufacture, supply and distribution of consumables for welding and allied processes EN 13445-4:2009, Unfired pressure vessels — Part 4: Fabrication EN 13445-5:2009, Unfired pressure vessels — Part 5: Inspection and testing EN 13479:2004, Welding consumables — General product standard for filler metals and fluxes for fusion welding of metallic materials EN 13480-1:2012, Metallic industrial piping — Part 1: General EN 13480-3:2012, Metallic industrial piping — Part 3: Design and calculation EN 13480-4:2012, Metallic industrial piping — Part 4: Fabrication and installation EN 13480-5:2012, Metallic industrial piping — Part 5: Inspection and testing EN 20898-2:1993, Mechanical properties of fasteners — Part 2: Nuts with specified proof load values — Coarse thread EN ISO 148-1:2010, Metallic materials — Charpy pendulum impact test — Part 1: Test method

(ISO 148-1:2009) EN ISO 898-1:2009, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread (ISO 898-1:2009) EN ISO 2566-1:1999, Steel — Conversion of elongation values — Part 1: Carbon and low alloy steels (ISO 2566-1:1984). EN ISO 2566-2:1999, Steel — Conversion of elongation values — Part 2: Austenitic steels (ISO 2566-2:1984) EN ISO 3506-1:1997, Mechanical properties of corrosion-resistant stainless steel fasteners — Part 1: Bolts, screws and studs (ISO 3506-1:1997) EN ISO 3506-2:1997, Mechanical properties of corrosion-resistant stainless steel fasteners — Part 2: Nuts (ISO 3506-2:1997) CEN ISO/TR 15608:2000, Welding — Guidelines for a metallic materials grouping system (ISO/TR 15608:2000) SIST EN 13480-2:2012

See also 3.1.2 and 3.1.3. 3.1.2 temperature adjustment term TS temperature relevant to the calculation of the design reference temperature TR and dependent on the calculated tensile membrane stress at the appropriate minimum metal temperature

Note 1 to entry

Values for temperature adjustment term TS are given in Table B.2-12. Note 2 to entry

For tensile membrane stress reference is made to EN 13480-3:2012, clause 12. 3.1.3 design reference temperature TR temperature used for determining the impact energy requirements and determined by adding the temperature adjustment TS to the minimum metal temperature TM SMRTTT 3.1.4 impact test temperature TKV temperature at which the required resistance to impact energy is achieved Note to entry

See B.2. 3.1.5 impact energy KV energy absorbed by a sample of material when subjected to a Charpy-V-notch impact test in accordance with EN ISO 148-1:2010 3.1.6 reference thickness eB thickness of a component to be used to relate the design reference temperature TR of the component with its required impact test temperature TKV Note 1 to entry

See Tables B.2-2 to B.2-7 and Figures B.2-1 to B.2-11. SIST EN 13480-2:2012

The reference thickness eB, defined in Table B.4-1, is based on the nominal thickness (including corrosion allowance). For butt welded components eB is the nominal wall thickness of the component at the edge of the weld preparation. 3.2 Symbols and units For the purposes of this Part of this European Standard, the symbols and units of EN 13480-1:2012 apply together with those given in Table 3.2-1. Table 1 — Symbols and units Symbol Characteristic Unit aK Form factor – b width mm C constant – eB reference thickness mm G shear modulus N/mm2 (MPa) HB Brinell hardness – HV Vickers hardness – h maximum permissible reinforcement of weld mm KV Impact rupture energy J Lo length (gauge length) mm P pressure bar PLM parameter according to Larson-Miller – Re yield strength N/mm2 (MPa) Rm T t creep rupture strength for T in h at temperature t N/mm2 (MPa) S0 original cross section area mm2 TM minimum metal temperature C TKV material impact test temperature °C TR design reference temperature °C TS temperature adjustment term C linear expansion coefficient K-1 strain % NOTE

1 N/mm2 = 1 MPa SIST EN 13480-2:2012

Materials shall be selected to be compatible with anticipated fabrication steps and to be suitable for the internal fluid and external environment. Both normal operating conditions and transient conditions occurring during fabrication, transport, testing, commissioning and decommissioning shall be taken into account when specifying the materials. NOTE 1 The requirements of 4.1 and 4.2 should also be fulfilled when technical delivery conditions are developed for European Standards for materials , European Approval of Materials or Particular Material Appraisals. NOTE 2 When technical delivery conditions for pressure-containing parts are developed, the structure and requirements of EN 764-4:2002 should be met. Exceptions should be technically justified. The materials shall be grouped in accordance with CEN ISO/TR 15608:2000 to relate manufacturing and inspection requirements to generic material types. NOTE 3 Materials have been allocated into these groups in accordance with their chemical composition and properties in relation to manufacture and heat treatment after welding. 4.1.2 Materials for pressure containing parts compliant with the requirements of this European Standard shall be certified on the basis of EN 10204:2004. NOTE

The certification should be in accordance with EN 764-5:2002. 4.1.3 The products shall be free from surface and internal defects which might impair their usability. 4.1.4 The specified minimum elongation of the steel after fracture shall be: 14 % for the transverse direction; and 16 % for the longitudinal direction, or where this is the less critical direction, the transverse direction; when measured on a gauge length, L0, calculated as follows:

SL065,50

(4.1-1) where

S0 is the original cross sectional area within the gauge length in order to fulfil formula 4.1-1.

taken by the parties concerned to compensate for these lower values and that compliance with the specific requirements is verifiable. NOTE Examples of appropriate measures: application of higher safety factors in design; performance of appropriate burst tests to demonstrate ductile material behaviour. 4.1.5 When measured on a gauge length other than that stated in 4.1.4, the minimum elongation after fracture shall be determined by converting the elongation given in 4.1.4 in accordance with: EN ISO 2566-1:1999 for carbon and low alloy steels; EN ISO 2566-2:1999 for austenitic steels.

4.1.6 Steels shall have a specified minimum impact energy measured on a Charpy V-notch impact test specimen (EN ISO 148-1:2010) as follows: 27 J for ferritic and 1,5 % to 5 % Ni alloyed steels; 40 J for steels of material groups 8, 9.3 and 10, at a test temperature in accordance with Annex B, but not higher than 20 C. The other requirements of Annex B shall also apply. 4.1.7 The chemical composition of steels intended for welding or forming shall not exceed the values given in Table 4.1-1. Exceptions shall be technically justified.

Maximum content of product analysis 0,25 %. b

For products to be machined a controlled sulphur content of 0,015 % to 0,030 % is permitted by agreement provided the resistance to corrosion is satisfied for the intended purpose.

4.2 Special provisions 4.2.1 Special properties 4.2.1.1 General Where the behaviour of a material can be affected by manufacturing processes or operating conditions, to an extent that would adversely affect the safety or service life of the piping system, this shall be taken into consideration when specifying the material. Adverse effects can arise from: manufacturing processes: e.g. degree of cold forming, heat treatment; operating conditions: e.g. hydrogen embrittlement, corrosion, scaling, ageing behaviour after cold forming. 4.2.1.2 Lamellar tearing Where lamellar tearing due to the joint design and loading needs to be addressed (see EN 13480-3:2012, 7.2.3.3), steels shall be used which have improved deformation properties perpendicular to the surface shall be specified and verified in accordance with EN 10164:2004. NOTE For guidance see EN 1011-2:2001.

For other than austenitic and austenitic-ferritic stainless steels, the specified value of ReH (Rp0,2) at room temperature may be used for temperatures less than or equal to 50 C. Interpolation for design temperatures between 50 C and 100 C shall be performed with the values of ReH at room temperature and at 100 °C, and using 20 °C as the starting point for interpolation. Above 100 C linear interpolation shall be performed between the tabulated values given in the appropriate material standards. In the case of creep rupture strength values or strength values for plastic strain in a given time, linear interpolation shall be permissible only if the difference between the two temperatures serving as starting points for the interpolation is equal to or less than 10 C. 4.2.2.2 Materials in the creep range shall not be used unless the creep rupture strength values or strength values for plastic strain needed for design are specified in the base material specification. The manufacturer of the piping system installation shall be assured by the material supplier that the material supplied is capable of complying with specified properties (within the normal scatter band) by a statement that the manufacturing processes have remained equivalent to those for the steel for which the test results were obtained. 4.2.3 Prevention of brittle fracture The requirements given in Annex B shall apply. 4.2.4 Specific requirements for fasteners Fasteners includes bolts, studs and nuts. Free cutting steel shall not be used. Fasteners made of carbon steel or low alloyed ferritic steel with > 3,5 % nickel shall not be used above 300 C. The specified minimum tensile strength of bar material of ferritic and martensitic steel for bolts shall not exceed 1 000 N/mm2. The minimum elongation after fracture of bar material shall be at least 14%.

Impact requirements for ferritic steels shall be in accordance with Table B.2.-9. Bolt material with a design temperature below –160 °C shall be impact tested at –196 °C. Hydrogen embrittlement, fatigue or relaxation properties shall be taken into account where appropriate. NOTE Detailed requirements on the surface condition and internal soundness of the bar can be necessary for some applications.

4.3.1 European Standards The European Standards for plates, strips, bars, tubes, forgings, fittings and castings for pressure purposes shall be used. NOTE 1 Table D.1-1 provides an informative summary of European Materials Standards for steels and steel components for pressure purposes. NOTE 2 Table D.2-1 provides an informative summary regarding materials for pressure purposes specified in harmonised standards grouped according to product forms. Special provisions due to fabrication and operation shall be taken into account, if appropriate. 4.3.2 European Approval for Materials A material specified in an EAM for piping system shall only be used within its range of application.

4.3.3 Particular Material Appraisals Materials other than those specified in 4.3.1 and 4.3.2 may also be used provided that they have been accepted by a particular material appraisal (PMA). 4.3.4 Clad products Technical delivery conditions for clad products for pressure parts shall be in accordance with the requirements of Annex C. NOTE 1 European Standards specifying technical delivery conditions for clad products for pressure purposes are not currently available. NOTE 2 Examples of documents covering technical delivery condition for clad steels are given within the publications [2] to [4] 4.3.5 Technical delivery conditions for welding consumables Technical delivery conditions for welding consumables used for the welding of pressure parts and attachments to pressure parts shall be in accordance with EN 10274:1999 and EN 13479-1:2004. NOTE Equivalent national/international specifications are accepted which fulfil the same criteria with respect to the requirements for the Quality System and the requirements for manufacture, supply distribution, test methods and evaluation of consumables.

Grouping system for steels for pressure equipment Steels shall be grouped as shown in Table A.1. The figures given in group 1 are referring to the ladle analysis of the materials. The figures given in group 4 to 10 are based on the element content used in the designation of the alloys. Table A.1 — Grouping system for steels (extract from CEN ISO/TR 15608:2000) Group Sub- group Type of steel 1

Steels with a specified minimum yield strength Re 460 N/mm2 a and with analysis in %: C 0,25 Si 0,60 Mn 1,70 Mo 0,70 b S 0,045 P 0,045 Cu 0,40 b Ni 0,5b Cr 0,3 (0,4 for castings) b Nb 0,05 V 0,12 b Ti 0,05

1.1 Steels with a specified minimum yield strength Re 275 N/mm2

1.2 Steels with a specified minimum yield strength 275 N/mm2 Re 360 N/mm2

1.3 Normalised fine grain steels with a specified minimum yield strength Re 360 N/mm2

1.4 Steels with improved atmospheric corrosion resistance whose analysis may exceed the requirements for the single elements as indicated under 1 2

Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength Re > 360 N/mm2

2.1 Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength 360 N/mm2 Re 460 N/mm2

2.2 Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength Re 460 N/mm2 3

Quenched and tempered steels and precipitation hardened steels except stainless steels with a specified minimum yield strength Re > 360 N/mm2

3.1 Quenched and tempered steels with a specified minimum yield strength 360 N/mm2 Re 690 N/mm2

3.2 Quenched and tempered steels with a specified minimum yield strength Re 690 N/mm2

3.3 Precipitation hardened steels except stainless steels SIST EN 13480-2:2012

Low vanadium alloyed Cr-Mo-(Ni) steels with Mo 0,7 % and V 0,1 %

4.1 Steels with Cr 0,3 % and Ni 0,7 %

4.2 Steels with Cr 0,7 % and Ni 1,5 % 5

Cr-Mo steels free of vanadium with C 0,35 % c

5.1 Steels with 0,75 % Cr 1,5 % and Mo 0,7 %

5.2 Steels with 1,5 % Cr 3,5 % and 0,7 Mo 1,2 %

5.3 Steels with 3,5 % Cr 7,0 % and 0,4 Mo 0,7 %

5.4 Steels with 7,0 % Cr 10 % and 0,7 Mo 1,2 % 6

High vanadium alloyed Cr-Mo-(Ni) steels

6.1 Steels with 0,3 % Cr 0,75 %, Mo 0,7 % and V 0,35 %

6.2 Steels with 0,75 % Cr 3,5 %, 0,7 % Mo 1,2 % and V 0,35 %

6.3 Steels with 3,5 % Cr 7,0 %, Mo 0,7 % and 0,45 % V 0,55 %

6.4 Steels with 7,0 % Cr 12,5 %, 0,7 % Mo 1,2 % and V 0,35 % 7

Ferritic, martensitic or precipitation hardened stainless steels with C 0,35 % and 10,5 % Cr 30 %

7.1 Ferritic stainless steels

7.2 Martensitic stainless steels

7.3 Precipitation hardened stainless steels 8

Austenitic steels

8.1 Austenitic stainless steels with Cr 19 %

8.2 Austenitic stainless steels with Cr 19 %

8.3 Manganese austenitic stainless steels with 4 % Mn 12 % 9

Nickel alloyed steels with Ni 10 %

9.1 Nickel alloyed steels with Ni 3 %

9.2 Nickel alloyed steels with 3,0 % Ni 8 %

9.3 Nickel alloyed steels with 8,0 % Ni 10 % 10

Austenitic ferritic stainless steels (duplex)

10.1 Austenitic ferritic stainless steels with Cr 24 %

10.2 Austenitic ferritic stainless steels with Cr 24 % a In accordance with the specification of the steel product standards, Re may be replaced by Rp0,2 or Rt0.5. b A higher value is accepted provided that Cr Mo Ni Cu V 0,75 %. c "Free of vanadium" means not deliberately added to the material.

Requirements for prevention of brittle fracture at low temperatures B.1 General This annex distinguishes between pressure equipment that has design temperature for normal operation higher or lower than 50 °C.

For pressure equipment with normal operation temperatures higher than 50 °C B.5 applies. If B.5 is not applicable, the following rules for lower normal operation temperatures shall be used.

For pressure equipment with design temperature equal to or less than 50 °C this annex specifies three alternative methods for establishing criteria for the prevention of low temperature brittle fracture1) of steels in the form of plate, strip, tubes, fittings, forgings, castings, flanges, fasteners and weldments used in pressure parts. In this case, the temperature for the design TR shall be determined2). The criteria are based on impact energy requirements at specified temperatures for the base material, heat affected zone (including the fusion line) and weld metals. The three methods are: Method 1 Code of Practice:

Technical requirements a) Technical requirements based on the choice of TR = T27J as specified in harmonised European Material Standards and on the assumption that it is possible to achieve these minimum properties after fabrication. Calculated from the principles of fracture mechanics used for method 2 for C and CMn steels with yield strength < 460 MPa and

b) based on operating experience for Ni-alloyed steels with Ni 8 3 % up to 9 %, for austenitic steels and for bolts and nuts.

1) Including temperatures at pressure tests 2)

See EN 13480-2:2012, 3.1.3. SIST EN 13480-2:2012

A more flexible approach than method 1 for derivation of technical requirements applicable to C, CMn and low alloy ferritic steels with a specified minimum yield strength 500 N/mm2 and for austenitic-ferritic steels with a specified minimum yield strength 550 N/mm2. This method can be applied for these steels to a wider range of thicknesses and temperatures than method 1 because TR must not be equal to T27J (see Figures B.2-1 to B.2-11). In addition for ferritic steels with max. 355 N/mm2 in PWHT condition operation experience was considered for higher thicknesses. Method 3 The application of a fracture mechanics analysis: This general method is applicable to cases not covered by methods 1 or 2. This method may also be used to justify deviations from the requirements of method 1 or 2. Only general guidance is given on the use of this method which shall only be used in agreement with the parties concerned. Each of the three methods may be used independently. It is only necessary to satisfy the requirement of any one method. All applicable combinations of the temperatures TM (minimum metal temperature) and TS (temperature adjustment term) shall be considered and the lowest possible TR-value (design reference temperature) shall be used for the determination of the required material impact test temperature. NOTE For definitions of temperature terms see 3.1.1 to 3.1.4. B.2 Material selection and impact energy requirements B.2.1 General The methods specified in B.2.1 (Method 1) or B.2.2 (Method 2) shall be used to determine the impact energy required to avoid brittle fracture. Alternatively, B.2.3 (Method 3) may be used to determine the required toughness. The method used shall be fully documented, in order to ensure that compliance can be verified. Reference thickness for constructional details is defined in Table B.5-1. B.2.2 Method 1 – Code of practice B.2.2.1 General Method 1 allows the selection of materials taken from harmonised European material standards with regard to prevention of brittle fracture. Table B.2-1 gives an overview to the following tables by steel type and product form.

The weld metal, the heat affected zone and other parts affected by manufacturing

processes shall satisfy the same impact energy requirements as the guaranteed minimum properties for the base material at TR given in the tables.

Bolts and nuts Ferritic steels Austenitic steels B.2.1.4 B.2–9 B.2–10 B.2–11 Austenitic steel grades Austenitic steels B.2.1.5 a For standardized fittings (Tees, Reducers, Elbows and Caps) TR may be taken from Tables B.2-2 to B.2-6 as for the applied material or product form. The reference thickness eB of the fitting shall be considered as equal to the reference thickness of the thicker of the mating pipes.

NOTE Requirements for austenitic-ferritic steels are only given in B.2.2 (Method 2). Where test pieces of at least 5 mm wide cannot be obtained, the material need not be subject to impact testing. For pipes with nominal thickness lower than 6,3 mm no impact testing is required. Values of the design reference temperature TR shall be calculated from the metal temperature TM using the values of the temperature adjustment TS given in Table B.2-12. B.2.2.2 Ferritic steels Tables B.2-2 to B.2-5 list ferritic steels taken from harmonised European material standards with specified impact properties below – 10 °C.

The tabulated value of TR is based on the impact test temperature TKV for KV = 27 J.

Table B.2-2 — General requirements for prevention of brittle fracture with reference thickness for plates and strips Plates and Strips No. as per Table D.2-1 European Standard EN Grade Material No. Max. reference thickness eB mm Design reference temperature TR

°C Material group to CEN ISO/TR 15608:2000 Remarks AW PWHT 1 10028-2:2009 P235GH 1.0345 35 90 – 20 1.1

2 P265GH 1.0425 35 75

3 P295GH 1.0481 35 65 1.2

4 P355GH 1.0473 35 55

29 10028-3:2009 P275NH 1.0487 35 75 – 20 1.1

30 P275NL1 1.0488 35 75 – 40

31 P275NL2 1.1104 35 90 – 50

32 P355N 1.0562 35 55 – 20 1.2

33 P355NH 1.0565 35 55 – 20

34 P355NL1 1.0566 35 55 – 40

35 P355NL2 1.1106 35 55 – 50

39 10028-4:2009 11MnNi5-3 1.6212 35 50 – 60 9.1

40 13MnNi6-3 1.6217 35 50 – 60

41 15NiMn6 1.6228 35 50 – 80

50 10028-5:2009 P355M 1.8821 30 - –

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...