EN 1501-1:1998+A2:2009

(Main)Refuse collection vehicles and their associated lifting devices - General requirements and safety requirements - Part 1: Rear-end loaded refuse collection vehicles

Refuse collection vehicles and their associated lifting devices - General requirements and safety requirements - Part 1: Rear-end loaded refuse collection vehicles

This Part of the European Standard specifies the safety and design requirements for the bodywork of (rear loaded) refuse collection vehicles (RCV) for the collection, transportation and discharge of solid waste materials and recyclable materials operated by hydraulic power.

Associated lifting devices and references to chassis interfaces are also covered in this document.

Further definitions, covering types and use of refuse collection vehicles (RCV) and lifting devices are given in clause 3 and 4.

Abfallsammelfahrzeuge und die dazugehörigen Schüttungen - Allgemeine Anforderungen und Sicherheitsanforderungen - Teil 1: Hecklader

Dieser Teil der Europäische Norm legt die Sicherheits und Konstruktionsanforderungen an die Aufbauten von hydraulisch betriebenen Hecklader Abfallsammelfahrzeugen (ASF); für die Sammlung, den Transport und die Entladung fester Abfälle und recycelbarer Materialien (Wertstoffe) fest.

Dazugehörige Schüttungen und Verweisungen auf Fahrgestell Elemente sind ebenfalls in dieser Norm angesprochen.

Definitionen zu Typen und der Nutzung von Abfallsammelfahrzeugen (ASF) sind in den Abschnitten 3 und 4 angeben.

Bennes de collecte des déchets et leurs lève-conteneurs associés - Exigences générales et exigences de sécurité - Partie 1: Bennes à chargement arrière

Cette norme européenne spécifie les exigences de sécurité et de conception pour la superstructure des bennes à ordures ménagères (B.O.M.) à chargement arrière, utilisant principalement l'énergie hydraulique, destinées à la collecte, au transport et au déchargement des déchets solides et de déchets recyclables.

Les lève-conteneurs associés et des ensembles importants de liaison avec le châssis sont également inclus dans cette norme européenne.

Des définitions supplémentaires, concernant les types et l'utilisation des bennes à ordures ménagères (B.O.M.) et des lève-conteneurs sont données aux articles 3 et 4.

Vozila za zbiranje odpadkov in pripadajoči iztresalniki - Splošne in varnostne zahteve - 1. del: Vozila za zbiranje odpadkov z nakladanjem zadaj

Ta del evropskega standarda določa varnostne in konstrukcijske zahteve za karoserijo vozil za zbiranje odpadkov (RCV) (z nakladanjem zadaj), za zbiranje, prevoz in odlaganje trdih odpadnih materialov in materialov, ki jih je mogoče reciklirati in ki delujejo na hidravlični pogon. Ta dokument pokriva tudi pripadajoče iztresalnike in reference na vmesnike za šasije. Nadaljnje definicije, ki zajemajo tipe in uporabo vozil za zbiranje odpadkov (RCV) in iztresalnikov, so podane v klavzuli 3 in 4.

General Information

- Status

- Withdrawn

- Publication Date

- 17-Nov-2009

- Withdrawal Date

- 23-Aug-2011

- Technical Committee

- CEN/TC 183 - Waste management

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Aug-2011

- Completion Date

- 24-Aug-2011

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

DQS Holding GmbH

German-based global certification body for management systems.

Sponsored listings

Frequently Asked Questions

EN 1501-1:1998+A2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Refuse collection vehicles and their associated lifting devices - General requirements and safety requirements - Part 1: Rear-end loaded refuse collection vehicles". This standard covers: This Part of the European Standard specifies the safety and design requirements for the bodywork of (rear loaded) refuse collection vehicles (RCV) for the collection, transportation and discharge of solid waste materials and recyclable materials operated by hydraulic power. Associated lifting devices and references to chassis interfaces are also covered in this document. Further definitions, covering types and use of refuse collection vehicles (RCV) and lifting devices are given in clause 3 and 4.

This Part of the European Standard specifies the safety and design requirements for the bodywork of (rear loaded) refuse collection vehicles (RCV) for the collection, transportation and discharge of solid waste materials and recyclable materials operated by hydraulic power. Associated lifting devices and references to chassis interfaces are also covered in this document. Further definitions, covering types and use of refuse collection vehicles (RCV) and lifting devices are given in clause 3 and 4.

EN 1501-1:1998+A2:2009 is classified under the following ICS (International Classification for Standards) categories: 43.160 - Special purpose vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1501-1:1998+A2:2009 has the following relationships with other standards: It is inter standard links to EN 1501-1:1998/FprA2, EN 1501-1:1998/A1:2004, EN 1501-1:1998, EN 1501-1:2011, EN 1501-5:2011, EN 14803:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1501-1:1998+A2:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396, M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1501-1:1998+A2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Abfallsammelfahrzeuge und die dazugehörigen Schüttungen - Allgemeine Anforderungen und Sicherheitsanforderungen - Teil 1: HeckladerBennes de collecte des déchets et leurs lève-conteneurs associés - Exigences générales et exigences de sécurité - Partie 1: Bennes à chargement arrièreRefuse collection vehicles and their associated lifting devices - General requirements and safety requirements - Part 1: Rear-end loaded refuse collection vehicles43.160Vozila za posebne nameneSpecial purpose vehiclesICS:Ta slovenski standard je istoveten z:EN 1501-1:1998+A2:2009SIST EN 1501-1:2000+A2:2010en,fr,de01-januar-2010SIST EN 1501-1:2000+A2:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1501-1:1998+A2

November 2009 ICS 43.160 Supersedes EN 1501-1:1998English Version

Refuse collection vehicles and their associated lifting devices - General requirements and safety requirements - Part 1: Rear-end loaded refuse collection vehicles

Bennes de collecte des déchets et leurs lève-conteneurs associés - Exigences générales et exigences de sécurité - Partie 1: Bennes à chargement arrière

Abfallsammelfahrzeuge und die dazugehörigen Schüttungen - Allgemeine Anforderungen und Sicherheitsanforderungen - Teil 1: Hecklader This European Standard was approved by CEN on 13 February 1998 and includes Amendment 1 approved by CEN on 2 February 2004 and Amendment 2 approved by CEN on 10 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1501-1:1998+A2:2009: ESIST EN 1501-1:2000+A2:2010

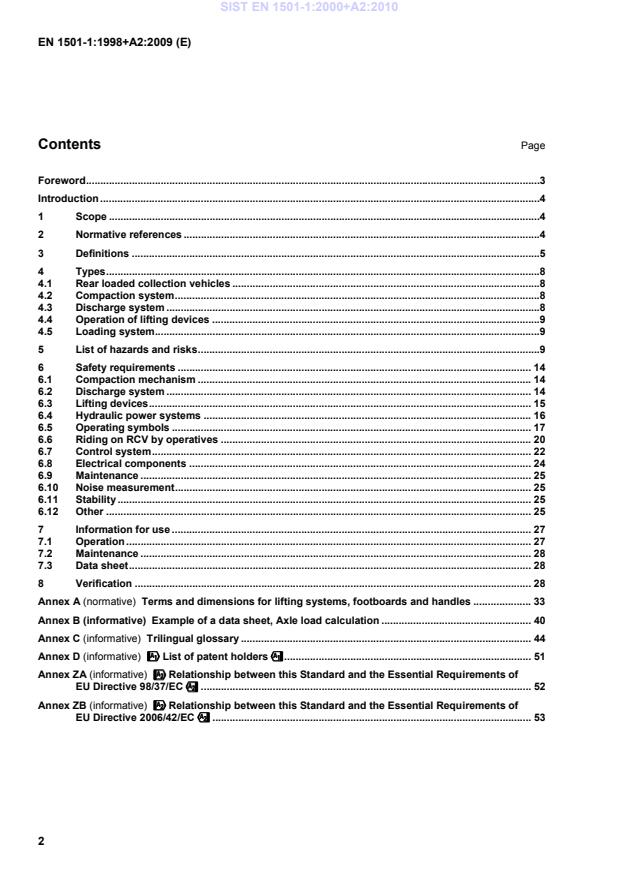

Terms and dimensions for lifting systems, footboards and handles . 33Annex B (informative)

Example of a data sheet, Axle load calculation . 40Annex C (informative)

Trilingual glossary . 44Annex D (informative)

!!!!List of patent holders"""" . 51Annex ZA (informative)

####Relationship between this Standard and the Essential Requirements of EU Directive 98/37/EC$$$$ . 52Annex ZB (informative)

####Relationship between this Standard and the Essential Requirements of EU Directive 2006/42/EC$$$$ . 53 SIST EN 1501-1:2000+A2:2010

!" and # $. This European Standard has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). #For relationship with EU Directive(s), see informative Annexes ZA and ZB, which are integral parts of this document.$ This European Standard is the first one of a series of coordinated standards dealing with specification, design, safety and testing of refuse collection vehicles (RCV) and associated lifting devices. Besides Part 1: Refuse collection vehicle and their associated lifting devices; Rear-end loaded RCV; the following parts of EN 1501 are in preparation: "Refuse collection vehicle and their associated lifting devices; Side loaded RCV" "Refuse collection vehicle and their associated lifting devices; Front loaded RCV" According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

3.8.1 capacity of bodywork The effective volume that can be filled with compacted waste. In case of blade compaction mechanisms, this capacity is defined as the one included between the eventual ejection plate in its retracted position and the compaction mechanism, the latter being positioned at the end of its compaction cycle. The capacity of the bodywork is stated in m3 rounded off to one decimal. 3.8.2 capacity of rotation drum system the volume of the cylindric body 3.8.3 capacity of hopper the effective volume of water the hopper theoretically can contain (see figure A.1). The capacity of the hopper is stated in m3. 3.9 loading height is measured from the upper edge of the rave rail (see figure A.1) to the level where the operator is standing, when the vehicle is empty and ready for loading SIST EN 1501-1:2000+A2:2010

1.1

Compaction system Falling into the hopper during operation

Operative's hand or arm caught by waste being compacted

Injuries by crushing operatives

Damage to limb or body Fatal

Serious to fatal 6.1.2.1

6.1.2.2 7.1 1.1.1

Static body Trapping between compaction mechanism and hopper floor or rave rail

Trapping between compaction mechanism and hopper floor during cleaning cycle when tailgate has been raised partially Injuries by crushing operatives

Damage to hand or arm Serious to fatal

Minor to serious 6.1.2.3, 6.1.2.4, 7.1.1

6.2.4

1.1.2

Rotation drum body

Trapping between tailgate structure and rotating mechanism

Trapping between body and rollers

Damage to limb or body

Damage to hand or arm

Minor to serious

Minor to serious

6.1.3

6.1.3

1.2

Discharge system

Trapping between tailgate and body when tailgate is being lowered

Cleaning of waste from the vehicle when compaction mechanism is in operation

Crush or shear trap when access door is open whilst discharging mechanism is moving

Failure of system that controls raising or lowering tailgate

Broken locks or hinges causing unintentional movement of tailgate

Injuries by hitting or crushing of operative

Damage to limb

Damage to limb

Damage to limb

Injuries due to hitting of operative

Serious to fatal

Serious

Serious to fatal

Serious to fatal

Minor to serious

6.2.3

6.2.3, 6.2.4

6.2.5

6.2.1, 6.2.2

6.1.1, 7.1, 7.2

(continued)

Lifting device Trapping between lifting device or waste container and ground during lowering operation

Trapping between lifting device and tailgate

Trapping between parts of the lifting device

Trapping between waste container and lifting device

Impact by moving lifting device or adapted waste container

Accidental operation of button or lever Injuries by crushing operative's foot

Injury to hand or head

Injury to hand

Injuries by catching operative's hand or clothing

Injury due to impact or bumping

Injury due to hitting by lifting device or waste container Minor to serious

Serious to fatal

Minor to serious

Minor to serious

Minor to serious

Minor 6.3.6, 6.3.8

6.3.3, 6.3.4, 6.3.8, 6.3.10, 7.1 6.3.4

6.3.8, 6.3.11, 7.1

6.3.5, 6.3.10, 6.3.12, 6.3.14

6.3.7, 6.3.12

1.4

Rear footboards Vehicle hits solid objects whilst reversing

Rear collision Injuries by crushing operative on footboard

Injuries by crushing operative on footboard Serious to fatal

Serious to fatal 6.6.3

6.8.3.2 2 Ejection of hydraulic fluid under high pressure

2.1

Lifting device, bodywork Hitting by high pressure oil jet caused by loose or broken oil hoses Operative gets oil injection Serious to fatal

6.4

3 Ejection of waste or waste containers falling off

Serious to fatal

3.1

Compaction mechanism Waste ejected from hopper Injuries by impact of waste Minor to serious 7.1, 7.1.3

(continued)

Lifting device Waste container not locked safely on the lifting device

Waste container incorrectly positioned on the lifting device

Mechanism not operating correctly due to damage

Hoist cable breaks due to design of winching device Injuries due to waste container falling onto operative

Injuries due to waste container falling onto operative

Injuries due to container falling onto operative

Injuries due to container falling onto operative Minor to serious

Minor

Minor to serious

Minor to fatal

6.3.1, 6.3.5, 6.3.11, 7.1.5

6.3.1, 6.3.5, 6.3.8, 7.1.5

7.2, 7.2.1

4 Falling of operative

4.1

Footboards Falling from footboards during reversing of vehicle

Falling or slipping from footboards during forward motion of vehicle e.g. on bends Injuries due to falling or overriding by RCV

Injuries due to falling or overriding by oncoming traffic Serious to fatal

Serious to fatal 6.6.4

6.6.4 5 Noise

5.1

RCV Too high sound pressure level

Noise level hinders oral communication and/or hearing of traffic signals Hearing irreversibly affected

Diverse Minor to serious

Minor to fatal

6.10

6.10 6 Explosion

6.1

Compaction mechanism Explosion within rotating drum vehicle Injuries due to impacts by components of RCV e.g. tailgate falling off or lifting device/waste containers thrown away Serious to fatal 6.12.5 7 Insufficient illumination

7.1

Loading area Various hazards e.g. by unsafe handing of load, containers and controls Various injuries Minor to serious 6.8.3 8 Maintenance

(continued)

Area underneath tailgate Person hit by tailgate or crushed between body and tailgate Crushing of limbs or body/injuries due to impacts Serious to fatal

6.9.1

8.2

Inside body Crushing or shearing by ejector plate Injuries to body/ - shearing of limbs Serious to fatal 6.9.2, 7.2.4 8.3

Inside tailgate Crushing by components of compaction mechanism, e.g. due to gravity Crushing of body and limbs Serious to fatal 6.9.2, 7.2.4 9 Various risks

9.1 Road traffic accident Rear of RCV Impact with vehicle or road Various injuries Minor to fatal

6.8.3, 6.12.4.2, 6.12.4.3, 9.2 9.2 Unintended operation of the mechanism Areas covered previously for risks due to mechanism Unauthorised modification of controls/control circuit

Accidental use of control switches or levers

Machine movement unintentionally started or emergency device set out of operation caused by short circuiting due to water ingress

Machine movement unintentionally started caused by recovered energy e.g. after unexpected engine stop

Unintentional starting or failure on stop functions due to bad design of controls/control circuit Various injuries

Various injuries

Various injuries

Various injuries

Various injuries Minor to fatal

Minor to fatal

Minor to serious

Minor to serious

Minor to fatal

6.8.1.3

6.3.7

6.8.2.1, 6.8.2.2

6.1.2.5, 6.3.14

6.7 9.3

Batteries Short circuit on batteries Burns Minor to serious 6.8.4 9.4

Working area around RCV Tipping over by lack of stability Various injuries

Serious to fatal 6.11 9.5

Instruction Insufficient clear instructions for operating maintenance and repair Various injuries

Minor to serious 6.5, 7.1, 7.2 9.6 Cutting, Toxic, Biological, Fire or Explosion from the waste Working area around RCV and inside the bodywork Various Various injuries

Minor to fatal 6.12.5, 7.1.12

lift Push: lower For rotary switch operation the sense of rotation shall comply with the corresponding response of moving parts. 6.3.8 When releasing an operating control on a manually operated lifting device, the movement of the lifting device shall automatically stop (hold-to-run control). 6.3.9 Operating controls for lifting devices shall be mounted outside of the zone covered by movement of the waste container. 6.3.10 It shall not be possible to initiate automatic or semi-automatic sequences of movements, unless the zone covered by movement of the waste container has been laterally guarded against the approach of persons. Suitable guards could be provided in the form of barriers (see e.g. figure B.4). 6.3.11 When working automatically or semi-automatically the waste container shall not be raised by more than 400 mm if it is not located correctly in the lifting device (see 6.3.1). This shall be achieved by a control that monitors the position of the waste container in the lifting device and by measuring the reference height of the waste container. 6.3.12 If lifting devices can be changed over from the manual to the automatic mode, the change-over operation shall only be possible in the lowest lift position and shall not initiate any lifting or tilting movement. Manual control shall cancel the automatic mode. 6.3.13 The lifting device shall be equipped with hose burst protection valves mounted directly on the lifting rams. 6.3.14 If for any reason the lifting device stops it shall not be able to automatically restart. 6.4 Hydraulic power systems All hydraulic hoses and fittings shall be designed to a safety factor of at least 2 x the working pressure. Where hoses are located within 500 mm of the operative, the operative shall be shielded from sudden hose failure (oil jet coming out). The protection shall be sufficiently sturdy to stop or divert fluids away from the operative. The hydraulic power system shall comply with the requirements of EN 982. SIST EN 1501-1:2000+A2:2010

Reversing packer plate

Operating packer plate

Carriage plate up

Carriage plate down

Compaction single cycle

Semi automatic compaction cycle

Reverse compaction cycle

Compaction continuous cycle

Compaction multi cycle

1) The numbers below 5000 are according to the pictograms of the International Standard ISO 7000:1989 and the numbers above 5000 to the pictograms of IEC 417:1992.

(continued)

Automatic cycle of lifting device

Rescue (return)

Raising of tailgate

Lowering of tailgate

Cleaning of raised tailgate

Ejecting the waste from the body

Ejecting the waste from the body with ejection plate

Retracting the ejection plate

Tipping the body

Lowering the body

1) See page 16.

(continued)

Lifting device up

Lifting device down

On

5007 23

Off

5008 24

Bell/Signal

5013 25

Flashing beacon

1141 26

Working lamp

Right rotation

0004 28

Left rotation

0004 1) See page 16.

6.5.2 Pictograms may be engraved, or fixed with stickers. Both designs shall be durable; stickers shall be permanently fixed. 6.5.3 Colours for pictograms: black or white, on a contrasting background. 6.5.4 Following colours are exclusive for operating elements which have to do with safety, also according to EN 60204-1. Red: stop/emergency stop Green: Start compaction mechanism SIST EN 1501-1:2000+A2:2010

6.6.4.3.1 Safety requirements for occupied footboard(s): If a person (persons) is standing on the footboard(s), the following requirements shall be automatically fulfilled: Compacting: Compacting shall be made impossible if, due to the presence of footboard(s), the loading system is to be considered as an open system due to 4.5.1, i.e. when the distance, as shown in Figure A.5, measured from the occupied footboard level, is less than 1 400 mm. Travelling forward at over 30 km/h: Travelling forwards at over 30 km/h shall be made impossible. In any case, the speed limitation system shall not cause deceleration higher than 2 m/s2 (0,2g). SIST EN 1501-1:2000+A2:2010

Reversing of the RCV shall be made impossible. If the vehicle is equipped with an air braking system, the prevention of reversing has to be achieved by activation of the brakes. For chassis without an air braking system, this has to be achieved by other systems, for example an engine stop. When, after an automatic stopping of the reversing of the vehicle, the safety device is no longer detecting a person, any further reversing shall be possible only by an intentional actuation of the gearbox by the driver, whatever the type of gearbox : manual, automatic, semi-automatic. This can be overridden under the conditions of 6.6.4.3.2. 6.6.4.3.2 Overriding the safety devices An additional control shall be provided so that in a road traffic emergency, it overrides the speed limitation and reversing safety device(s). This additional control shall be located within easy reach of the driver’s seat. This control shall also stop the hydraulic power and require the control to be reset before the compaction mechanism, the discharge system and the lifting device can restart. The reset sequence can start only when the RCV is stopped and the engine is running. After the reset command is given, the safety devices for speed limitation and reversing shall be activated again and it shall take at least 5 minutes before the RCV is ready for use again. It shall not be possible to reduce the reset sequence time. The reset procedure shall be described in the information for use manual. 6.6.4.3.3 Detection of a person (persons) The detection of a person (persons) standing on the footboard(s) can be achieved by one of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...