EN 15875:2011

(Main)Characterization of waste - Static test for determination of acid potential and neutralisation potential of sulfidic waste

Characterization of waste - Static test for determination of acid potential and neutralisation potential of sulfidic waste

This European standard specifies methods to determine the potential of sulfide bearing materials for the formation of acidic drainage. Specified are methods for determining both the acid potential (AP) and the neutralisation potential (NP) of the material. From these results the net neutralisation potential (NNP) and the neutralisation potential ratio (NPR) are calculated.

This European standard is applicable to all sulfide bearing wastes from the extractive industries excluding wastes which will have pH < 2 in the initial step of the procedure described in 8.2.3.

Charakterisierung von Abfällen - Statische Prüfung zur Bestimmung des Säurebildungspotenzials und des Neutralisationspotenzials von sulfidhaltigen Abfällen

Diese Europäische Norm legt Verfahren zur Bestimmung des Potenzials von sulfidhaltigen Materialien zur

Säurebildung fest. Festgelegt werden Verfahren zur Bestimmung sowohl des Säurebildungspotenzials

(en: acid potential, AP) als auch des Neutralisationspotenzials (en: neutralisation potential, NP) des Materials.

Aus diesen Ergebnissen werden das Nettoneutralisationspotenzial (en: net neutralisation potential, NNP) und

der Pufferungsquotient (en: neutralisation potential ratio, NPR) berechnet.

Diese Europäische Norm ist auf sämtliche sulfidhaltigen Abfälle aus der mineralgewinnenden Industrie

anwendbar, mit Ausnahme von Abfällen, deren pH-Wert beim ersten Schritt des in 8.2.3 beschriebenen

Verfahrens kleiner als 2 ist.

Caractérisation des déchets - Essai statique pour la détermination du potentiel de génération d'acide et du potentiel de neutralisation des déchets sulfurés

La présente Norme européenne spécifie des méthodes permettant de déterminer le potentiel des matériaux sulfurés à former des eaux de drainage acides. Les méthodes spécifiées permettent de déterminer à la fois le potentiel de génération d’acide (AP) et le potentiel de neutralisation (NP) du matériau. A partir de ces résultats, le potentiel de neutralisation net (NNP) et le rapport de potentiel de neutralisation (NPR) sont calculés.

La présente Norme européenne est applicable à tous les déchets sulfurés de l’industrie extractive, à l’exclusion des déchets qui auront un pH inférieur à 2 lors de l’étape initiale du mode opératoire décrit en 8.2.3.

Karakterizacija odpadkov - Statični preskus za določevanje kislinske in nevtralizacijske kapacitete odpadkov, ki vsebujejo sulfid

Ta evropski standard določa metode za določevanje kapacitete materialov, ki vsebujejo sulfid, za tvorbo kisle drenaže. Opredeljene so metode za določevanje kislinske (AP) in nevtralizacijske kapacitete (NP) materiala. Iz teh rezultatov se računa neto nevtralizacijska kapaciteta (NNP) in razmerje nevtralizacijske kapacitete (NPR). Ta evropski standard se uporablja za vse odpadke ekstraktivne industrije, ki vsebujejo sulfid, razen odpadkov, katerih pH v prvi fazi postopka, opisanega v 8.2.3, znaša < 2.

General Information

- Status

- Published

- Publication Date

- 25-Oct-2011

- Withdrawal Date

- 29-Apr-2012

- Technical Committee

- CEN/TC 444 - Environmental characterization

- Drafting Committee

- CEN/TC 444/WG 6 - Cross cutting issues

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 23-May-2023

- Completion Date

- 09-Feb-2026

Relations

- Refers

EN 15002:2015 - Characterization of waste - Preparation of test portions from the laboratory sample - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 25-Jul-2012

Overview

EN 15875:2011 - Characterization of waste: Static test for determination of acid potential (AP) and neutralisation potential (NP) of sulfidic waste - is a CEN standard for assessing the propensity of sulfide-bearing materials (mainly from the extractive industries) to generate acidic drainage. The standard specifies a static laboratory test procedure to determine AP and NP, and to calculate net neutralisation potential (NNP) and neutralisation potential ratio (NPR). It supports implementation of EU Directive 2006/21/EC on waste from extractive industries.

Key topics and technical requirements

- Purpose: Provide a standardized static method to evaluate maximum acid generation (AP) and buffering capacity (NP) of sulfidic wastes.

- AP determination: Based on total sulfur measured by oxygen combustion (EN 14582) or high-temperature combustion (ISO 15178); AP is expressed as H+ mol/kg and convertible to CaCO3 equivalents.

- NP determination: Acid addition using HCl (1 mol/L) to reach pH 2–2.5, 24 h reaction, then back-titration with NaOH (0.1 mol/L) to pH 8.3. Results expressed in H+ mol/kg.

- Calculations: NNP = NP − AP; NPR = NP / AP. These help classify material as net-acid generating or neutralising.

- Sample preparation: Laboratory sample ≥ 1 kg (dry mass); test sample milled so 95% < 0.125 mm; dry residue measured at 105 °C (EN 14346). Moist samples may be dried ≤ 40 °C or freeze-dried (ISO 16720).

- Equipment & QA: pH meter accuracy ±0.05 pH units; inert 250 mL vessels; magnetic stirring; sieves per ISO 3310-1. The procedure excludes wastes that show pH < 2 at the initial acid-step (8.2.3).

- Limitations: Static tests give indicative results based on total composition. Mineralogical analysis and kinetic tests are recommended when site-specific behaviour and reaction rates are needed.

Applications and users

- Who uses it:

- Environmental laboratories and testing facilities

- Mining and extractive-industry operators (waste characterization and permitting)

- Environmental consultants, geochemists and mine-closure planners

- Regulators implementing Directive 2006/21/EC and national waste management rules

- Practical uses:

- Screening sulfidic wastes for acid-generation risk (acid mine drainage potential)

- Supporting design of waste management, containment and treatment measures

- Comparative classification of waste streams (e.g., disposal vs. reuse)

- Baseline data for environmental impact assessments and permitting

Related standards

- EN 14582 (total S by combustion), ISO 15178 (total sulfur), EN 14346 (dry residue), EN 13137 (TOC), EN 14899 (sampling), EN 15002 (test portion prep), ISO 3310-1 (sieves), ISO 16720 (freeze-drying).

Keywords: EN 15875:2011, sulfidic waste, acid potential, neutralisation potential, AP, NP, NNP, NPR, static test, extractive industries, acid mine drainage, waste characterization.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15875:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Characterization of waste - Static test for determination of acid potential and neutralisation potential of sulfidic waste". This standard covers: This European standard specifies methods to determine the potential of sulfide bearing materials for the formation of acidic drainage. Specified are methods for determining both the acid potential (AP) and the neutralisation potential (NP) of the material. From these results the net neutralisation potential (NNP) and the neutralisation potential ratio (NPR) are calculated. This European standard is applicable to all sulfide bearing wastes from the extractive industries excluding wastes which will have pH < 2 in the initial step of the procedure described in 8.2.3.

This European standard specifies methods to determine the potential of sulfide bearing materials for the formation of acidic drainage. Specified are methods for determining both the acid potential (AP) and the neutralisation potential (NP) of the material. From these results the net neutralisation potential (NNP) and the neutralisation potential ratio (NPR) are calculated. This European standard is applicable to all sulfide bearing wastes from the extractive industries excluding wastes which will have pH < 2 in the initial step of the procedure described in 8.2.3.

EN 15875:2011 is classified under the following ICS (International Classification for Standards) categories: 13.030.10 - Solid wastes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15875:2011 has the following relationships with other standards: It is inter standard links to EN 15002:2015, EN 13137:2001, EN 15316-4-5:2007, EN ISO 11465:2025, EN 14582:2016, EN 12915-2:2009, EN 14630:2006, EN 14899:2005, EN 16907-7:2021, EN 16457:2014, EN 15875:2011/AC:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15875:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/21/EC; Standardization Mandates: M/395. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15875:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Charakterisierung von Abfällen - Statische Prüfung zur Bestimmung des Säurebildungspotenzials und des Neutralisationspotenzials von sulfidhaltigen AbfällenCaractérisation des déchets - Essai statique pour la détermination du potentiel de génération d'acide et du potentiel de neutralisation des déchets sulfurésCharacterization of waste - Static test for determination of acid potential and neutralisation potential of sulfidic waste13.030.10Trdni odpadkiSolid wastesICS:Ta slovenski standard je istoveten z:EN 15875:2011SIST EN 15875:2012en,fr,de01-februar-2012SIST EN 15875:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15875

October 2011 ICS 13.030.10 English Version

Characterization of waste - Static test for determination of acid potential and neutralisation potential of sulfidic waste

Caractérisation des déchets - Essai statique pour la détermination du potentiel de génération d'acide et du potentiel de neutralisation des déchets sulfurés

Charakterisierung von Abfällen - Statische Prüfung zur Bestimmung des Säurebildungspotenzials und des Neutralisationspotenzials von sulfidhaltigen Abfällen This European Standard was approved by CEN on 17 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15875:2011: ESIST EN 15875:2012

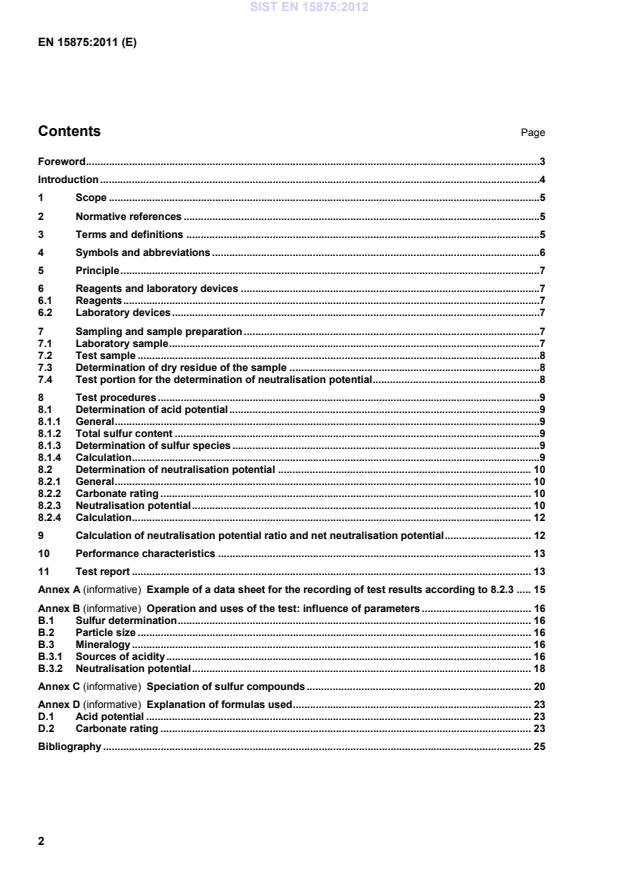

Example of a data sheet for the recording of test results according to 8.2.3 . 15Annex B (informative)

Operation and uses of the test: influence of parameters . 16B.1 Sulfur determination . 16B.2 Particle size . 16B.3 Mineralogy . 16B.3.1 Sources of acidity . 16B.3.2 Neutralisation potential . 18Annex C (informative)

Speciation of sulfur compounds . 20Annex D (informative)

Explanation of formulas used . 23D.1 Acid potential . 23D.2 Carbonate rating . 23Bibliography . 25 SIST EN 15875:2012

To carry out a more precise assessment of the acid generation potential and buffering capacity mineralogical information is required. A number of special cases can be identified: e.g. presence of sulfate (e.g. gypsum), non-acid producing sulfides or carbonates with no buffering capacity. Acid neutralisation behaviour as obtained by other methods can provide additional information in circumstances of uncertainty.

This European standard is applicable to all sulfide bearing wastes from the extractive industries excluding wastes which will have pH < 2 in the initial step of the procedure described in 8.2.3. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13137:2001, Characterization of waste — Determination of total organic carbon (TOC) in waste, sludges and sediments EN 14346, Characterization of waste — Calculation of dry matter by determination of dry residue or water content EN 14582, Characterization of waste — Halogen and sulfur content — Oxygen combustion in closed systems and determination methods

EN 14899, Characterization of waste — Sampling of waste materials — Framework for the preparation and application of a Sampling Plan EN 15002, Characterization of waste — Preparation of test portions from the laboratory sample ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth ISO 15178, Soil quality — Determination of total sulfur by dry combustion ISO 16720, Soil quality — Pretreatment of samples by freeze-drying for subsequent analysis 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 laboratory sample

sample sent to or received by the laboratory 3.2 test sample sample, prepared from the laboratory sample, from which test portions are removed for testing or analysis 3.3 test portion

quantity of material of proper size, for measurement of the concentration or other properties of interest, taken from the test sample NOTE The test portion may be taken from the laboratory sample directly if no preparation of sample is required (e.g. samples of proper homogeneity, size and fineness). SIST EN 15875:2012

maximum potential acid generation from a sample assuming that all sulfur occurs as pyrite and that acidity will result from its complete oxidation

3.5 neutralisation potential

capacity of a sample to neutralise the generated acidity 3.6 carbonate rating

carbonate content of the sample used to specify the volume(s) of acid to be added during the procedure NOTE In this European standard the carbonate rating to specify the volume(s) of acid to be added during the procedure is described in 8.2.3. 3.7 net neutralisation potential difference between neutralisation potential and acid potential 3.8 neutralisation potential ratio

ratio of neutralisation potential and acid potential 4 Symbols and abbreviations AP acid potential NP neutralisation potential CR carbonate rating Md dry mass of the test portion Mw un-dried mass of the test portion md mass after drying at 105 °C mw mass before drying

Ms

molecular weight of sulfur NNP net neutralisation potential NPR

neutralisation potential ratio t = 0 time at the start of the test (after 15 min ± 5 min stirring) VA/B volume of acid or base added VA, t=0 volume of acid added at t = 0 VA, t=22h volume of acid added at t = 22 h wdr dry residue of the sample SIST EN 15875:2012

Determination of carbonate content by dry combustion (EN 13137:2001, method A) to give the carbonate rating (CR). Determination of the neutralisation potential (NP) by hydrochloric acid addition to reach pH = 2 to 2,5 and back titration with sodium hydroxide to reach pH = 8,3 after reaction time of 24 h.

Calculations of the net neutralisation potential (NNP) and the neutralisation potential ratio (NPR) based on AP and NP.

AP and NP are expressed as H+ content in mol/kg. The conversion factor is given for expression as carbonate equivalents (CaCO3) in kg/t.

6 Reagents and laboratory devices

6.1 Reagents 6.1.1 Distilled or demineralised water 6.1.2 Hydrochloric acid (analysis grade), c(HCl) = 1 mol/l

6.1.3 Sodium hydroxide (analysis grade), c(NaOH) = 0,1 mol/l 6.2 Laboratory devices 6.2.1 Analytical balance, with an accuracy of 0,05 g

6.2.2 Bottles or vessels (250 ml) made of inert material such as glass or high density polyethylene (HDPE) or polypropylene (PP) and supplied with a lid of inert material (e.g. PTFE). Rinsing is compulsory. When using magnetic bar in stirring (see 6.2.4) it is crucial to use a test vessel or bottle with flat bottom in order to guarantee good mixing.

6.2.3 Size reducing equipment, e.g. a jaw crusher, rotary swing mill, ball mill or similar device. 6.2.4 Stirring device or magnetic stirring device with magnetic bar coated with PTFE. The parts in contact with the sample and reagents shall be made of materials not affecting the outcome of the test like glass, PTFE. 6.2.5 pH meter with a measurement accuracy of at least ± 0,05 pH units. 6.2.6 Sample dividers (e.g. rotary splitter or riffle divider)

6.2.7 Sieves, conforming to the requirements of ISO 3310-1, with screen size of 0,125 mm. 7 Sampling and sample preparation 7.1 Laboratory sample Perform sampling in accordance with EN 14899 in order to obtain a representative laboratory sample.

The laboratory sample shall have a mass of at least 1 kg (dry mass). SIST EN 15875:2012

7.2 Test sample The test sample shall have a particle size of 95 % less than 0,125 mm. For material with larger particle sizes the following shall apply: Crush the laboratory sample to < 2 mm following the procedures given in EN 15002. Take a subsample from the crushed material by using a suitable divider (6.2.6) or by coning and quartering. The subsample of approximately 100 g is then milled to a particle size of 95 % less than 0,125 mm.

Moist material that is not possible to sieve is dried prior to sieving and/or crushing. The drying temperature shall not exceed 40 °C in order to avoid unwanted reactions. Alternatively, freeze drying according to ISO 16720 can be used. The crushed material can change upon storage due to ageing of fresh surfaces. It is therefore recommended to test the material as soon as possible after crushing. If short-term storage is needed, crushed material should be stored cold and dark. For long-term storage material should be dried (at temperatures not exceeding 40 °C) prior to storage to prevent acid generating reactions. 7.3 Determination of dry residue of the sample

The whole test sample, complying with the size criteria in 7.2 shall not be dried any further. The dry residue (wdr) of the test sample shall be determined on a separate test portion according to EN 14346.

The dry residue of the sample shall be determined at 105 °C ± 5 °C according to EN 14346. The dry residue expressed as mass fraction in percent is calculated according to Equation (1): wddr100mmw×= (1) where wdr is the dry residue of the sample expressed as mass fraction in percent; md is the mass after drying expressed in grams (g); mw is the mass of the sample after sample pretreatment as described in 7.2 and before drying expressed in grams (g).

7.4 Test portion for the determination of neutralisation potential Prepare a representative test portion in accordance with EN 15002.

Calculate the mass of the test portion Mw in grams to be used for the test in accordance with Equation (2): 100drdw×=wMM (2) where

Md is the dry mass of the test portion expressed in grams (g); Mw is the total mass of the test portion expressed in grams (g). SIST EN 15875:2012

NOTE The main source for acidity is the oxidation of sulfides. Total sulfur is used as a conservative approximation of sulfide content. If a significant part of total sulfur is sulfate this will lead to a significant overestimation of AP, in which case a more realistic assessment will be achieved if the AP determination is based on sulfide content. 8.1.2 Total sulfur content Total sulfur content is determined either by bomb combustion according EN 14582 or by high temperature combustion according ISO 15178.

The bomb combustion method described in EN 14582 usually gives high recoveries when inorganic salts are analysed. However, depending on the material to be analysed, suitable pure inorganic compounds with similar sulfur binding shall be used to test recovery rates. When using high temperature combustion techniques, appropriate operating conditions of the analysis

shall be chosen, to ensure the detection of all sulphur components, including temperature stable inorganic sulphates (e.g. calcium sulfate). This can be achieved by increasing the temperature (e.g. up to 1 500 °C) or the use of tin capsules (which burn in an exothermic reaction resulting in high temperatures). Also measuring time may be increased as these stable compounds react slower. Calibration has to be made with calibrants having the same range of sulfur concentration as the material to be analysed. 8.1.3 Determination of sulfur species The main purpose of all species analyses is the determination of sulfides, mainly pyrite. This can be done either by direct determination of pyrite or by subtraction of the sulfate sulfur fraction from the total sulfur content (assuming no other sulfur species like elemental sulfur is present). The choice of direct or indirect approach depends on the mineralogical composition of the sample. There are no CEN or ISO standards for the determination of sulfur species (sulfate-, sulfide-, disulfide-, sulfur) in waste described in this standard. However, guidance is given in the informative Annex C. NOTE Some sulfides do not contribute to AP, this can only be assessed through more detailed characterisation, such as mineralogy. 8.1.4 Calculation The acid potential (AP) is calculated based on the sulfur content (either total or sulfide sulfur) as follows: NOTE 1 Calculation of acid potential assumes all sulfur to appear as pyrite a) expressed as H+ content in mol/kg (Equation (3)) S0,625APw×= (3) SIST EN 15875:2012

0,625 is the conversion factor (taking into account the conversion of units and that 1 mol of sulfur in pyrite creates 2 moles of H+) (for further explanation see Annex D); wS is the sulfur (either total or sulfide sulfur) content as mass fraction in percent. b) expressed as carbonate equivalents (CaCO3) in kg/t (Equation (4)) S 31,25APw×= (4) where

31,25 is the conversion factor (ratio of molecular masses of calcium carbonate (100 g/mol) and sulfur (32 g/mol)) (for further explanation see Annex D); wS

is the sulfur (either total or sulfide sulfur) content as mass fraction in percent. NOTE 2 AP and NP values expressed as H+ content in mol/kg can be converted to carbonate equivalents (CaCO3) in kg/t by multiplying by 50. Likewise a AP or NP expressed in carbonate equivalents (CaCO3) in kg/t can be converted to H+ content in mol/kg by multiplying by 0,02.

8.2 Determination of neutralisation potential 8.2.1 General The amount of acid added for the test is crucial for the results obtained. Therefore, the carbonate content is determined first to give the carbonate rating. From this, the required hydrochloric acid addition is taken from Table 1. 8.2.2 Carbonate rating Determine the carbonate content following the procedure in EN 13137:2001, method A. The carbonate carbon content obtained from EN 13137:2001 (there named “inorganic carbon”) is expressed as mass fraction in percent, it is used as carbonate rating in 8.2.3 (for further explanation see Annex D). 8.2.3 Neutralisation potential Weigh test portion Mw corresponding to 2,00 g ± 0,10 g of dry mass (Md) into a test vessel or bottle (6.2.2). Record the exact weight of the sample.

Add 90 ml ± 5 ml of demineralised water (6.1.1). Start mixing using an appropriate stirring device (6.2.4). Maintain the temperature at 20 °C ± 5 °C during the whole test. NOTE 1 Some materials may form gas when in contact with water in acidic conditions. Therefore, it is highly recommended to allow possible gas exit by making a small hole in to the lid of the vessel or bottle. Test portion and water are stirred for 15 min ± 5 min and the pH of the slurry is measured and recorded before the acid addition. If pH < 2 already, this sample cannot be characterised with this test. After 15 min ± 5 min of stirring hydrochloric acid (6.1.2) is added based on the carbonate rating (8.2.2) of the test sample (see Table 1). This is considered the starting point of the test (t = 0). Stir the slurry throughout the test.

If VA, t=22h exceeds 50 % of total volume of acid (VA, t=0 + VA, t=22h), terminate the test at t = 22 h and start again as follows: Based on the total volume of acid added, choose a new volume for acid addition at t = 0 from table 1 so that VA, t=0 in the new test corresponds to the highest volume in the table that does not exceed the total volume of acid used in the discarded test (this is usually the volume of HCl addition one or two lines below in Table 1 of the discarded test). EXAMPLE 2 VA, t=0 = 1,5 ml is used corresponding to line 2 in Table 1. 3 ml of acid is needed at t = 22 h to reach pH 2,0.

VA, t=0 + VA, t=22h = 4,5 ml and the addition at t = 22 h is 66, 7% of the total additi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...