EN 14917:2021

(Main)Metal bellows expansion joints for pressure applications

Metal bellows expansion joints for pressure applications

This document specifies the requirements for design, manufacture and installation of metal bellows expansion joints with circular cross section for pressure applications with maximum allowable pressure greater than 0,5 bar.

Kompensatoren mit metallischen Bälgen für Druckanwendungen

Dieses Dokument legt Anforderungen an die Konstruktion, Herstellung und den Einbau von Kompensatoren mit metallischen Bälgen mit kreisförmigem Querschnitt für Druckanwendungen mit einem maximal zulässigen Druck über 0,5 bar.

Compensateurs de dilatation à soufflets métalliques pour appareils à pression

La présente Norme européenne spécifie les exigences de conception, de fabrication et d’installation applicables aux compensateurs de dilatation à soufflets métalliques à section transversale circulaire pour des applications sous pression, avec des pressions maximales admissibles supérieures à 0,5 bar.

Kompenzatorji s kovinskimi mehovi v tlačnih cevovodih

General Information

- Status

- Published

- Publication Date

- 27-Jul-2021

- Withdrawal Date

- 30-Jan-2022

- Technical Committee

- CEN/TC 342 - Metal hoses, hose assemblies, bellows and expansion joints

- Drafting Committee

- CEN/TC 342/WG 2 - Expansion joints

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 28-Jul-2021

- Due Date

- 15-Apr-2021

- Completion Date

- 28-Jul-2021

Relations

- Effective Date

- 04-Aug-2021

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14917:2021 (EN 14917:2021) is the European standard that specifies requirements for the design, manufacture and installation of metal bellows expansion joints with circular cross section for pressure applications. It applies to expansion joints used in systems where the maximum allowable pressure is greater than 0.5 bar. This edition supersedes EN 14917:2009+A1:2012 and is published by CEN and adopted by SIST.

Key topics and technical requirements

The standard provides comprehensive technical guidance across the product lifecycle, including:

- Classification of expansion joints (axial, angular, lateral, universal, pressure-balanced) and of component parts (main pressure-bearing parts, attachments, other parts).

- Materials: requirements for pressure-bearing parts (bellows and other components), ductility and brittle fracture considerations, and material documentation/traceability.

- Design principles and symbols, allowable stresses, additional loading, and detailed bellows design methods (U-shaped unreinforced, U-shaped reinforced, toroidal), fatigue assessment, equivalent axial displacement, and forces/moments including torsion.

- Internal sleeves and flow velocity/design conditions where applicable.

- Hardware and permanent joints design parameters and assembly.

- Manufacturing processes: forming, heat treatment, tolerances, repairs and rework, and production testing.

- Testing, inspection and documentation: in‑process inspection, non‑destructive testing (NDT) of welds, acceptance levels, personnel qualification, final assessment, and required documentation and certification.

- Marking, labelling, handling and installation instructions, packaging/storage and guidance for restrained vs. unrestrained expansion joints.

- Annexes include categorization of expansion joints and fluid groups.

Practical applications and users

This standard is essential for professionals involved with pressure-retaining pipework and systems that require flexible connections to absorb thermal movements, vibration and misalignment. Typical users include:

- Design engineers specifying expansion joints for petrochemical, power generation, oil & gas, HVAC, and process industries.

- Manufacturers and fabricators producing metal bellows expansion joints to meet traceability, welding and testing requirements.

- Quality, inspection and NDT personnel ensuring compliance with production and final testing criteria.

- Procurement and maintenance teams selecting certified components and following installation/handling best practices.

- Plant engineers and integrators responsible for piping layout, supports and pressure system safety.

Related standards and references

- Supersedes: EN 14917:2009+A1:2012 (now replaced by EN 14917:2021 / EN 14917:2021).

- Classified under ICS 23.040.99 (pipeline components).

(Consult national CEN member bodies or SIST for bibliographic references and applicable national implementations.)

Keywords: metal bellows expansion joints, EN 14917, pressure applications, design manufacture installation, bellows design, fatigue, NDT, pressure-bearing parts, expansion joint standards.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14917:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metal bellows expansion joints for pressure applications". This standard covers: This document specifies the requirements for design, manufacture and installation of metal bellows expansion joints with circular cross section for pressure applications with maximum allowable pressure greater than 0,5 bar.

This document specifies the requirements for design, manufacture and installation of metal bellows expansion joints with circular cross section for pressure applications with maximum allowable pressure greater than 0,5 bar.

EN 14917:2021 is classified under the following ICS (International Classification for Standards) categories: 23.040.99 - Other pipeline components. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14917:2021 has the following relationships with other standards: It is inter standard links to EN 14917:2009+A1:2012, EN ISO 9445-1:2010, EN ISO 15609-6:2013, EN 10222-4:2017, EN 13445-3:2014, EN ISO 15614-2:2005, EN ISO 15609-2:2019, EN 13184:2001, EN 10222-3:2017, EN ISO 15614-6:2006, EN ISO 15613:2004, EN ISO 9606-1:2017, EN 10222-2:2017, EN ISO 15614-11:2002, EN ISO 15614-1:2017/A1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14917:2021 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14917:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2021

Nadomešča:

SIST EN 14917:2009+A1:2012

Kompenzatorji s kovinskimi mehovi v tlačnih cevovodih

Metal bellows expansion joints for pressure applications

Kompensatoren mit metallischen Bälgen für Druckanwendungen

Compensateurs de dilatation à soufflets métalliques pour appareils à pression

Ta slovenski standard je istoveten z: EN 14917:2021

ICS:

23.040.99 Drugi sestavni deli za Other pipeline components

cevovode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14917

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2021

EUROPÄISCHE NORM

ICS 23.040.99 Supersedes EN 14917:2009+A1:2012

English Version

Metal bellows expansion joints for pressure applications

Compensateurs de dilatation à soufflets métalliques Kompensatoren mit metallischen Bälgen für

pour appareils à pression Druckanwendungen

This European Standard was approved by CEN on 21 June 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14917:2021 E

worldwide for CEN national Members.

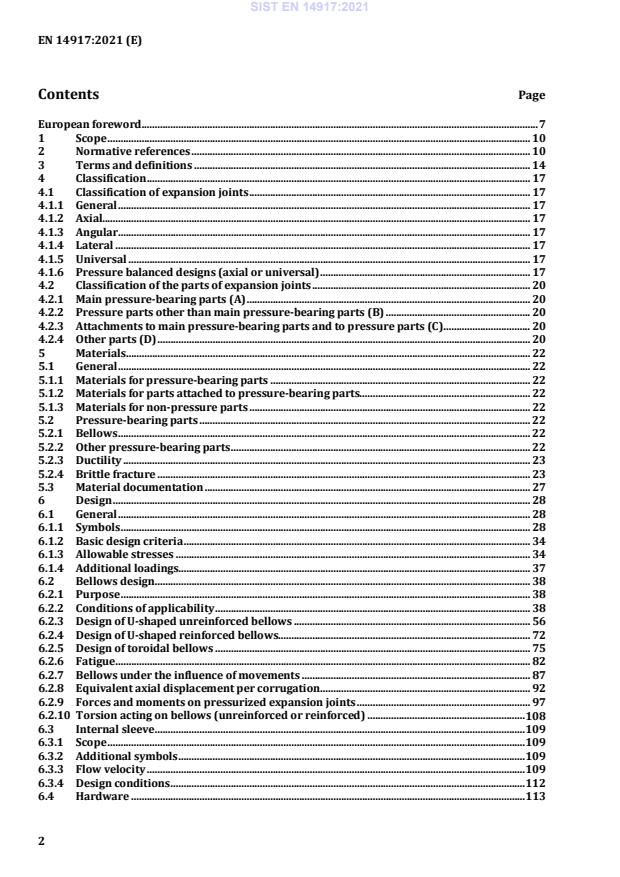

Contents Page

European foreword . 7

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 14

4 Classification . 17

4.1 Classification of expansion joints . 17

4.1.1 General . 17

4.1.2 Axial. 17

4.1.3 Angular . 17

4.1.4 Lateral . 17

4.1.5 Universal . 17

4.1.6 Pressure balanced designs (axial or universal) . 17

4.2 Classification of the parts of expansion joints . 20

4.2.1 Main pressure-bearing parts (A) . 20

4.2.2 Pressure parts other than main pressure-bearing parts (B) . 20

4.2.3 Attachments to main pressure-bearing parts and to pressure parts (C) . 20

4.2.4 Other parts (D) . 20

5 Materials . 22

5.1 General . 22

5.1.1 Materials for pressure-bearing parts . 22

5.1.2 Materials for parts attached to pressure-bearing parts. 22

5.1.3 Materials for non-pressure parts . 22

5.2 Pressure-bearing parts . 22

5.2.1 Bellows . 22

5.2.2 Other pressure-bearing parts . 22

5.2.3 Ductility . 23

5.2.4 Brittle fracture . 23

5.3 Material documentation . 27

6 Design . 28

6.1 General . 28

6.1.1 Symbols . 28

6.1.2 Basic design criteria . 34

6.1.3 Allowable stresses . 34

6.1.4 Additional loadings. 37

6.2 Bellows design . 38

6.2.1 Purpose . 38

6.2.2 Conditions of applicability . 38

6.2.3 Design of U-shaped unreinforced bellows . 56

6.2.4 Design of U-shaped reinforced bellows. 72

6.2.5 Design of toroidal bellows . 75

6.2.6 Fatigue . 82

6.2.7 Bellows under the influence of movements . 87

6.2.8 Equivalent axial displacement per corrugation . 92

6.2.9 Forces and moments on pressurized expansion joints . 97

6.2.10 Torsion acting on bellows (unreinforced or reinforced) . 108

6.3 Internal sleeve . 109

6.3.1 Scope . 109

6.3.2 Additional symbols . 109

6.3.3 Flow velocity . 109

6.3.4 Design conditions . 112

6.4 Hardware . 113

6.4.1 General . 113

6.4.2 Design parameters . 113

6.4.3 Hardware parts . 115

6.4.4 Permanent joints . 116

7 Manufacturing. 118

7.1 General . 118

7.2 Materials . 118

7.2.1 General . 118

7.2.2 Material traceability . 118

7.3 Permanent joints . 119

7.3.1 General . 119

7.3.2 Process and personal . 119

7.3.3 Repair and rework during manufacturing . 120

7.4 Forming of the bellows . 120

7.4.1 Forming processes . 120

7.4.2 Heat treatment. 121

7.5 Tolerances . 122

7.5.1 General . 122

7.5.2 Bellows . 122

7.5.3 Expansion joint . 123

7.6 Production tests . 123

8 Testing, inspection and documentation . 124

8.1 General . 124

8.2 Abbreviations . 124

8.3 Documents . 124

8.4 In-process inspection and testing . 125

8.4.1 General . 125

8.4.2 Materials . 125

8.4.3 Permanent joints . 125

8.4.4 Non-destructive testing of welds . 127

8.5 NDT methods . 134

8.5.1 Quality level . 134

8.5.2 Acceptance levels and testing techniques . 134

8.5.3 Non-destructive testing Personnel qualifications and approval . 135

8.5.4 Non-destructive testing documentation. 135

8.6 Final assessment and documentation . 137

8.6.1 General . 137

8.6.2 Final inspection . 138

8.7 Documentation . 140

8.7.1 Final documentation package . 140

8.7.2 Declaration/certification . 140

8.7.3 Operating instructions . 141

9 Marking and labelling . 141

10 Handling and installation . 141

10.1 General instructions . 141

10.2 Packaging and storage . 142

10.3 Installation . 142

10.4 Unrestrained expansion joints . 142

10.5 Restrained expansions joints . 142

Annex A (informative) Categories of expansion joints . 143

A.1 General . 143

A.2 Determination of expansion joints categories . 143

A.3 Fluid groups . 143

A.3.1 General . 143

A.3.2 Group 1. 143

A.3.3 Group 2. 144

A.4 Technical requirements. 144

A.4.1 Expansion joints for vessels . 144

A.4.2 Expansion joints for piping . 144

A.4.3 Sound engineering practice (SEP) . 145

A.5 Expansion joint category . 145

Annex B (informative) Specification for materials 1.4828, 1.4876, 2.4360 and 2.4858 . 147

Annex C (informative) Incorporation of expansion joints into piping or pressure vessels . 154

C.1 General . 154

C.2 Specific symbols and definitions . 155

C.3 Application criteria for expansion joints in piping . 156

C.3.1 General . 156

C.3.2 Use of axial expansion joints . 156

C.3.3 Use of restraint expansion joints . 162

C.3.4 Use of universal expansion joints . 168

C.3.5 Indeterminate configurations of expansion joints . 170

C.4 Application criteria for expansion joints in pressure vessels . 173

C.4.1 General . 173

C.4.2 Axial expansion joint installed in the shell . 173

C.4.3 Axial expansion joint installed at the floating head . 174

Annex D (informative) Calculation methods for systems of pipes containing expansion joints . 175

D.1 General . 175

D.1.1 Preliminary remarks . 175

D.1.2 Determining movement values . 175

D.1.3 Thermal expansion . 175

D.2 Approximate calculation of bellows movement . 177

D.2.1 General . 177

D.2.2 Hinged systems . 178

D.2.3 Definitions . 178

D.3 Exact calculation of bellows movement . 182

D.3.1 Two hinges in a plane system (Z-system) . 182

D.3.2 Two gimbals in a three-dimensional system (Z-system) . 183

D.3.3 Three hinges in a plane system (U-system) . 184

D.3.4 Three hinges in a plane system (L-system) . 185

D.3.5 Three hinges in a three-dimensional system (Z-system) . 187

D.4 Calculation of forces and moments . 190

Annex E (informative) Explanatory notes on the design of expansion bellows. 191

E.1 General . 191

E.2 Calculation design . 191

E.3 Types of bellows . 192

E.3.1 Corrugation shape. 192

E.3.2 Number of plies . 192

E.4 Fatigue life expectancy . 192

E.5 Instability . 193

E.5.1 General . 193

E.5.2 Column instability . 193

E.5.3 In-plane instability . 193

E.5.4 Buckling . 193

E.6 Bellows spring rate . 194

Annex F (informative) Procedure for setting-up a design fatigue curve . 196

F.1 General . 196

F.2 Procedure for setting up a design fatigue curve for expansion bellows. 196

F.2.1 General . 196

F.2.2 Number of tests . 196

F.2.3 Extrapolation range . 196

F.2.4 Manufacturing methods . 196

F.2.5 Bellows material . 197

F.3 Tests . 197

F.3.1 Movement . 197

F.3.2 Test pressure. 197

F.3.3 Other test conditions . 197

F.3.4 Fatigue test equipment . 198

F.4 Evaluation of the test results . 199

F.5 Linear regression . 204

Annex G (informative) Polynomial approximations for coefficients C , C , C . 205

p f d

G.1 Coefficient C . 205

p

G.2 Coefficient C . 206

f

G.3 Coefficient C . 207

d

G.4 Linear interpolation . 208

Annex H (informative) Required design data and information . 210

H.1 Required design conditions . 210

H.2 Additional information . 210

Annex I (informative) Expansion joints risk analyses . 211

Annex J (informative) Additional material properties. 212

Annex K (normative) Hardware calculation . 217

K.1 General . 217

K.2 Additional symbols . 217

K.3 Force due to pressure. 220

K.4 Tie bar . 221

K.4.1 General . 221

K.4.2 Tie bar in tension . 221

K.4.3 Tie bar in compression . 222

K.5 Pin . 222

K.6 Lug with bore . 225

K.6.1 General . 225

K.6.2 Forces due to pressure. 225

K.6.3 Stresses due to reaction force . 226

K.7 Gimbal, square and round . 227

K.7.1 General . 227

K.7.2 Stresses in bored section . 227

K.7.3 Square type gimbal. 228

K.7.4 Round type gimbal . 231

K.8 Attachment plate. 233

K.8.1 Attachment plate (closed/open) with 2 restraining parts . 233

K.8.2 Circular attachment plate with 3 or more tie bars valid up to DN 800 . 241

K.9 Lug-plate connection (hinge/gimbal) . 244

K.9.1 General . 244

K.9.2 Lug-plate for form-lock connection . 245

K.9.3 Lug-plate for welded buttonhole connection . 248

K.10 Tie bar and lug attachment on flanges . 249

K.10.1 Integral flange . 249

K.10.2 Plate welded on flange . 253

K.11 Gusset . 256

K.12 Gusset with reinforcing rings. 256

K.12.1 General . 256

K.12.2 Basic definitions . 258

K.12.3 Stresses in the gussets . 259

K.12.4 Stresses in the ring and pipe . 259

K.12.5 Stresses in welds a , a and a . 260

7 8 9

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2014/68/EU . 262

Bibliography . 264

European foreword

This document (EN 14917:2021) has been prepared by Technical Committee CEN/TC 342 “Metal hoses,

hose assemblies, bellows and expansion joints”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2022, and conflicting national standards shall

be withdrawn at the latest by January 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14917:2009+A1:2012.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Modifications to EN 14917:2009+A1:2012:

— adaptation to Directive 2014/68/EU;

— general revision and correction;

— complete revision and restructuring of Clause 6, i.a.;

— addition of design in the creep range;

— modification of stress calculation for internal pressure capability;

— reformulation of column instability calculation;

— modification of in-plane instability calculation;

— harmonisation of fatigue calculation for all bellows types and introduction of 4 fatigue curves for

different material classes;

— extension of material characteristics for calculating forces and moments on pressurised

expansion joints;

— addition of Annex K for stress calculation of hardware;

— revision of Testing, inspection and documentation;

— revision of material properties in Annex B and Annex J;

— correction of Coefficient C .

p

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Metal bellows expansion joints are used as parts in pressure vessels or piping components.

If an expansion joint is designed and manufactured covered by EU-Directive 2014/68/EU a risk

assessment has to be done. The possible risks of an expansion joint and how they have been dealt in this

document are described in Annex I.

1 Scope

This document specifies the requirements for design, manufacture and installation of metal bellows

expansion joints with circular cross section for pressure applications with maximum allowable pressure

greater than 0,5 bar.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 764-4:2014, Pressure equipment — Part 4: Establishment of technical delivery conditions for metallic

materials

EN 764-5:2014, Pressure equipment — Part 5: Inspection documentation of metallic materials and

compliance with the material specification

EN 1092-1:2018, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 1: Steel flanges

EN 1591-1:2013, Flanges and their joints — Design rules for gasketed circular flange connections — Part 1:

Calculation

EN 1759-1:2004, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, Class

designated — Part 1: Steel flanges, NPS 1/2 to 24

EN 10028-1:2017, Flat products made of steels for pressure purposes — Part 1: General requirements

EN 10028-2:2017, Flat products made of steels for pressure purposes — Part 2: Non-alloy and alloy steels

with specified elevated temperature properties

EN 10028-3:2017, Flat products made of steels for pressure purposes — Part 3: Weldable fine grain steels,

normalized

EN 10028-4:2017, Flat products made of steels for pressure purposes — Part 4: Nickel alloy steels with

specified low temperature properties

EN 10028-7:2016, Flat products made of steels for pressure purposes — Part 7: Stainless steels

EN 10204:2004, Metallic products — Types of inspection documents

EN 10216-1:2013, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 1:

Non-alloy steel tubes with specified room temperature properties

EN 10216-2:2013+A1:2019, Seamless steel tubes for pressure purposes — Technical delivery conditions —

Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-3:2013, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 3:

Alloy fine grain steel tubes

EN 10216-4:2013, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 4:

Non-alloy and alloy steel tubes with specified low temperature properties

EN 10216-5:2013, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 5:

Stainless steel tubes

EN 10217-1:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 1:

Electric welded and submerged arc welded non-alloy steel tubes with specified room temperature properties

EN 10217-2:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 2:

Electric welded non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10217-3:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 3:

Electric welded and submerged arc welded alloy fine grain steel tubes with specified room, elevated and low

temperature properties

EN 10217-4:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 4:

Electric welded non-alloy steel tubes with specified low temperature properties

EN 10217-5:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 5:

Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10217-6:2019, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 6:

Submerged arc welded non-alloy steel tubes with specified low temperature properties

EN 10217-7:2014, Welded steel tubes for pressure purposes — Technical delivery conditions — Part 7:

Stainless steel tubes

EN 10222-2:2017, Steel forgings for pressure purposes — Part 2: Ferritic and martensitic steels with

specified elevated temperatures properties

EN 10222-3:2017, Steel forgings for pressure purposes — Pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...