EN 12409:2008

(Main)Plastics and rubber machines - Thermoforming machines - Safety requirements

Plastics and rubber machines - Thermoforming machines - Safety requirements

This European Standard deals with all significant hazards, hazardous situations and events relevant to thermoforming machines for continuous sheets and single sheets of thermoplastics materials, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4).

A thermoforming machine may consist of a forming unit or a forming unit linked to one or more additional units. This standard covers the following units:

- continuous sheet unwind unit;

- single sheet feed unit;

- material intake;

- conveying equipment;

- heating unit;

- preheating unit;

- edge heating unit;

- component feeding/inserting unit;

- forming station;

- finishing station;

- stacking station;

- discharge station;

- residual sheet winding unit;

- sheet cutting unit.

This European standard does not apply to units mounted upstream or downstream of the thermoforming machine:

- which have a separate control system; and/or

- are located separately.

NOTE 1 This European Standard specifies requirements for machines supplied as a single forming unit or a number of units designed to operate as a single machine. Additional units that may be introduced at a later stage should be considered separately applying relevant standards and taking into account any hazards arising through their interaction with the thermoforming machine.

This European Standard does not apply to units which are integrated into form, fill and seal machines. These are covered in EN 415-3:1999.

This European standard does not apply to units which incorporate heating systems which are fuelled by gas.

NOTE 2 Thermoforming machines generally do not create explosive atmospheres. In principle they therefore correspond with line F of Table 2 of the ATEX Guideline and consequently do not fall within the scope of Directive 94/9/EC.

This European Standard is not applicable to thermoforming machines which are manufactured before the date of its publication as EN.

Kunststoff- und Gummimaschinen - Warmformmaschinen - Sicherheitsanforderungen

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Warmformmaschinen für Folien und Platten aus thermoplastischen Materialien zutreffen, wenn sie bestimmungsgemäß und unter Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden (siehe Abschnitt 4).

Eine Warmformmaschine kann aus einer Formstation oder aus einer Formstation, die mit einer oder mehreren zusätzlichen Baugruppen verbunden ist, bestehen. Diese Norm behandelt folgende Baugruppen:

Folienabwickeleinrichtung;

Plattenzuführungseinrichtung;

Materialeinlauf;

Transporteinrichtung;

Heizung;

Vorheizung;

Randheizung;

Beschickungs-/Einlegeeinrichtung für Komponenten;

Formstation;

Nachbearbeitungsstation;

Stapelstation;

Austragsstation;

Restfolienwickeleinrichtung;

Folienschneideinrichtung.

Diese Europäische Norm gilt nicht für Baugruppen, die der Warmformmaschine vor- oder nachgeschaltet sind, und die

ein eigenes Steuerungssystem haben und/oder

separat angeordnet sind.

ANMERKUNG 1 Diese Europäische Norm legt die Anforderungen für Maschinen fest, die als Einzelformstation geliefert werden oder die aus einer Vielzahl einzelner Stationen konzipiert sind und wie eine Einzelmaschine betrieben werden. Weitere Baugruppen, die in einem späteren Stadium einbezogen werden, sollten unter Beachtung der relevanten Normen und unter Berücksichtigung jeglicher Gefährdungen, die sich aus dem Zusammenwirken mit der Warmformmaschine ergeben, gesondert betrachtet werden.

Diese Europäische Norm gilt nicht für Baugruppen, die in Form-, Füll- und Verschließmaschinen integriert sind. Diese sind in EN 415-3:1999 behandelt.

Diese Europäische Norm gilt nicht für Baugruppen, die Heizungssysteme enthalten, die mit Gas betrieben werden.

Machines pour les matières plastiques et le caoutchouc - Machines de thermoformage - Prescriptions de sécurité

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs concernant les machines de thermoformage pour film continu et feuilles unitaires de matière thermoplastique, que ce soit en utilisation normale ou lors de mauvais usages raisonnablement prévisibles par le fabricant (voir Article 4).

Une machine de thermoformage peut comprendre une seule unité de formage ou une unité de formage associée à une ou plusieurs unités complémentaires. La présente norme couvre les unités suivantes :

- dérouleur de film ;

- unité d'alimentation feuille à feuille ;

- dispositif d'alimentation de matière ;

- équipement de transfert ;

- unité de chauffage ;

- unité de préchauffage ;

- unité de chauffage des bords ;

- dispositif d’introduction/d’insertion de composants ;

- poste de formage ;

- poste de finition ;

- poste d'empilage ;

- poste de déchargement ;

- enrouleur de feuille résiduelle ;

- unité de coupe.

La présente Norme européenne ne s'applique pas aux équipements situés en amont ou en aval de la machine de thermoformage :

- qui sont commandés séparément ; et/ou

- qui sont implantés séparément.

NOTE 1 La présente Norme européenne spécifie les prescriptions relatives aux machines livrées sous forme d’une seule unité de formage ou sous forme d’un ensemble d’unités destinées à fonctionner comme une seule machine. Il convient de traiter séparément toute unité supplémentaire ajoutée à un stade ultérieur en appliquant les normes pertinentes et en prenant en compte tout phénomène dangereux provoqué par l’interaction de cette unité avec la machine de thermoformage.

La présente Norme européenne ne s'applique pas aux unités qui sont incorporées dans les machines d'emballage à former, remplir et sceller. Ces unités sont traitées dans l’EN 415-3:1999.

La présente Norme européenne ne s'applique pas aux unités comportant des systèmes de chauffage alimentés au gaz.

(...)

Stroji za predelavo gume in plastike - Stroji za toplotno oblikovanje - Varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 14-Oct-2008

- Withdrawal Date

- 11-Oct-2011

- Technical Committee

- CEN/TC 145 - Rubber and plastics machines - Safety

- Drafting Committee

- CEN/TC 145/WG 10 - Thermoforming machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Oct-2011

- Completion Date

- 12-Oct-2011

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 22-Dec-2008

- Merged Into

EN 12409:2008+A1:2011 - Plastics and rubber machines - Thermoforming machines - Safety requirements - Effective Date

- 13-Aug-2011

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 12409:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics and rubber machines - Thermoforming machines - Safety requirements". This standard covers: This European Standard deals with all significant hazards, hazardous situations and events relevant to thermoforming machines for continuous sheets and single sheets of thermoplastics materials, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4). A thermoforming machine may consist of a forming unit or a forming unit linked to one or more additional units. This standard covers the following units: - continuous sheet unwind unit; - single sheet feed unit; - material intake; - conveying equipment; - heating unit; - preheating unit; - edge heating unit; - component feeding/inserting unit; - forming station; - finishing station; - stacking station; - discharge station; - residual sheet winding unit; - sheet cutting unit. This European standard does not apply to units mounted upstream or downstream of the thermoforming machine: - which have a separate control system; and/or - are located separately. NOTE 1 This European Standard specifies requirements for machines supplied as a single forming unit or a number of units designed to operate as a single machine. Additional units that may be introduced at a later stage should be considered separately applying relevant standards and taking into account any hazards arising through their interaction with the thermoforming machine. This European Standard does not apply to units which are integrated into form, fill and seal machines. These are covered in EN 415-3:1999. This European standard does not apply to units which incorporate heating systems which are fuelled by gas. NOTE 2 Thermoforming machines generally do not create explosive atmospheres. In principle they therefore correspond with line F of Table 2 of the ATEX Guideline and consequently do not fall within the scope of Directive 94/9/EC. This European Standard is not applicable to thermoforming machines which are manufactured before the date of its publication as EN.

This European Standard deals with all significant hazards, hazardous situations and events relevant to thermoforming machines for continuous sheets and single sheets of thermoplastics materials, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4). A thermoforming machine may consist of a forming unit or a forming unit linked to one or more additional units. This standard covers the following units: - continuous sheet unwind unit; - single sheet feed unit; - material intake; - conveying equipment; - heating unit; - preheating unit; - edge heating unit; - component feeding/inserting unit; - forming station; - finishing station; - stacking station; - discharge station; - residual sheet winding unit; - sheet cutting unit. This European standard does not apply to units mounted upstream or downstream of the thermoforming machine: - which have a separate control system; and/or - are located separately. NOTE 1 This European Standard specifies requirements for machines supplied as a single forming unit or a number of units designed to operate as a single machine. Additional units that may be introduced at a later stage should be considered separately applying relevant standards and taking into account any hazards arising through their interaction with the thermoforming machine. This European Standard does not apply to units which are integrated into form, fill and seal machines. These are covered in EN 415-3:1999. This European standard does not apply to units which incorporate heating systems which are fuelled by gas. NOTE 2 Thermoforming machines generally do not create explosive atmospheres. In principle they therefore correspond with line F of Table 2 of the ATEX Guideline and consequently do not fall within the scope of Directive 94/9/EC. This European Standard is not applicable to thermoforming machines which are manufactured before the date of its publication as EN.

EN 12409:2008 is classified under the following ICS (International Classification for Standards) categories: 83.200 - Equipment for the rubber and plastics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12409:2008 has the following relationships with other standards: It is inter standard links to EN 12409:1999, EN 12409:2008+A1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12409:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12409:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo gume in plastike - Stroji za toplotno oblikovanje - Varnostne zahteveKunststoff- und Gummimaschinen - Warmformmaschinen - SicherheitsanforderungenMachines pour les matières plastiques et le caoutchouc - Machines de thermoformage - Prescriptions de sécuritéPlastics and rubber machines - Thermoforming machines - Safety requirements83.200Oprema za gumarsko industrijo in industrijo polimernih materialovEquipment for the rubber and plastics industriesICS:Ta slovenski standard je istoveten z:EN 12409:2008SIST EN 12409:2008en01-december-2008SIST EN 12409:2008SLOVENSKI

STANDARDSIST EN 12409:20001DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12409October 2008ICS 83.200Supersedes EN 12409:1999

English VersionPlastics and rubber machines - Thermoforming machines -Safety requirementsMachines pour les matières plastiques et le caoutchouc -Machines de thermoformage - Prescriptions de sécuritéKunststoff- und Gummimaschinen - Warmformmaschinen -SicherheitsanforderungenThis European Standard was approved by CEN on 24 August 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12409:2008: ESIST EN 12409:2008

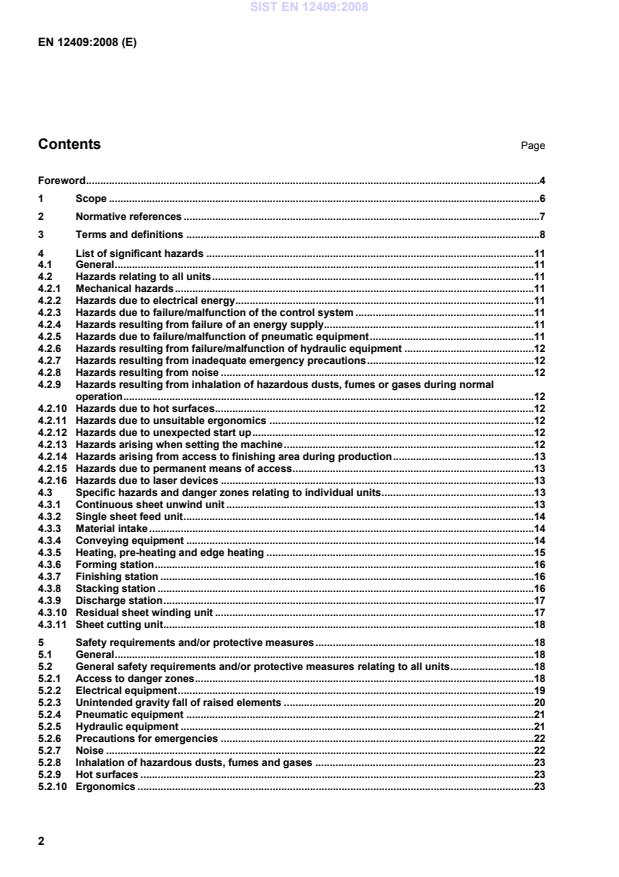

EN 12049:2008 (E) 3 5.2.11 Unexpected start up.23 5.2.12 Setting mode.23 5.2.13 Access during production.24 5.2.14 Laser devices.24 5.2.15 Permanent means of access.24 5.2.16 Common safeguarding system.25 5.2.17 Fixing systems of fixed guards.25 5.3 Specific safety requirements and/or protective measures relating to individual units.25 5.3.1 Continuous sheet unwind unit.25 5.3.2 Single sheet feed unit.26 5.3.3 Material intake.27 5.3.4 Conveying equipment.28 5.3.5 Heating, pre-heating and edge heating.29 5.3.6 Forming station.30 5.3.7 Finishing station.31 5.3.8 Stacking zone.33 5.3.9 Discharge station.33 5.3.10 Residual sheet winding unit.34 5.3.11 Sheet cutting unit.35 6 Verification of safety requirements and/or protective measures.35 7 Information for use.38 7.1 Marking on the machine.38 7.1.1 Minimum marking.38 7.1.2 Additional markings.39 7.2 Instruction manual.39 7.2.1 General requirements.39 7.2.2 Hot surfaces.39 7.2.3 Use of personal protective equipment.39 7.2.4 Noise declaration.39 7.2.5 Extraction of dusts, fumes or gases.40 7.2.6 Electrostatic phenomena.40 7.2.7 Manual handling.41 7.2.8 Fire prevention.41 7.2.9 Manual intervention at the stacking zone.41 7.2.10 Safe cleaning.41 7.2.11 Use of acknowledge switch.41 7.2.12 Inspection of electrical drives.41 7.2.13 Single sheet feed malfunction.41 Annex A (informative)

Single sheet machine (alternatively material feed from single sheet magazine or continuous sheet roll).42 Annex B (informative)

Continuous sheet machine (combined forming and finishing).43 Annex C (informative)

Continuous sheet machine (separate forming and finishing).44 Annex ZA (informative)

Relationship between this

European

Standard and the Essential Requirements

of EU Directive 98/37/EC.45 Annex ZB (informative)

Relationship between this

European

Standard and the Essential Requirements

of EU Directive 2006/42/EC.46 Bibliography.47

EN 12049:2008 (E) 5 Introduction This document is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard. SIST EN 12409:2008

1 Scope This European Standard deals with all significant hazards, hazardous situations and events relevant to thermoforming machines for continuous sheet and single sheets of thermoplastics materials, when they are used as intended and under conditions of misuse which are foreseeable by the manufacturer (see Clause 4). A thermoforming machine may consist of a forming unit or a forming unit linked to one or more additional units. This standard covers the following units: continuous sheet unwind unit; single sheet feed unit; material intake; conveying equipment; heating unit; preheating unit; edge heating unit; component feeding/inserting unit; forming station; finishing station; stacking station;

discharge station; residual sheet winding unit; sheet cutting unit. This European standard does not apply to units mounted upstream or downstream of the thermoforming machine: which have a separate control system; and/or are located separately. NOTE 1 This European Standard specifies requirements for machines supplied as a single forming unit or a number of units designed to operate as a single machine. Additional units that may be introduced at a later stage should be considered separately applying relevant standards and taking into account any hazards arising through their interaction with the thermoforming machine. This European Standard does not apply to units which are integrated into form, fill and seal machines. These are covered in EN 415-3:1999. This European standard does not apply to units which incorporate heating systems which are fuelled by gas. SIST EN 12409:2008

EN 12049:2008 (E) 7 NOTE 2 Thermoforming machines generally do not create explosive atmospheres. In principle they therefore correspond with line F of Table 2 of the ATEX Guideline and consequently do not fall within the scope of Directive 94/9/EC. This European Standard is not applicable to thermoforming machines which are manufactured before the date of its publication as EN. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 574:1996, Safety of machinery — Two-hand control devices — Functional aspects — Principles for design EN 614-1:2006, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 626-1:1994, Safety of machinery — Reduction of risks to health from hazardous substances emitted by machinery — Part 1: Principals and specifications for machinery manufacturers EN 953:1997, Safety of Machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 982:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 983:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Pneumatics EN 999:1998, Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts of the human body EN 1037:1995, Safety of machinery — Prevention of unexpected start-up EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principals for design and selection EN 1760-1:1997, Safety of machinery — Pressure sensitive protective devices — Part 1: General principles for the design and testing of pressure sensitive mats and pressure sensitive floors EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) SIST EN 12409:2008

3.2 continuous sheet unwind unit unit where a continuous sheet roll is clamped and unwound as required by the manufacturing process 3.3 sheet roll continuous sheet wound on a core with or without an integral shaft SIST EN 12409:2008

EN 12049:2008 (E) 9 3.4 single sheet feed unit unit which consists of a single sheet magazine and a handling device that picks up sheets individually and feeds them into the material intake of the thermoforming machine 3.5 material intake unit where the orientation and guidance of continuous sheet or single sheets takes place before being grasped by conveying equipment 3.6 conveying equipment device equipped with spikes or clamps, which conveys continuous sheet, or single sheets, in cycles, between various units of a thermoforming machine EXAMPLE Chain conveyor. 3.7 heating unit device which heats the thermoplastic material prior to forming EXAMPLE Heating radiators, contact heating plates, contact heating rolls or hot air installations. NOTE The heating may be integrated into the forming station. 3.8 pre-heating unit device which heats the thermoplastic material upstream of the heating system EXAMPLE Heating radiators, contact heating plates, contact heating rolls or hot air installations. 3.9 edge heating unit device which heats the edges of the continuous sheet or single sheets before they are grasped by the conveying equipment EXAMPLE Radiators, contact heating plates or hot air installations. 3.10 component feeding/inserting unit device for feeding/inserting components other than sheet material 3.11 forming station unit where thermoplastic continuous sheet or single sheets are formed and that includes all devices which: actuate closing, clamping and opening of moulds; serve as forming aids, e. g. stretching punches, pre blow boxes etc.; locate or clamp thermoplastic sheet during the forming process 3.12 mould component in which the continuous sheet or a single sheet is formed 3.13 stretching punch mechanical aid to support the forming process SIST EN 12409:2008

stacking cage device receiving and stacking the finished parts 3.20 stacking loader device pressing the finished parts into the stacking cage 3.21 stacking unloader device pushing the finished and stacked formed parts out of the stacking cage 3.22 discharge station zone where formed sheet or formed parts, either individually or in larger units, are discharged from the thermoforming machine 3.23 residual sheet winding unit unit where residual sheet, from the finishing station, is wound up 3.24 sheet cutting unit guillotine or other cutting device which cuts sheet in the longitudinal or transverse direction NOTE Sheet may, for example, be cut either before or after the forming station, so as to split formed parts, or after the finishing station, so as to improve scrap handling. 3.25 whole body access access where there is sufficient space for an operator to remain in an enclosed area with interlocked guards closed and/or other protective devices initiated to prevent access SIST EN 12409:2008

EN 12049:2008 (E) 11 3.26 acknowledge switch manually operated switching mechanism, e. g. a key switch, by which the control system is informed, after the opening and closing of guards and/or the actuation of other protective devices, that a danger zone where whole body access is possible is clear before the machine can be started 3.27 cyclic manual intervention intervention by the operator during each working cycle 3.28 non-cyclic manual intervention intervention which occurs only occasionally during the machine operation, e. g. intervention for machine adjustment during continuous operation in automatic mode 4 List of significant hazards 4.1 General This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in this European Standard, identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk. 4.2 Hazards relating to all units NOTE Hazards and danger zones specific to individual units are described in 4.3. 4.2.1 Mechanical hazards Crushing, shearing, impact, drawing-in or trapping hazards by dangerous movements of machine parts, for example, platen, dies, clamping frames, drive and power transmission systems. 4.2.2 Hazards due to electrical energy Hazards due to electrical shock or burns caused by direct or indirect contact with live parts. 4.2.3 Hazards due to failure/malfunction of the control system Crushing, shearing, impact, drawing-in or trapping hazards due to unexpected movements, unexpected start-up (see also 4.2.12) or continuing operation. 4.2.4 Hazards resulting from failure of an energy supply Crushing, shearing, impact, drawing-in or trapping hazards due to sudden fall of raised parts due to gravity, for example sheet roll, platen, clamping frame or stacking unit. 4.2.5 Hazards due to failure/malfunction of pneumatic equipment Impact hazards due to whiplash of hoses resulting from fracture of flexible hoses. Impact, crushing shearing, drawing-in or trapping hazards resulting from unexpected movement of machine parts. SIST EN 12409:2008

EN 12049:2008 (E) 13 4.2.14 Hazards arising from access to finishing area during production Impact, crushing, shearing or drawing-in or trapping hazards. 4.2.15 Hazards due to permanent means of access Harm caused by slipping at or falling from working platforms, steps or walkways provided for use with the machine. 4.2.16 Hazards due to laser devices Hazards due to high intensity radiation can cause eye injury. 4.3 Specific hazards and danger zones relating to individual units 4.3.1 Continuous sheet unwind unit 4.3.1.1 Mechanical hazards 4.3.1.1.1 Hazards during movement of roll loading devices Impact, crushing or shearing hazards. 4.3.1.1.2 Hazards between the sheet rolls and the fixed parts of the unwind unit (e.g. supports and frame) during loading Crushing or shearing hazards. 4.3.1.1.3 Hazards between rotating haul-off rolls and by moving parts of haul-off roll drives Drawing-in or trapping hazards. 4.3.1.1.4 Hazards due to sheet rolls and shafts falling from their bearing Impact or crushing hazards. 4.3.1.1.5 Hazards due to sheet rolls falling from shafts fixed at one end Impact or crushing hazards. 4.3.1.1.6 Hazards due to instability of the unwind unit causing it to fall over Impact or crushing hazards. 4.3.1.1.7 Hazards due to sheet unwinding Cutting hazards due to sharp edges of the sheet. 4.3.1.2 Hazards due to electrostatic charges Hazards due to electrical shock due to discharge of electrostatic charges, which may occur during unwinding of some materials. SIST EN 12409:2008

EN 12049:2008 (E) 15 4.3.4.1.2 Hazards during movement of chain conveyors equipped with spikes or clamps Puncture, penetration, cutting, crushing, shearing or drawing-in or trapping hazards. 4.3.4.1.3 Hazards during movement of sheet or parts of a conveying system Impact or drawing-in or trapping hazards. 4.3.4.2 Hazards due to electrostatic charges Hazards due to electrical shock due to discharge of electrostatic charges, which may occur during separation of some materials. 4.3.5 Heating, pre-heating and edge heating 4.3.5.1 Mechanical hazards 4.3.5.1.1 Hazards during movement of a heating, pre-heating or edge heating device Crushing, shearing or impact hazards. 4.3.5.1.2 Hazards in the areas between rotating rolls (for example heating, diverting or driving rolls) or between sheet and rolls or between fixed machine parts and rotating rolls or moving sheet Drawing-in or trapping hazards. 4.3.5.2 Hazards due to electrical energy Hazards due to contact with live parts of the heating, pre-heating or edge heating devices. 4.3.5.3 Burning hazard Hazards due to contact with hot parts of the heating, pre-heating or edge heating devices or due to contact with hot sheet. 4.3.5.4 Hazards due to inhalation of health hazardous dusts, fumes and gases a) Hazards caused by overheating of material, for example due to: 1) failure of the conveying system; 2) failure of the heating unit retraction/opening system; 3) failure of the heating control system; 4) excessive delay time in/on the heating system; 5) material falling or drooping from the conveying system; 6) energy failure. b) Hazards caused by leakage of hydraulic fluids onto hot parts. c) Hazards caused by abrasion and perforation during material transport. SIST EN 12409:2008

EN 12049:2008 (E) 17 4.3.8.1.2 Hazards during movement of part of a conveyor belt Drawing-in or trapping hazards. 4.3.8.2 Hazards due to failure/malfunction of the control system Hazards due to unexpected start-up or continuing operation. 4.3.8.3 Intervention during operation or as a result of a malfunction Hazards due to moving machine parts, product or residue sheet when manual intervention is necessary during normal operation or as a result of a malfunction. 4.3.8.4 Hazards due to electrostatic charges Hazards due to electrical shock due to discharge of electrostatic charges, which may occur during unwinding of some materials. 4.3.9 Discharge station 4.3.9.1 Mechanical hazards during movement of product or machine parts Impact, crushing, shearing, drawing-in or trapping hazards or cutting hazards due to sharp edge of the sheet. 4.3.9.2 Hazard due to the accessibility of parts of a unit from another unit Hazards described in 4.3.6, 4.3.7 or 4.3.8 may occur if it is possible to reach the area of the conveying equipment, forming station, finishing station or stacking station from the discharge opening. 4.3.9.3 Burning hazards Hazards due to contact with hot products. 4.3.9.4 Hazards due to electrostatic charges Hazards due to electrical shock due to discharge of electrostatic charges, which may occur during unwinding of some materials. 4.3.10 Residual sheet winding unit 4.3.10.1 Mechanical hazards 4.3.10.1.1 Hazards during movement of a sharp-edged sheet Cutting hazards. 4.3.10.1.2 Hazards during winding of residual sheet Entanglement or drawing-in or trapping hazards. SIST EN 12409:2008

EN 12049:2008 (E) 19 interlocking guards in accordance with EN 953:1997, 3.5 or, if necessary in accordance with the choice criteria of EN 1088:1995, interlocking guards with guard locking in accordance with EN 953:1997, 3.6; for safety related parts of the control system PLr 'd' of EN ISO 13849-1:2006 shall apply; or sensitive protective equipment in accordance with EN ISO 12100-1:2003, 3.26.5 and in accordance with PLr 'd' of EN ISO 13849-1:2006 for the safety related parts of the control system, positioned such that the hazard is eliminated before access is possible, (see EN 999:1998), or for maintenance operations only and where access is required no more than once per shift, fixed guards in accordance with EN 953:1997, 3.2. 5.2.1.3 Additional requirements where whole body access is possible An acknowledge switch shall be provided when whole body access is possible between guards or sensitive protective equipment and any danger zone they enclose. The acknowledge switch shall be designed as a safety related part of the control system. Any failure/malfunction of the acknowledge switch shall not lead to a degradation of the performance level of the related control system. The acknowledge switch shall be located in the immediate vicinity of any access point to the danger zones. The switch shall need to be operated by the person leaving the danger zone before the start command can be given by a separate switch. If a guard is opened or other protective device is activated between the operation of the acknowledge switch and the provision of a start command the initiation of a start command shall be prevented. It shall not be possible to actuate an acknowledge switch from the danger zone. The position from which the acknowledge switch is actuated shall allow a good overview of the danger zone and, if required, aids to vision shall be provided. When an interlocking guard is open, and gives a stop command to the control system, it shall not be possible to cancel this command by actuating the acknowledge switch. The start command shall only become effective once all interlocking guards are closed and the acknowledge switch has been actuated. It shall not be possible to store the start command before actuating the acknowledge switch. An acknowledge switch is not required if its function is substituted by an interlocking device requiring delibe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...