EN 13480-5:2024

(Main)Metallic industrial piping - Part 5: Inspection and testing

Metallic industrial piping - Part 5: Inspection and testing

This document specifies the requirements for inspection and testing of industrial piping as specified in EN 13480-1:2024 to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3:2024 and EN 13480-6:2024 (if applicable), and fabricated and installed in accordance with EN 13480-4:2024.

Metallische industrielle Rohrleitungen - Teil 5: Prüfung

Dieses Dokument legt die Anforderungen an die Prüfungen von metallischen industriellen Rohrleitungen fest nach den Festlegungen in EN 13480-1:2024, die bei Fertigung und Verlegung nach EN 13480-4:2024 an einzelnen, nach EN 13480-3:2024 und EN 13480-6:2024 (falls anwendbar) ausgelegten vorgefertigten Baugruppen (Spools) oder Rohrleitungssystemen einschließlich Halterungen, durchzuführen sind.

Tuyauteries industrielles métalliques - Partie 5: Inspection et contrôle

Le présent document spécifie les exigences relatives à l'inspection et au contrôle des tuyauteries industrielles telles que spécifiées dans l’EN 13480-1:2024, à exécuter sur les éléments de tuyauteries préfabriqués ou sur les réseaux de tuyauteries, supports compris, conçus conformément à l’EN 13480-3:2024 et à l’EN 13480-6:2024 (le cas échéant), et fabriqués et installés conformément à l’EN 13480-4:2024.

Kovinski industrijski cevovodi - 5. del: Pregled in preskušanje

Ta dokument določa zahteve za pregled in preskušanje industrijskih cevovodov, kot določa standard EN 13480-1:2024, ki ju je treba izvesti na posameznih navitjih cevovodov, vključno z nosilci, ki so konstruirani v skladu s standardoma EN 13480-3:2024 in EN 13480-6:2024 (če je to potrebno) ter izdelani in vgrajeni v skladu s standardom EN 13480-4:2024.

General Information

- Status

- Published

- Publication Date

- 23-Jul-2024

- Technical Committee

- CEN/TC 267 - Industrial piping and pipelines

- Drafting Committee

- CEN/TC 267/WG 5 - Inspection and testing

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 24-Jul-2024

- Due Date

- 09-Aug-2024

- Completion Date

- 24-Jul-2024

Relations

- Effective Date

- 31-Jul-2024

- Effective Date

- 31-Jul-2024

- Effective Date

- 18-Jan-2023

- Refers

EN 13480-6:2024 - Metallic industrial piping - Part 6: Additional requirements for buried piping - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13480-5:2024 - Metallic industrial piping: Part 5 - Inspection and testing (CEN) sets out the inspection, testing and documentation requirements for metallic industrial piping systems. It applies to individual spools or complete piping systems (including supports) designed in accordance with EN 13480-3:2024, fabricated/installed per EN 13480-4:2024 and, where applicable, incorporating buried piping requirements from EN 13480-6:2024. The standard updates and supersedes the 2017 edition and integrates previous amendments.

Key topics and requirements

- Scope and classification: Defines how piping is classified for inspection and testing based on design and service conditions.

- Design review: Requirements for verifying that design documents meet inspection and test needs before fabrication.

- In-process inspection:

- Verification of materials and formed pressure-retaining parts.

- Controls for welding (pre-weld, during-weld and post-weld inspections).

- Verification of heat treatment processes where applicable.

- Non-destructive testing (NDT) of welds:

- Application principles and sampling strategy.

- Extent of testing for circumferential, branch, fillet and longitudinal welds.

- Testing methods (visual, radiographic, ultrasonic, magnetic particle, dye penetrant) and selection criteria.

- Personnel qualification and acceptance levels.

- Final assessment and documentation:

- Visual inspections pre- and post-proof test.

- Proof testing procedures, including hydrostatic and pneumatic tests and other functional checks.

- Requirements for final documentation packages, operating instructions and declarations of compliance.

- Annexes and guidance: Includes initial leak test guidance, declarations of conformity and a history of changes (Annex Y).

Practical applications and users

EN 13480-5:2024 is used by professionals involved in the lifecycle of metallic industrial piping:

- Design engineers and project managers ensuring testability and compliance.

- Fabricators and welding supervisors for in-process inspection and weld quality control.

- NDT technicians and inspection bodies applying method selection, sampling and acceptance criteria.

- Plant owners, purchasers and asset operators requiring documented proof tests and final documentation. Typical industries: oil & gas, chemical and petrochemical, power generation, water treatment and general process plants where reliable pressure piping is critical.

Related standards

- EN 13480-1 to EN 13480-4, EN 13480-6 (Parts 1–4, 6)

- CEN/TR 13480-7 (conformity guidance)

- EN 14917 (metal bellows joints)

- EN ISO 5817 (welding quality acceptance)

Keywords: EN 13480-5:2024, metallic industrial piping, inspection and testing, NDT, hydrostatic test, weld inspection, piping spools, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13480-5:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metallic industrial piping - Part 5: Inspection and testing". This standard covers: This document specifies the requirements for inspection and testing of industrial piping as specified in EN 13480-1:2024 to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3:2024 and EN 13480-6:2024 (if applicable), and fabricated and installed in accordance with EN 13480-4:2024.

This document specifies the requirements for inspection and testing of industrial piping as specified in EN 13480-1:2024 to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3:2024 and EN 13480-6:2024 (if applicable), and fabricated and installed in accordance with EN 13480-4:2024.

EN 13480-5:2024 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13480-5:2024 has the following relationships with other standards: It is inter standard links to EN 13480-5:2017/A2:2021, EN 13480-5:2017/A1:2019, EN 13480-5:2017, EN 13480-6:2024, EN 14917:2021, EN ISO 9712:2022, CEN/TR 13480-7:2017, EN 13480-2:2024, EN 13480-1:2024, EN 3-6:1995/A1:1999, EN ISO 17640:2018, EN ISO 10893-5:2011, EN ISO 17635:2016, EN 13480-3:2024, EN 13480-4:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13480-5:2024 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13480-5:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Nadomešča:

SIST EN 13480-5:2018

SIST EN 13480-5:2018/A1:2019

SIST EN 13480-5:2018/A2:2021

Kovinski industrijski cevovodi - 5. del: Pregled in preskušanje

Metallic industrial piping - Part 5: Inspection and testing

Metallische industrielle Rohrleitungen - Teil 5: Prüfung

Tuyauteries industrielles métalliques - Partie 5: Inspection et contrôle

Ta slovenski standard je istoveten z: EN 13480-5:2024

ICS:

23.040.10 Železne in jeklene cevi Iron and steel pipes

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13480-5

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2024

EUROPÄISCHE NORM

ICS 23.040.01 Supersedes EN 13480-5:2017

English Version

Metallic industrial piping - Part 5: Inspection and testing

Tuyauteries industrielles métalliques - Partie 5: Metallische industrielle Rohrleitungen - Teil 5: Prüfung

Inspection et contrôle

This European Standard was approved by CEN on 9 July 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13480-5:2024 E

worldwide for CEN national Members.

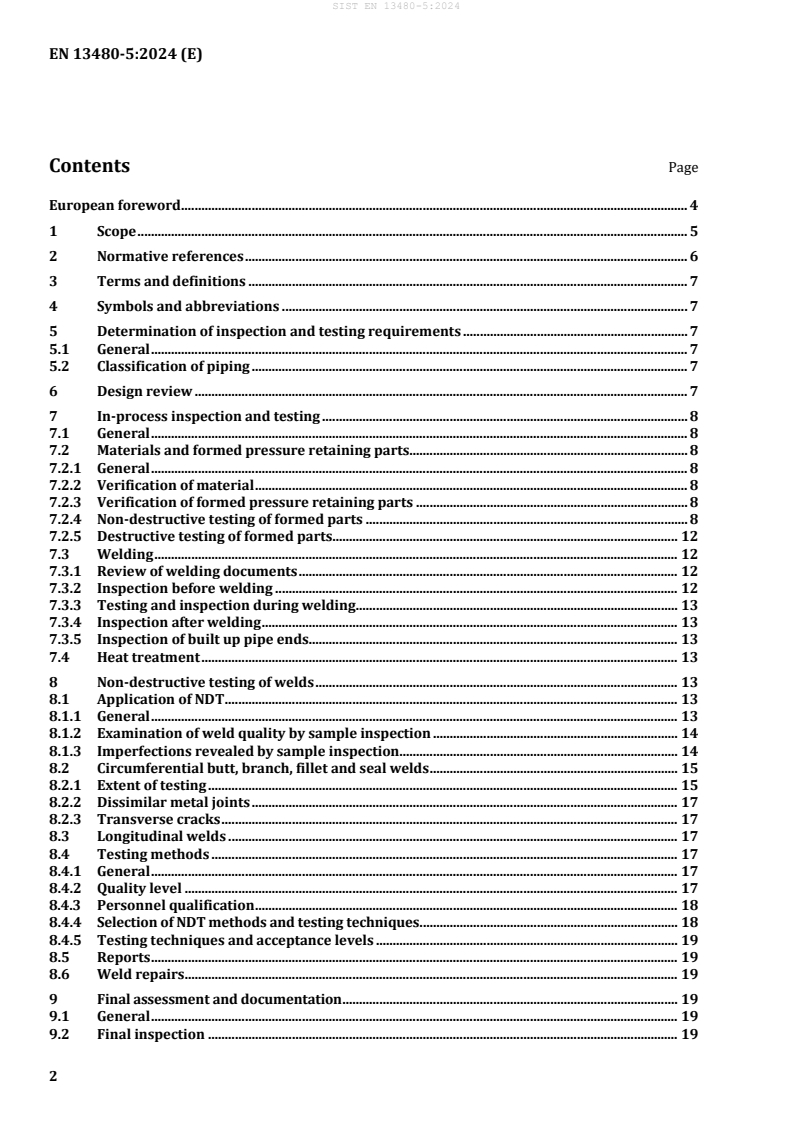

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 7

5 Determination of inspection and testing requirements . 7

5.1 General . 7

5.2 Classification of piping . 7

6 Design review . 7

7 In-process inspection and testing . 8

7.1 General . 8

7.2 Materials and formed pressure retaining parts. 8

7.2.1 General . 8

7.2.2 Verification of material . 8

7.2.3 Verification of formed pressure retaining parts . 8

7.2.4 Non-destructive testing of formed parts . 8

7.2.5 Destructive testing of formed parts. 12

7.3 Welding . 12

7.3.1 Review of welding documents . 12

7.3.2 Inspection before welding . 12

7.3.3 Testing and inspection during welding . 13

7.3.4 Inspection after welding . 13

7.3.5 Inspection of built up pipe ends. 13

7.4 Heat treatment . 13

8 Non-destructive testing of welds . 13

8.1 Application of NDT . 13

8.1.1 General . 13

8.1.2 Examination of weld quality by sample inspection . 14

8.1.3 Imperfections revealed by sample inspection. 14

8.2 Circumferential butt, branch, fillet and seal welds . 15

8.2.1 Extent of testing . 15

8.2.2 Dissimilar metal joints . 17

8.2.3 Transverse cracks . 17

8.3 Longitudinal welds . 17

8.4 Testing methods . 17

8.4.1 General . 17

8.4.2 Quality level . 17

8.4.3 Personnel qualification . 18

8.4.4 Selection of NDT methods and testing techniques . 18

8.4.5 Testing techniques and acceptance levels . 19

8.5 Reports . 19

8.6 Weld repairs. 19

9 Final assessment and documentation . 19

9.1 General . 19

9.2 Final inspection . 19

9.2.1 General . 19

9.2.2 Visual inspection before the proof test . 19

9.2.3 Visual inspection after the proof test . 20

9.2.4 Review of the manufacturing documents . 20

9.3 Proof test. 20

9.3.1 General . 20

9.3.2 Hydrostatic pressure test . 20

9.3.3 Pneumatic pressure test . 23

9.3.4 Other tests . 25

9.3.5 Documentation of the proof test . 25

9.4 Documentation . 25

9.4.1 Final documentation package . 25

9.4.2 Design and manufacturing documentation package . 27

9.4.3 Operating instructions . 27

9.4.4 Documentation for the purchaser . 27

10 Declaration. 27

Annex A (informative) Declaration of compliance with EN 13480 . 28

A.1 Declaration for design . 28

A.2 Declaration for fabrication, installation and testing . 29

A.3 Declaration for compliance for piping with EN 13480 . 30

Annex B (informative) Initial Leak Test . 31

B.1 Initial Service Leak Test . 31

B.1.1 General . 31

B.1.2 Examination Procedure for service fluid gas or vapor . 31

B.1.3 Examination Procedure for service fluid liquid . 31

B.2 Initial Leak Test . 31

Annex Y (informative) History of EN 13480-5 . 32

Y.1 Differences between EN 13480-5:2017 and EN 13480-5:2024 . 32

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2014/68/EU aimed to be covered . 33

Bibliography . 34

European foreword

This document (EN 13480-5:2024) has been prepared by Technical Committee CEN/TC 267 “Industrial piping

and pipelines”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by December 2024, and conflicting national standards shall be withdrawn

at the latest by December 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13480-5:2017.

This new edition incorporates the Amendments which have been approved previously by CEN members, and

the corrected pages up to Issue 2 without any further technical change. Annex Y provides details of significant

technical changes between this European Standard and the previous edition.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this document.

This European Standard EN 13480 for metallic industrial piping consists of eight interdependent and not

dissociable Parts which are:

Part 1: General;

Part 2: Materials;

Part 3: Design and calculation;

Part 4: Fabrication and installation;

Part 5: Inspection and testing;

Part 6: Additional requirements for buried piping;

CEN/TR 13480-7, Guidance on the use of conformity assessment procedures;

Part 8: Additional requirements for aluminium and aluminium alloy piping.

Although these Parts may be obtained separately, it should be recognized that the Parts are inter-dependant.

As such the manufacture of metallic industrial piping requires the application of all the relevant Parts in order

for the requirements of the Standard to be satisfactorily fulfilled.

This European Standard will be maintained by a Maintenance MHD working group whose scope of working is

limited to corrections and interpretations related to EN 13480. The contact to submit queries can be found at

https://unm.fr/en/maintenance-agencies/maintenance-agency-en-13480/. A form for submitting questions

can be downloaded from the link to the MHD website. After subject experts have agreed an answer, the answer

will be communicated to the questioner. Interpretation sheets will be posted on the website of the MHD.

Amendments to this new edition may be issued from time to time and then used immediately as alternatives

to rules contained herein. These amendments will be consolidated within EN 13480:2024 in accordance with

the maintenance system of EN 13480 series approved by CEN/BT Decision C172/2021.

Any feedback and questions on this document should be directed to the users’ national standards body. A

complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia,

Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United Kingdom.

1 Scope

This document specifies the requirements for inspection and testing of industrial piping as specified in

EN 13480-1:2024 to be performed on individual spools or piping systems, including supports, designed in

accordance with EN 13480-3:2024 and EN 13480-6:2024 (if applicable), and fabricated and installed in

accordance with EN 13480-4:2024.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 13480-1:2024, Metallic industrial piping — Part 1: General

EN 13480-2:2024, Metallic industrial piping — Part 2: Materials

EN 13480-3:2024, Metallic industrial piping — Part 3: Design and calculation

EN 13480-4:2024, Metallic industrial piping — Part 4: Fabrication and installation

EN 13480-6:2024, Metallic industrial piping — Part 6: Additional requirements for buried piping

CEN/TR 13480-7:2017, Metallic industrial piping — Part 7: Guidance on the use of conformity assessment

procedures

EN 14917:2021, Metal bellows expansion joints for pressure applications

EN ISO 5817:2023, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections (ISO 5817:2023)

EN ISO 9712:2022, Non-destructive testing — Qualification and certification of NDT personnel (ISO 9712:2021)

EN ISO 10893-5:2011, Non-destructive testing of steel tubes — Part 5: Magnetic particle inspection of seamless

and welded ferromagnetic steel tubes for the detection of surface imperfections (ISO 10893-5:2011)

EN ISO 17635:2016, Non-destructive testing of welds — General rules for metallic materials

(ISO 17635:2016)

EN ISO 17640:2018, Non-destructive testing of welds — Ultrasonic testing — Techniques, testing levels, and

assessment (ISO 17640:2018)

ISO 3057:1998, Non-destructive testing — Metallographic replica techniques of surface examination

As impacted by EN ISO 10893-5:2011/A1:2020.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13480-1:2024 apply.

4 Symbols and abbreviations

For the purposes of this document, the symbols given in EN 13480-1:2024 apply together with the following

abbreviations.

NDT Non-destructive testing

MT Magnetic particle testing

PT Penetrant testing

RT Radiographic testing

UT Ultrasonic testing

VT Visual testing

PWHT Post-weld heat treatment

PED Pressure Equipment Directive.

5 Determination of inspection and testing requirements

5.1 General

The manufacturer shall be responsible for the fabrication and the installation, even if this work will be

sub-contracted to other fabricators and/or installers.

The fabricator and/or installer shall be responsible for carrying out the inspection and testing including

subcontracted NDT (if any) specified in this European Standard, for all piping.

NOTE For guidance on the use of conformity assessment procedures see CEN/TR 13480-7:2017.

5.2 Classification of piping

Industrial piping shall be classified in accordance with EN 13480-1:2024, Table 5.1-1.

NOTE Categories I to III are identical to categories I to III of the Pressure Equipment Directive.

6 Design review

Before fabrication/installation commences, a review of the piping design and its supports shall be performed.

Where design and fabrication are carried out by separate organisations, the piping designer shall prepare a

confirmation for the manufacturer that the design is in compliance with the requirements of this European

Standard.

A list of the relevant drawings shall be attached to the confirmation.

Where the design of parts has already been reviewed in accordance with this European Standard, and where

an appropriate confirmation is available, a further design review shall not be required.

NOTE For guidance on the use of conformity assessment procedures see CEN/TR 13480-7:2017.

7 In-process inspection and testing

7.1 General

Testing and inspection shall be carried out by personnel qualified for the method used. European Standards,

specifications or written procedures (if necessary) shall be available to all testing personnel and inspectors

prior to the testing/inspection.

Reports on NDT specified in 7.2.4 and Clause 8 and reports on destructive testing specified in 7.2.5 shall be

prepared to demonstrate that all required testing has been carried out and that the results are acceptable.

7.2 Materials and formed pressure retaining parts

7.2.1 General

The testing and inspection specified below shall be restricted to parts formed during the fabrication process,

especially induction bending. Formed bought out standardized parts and components shall not be a part of

this requirement.

Formed parts shall be subject to appropriate testing in accordance with the fabricators/installers test

programme.

7.2.2 Verification of material

A verification shall be performed that materials are in accordance with the specified material standard or

purchase order.

7.2.3 Verification of formed pressure retaining parts

It shall be verified that all formed pressure retaining parts comply with the specified shape and dimensional

requirements, and have received the specified finish or heat treatment.

7.2.4 Non-destructive testing of formed parts

7.2.4.1 General

All formed parts shall be subject to non-destructive testing. Depending on material, dimensions and type of

forming process testing can include:

a) visual testing;

b) wall thickness measurements;

c) dimensional checks (ovality, angle of bend etc.) and tolerances (see EN 13480-4:2024);

d) hardness tests;

e) testing for surface imperfections (magnetic particle or penetrant testing);

on formed parts of each component or batch of identical components.

Material, heat treatment conditions, heat treatment lot, degree of deformation shall be considered in the

definition of the batch.

Replicas of the surface structure in the tension zone can be required in case of lifetime monitoring for creep

range application.

Ultrasonic testing can be performed if specified. Specification shall include area, extent, method and

acceptance criteria.

NOTE A customary interpretation of a heat treatment lot is the entire content of a furnace of a single heat treatment.

7.2.4.2 Induction bending

Material surfaces shall be suitable for induction bending. EN ISO 10893-5:2011 specifies surface qualities and

acceptance levels. The acceptance levels shall be agreed, considering material, dimensions and service (creep,

fatigue).

Induction bends shall be tested according to Table 7.2.4.2-1.

Heat treatment shall be done if required by EN 13480-4:2024. Subsequent hardness testing shall be

performed on the straight length and within bending zone to verify the homogeneity of annealing.

If no heat treatment is required after forming, hardness testing is required in the bending zone only if specified

for service reasons.

Dimensional checks shall include ovality, angle of bend, wall thickness and tolerances

(see EN 13480-4:2024).

MT/PT testing shall be performed to verify that the outside surface in the bended zone is free of cracks.

If specified for the component or by Table 7.2.4.2-1, replicas of the surface structure in the tension zone shall

be taken on each component or batch of identical components. Replicas shall be made in accordance with

ISO 3057:1998.

The material grade, the heat treatment conditions of the material, the heat treatment lot after bending and the

forming conditions shall be considered in the definition of the batch.

Table 7.2.4.2-1 — NDT for induction bends

Material Group

Dimensional Hardness

(see EN 13480 VT MT/PT Replicas

check testing

-2:2024)

1.1, 1.2, 1.3, 8, 9 c c — b5e —

1.4, 3, 5.3, 5.4, 6 c c c cf —

2 c c c b5e —

4 c c c ce —

5.1, 5.2 c c b10e b10e —

10 c c — cf yes

NOTE

b5e – 5 % of batch on extrados

b10e – 10 % of batch on extrados

c – testing per component

ce – testing per component extrados

cf – component forming area

7.2.4.3 Cold formed pipes

Cold formed pipes shall be tested according to Table 7.2.4.3-1.

Heat treatment shall be done if required by EN 13480-4:2024. Subsequent hardness testing shall be

performed on the straight length and within bending zone to verify the homogeneity of annealing.

If no heat treatment is required after forming, hardness testing is required in the bending zone only if specified

by the purchaser for service reasons.

Dimensional checks shall be performed after tooling of the bending machine and start of production to the

same extent as specified for MT/PT (see Table 7.2.4.3-1) and shall include ovality, angle of bend and tolerances

(see EN 13480-4:2024).

Wall thickness measurement at the extrados is required for all cold formed pipes with r ≤ 1,3 d .

m o

MT/PT testing shall be performed to verify that the outside surface in the bended zone is free of cracks.

Table 7.2.4.3-1 — NDT after cold forming of pipes

Surface testing (MT/PT)

Material Hardness testing

%

VT

group (see

Category

EN 13480

% 1,3 d < r < 2,5

o m

r ≤ 1,3 d 2,5 d ≤ r r ≤ 1,3 d

-2:2024) m o o m m o

d

o

I

1.1, 1.2, 1.3,

II 100 0 0 0

8.1, 8.2, 9.1

III b5e

I 0 0 0

2.1, 2.2, 4.1,

c

4.2, 5.1, 5.2,

II 0 0

100 (only for material groups 2.1, 2.2, 4.1, 4,2)

7.1, 8.3,

b5e

9.2, 9.3

III b5e 0

1.4, 3.1, 3.2,

I b5f

3.3,

c

b5f b5f

5.3,

(only for material groups 3.1, 3.2, 3.3, 5.3, 5,4, 6.1, 6.2,

II

5.4, 6.1, 6.2, 100

6.3, 6.4)

6.3, 6.4,

b25f

7.2, 7.3, 10.1,

III b10f

10.2

NOTE

b5e – 5 % of batch on extrados

b5f – 5 % of batch on forming area

b10f – 10 % of batch on forming area

b25f – 25 % of batch on forming area

c - testing per component

7.2.5 Destructive testing of formed parts

Testing shall be performed to verify the heat treatment of the formed parts (induction bends with or

without subsequent heat treatment, cold formed parts with subsequent heat treatment, hot formed parts

with or without subsequent heat treatment) and shall include:

a) tensile test at room temperature;

b) impact test;

c) other tests specified in European Standards for base materials.

Testing shall be performed as specified in the European Standards for the base materials.

The tests shall be performed on test pieces from the end of the component itself, or from test pieces placed

together with the components in the heat treatment furnaces.

Production test coupons for destructive testing shall be representative for one heat treatment lot defined

by the same dimension, material heat and similar forming conditions.

Low alloyed steels (up to 5 % total alloying content) can be representatively tested by a single production

test coupon, representative for several furnace loads if:

1) comparable furnace parameters are applied and

2) the heat treatment parameters are recorded for each furnace load by a thermocouple attached to the

component.

7.3 Welding

7.3.1 Review of welding documents

Prior to carrying out any welding activity, the fabricator shall verify that the welding procedures and the

welding personnel are qualified for the relevant work. This shall be reviewed by the manufacturer.

7.3.2 Inspection before welding

Prior to carrying out any welding, each joint preparation shall be visually inspected. The inspection shall

verify compliance with the drawing and WPS, by ensuring the following:

a) the correct materials are used;

b) dimensions are within tolerance, including position, alignment, and orientation of branches, nozzles,

attachments and anchors, etc.;

c) cleanliness and freedom from imperfections which can give rise to defects in the completed joint;

d) nozzles, branches etc., properly fit the curvature of the pipe;

e) tack welds that are to be incorporated into the final weld are free from cracks or other defects.

7.3.3 Testing and inspection during welding

The following testing and inspection shall be carried out, where appropriate, at suitable stages during the

welding operation to verify that the specified WPS is being followed for:

a) correct preheat;

b) correct welding process;

c) correct welding consumables;

d) correct electrical characteristics;

e) correct interpass temperature and cleaning;

f) other requirements of the WPS;

g) all tack welds and temporary attachments are welded in accordance with an approved WPS.

7.3.4 Inspection after welding

The following inspection shall be carried out on completion of welding:

a) verification for compliance with drawings;

b) verification that welds are correctly identified and traceable to the welder/operator;

c) verification that temporary attachments have been properly removed.

7.3.5 Inspection of built up pipe ends

All built up pipe ends shall be subject to 100 % non-destructive testing of internal and surface

imperfections.

7.4 Heat treatment

For post-forming and post-weld heat treatment (PWHT), where applicable, it shall be verified by a review

of the heat treatment reports that the heat treatment carried out complies with the heat treatment

procedure.

If additional examinations (e.g. replica, hardness) after post-forming and post-weld heat treatment are

required, this testing shall be reported and the reports shall be reviewed.

8 Non-destructive testing of welds

8.1 Application of NDT

8.1.1 General

8.1.1.1 The following shall be applicable to all welded joints:

a) welded joints shall be visually examined before any other NDT is performed;

b) the area to be examined shall include the weld metal and the heat affected zones;

c) surface examination stipulated in Table 8.2-1 shall be performed on the outer surface;

d) where a welded joint is to be subsequently formed or heat treated, the required NDT shall be carried

out on the weld in the final condition. If a weld will not be accessible for examination after heat

treatment or forming, a suitable alternative shall be agreed;

e) NDT-methods used and acceptance criteria for all NDT shall be in accordance with 8.4.5;

f) weld imperfections, which have been assessed as weld defects, shall be repaired in accordance with

EN 13480-4 and inspected again after repair.

8.1.1.2 Arc strikes and contact points with fused material shall be ground smooth and subjected to

surface examination appropriate to the material used.

8.1.2 Examination of weld quality by sample inspection

Where the required extent of non-destructive testing is less than 100 %, the specified NDT techniques

shall be employed at the earliest stage practicable in the fabrication process to ensure that sound welds

are achieved. The timing shall be agreed. Sample welds to be examined shall be:

a) randomly selected;

b) representative of a batch of welds.

At least one complete sample weld shall be examined over the whole length.

Where the number of sample welds required is small, combinations of thicker sections and smaller

diameters or thinner sections and greater diameters shall be given preference. All welders and welding

operators shall be covered.

A batch of welds is a quantity of welds, welded by one welder or welding operator, in accordance with a

specific welding procedure specification.

8.1.3 Imperfections revealed by sample inspection

When sample inspection reveals imperfections in one weld which are not acceptable to this European

Standard, the following shall apply for each defective weld:

a) Two additional welds of the same batch shall be examined by the same method(s);

b) If these additional welds are acceptable, the initial weld shall be repaired or replaced and re-

examined by the original method(s);

c) If any one of these additional welds required by a) reveal an unacceptable imperfection, two further

additional welds of the same batch shall be examined by the same method(s).

d) If the two additional welds required by c) are acceptable, the initial weld and the weld(s) examined

under c) with unacceptable imperfections shall be repaired or replaced and re-examined by the

original method(s).

e) If any one of the two additional welds required by c) reveal an unacceptable imperfection, all welds

in that batch represented by the sample inspection shall be examined and, as necessary, repaired or

replaced and re-examined.

When defining the represented sample inspection one can distinguish between:

1) piping installation at construction sites; or

2) piping manufacturing (series or mass production) in workshops.

1) is normally used if 2) is not applicable. For this piping, a group of welds represented by the same

sample inspection can be specified per piping system or per line number.

2) is normally used for piping integrated in packaged units such as machinery. For this piping a group of

welds represented by the same sample inspection can be specified as per 1) above or per production lot

or any other sample inspection system as long as the minimum extent of NDT of this standard is kept.

8.2 Circumferential butt, branch, fillet and seal welds

8.2.1 Extent of testing

The type of NDT required and its extent shall be determined in accordance with Table 8.2-1, taking into

account the category the piping is classified to and also wall thicknesses and material grouping.

For piping where creep or fatigue is the controlling factor in design:

a) additional extent of NDT is required by Table 8.2-1, Note f, critical areas shall be included in the test;

b) the quality level given in Table 8.4.2-1 for these service conditions shall be met.

For piping of pipe category 0, piping operating at or below 0,5 bar and piping of category I the following

special rules apply:

1) for piping of pipe category 0 and piping operating at or below 0,5 bar, the amount of NDT shall

be suitable to ensure weld quality;

If volumetric testing is applied, a minimum amount of 2 % is recommended.

2) when agreed in the purchase order, for piping of category I made of material of material group

1.1, 1.2 and 8.1 an amount of 2% volumetric testing can be sufficient, if satisfactory experience

exists;

when pneumatic testing is used, the extent of testing according to Table 8.2-1, Note g (test P according

t

to 9.3.3 f)) and Table 9.3.3-1 applies.

Table 8.2-1 — Extent of testing for circumferential, branch, fillet and seal welds

l l

Material group Category All welds Circumferential welds Branch welds Socket/fillet welds Seal welds

a

Volumetric

b,k

Surface testing Surface testing Volumetric testing Surface testing Surface testing

b

testing

h c h

RT/UT e MT/PT e RT/UT e MT/PT e MT/PT

VT Branch n Branch n n n

mm c

en MT/PT %

i

% diameter diameter

% mm % mm % mm % mm %

I

1.1, 5 0

All 0 0 0

g f,g

(10) (5)

1.2, II 100 All All All

f,g

(5)

8.1

III 10 10 > DN 100 > 15 10 10 10

≤ 30 5 10

I

1.3, 1.4, 1.5,

> 30 10 10

e e e

All All 0 All 10 All 5

2.1, 2.2,

≤ 30 5 10

4.1, 4.2, II

> 30 10 10

g

5.1, 5.2,

100 10 (25)

8.2, 8.3,

≤ 30 5

f,g

(25)

9.1, 9.2, 9.3,

III All > DN 100 > 15 10 All 25 All 25

10.1, 10.2 10

> 30 10

d f,g

(25 )

≤ 30 10 25

I

> 30 25 25

25 25 25 10

≤ 30 25 25

3.1, 3.2, 3.3, 5.3,

5.4,

II

> 30 25

d f,g

6.1, 6.2, All > DN 100 > 15 All All

100 (25 )

6.3, 6.4,

≤ 30 100

7.1, 7.2

f,g

(100)

III 100 100 100 100

> 30 100 25

d f,g

(100 )

a

Material group, see CEN ISO/TR 15608:2017.

b

For the selection of the appropriate NDT-method for volumetric testing, see 8.4.4.3.

c

See 8.4.4.2.

d

Additional testing for transverse defects from weld surface (see EN ISO 17640:2018).

e

Only if PWHT has been carried out.

f

Value in brackets applies to piping where creep or fatigue is the controlling factor in design.

g

Value in brackets applies to piping with pneumatic pressure test with 1,1 times the maximum allowable pressure.

h

en is the nominal thickness of the branch pipe at the weld (see W3, W3.1 and W6 in EN 13480-4:2024, Figure 9.14.4–1 and Figure 9.14.4–2).

i

For parts without DN designation d > 120 mm can be used instead of DN > 100.

i

k

Volumetric testing is required if both criteria (branch diameter and nominal thickness) are satisfied.

l

The number of welds shall be used up to DN ≤ 600, from DN > 600, the total length of the welds can be used.

8.2.2 Dissimilar metal joints

The test methods and extent of testing for welds between different materials (e.g. austenitic, nickel-based

alloys) shall be according to the material group with the higher extent of testing which is applicable to the

base materials.

8.2.3 Transverse cracks

For material groups 5.3, 5.4 and 6 with wall thicknesses above 30 mm testing for transverse defects from

weld surface (see EN ISO 17640:2018, testing level C) is required. For extent of testing see Table 8.2-1.

8.3 Longitudinal welds

Longitudinal welds, except those in components made to material specifications acceptable to this

European Standard (e.g. longitudinal welded steel tubes for pressure purposes acc. EN 10217:2019 series),

shall be subject to the level of NDT appropriate to the joint coefficient required (see Table 8.3-1).

Table 8.3-1 — Extent of NDT for longitudinal welds

a b

Joint coefficient VT MT or PT RT or UT

z

% % %

z ≤ 0,7 100 0 0

100 10 10

0,7 < z ≤ 0,85

100 100 100

0,85 < z ≤ 1,0

a

See 8.4.4.2

b

See 8.4.4.3

8.4 Testing methods

8.4.1 General

The testing methods specified in the following clauses shall be performed in accordance with written

procedures, and, where appropriate, with instructions.

8.4.2 Quality level

The quality level shall be in accordance with Table 8.4.2-1.

Table 8.4.2-1 — Quality level according to EN ISO 5817:2023 depending on service conditions

and test methods

Surface Imperfections and Imperfections in Internal Imperfections

joint geometry

Service conditions

Visual testing VT Surface testing Volumetric testing

Standard level C C C

Fatigue B B C

Creep B B B

8.4.3 Personnel qualification

Testing shall be carried out by an individual certified to at least EN ISO 9712:2022, level 1, under the

supervision of personnel certified to level 2 or level 3 who shall also be responsible for the evaluation of

the results.

Visual testing shall be performed and evaluated by an individual with sufficient knowledge and

experience with the relevant standards and specifications. Certifications in accordance with

EN ISO 9712:2022 are not required.

Ultrasonic testing shall be performed and evaluated by an individual certified to at least

EN ISO 9712:2022, level 2.

Prior to carrying out any testing activity, the fabricator shall verify that the personnel are qualified for

the relevant work. This shall be reviewed by the manufacturer.

NOTE Qualifications and certifications according to EN 473:2008 remain valid until their expiring date.

8.4.4 Selection of NDT methods and testing techniques

8.4.4.1 Visual inspection and testing

The term “visual inspection and testing” shall be understood to mean observation of the portion of

components, joints, and other piping elements and supports that are or can be exposed to view before,

during, or after manufacture, fabrication, assembly or installation.

NOTE This inspection can include verification of dimensions, weld edge, joint preparation, alignment, joining

(welding, bonding, brazing, or other methods of joining) supports, assembly and installation.

Visual testing of welds shall be in accordance to EN ISO 17635:2016, Table A.1 (VT).

8.4.4.2 Surface testing

Methods shall be MT or PT according to EN ISO 17635:2016, Table 2.

Testing techniques shall be in accordance to EN ISO 17635:2016, Table A.2 (PT) and Table A.3 (MT).

For ferritic steels MT is recommended instead of PT. For austenitic-ferritic steels PT is recommended.

8.4.4.3 Volumetric testing

Methods shall be selected according to EN ISO 17635:2016, Table 3.

Testing techniques shall be in accordance to EN ISO 17635:2016, Tables A.5 (RT-F), A.6 (RT-D), (RT-CR)

or (DDA), A.7 (UT), A.8 (TOFD) and A.9 (PAUT).

NDT techniques A.7, A.8 and A.9 can be used for other than ferritic materials providing they are proven

to satisfy the required quality level given in Table 8.4.2-1.

8.4.5 Testing techniques and acceptance levels

Depending on the quality levels of Table 8.4.2-1 testing techniques and levels and acceptance levels shall

be selected according to EN ISO 17635:2016, Annex A.

8.5 Reports

Reports of non-destructive testing shall be drawn up in accordance with the European Standard for the

testing method.

8.6 Weld repairs

Welding procedures shall be in accordance with EN 13480-4:2024.

Repaired welds shall be retested with the same NDT methods and testing techniques.

NOTE The evaluation of weld imperfections can require additional inspections durin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...