EN 15194:2009+A1:2011

(Main + Amendment)Cycles - Electrically power assisted cycles - EPAC Bicycles

Cycles - Electrically power assisted cycles - EPAC Bicycles

This European Standard is intended to cover electrically power assisted cycles of a type which have a maximum continuous rated power of 0,25 kW, of which the output is progressively reduced and finally cut off as the vehicle reaches a speed of 25 km/h, or sooner, if the cyclist stops pedalling.

This European Standard specifies safety requirements and test methods for the assessment of the design and assembly of electrically power assisted bicycles and sub-assemblies for systems using battery voltage up to 48 VDC or integrated a battery charger with a 230 V input.

This European Standard specifies requirements and test methods for engine power management systems, electrical circuits including the charging system for the assessment of the design and assembly of electrically power assisted cycles and sub-assemblies for systems having a voltage up to and including 48 VDC or integrated a battery charger with a 230 V input.

Fahrräder - Elektromotorisch unterstützte Räder - EPAC-Fahrräder

Diese Europäische Norm ist für elektromotorisch unterstützte Rädertypen mit einer maximalen Nenndauer-leistung von 0,25 kW vorgesehen, wobei die Leistungsabgabe schrittweise reduziert und schließlich abgeschaltet wird, sobald das Fahrzeug eine Geschwindigkeit von 25 km/h erreicht oder vorher, wenn der Fahrer den Pedalantrieb einstellt.

Diese Europäische Norm legt sicherheitstechnische Anforderungen und Prüfverfahren zur Bewertung der Konstruktion und des Zusammenbaus von elektromotorisch unterstützten Fahrrädern und deren Baugruppen für Anlagen mit einer Batterie Spannung bis 48 V Gleichstrom oder einem eingebauten Batterieladegerät mit einem Spannungseingang von 230 V fest.

Diese Europäische Norm legt Anforderungen und Prüfverfahren für Motorleistungs Managementsysteme, elektrische Stromkreise einschließlich des Ladesystems, zur Bewertung der Konstruktion und des Zusammen-baus von elektromotorisch unterstützen Rädern und deren Baugruppen für Systeme mit einer Spannung bis einschließlich 48 V Gleichstrom oder einem eingebauten Batterieladegerät mit einem Spannungseingang von 230 V fest.

Cycles - Cycles à assistance électrique - Bicyclettes EPAC

La présente norme européenne s’applique aux cycles à assistance électrique d’une puissance nominale continue

maximale de 0,25 kW, dont l’alimentation est réduite progressivement et finalement interrompue lorsque le véhicule

atteint une vitesse de 25 km/h, ou plus tôt, si le cycliste arrête de pédaler.

La présente norme européenne spécifie les exigences de sécurité et les méthodes d’essai relatives à l’évaluation

de la conception et de l’assemblage des bicyclettes à assistance électrique et des sous-ensembles dédiés

à des systèmes utilisant une tension de batterie allant jusqu’à 48 VDC ou bien un chargeur de batterie intégré avec

une entrée de 230 V.

La présente norme européenne spécifie les exigences et les méthodes d’essai relatives aux systèmes de gestion de

la puissance du moteur, aux circuits électriques y compris au système de chargement pour évaluer la conception et

l’assemblage des cycles à assistance électriques et des sous-ensembles dédiés à des systèmes présentant une

tension allant jusqu’à 48 V DC inclus ou intégrant un chargeur de batterie avec une entrée de 230 V.

Kolesa - Kolesa z električnim pomožnim pogonom - Kolo KEPP

Ta evropski standard je namenjen obravnavi koles z električnim pomožnim pogonom, ki imajo največjo trajno nazivno moč 0,25 kW, pri čemer se izhodna moč postopno zmanjšuje in končno prekine, ko vozilo doseže hitrost 25 km/h ali prej, če kolesar preneha poganjati pedale. Ta evropski standard določa varnostne zahteve in preskusne metode za oceno načrta in montaže koles z električnim pomožnim pogonom ter podsklopov za sisteme, ki uporabljajo akumulator z enosmerno napetostjo do 48 V ali integrirani polnilnik akumulatorja z vhodno močjo 230 V. Ta evropski standard določa zahteve in preskusne metode za sisteme upravljanja porabe motorja, električne tokokroge, vključno s sistemom polnjenja, za oceno načrta in montaže koles z električnim pomožnim pogonom ter podsklopov za sisteme, ki uporabljajo akumulator z enosmerno napetostjo do vključno 48 V ali integrirani polnilnik akumulatorja z vhodno močjo 230 V.

General Information

- Status

- Withdrawn

- Publication Date

- 29-Nov-2011

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 333 - Cycles

- Drafting Committee

- CEN/TC 333/WG 5 - Electric power assisted cycles

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 04-Oct-2017

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 14-Nov-2012

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

EN 15194:2009+A1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Cycles - Electrically power assisted cycles - EPAC Bicycles". This standard covers: This European Standard is intended to cover electrically power assisted cycles of a type which have a maximum continuous rated power of 0,25 kW, of which the output is progressively reduced and finally cut off as the vehicle reaches a speed of 25 km/h, or sooner, if the cyclist stops pedalling. This European Standard specifies safety requirements and test methods for the assessment of the design and assembly of electrically power assisted bicycles and sub-assemblies for systems using battery voltage up to 48 VDC or integrated a battery charger with a 230 V input. This European Standard specifies requirements and test methods for engine power management systems, electrical circuits including the charging system for the assessment of the design and assembly of electrically power assisted cycles and sub-assemblies for systems having a voltage up to and including 48 VDC or integrated a battery charger with a 230 V input.

This European Standard is intended to cover electrically power assisted cycles of a type which have a maximum continuous rated power of 0,25 kW, of which the output is progressively reduced and finally cut off as the vehicle reaches a speed of 25 km/h, or sooner, if the cyclist stops pedalling. This European Standard specifies safety requirements and test methods for the assessment of the design and assembly of electrically power assisted bicycles and sub-assemblies for systems using battery voltage up to 48 VDC or integrated a battery charger with a 230 V input. This European Standard specifies requirements and test methods for engine power management systems, electrical circuits including the charging system for the assessment of the design and assembly of electrically power assisted cycles and sub-assemblies for systems having a voltage up to and including 48 VDC or integrated a battery charger with a 230 V input.

EN 15194:2009+A1:2011 is classified under the following ICS (International Classification for Standards) categories: 43.120 - Electric road vehicles; 43.150 - Cycles. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15194:2009+A1:2011 has the following relationships with other standards: It is inter standard links to EN 15194:2009/FprA1, EN 15194:2009, EN 15194:2017, ISO 11452-4:2011, EN IEC 55014-1:2021, IEC 60068-2-75:1997, EN IEC 55014-2:2021, EN IEC 61000-3-2:2019, EN 60034-1:2010, ISO 2575:2010, EN 61000-3-3:2013, EN 14764:2005, EN ISO 11348-1:1998, prEN 1459-1, EN 12090:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15194:2009+A1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Fahrräder - Elektromotorisch unterstützte Räder - EPAC-FahrräderCycles - Cycles à assistance électrique - Bicyclettes EPACCycles - Electrically power assisted cycles - EPAC Bicycles43.150KolesaCycles43.120Electric road vehiclesICS:Ta slovenski standard je istoveten z:EN 15194:2009+A1:2011SIST EN 15194:2009+A1:2012en,de01-februar-2012SIST EN 15194:2009+A1:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15194:2009+A1

November 2011 ICS 43.120; 43.150 Supersedes EN 15194:2009English Version

Cycles - Electrically power assisted cycles - EPAC Bicycles

Cycles - Cycles à assistance électrique - Bicyclettes EPAC Fahrräder - Elektromotorisch unterstützte Räder - EPAC-Fahrräder This European Standard

was approved by CEN on 22 November 2008 and includes Amendment 1 approved by CEN on 8 October 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15194:2009+A1:2011: ESIST EN 15194:2009+A1:2012

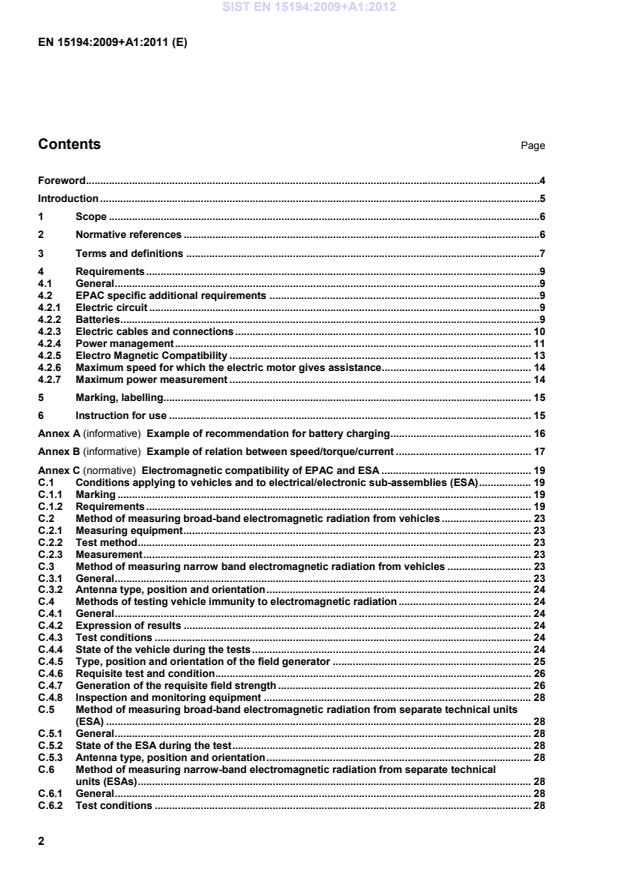

Example of recommendation for battery charging . 16Annex B (informative)

Example of relation between speed/torque/current . 17Annex C (normative)

Electromagnetic compatibility of EPAC and ESA . 19C.1 Conditions applying to vehicles and to electrical/electronic sub-assemblies (ESA) . 19C.1.1 Marking . 19C.1.2 Requirements . 19C.2 Method of measuring broad-band electromagnetic radiation from vehicles . 23C.2.1 Measuring equipment . 23C.2.2 Test method . 23C.2.3 Measurement . 23C.3 Method of measuring narrow band electromagnetic radiation from vehicles . 23C.3.1 General . 23C.3.2 Antenna type, position and orientation . 24C.4 Methods of testing vehicle immunity to electromagnetic radiation . 24C.4.1 General . 24C.4.2 Expression of results . 24C.4.3 Test conditions . 24C.4.4 State of the vehicle during the tests . 24C.4.5 Type, position and orientation of the field generator . 25C.4.6 Requisite test and condition . 26C.4.7 Generation of the requisite field strength . 26C.4.8 Inspection and monitoring equipment . 28C.5 Method of measuring broad-band electromagnetic radiation from separate technical units (ESA) . 28C.5.1 General . 28C.5.2 State of the ESA during the test . 28C.5.3 Antenna type, position and orientation . 28C.6 Method of measuring narrow-band electromagnetic radiation from separate technical units (ESAs) . 28C.6.1 General . 28C.6.2 Test conditions . 28SIST EN 15194:2009+A1:2012

Maximum power measurement - Alternative method . 32D.1 Generalities . 32D.2 Test conditions . 32D.3 Test procedure . 32Bibliography . 34 SIST EN 15194:2009+A1:2012

!". According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 15194:2009+A1:2012

This European Standard has been developed in response to demand throughout Europe. Its aim is to provide a standard for the assessment of electrically powered cycles of a type which are excluded from type approval by Directive 2002/24/EC. Due to the limitation of the voltage to 48 VDC, there are no special requirements applicable to the EPAC in regard to protection against electrical hazards.

EPACs are vehicles which use the same traffic areas as cars, lorries and motorcycles, which is predominantly the street. For this reason the products concerning EMC-testing have the same basic conditions. Chapter 8 of the EC Directive 97/24 contains a very high value concerning the immunity test of electronic components with 30 V/m, nevertheless based on the application area it comes up of the implementation. Manipulation of the electronic system of EPAC by other source of interference in the scope of the public road traffic could signify considerable risks of safety regulations for the user of EPAC. The standards EN 61000-6-1 as well as EN 61000-6-3 are standards for appliances in residential, commercial and light-industrial environments which do not reach the values for the EMC immunity-test necessary in the road traffic area. In these standards the EMC immunity of the electric and electronic systems will be tested only with 3 V/m, which is the tenth part of the requirements in chapter 8 of the EC Directive 97/24. These standards are unsuitable to obtain the urgent and necessary security level. SIST EN 15194:2009+A1:2012

This European Standard specifies safety requirements and test methods for the assessment of the design and assembly of electrically power assisted bicycles and sub-assemblies for systems using battery voltage up to 48 VDC or integrated a battery charger with a 230 V input.

This European Standard specifies requirements and test methods for engine power management systems, electrical circuits including the charging system for the assessment of the design and assembly of electrically power assisted cycles and sub-assemblies for systems having a voltage up to and including 48 VDC or integrated a battery charger with a 230 V input.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 14764:2005, City and trekking bicycles Safety requirements and test methods

EN 55014-1, Electromagnetic compatibility Requirements for household appliances, electric tools and similar apparatus Part 1: Emission

EN 55014-2, Electromagnetic compatibility Requirements for household appliances, electric tools and similar apparatus Part 2: Immunity product family standard EN 60034-1, Rotating electrical machines Part 1: Rating and performance

EN 61000-3-2, Electromagnetic compatibility (EMC) Part 3-2: Limits Limits for harmonic current emissions (equipment input current ≤ 16A per phase)

EN 61000-3-3, Electromagnetic compatibility (EMC) Part 3-3: Limits Section 3: Limitation of voltage fluctuations and flicker in low-voltage supply systems for equipment with rated current ≤ 16 A ISO 2575, Road vehicles Symbols for controls, indicators and tell tales ISO 11451-1, Road vehicles Vehicle test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 1: General principles and terminology ISO 11452-1, Road vehicles Component test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 1: General principles and terminology ISO 11452-2, Road vehicles Component test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 2: Absorber-lined shielded enclosure ISO 11452-3, Road vehicles Component test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 3: Transverse electromagnetic mode (TEM) cell ISO 11452-4, Road vehicles Component test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 4: Bulk current injection (BCI) ISO 11452-5, Road vehicles Component test methods for electrical disturbances from narrowband radiated electromagnetic energy Part 5: Stripline SIST EN 15194:2009+A1:2012

vehicle that has at least two wheels and is propelled solely or mainly by the muscular energy of the person in that vehicle, in particular by means of pedals

3.2 bicycle two-wheeled cycle

3.3 fully assembled bicycle

bicycle fitted with all the components necessary for its intended use

3.4 electrically power assisted cycle EPAC cycle, equipped with pedals and an auxiliary electric motor, which cannot be propelled exclusively by means of this auxiliary electric motor

3.5 no load current point

current for which there is no torque on the driving wheel

3.6 full discharge of the battery

point at which the battery does not deliver any power/energy to the motor, according to the manufacturer’s specifications

3.7 cut off speed

speed reached, by the EPAC, at the moment the current has dropped to zero or to the no load current value

3.8 maximum assisted speed by design

maximum design speed up to which assistance is provided

3.9 electromagnetic compatibility

ability of a vehicle or one of its electrical/electronic systems to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment

3.11 electromagnetic immunity ability of a vehicle or one of its electronic/electrical systems to perform without degradation of its performance in the presence of specific electromagnetic disturbance

3.12 electromagnetic environment all electromagnetic phenomena present in a given situation

3.13

reference limit

nominal level to which both the component type-approval of the vehicle and the conformity-of-production limit value refer

3.14 reference antenna balanced half-wave dipole tuned to the measured frequency

3.15 wide-band emission emission which has a bandwidth exceeding that of a specific receiver or measuring instrument 3.16 narrow-band emission

emission which has a bandwidth less than that of a specific receiver or measuring instrument

3.17 electronic/electrical subassembly (ESA)

electronic and/or electrical component, or an assembly of components provided for installation into a vehicle, together with all electrical connections and associated wiring for the execution of several specific functions

3.18 ESA test test carried out on one or more specific ESAs 3.19 vehicle type with regard to electromagnetic compatibility vehicles that do not differ essentially in design and construction from the following aspect: general layout of the electronic and/or electrical components;

overall size, layout and shape of the engine mounting and the disposition of the high-voltage wiring (where present);

raw material from which both the vehicle chassis and bodywork are constructed (e.g., a chassis or body made of glass fibre, aluminium or steel)

3.20 ESA type in relation to electromagnetic compatibility separate technical ESA unit that does not differ from other units in its essential design and construction aspects SIST EN 15194:2009+A1:2012

− the general layout of the electronic and/or electrical components;

− direct vehicle control performed by the rider acting on the steering, the brakes and the accelerator control.

3.21 rated voltage voltage declared by the manufacturer of the bicycle 3.22 continuous rated power continuous (or constant) output power specified by manufacturer, at which the motor reaches its thermal equilibrium at given ambient conditions NOTE Thermal equilibrium: temperatures of

motor parts do not vary more than 2K per hour. 3.23 brake lever cut-off switch device that cuts off the motor assistance while using the brake lever 3.24 integrated charger charger which is a part of the bicycle and needs tools to be disassembled from it 4 Requirements 4.1 General Electrically power-assisted bicycles shall comply with Clause 4, 5 and 6 of the European Standard EN 14764:2005 in addition to the specific requirements in Clause 4.2 of this standard. 4.2 EPAC specific additional requirements

4.2.1 Electric circuit The electrical control system shall be designed so that, should it malfunction in a hazardous manner, it shall switch off power to the electric motor.

!If a symbol shows a function that is described by a symbol included in ISO 2575, the symbol shall be in accordance with that standard." 4.2.2 Batteries

4.2.2.1 Requirements EPAC and pack of batteries shall be designed in order to avoid risk of fire, mechanical deterioration resulting from abnormal use. Compliance is checked by the test described in 4.2.2.2.

During the test the EPAC and the batteries shall not emit flames, molten metal or poisonous ignitable gas in hazardous amounts and any enclosure shall show no damage that could impair compliance with this European Standard. Safety and compatibility of the combination battery/charger combination shall be ensured, according to the manufacturer's specifications. SIST EN 15194:2009+A1:2012

NOTE Indication and example of solutions are given in Annex A. Batteries and the charger unit shall be labelled in order to be able to check their compatibility. 4.2.2.2 Test method 1) Battery terminals are short-circuited with the batteries in a fully charged condition. 2) Motor terminals are short-circuited; all commands are in ON position, whilst the batteries are fully charged. 3) The EPAC is operated with the electric motor or drive system locked up so as to fully discharge the battery or until the system stops. 4) The battery is charged for double the recommended charging period or for 24 hours depending upon which is the longest period.

4.2.3 Electric cables and connections

4.2.3.1 Requirements Cable and plug temperature shall be lower than that specified by the manufacturer of the cables and plugs. There shall be no corrosion on plug pins and no damage to cable and plug insulation. 4.2.3.2 Test method Discharge the fully charged EPAC battery to the discharging limit specified by the EPAC or ESA manufacturer at the maximum current allowable by the system and record it, giving consideration to the electric motor and/or the controller and/or the battery controller. Measure the cable and plug temperatures and ensure, by examination, that there is no deterioration of the insulation on either assembly. 4.2.3.3 Wiring a) Wire ways shall be smooth and free from sharp edges.

b) Wires shall be protected so that they do not come into contact with burrs, cooling fins or similar sharp edges that may cause damage to their insulation. Holes in metal through which insulated wires pass shall have smooth well-rounded surfaces or be provided with bushings.

c) Wiring shall be effectively prevented from coming into contact with moving parts.

Separate parts of the EPAC that can move in normal use or during user maintenance relative to each other, shall not cause undue stress to electrical connections and internal conductors, including those providing earthing continuity.

Compliance with a), b), c) shall be checked by inspection.

d) If an open coil spring is used, it shall be correctly installed and insulated. Flexible metallic tubes shall not cause damage to the insulation of the conductors contained within them.

Compliance with d) shall be checked by inspection and by the following test method.

If flexing occurs in normal use, the appliance is placed in its normal operational position and is supplied at rated voltage under normal operation.

For conductors that are flexed in normal use, flex movable part for 10 000 cycles at a test frequency of 0,5 Hz.

For conductors that are flexed during user maintenance, flex the movable part for 100 cycles at the same frequency at (20 ± 5) °C.

The wiring and its connections shall withstand the electrical strength test. The test voltage expressed in V shall be equal to)2500(Vr×+ for 2 min and applied between live parts and other metal parts only.

NOTE Vr is the rated voltage. f) The insulation of internal wiring shall withstand the electrical stress likely to occur in normal use.

g) In case of integrated battery charger, electric safety of battery charger applies. 4.2.3.4 Power cables and conduits Conduit entries, cable entries and knock-outs shall be constructed or located so that the introduction of the conduit or cable does not reduce the protection measures adopted by the manufacturer.

Compliance is checked by inspection.

NOTE Power cables selection should be made referring to IEC 60364-5-52:2001, Clauses 522.1.2, 523.1523.3 and Table A 52-10. 4.2.3.5 External and internal electrical connections Electrical connection shall comply with IEC 60364-5-52:2001, Clauses 526.1 and 526.2. 4.2.3.6 Moisture resistance The EPAC are subjected to the test of IEC 60529 as follows: IPX4 appliances as described in Clause 14.2.4.a. 4.2.3.7 Mechanical strength EPAC shall have adequate mechanical strength and be constructed to withstand such rough handling that may be expected in normal use. Compliance is checked by:

applying impacts to the battery pack mounted on the EPAC by means of the spring hammer as specified in IEC 60068-2-75. The battery pack is rigidly supported and three impacts are applied to every point of the enclosure that is likely to be weak with an impact energy of (0,7 ± 0,05) J. After the test the battery pack shall show no damage that could impair compliance with this European Standard; detachable battery packs are submitted to free fall at a height of 0,90 meter in three different positions. After the test the battery pack shall show no damage that could lead to emission of dangerous substances (gas or liquid) ignition, fire or overheating. NOTE It is recalled to the attention that batteries had to fulfil all relevant tests to ensure safety. 4.2.4 Power management 4.2.4.1 Requirements

When tested by the method described in 4.2.4.2 the recordings shall show that:

exceed 5 m with the use of brake lever cut off switch or 2 m without the use of brake lever cut off switch. This requirement has to be checked according to the test methods described in 4.2.4.2.2 b); c) the output or assistance shall be progressively reduced (see Annex B) and finally cut off as the vehicle reaches the maximum assistance speed as designed. This requirement has to be checked according to the test methods described in 4.2.4.2; d) the assistance shall be progressively and smoothly managed. 4.2.4.2 Test method – Electric motor management 4.2.4.2.1 Test conditions a) The test may be performed either on a test track, a test bench or on a stand which keeps the motor driven wheel free of the ground.

b) The test track shall be according to EN 14764:2005, Clause 4.6.8.5.1.1. c) The time-measuring device shall have an accuracy of ± 2%. d) The ambient temperature shall be between 5 °C and 35 °C. e) Maximum wind speed shall not exceed 3 m/s. f) The battery shall be fully charged according to the manufacturer's instructions. 4.2.4.2.2 Test procedure a) Check that there is no electric motor assistance when pedalling backwards. The test to ensure the compliance to this clause shall be adapted to the technology used. For example, pedal backwards and check the no load current point or that no torque is delivered on the driving wheel.

b) Worst case conditions of gear ratio and speed shall be applied. c) Worst condition for speed is defined as 90% of cut off speed. d) Measure the distance travelled from cessation of pedalling and actuating the switch brake simultaneously (if any) to no power corresponding to no load current point provided by the electric motor by using: 1) speed versus time measurement, 2) direct or indirect torque versus distance measurement (e.g. motor current), 3) or any other appropriate method. e) Carry out the test ten times and then average. 4.2.4.3 Start up assistance mode 4.2.4.3.1 Requirements EPAC can be equipped with a start up assistance mode up to 6 km/h designed speed or lower values as specified by the manufacturer. Unauthorized use shall be prevented. SIST EN 15194:2009+A1:2012

4.2.4.3.2 Test method 4.2.4.3.2.1 Test conditions a) The test may be performed either on a test track, a test bench or on a stand that keeps the motor driven wheel free of the ground. b) The speed-measuring device shall have the following characteristics: 1) Accuracy: ± 2%

2) Resolution: 0,1 km/h c) The ambient temperature shall be between 5 °C and 35 °C. d) Maximum wind speed: 3 m/s. e) The battery shall be fully charged according to the manufacturer's instructions. 4.2.4.3.2.2 Test procedure a) Pre-condition the EPAC by running it for 5 min at 80% of the maximum assistance speed as declared by the manufacturer, then stop. b) Activate the start up assistance mode and verify that the speed increases up to 6 km/h maximum designed speed or lower value. c) Verify that speed is going down to 0 km/h when start up assistance mode is deactivated and the current drops to a value equal to or less than no load current point when free rolling. !deleted text" d) Activate the start up assistance mode and maintain it for 1 min. e) Verify that speed is equal to or less than 6 km/h. 4.2.5 Electro Magnetic Compatibility

4.2.5.1 Emission

The EPAC and ESA shall conform to Annex C.

4.2.5.2 Immunity The EPAC and ESA shall conform to Annex C.

4.2.5.3

Battery charger

As an EPAC is not intended to be used while charging, for integrated charger the whole EPAC plus integrated charger shall be tested.

The following European standards apply for battery charger: EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3. SIST EN 15194:2009+A1:2012

4.2.6.1 Requirements

The maximum speed for which the electric motor gives assistance may differ by ± 5% of the speed indicated on the label described within Clause 5 when determined according to the test method described in 4.2.6.2, from 25 km/h or lower values as specified by the manufacturer.

During a production conformity check, the maximum speed may differ by ± 10% from the above-mentioned determined value.

4.2.6.2 Test method 4.2.6.2.1 Test conditions a) The test may be performed either on a test track, a test bench or on a stand that keeps the motor driven wheel free of the ground. b) The speed-measuring device shall have the following characteristics: 1) Accuracy: ± 2%

2) Resolution: 0,1 km/h c) The ambient temperature shall be between 5 °C and 35 °C. d) Maximum wind speed: 3 m/s. e) The battery shall be fully charged according to the manufacturer instructions. 4.2.6.2.2 Test procedure Any appropriate method for checking for this requirement is acceptable; one solution is to measure the cut-off speed, another being to measure the torque output. The following example describes the cut-off speed test. a) Pre-condition the EPAC by running it for 5 min at 80% of the maximum assistance speed as declared by the manufacturer.

b) Record continuously the current and note the speed at which the current drops to a value equal to or less than “no load current point”.

c) Whilst pedalling, ride steadily to reach a speed equal to 1,25 times (if possible by design) the maximum assistance speed as declared by the manufacturer.

! d) Verify that the noted value in b) is in accordance with 4.2.6.1." 4.2.7 Maximum power measurement

4.2.7.1 Measurement at the engine shaft The maximum continuous rated power shall be measured according to EN 60034-1 when the motor reaches its thermal equilibrium as specified by the manufacturer. NOTE Thermal equilibrium: temperatures of motor parts do not vary more than 2K per hour. SIST EN 15194:2009+A1:2012

4.2.7.2 Alternative method When the power is measured at the wheel, the result of the measurement is the reading value. Annex D gives guidance on how to measure the power at the wheel. 5 Marking, labelling In addition to the requirements of EN 14764, the EPAC shall be visibly and durably marked according to EN 15194 as follows: EPAC According to EN 15194: XX km/h1)

XX W2)

6 Instruction for use In addition to the instructions required by the bicycles standard EN 14764, each EPAC shall be provided with a set of instructions containing information on:

1) concept and description of electric assistance;

2) recommendation for washing;

3) control and tell tales;

4) specific EPAC recommendations for use;

5) specific EPAC warnings;

6) recommendations about battery charging and charger use as well as the importance of following the instruction contained on the label

of the battery charger.

1) Cut off speed. 2) Electric motor maximum continuous rated power. SIST EN 15194:2009+A1:2012

Example of recommendation for battery charging Safety and quality of battery charging can be greatly improved by sensing the battery temperature during charging.

Most battery charger manufacturers set their chargers to have an optimal ambient temperature of 20 °C to 25 °C. Lower temperatures result in under charge, higher temperatures result in over charge.

Whilst it is normal when building battery packs from Ni-Cad, Ni-Mh and Li-ion battery cells, to include temperature sensing, this is not always the case with valve regulated lead acid (VRLA) batteries.

The main reason for including temperature sensing in VRLA batteries is to protect against one or more cells within the battery pack becoming short circuited. This lowers the terminal voltage and can allow the charger to supply more power than is required, which can lead to a dangerous thermal situation.

Temperature sensors should be fitted to each battery within the pack and this information fed back to the battery charger.

It is recommended that positive temperature coefficient (PTC) thermistors are used. All thermistors should be connected in series between the charger temperature pin (T) and the battery pack negative pin (-). Should any battery or cells within the pack reach the temperature given by the battery manufacturer (e.g.; 60 °C, 70 °C…) the charger thermal detection circuitry should be adjusted to detect this condition and take suitable measures to stop any further increase in temperature.

Example of relation between speed/torque/current This Annex gives one example of relation between speed/torque/current with progressively reduced output power (see Figure B.1).

Key Quantities Indices

U

voltage [V] M

torque [Nm] n

speed [rpm] v

speed [km/h] I

current [A] P

output-power [W] cr

continuous rated s

standstill 0

no load 1

load point n0 A v0 δ 25km/h

Figure B.1 — Relation between P, n and M The relationship between motor current I and torque M is linear according to: )(0IIkM−= (B.1) where M torque [Nm] k torque constant [Nm/A] I current [A] I0 no load current [A] The relation of power is: nMP×××=π2 (B.2) SIST EN 15194:2009+A1:2012

Figure B.2 — Speed-torque diagram function Because the natural speed-torque-diagram is a linear falling function (at constant voltage U) the output-power-torque and the output-power-speed function is a parabolic one (see Figure B.2). Therefore, if the torque falls linear from Mcr (torque at Pcr – continuous rated power) to zero, the motor current falls linear to I0 and the power P falls progressively from Pcr to zero. The corresponding relations are:

11PPPcr−>

or

21crPP>

if

2)(01nnncr+=

(B.3) One can verify this relation in two steps: Firstly, reducing the torque to 2crMrespectively increasing the speed to 2)(01nnncr+=, corresponding to 2)(01IIIcr−= Secondly, reducing the torque from 2crMto zero respectively increasing the speed to no load speed n0, corresponding to no load current. In the first step, the reduction of power is smaller than in the second one. So, the power is progressively reduced and finally cut off as the vehicle reaches the maximum assistance speed. SIST EN 15194:2009+A1:2012

Electromagnetic compatibility of EPAC and ESA C.1 Conditions applying to vehicles and to electrical/electronic sub-assemblies (ESA)

C.1.1 Marking All ESAs, with the exception of cables shall bear the following and these marks shall be indelible and clearly legible: a) make or name of the manufacturer of the ESAs and their components;

b) trade description. C.1.2 Requirements C.1.2.1 General requirements All vehicles and ESAs shall be designed and constructed in such a way that, under normal conditions of use, they meet the conditions laid down in this annex. NOTE An overview of the electromagnetic radiation emission reference limits is given in Figure C.1. SIST EN 15194:2009+A1:2012

Key X

frequency f in MHz Y

reference limits L in dB [µV/m) C1

requirements relating to narrow-band radiation emission from vehicle, antenna at 10 m C2

requirements relating to broad-band radiation emission from vehicle, antenna at 10 m

C3

requirements relating to narrow-band ESA radiation emission, antenna at 1m C4

requirements relating to broad-band ESA radiation emission, antenna at 1 m

C5

requirements relating to narrow-band radiation emission from vehicle, antenna at 3 m

C6

requirements relating to broad-band radiation emission from vehicle, antenna at 3 m

Figure C.1 — Overview of electromagnetic radiation emissions reference limits Table C.1 — Overview of electromagnetic radiation emissions reference limits – Curves characteristics Characteristic Value Band-width Antenna distance

[m] Equation for L [dB(µV/m)] within f [MHz] 30…75 75…400 400…1000 C 1 mean value narrow-band 10 ± 0,2 24=const. 24+15,13⋅log(f/75) 35=const. C 2 quasi-peak broad-band 10 ± 0,2 34=const. 34+15,13⋅log(f/75) 45=const. C 3 mean value narrow-band 1,0 ± 0,05 54-25,13⋅log(f/30) 44+15,13⋅log(f/75) 55=const. C 4 quasi-peak broad-band 1,0 ± 0,05 64-25,13⋅log(f/30) 54+15,13⋅log(f/75) 65=const. C 5 mean value narrow-band 3 ± 0,05 34=const. 34+15,13⋅log(f/75) 45=const. C 6 quasi-peak broad-band 3 ± 0,05 44=const. 44+15,13⋅log(f/75) 55=const.

However, the measuring methods used in checking the immunity of vehicles and ESAs to electromagnetic radiation are described in C.4 and C.7. SIST EN 15194:2009+A1:2012

C.1.2.2.1 General The electromagnetic radiation generated by the vehicle type submitted for testing are to be measured by the method described in C.2. C.1.2.2.2 Vehicle reference limits (broad-band)

C.1.2.2.2.1 If measurements are taken using the method described in C.2, in respect of a vehicle-antenna distance of (10,0 ± 0,2) m, the radiation reference limit will be 34 dB microvolts/m in the 30-75 MHz frequency band and 34-45 dB microvolts/m in the 75 to 400 MHz frequency band. This limit will increase by the frequency logarithm for frequencies above 75 MHz. In the 400-1 000 MHz frequency band the limit remains constant at 45 dB. C.1.2.2.2.2 If measurements are taken using the method described in C.2, in respect of a vehicle-antenna distance of

(3,0 ± 0,05) m, 10 dB shall be added to the limit. C.1.2.2.2.3 The measured values expressed in dB (microvolts/m) shall be 2 dB below the reference limit for the vehicle submitted for testing. C.1.2.3 Requirements relating to narrow-band radiation emissions from vehicles

C.1.2.3.1 General The electromagnetic radiation from the vehicle submitted for testing is to be measured by the method described in C.3. C.1.2.3.2 Vehicle reference limits for vehicle narrow-band radiation

C.1.2.3.2.1 If measurements are taken using the method described in C.3, in respect of a vehicle-antenna distance of (10,0 ± 0,2) m, the radiation reference limit will be 24 dB in the 30-75 MHz frequency band and 24-35 dB in the 75-400 MHz frequency band. This limit will increase by the frequency logarithm for frequencies above 75 MHz. In the 400-1 000 MHz frequency band the limit remains constant at 35 dB. C.1.2.3.2.2 If measurements are taken using the method described in C.3, in respect of a vehicle-antenna distance of (3,0 ± 0,05) m, 10 dB shall be added to the limit. C.1.2.3.2.3 The measured values for the vehicle type submitted for testing expressed in dB (microvolts/m), shall be 2 below the reference limit. For conformity of production testing do not remove the 2 dB from the reference limit. C.1.2.4 Requirements regarding vehicle immunity to electromagnetic radiation C.1.2.4.1 Measuring method

Tests to determine the immunity of the vehicle type to electromagnetic radiation shall be conducted in accordance with the method described in C.4.

C.1.2.4.2 Vehicle immunity reference limits

C.1.2.4.2.1 If measurements are taken using the method described in C.4, the field stren

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...