EN 1591-1:2013

(Main)Flanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation

Flanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation

This European Standard defines a calculation method for bolted, gasketed, circular flange joints. Its purpose is to ensure structural integrity and control of leak tightness. It uses gasket parameters based on definitions and test methods specified in EN 13555.

The calculation method is not applicable to joints with a metallic contact out of the sealing face or to joints whose rigidity varies appreciably across gasket width. For gaskets in incompressible materials, which permit large deformations, the results given by the calculation method can be excessively conservative (i.e. required bolting load too high, allowable pressure of the fluid too low, required flange thickness too large, etc.).

Flansche und ihre Verbindungen - Regeln für die Auslegung von Flanschverbindungen mit runden Flanschen und Dichtung - Teil 1: Berechnung

Diese Europäische Norm legt eine Berechnungsmethode für Flanschverbindungen mit runden Flanschen, Schrauben und Dichtung fest. Sie hat den Zweck, die Festigkeit der Konstruktion sicherzustellen und die Dichtigkeit zu kontrollieren. Dafür werden Dichtungskennwerte angewendet, die auf Definitionen und Prüf-verfahren nach EN 13555 beruhen.

Die Berechnungsmethode ist nicht anwendbar auf Flanschverbindungen mit einem metallischen Dichtflächen-kontakt und auf Flanschverbindungen, deren Steifigkeit über die Dichtungsbreite stark schwankt. Bei Dichtungen in unelastischen Werkstoffen, die starke Verformungen zulassen, können die Ergebnisse nach dieser Berechnungsmethode übermäßig konservativ sein (d. h. erforderliche Schraubenkraft zu hoch, zulässiger Mediendruck zu gering, erforderliche Flanschdicke zu groß usw.).

Brides et leurs assemblages - Règles de calcul des assemblages à brides circulaires avec joint - Partie 1: Méthode de calcul

La présente Norme européenne définit une méthode de calcul des assemblages à brides circulaires boulonnés avec joint. Son objectif est d'en assurer l'intégrité structurale et la maîtrise de l'étanchéité. Elle utilise des paramètres de joints basés sur les définitions et les modes opératoires d'essais spécifiés dans l'EN 13555.

La méthode de calcul ne s'applique pas aux assemblages à contact métallique en dehors de la face d'étanchéité ni aux assemblages dont la rigidité varie de façon notable sur la largeur du joint. En ce qui concerne les joints en matériau incompressible qui présentent des déformations importantes, les résultats fournis par la méthode de calcul peuvent être excessivement conservateurs (c'est-à-dire effort de boulonnage requis trop élevé, pression admissible de fluide trop faible, épaisseur de bride nécessaire trop importante, etc.).

Prirobnice in prirobnični spoji - Pravila za konstruiranje prirobničnih spojev, sestavljenih iz okroglih prirobnic in tesnil - 1. del: Izračun

General Information

- Status

- Withdrawn

- Publication Date

- 17-Dec-2013

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 74 - Flanges and their joints

- Drafting Committee

- CEN/TC 74/WG 10 - Calculation methods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Oct-2024

- Completion Date

- 09-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 25-Dec-2013

- Effective Date

- 25-Dec-2013

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1591-1:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Flanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation". This standard covers: This European Standard defines a calculation method for bolted, gasketed, circular flange joints. Its purpose is to ensure structural integrity and control of leak tightness. It uses gasket parameters based on definitions and test methods specified in EN 13555. The calculation method is not applicable to joints with a metallic contact out of the sealing face or to joints whose rigidity varies appreciably across gasket width. For gaskets in incompressible materials, which permit large deformations, the results given by the calculation method can be excessively conservative (i.e. required bolting load too high, allowable pressure of the fluid too low, required flange thickness too large, etc.).

This European Standard defines a calculation method for bolted, gasketed, circular flange joints. Its purpose is to ensure structural integrity and control of leak tightness. It uses gasket parameters based on definitions and test methods specified in EN 13555. The calculation method is not applicable to joints with a metallic contact out of the sealing face or to joints whose rigidity varies appreciably across gasket width. For gaskets in incompressible materials, which permit large deformations, the results given by the calculation method can be excessively conservative (i.e. required bolting load too high, allowable pressure of the fluid too low, required flange thickness too large, etc.).

EN 1591-1:2013 is classified under the following ICS (International Classification for Standards) categories: 23.040.60 - Flanges, couplings and joints. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1591-1:2013 has the following relationships with other standards: It is inter standard links to EN 1591-1:2001+A1:2009, EN 1591-1:2001+A1:2009/AC:2011, EN 1591-1:2024, EN 13555:2004, EN 12516-2:2014+A1:2021, EN 13480-2:2024, EN 1092-1:2018, EN 14917:2021, EN 13480-2:2017, EN 12516-2:2014, EN 13445-3:2014, EN 13445-3:2021, EN 14585:2024, EN 13555:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1591-1:2013 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1591-1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Flansche und Flanschverbindungen - Regeln für die Auslegung von Flanschverbindungen mit runden Flanschen und Dichtung - Teil 1: BerechnungBrides et leurs assemblages - Règles de calcul des assemblages à brides circulaires avec joint - Partie 1: Méthode de calculFlanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation23.040.60Prirobnice, oglavki in spojni elementiFlanges, couplings and jointsICS:Ta slovenski standard je istoveten z:EN 1591-1:2013SIST EN 1591-1:2014en,fr,de01-februar-2014SIST EN 1591-1:2014SLOVENSKI

STANDARDSIST EN 1591-1:2002+A1:2009/AC:2011SIST EN 1591-1:2002+A1:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1591-1

December 2013 ICS 23.040.60 Supersedes EN 1591-1:2001+A1:2009English Version

Flanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation

Brides et leurs assemblages - Règles de calcul des assemblages à brides circulaires avec joint - Partie 1: Méthode de calcul

Flansche und ihre Verbindungen - Regeln für die Auslegung von Flanschverbindungen mit runden Flanschen - Teil 1: Berechnung This European Standard was approved by CEN on 12 October 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1591-1:2013 ESIST EN 1591-1:2014

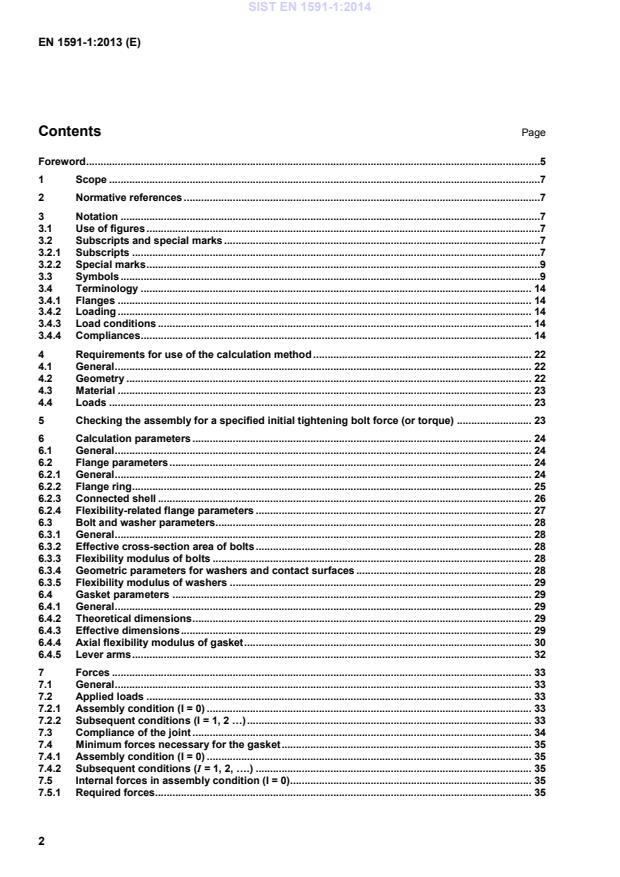

Dimensions of standard metric bolts . 43 Annex B (informative)

Tightening . 44 B.1 Scatter of initial bolt load of a single bolt — Indicative values 01- and 01+ for a single bolt . 44 B.2 Scatter for the global load of all the bolts. 44 B.3 Manual uncontrolled tightening . 45 B.4 Assembly using torque wrench . 45 B.5 Assembly using bolt tensioner . 46 Annex C (informative)

Flange rotations . 48 C.1 General . 48 C.2 Use of flange rotation. 48 C.3 Calculation of flange rotations . 48 Annex D (informative)

Use of the calculation method . 50 D.1 Calculation method principle . 50 D.2 Mechanical model . 51 D.3 Required checks . 52 D.4 Calculation sequence. 52 Annex E (informative)

Gasket/flange face friction coefficients examples . 54 Annex F (normative)

Determination of ∆eGc,I based on a given PQR . 55 F.1 Determination of the deflection occurring during a PQR test . 55 F.2 Determination of the deflection to be taken into account in the calculation . 56 Annex G (informative)

Sealing gasket parameter when no leakage rate is specified . 57 Annex H (informative)

Alternative calculation procedure taking into account the plastic deformation of the gasket in subsequent load conditions procedures (after assembly) . 58 H.1 Introduction . 58 H.2 Calculation procedure. 58 H.2.1 General description . 58 H.2.2 No additional plastic deformation . 59 H.2.3 Additional plastic deformation . 59 H.3 Flat gaskets . 59 H.3.1 Flat gaskets with small or median deformations . 59 H.3.2 Flat gaskets with greater deformations . 61 H.4 Metal gaskets with curved surfaces (Figures 3b, c, e, f ) . 62 H.5 Metal gaskets with octagonal section (Figure 3d) . 62 Annex I (informative)

Available, incomplete models for conversion of the leakage rates in different conditions (based on certain flow models) . 63 I.1 Introduction and warning . 63 I.2 Flow theory fundamentals . 63 I.2.1 Transport modes . 63 I.2.2 Case of gases . 64 I.2.3 Case of liquids: Parallel capillary model. 65 I.3 Factors of influence on the leakage rate of gaskets and gasketed joints . 65 I.3.1 List of identified factors . 65 I.3.2 Limits and restriction of the proposed models . 65 I.3.3 Dependence on pressure . 66 I.3.4 Dependence on temperature . 67 SIST EN 1591-1:2014

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC . 74 Bibliography . 75

(Annex G). This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document. EN 1591 consists of several parts: EN 1591-1, Flanges and their joints — Design rules for gasketed circular flange connections — Part 1: Calculation EN 1591-2, Flanges and their joints — Design rules for gasketed circular flange connections — Part 2: Gasket parameters CEN/TS 1591-3, Flanges and their joints — Design rules for gasketed circular flange connections — Part 3: Calculation method for metal to metal contact type flanged joint EN 1591-4, Flanges and their joints — Part 4: Qualification of personnel competency in the assembly of the bolted connections of critical service pressurized systems SIST EN 1591-1:2014

The use of this calculation method is particularly useful for joints where the bolt load is monitored when bolting up. The greater the precision of this, the more benefit can be gained from application of the calculation method. According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Figure 12 Type 05

Figure 11 Type 07

Figure 12 Type 11

Figure 6 Type 12

Figure 13 Type 13

Figure 14 Type 21

Figures 6 to 9

3.2 Subscripts and special marks 3.2.1 Subscripts A – Additional (FA, MA) B – Bolt SIST EN 1591-1:2014

L – Loose flange, Lateral (FLI) M – Moment N – Nut P – Fluid pressure Q – Net axial force due to pressure R – Net axial force due to external force S – Shell, shear

T – Shell, modified TG – Torsion (MTG) X – Flange weakest cross section W – Washer ∆ – Symbol for change or difference av – average c – calculated d – design

e – effective i – Interim value max – maximum min – minimum nom – nominal opt – optimal req – required SIST EN 1591-1:2014

3.3 Symbols Where units are applicable, they are shown in brackets. Where units are not applicable, no indication is given.

AB Effective total cross-section area of all bolts [mm2], Formula (41) AF, AL Gross radial cross-section area (including bolt holes) of flange ring, loose flange [mm2], Formulae (10), (13) and (16) AGe, AGt Gasket area, effective, theoretical [mm2], Formulae (56), (53) AQ Effective area for the axial fluid-pressure force [mm2], Formula (90) EB, EF, EL EW Modulus of elasticity of the part designated by the subscript, at the temperature of the part [MPa] EG, Modulus of elasticity of the gasket for unloading/reloading at the considered temperature, considering the initial compressed thickness [MPa]

FA Additional external axial force [N], tensile force > 0, compressive force < 0, see Figure 1, Formulae (92) and (96) FB Bolt force (sum of all bolts) [N] FG Gasket force [N] FG∆,

Minimum gasket force in assembly condition [N] that guarantees, after all load changes, to subsequent conditions the required gasket force, Formulae (105), (106)

FL Force resulting from the additional radial forces [N], Formula (93) and (104) FQ Axial fluid-pressure force [N], Formula (91) FR Force resulting from the additional external loads [N], Formula (96) FX, FY, FZ Additional forces along X, Y and Z-axis at gasket interface [N], Formulae (92) and (93) I Load condition identifier, for assembly condition I = 0, for subsequent conditions I = 1, 2, 3,. MA Resulting external bending moment [N × mm], Figure 1, Formula (94) and (104) Mt Bolt assembly torque [N × mm], Formula (B.4) SIST EN 1591-1:2014

Temperature (average) of the part designated by the subscript [°C] or [K], Formula (97) TO Temperature of joint at assembly [°C] or [K] (usually + 20 °C), Formula (97)

UT Axial displacement due to thermal effect xmm]; ∆rT according to Formula (97)

WF, WL, WX Resistance of the part and/or cross-section designated by the subscript [N × mm], Formulae (130), (146), (150), (148) XB, XG, Xw Axial flexibility modulus of bolts, gasket, washer [1/ mm], Formulae (42), (63), (43), (49), (50) YB,YG, YQ, YR Axial compliance of the bolted joint, related to FB, FG, FQ, FR [mm/N], Formulae

(99), (100), (101), (102) ZF, ZL Rotational flexibility modulus of flange, loose flange [mm -3], Formulae (34), (38), (35), (39), (40) b0 Width of chamfer (or radius) of a loose flange such that: d7min = d6+2×b0 [mm], Figure 12, Formula (85) SIST EN 1591-1:2014

Contact widths bolt side [mm], Formula (48) bW Width of a washer [mm], Formula (44) cA, cB, cF, cM, cS Correction factors [-],Formulae

(123) to (127), (28), (134), (135) d0 Inside diameter of flange ring [mm] and also the outside diameter of central part of blank flange (with thickness e0), in no case greater than inside diameter of gasket [mm], Figures 6 to 14 d1 Average diameter of hub, thin end [mm], Figures 6, 7, 13 and 14 d2 Average diameter of hub, thick end [mm], Figures 6, 7, 13 and 14 d3, d3e Bolt circle diameter, real, effective [mm], Figures 6 to 14, Formula (6)

d4 Outside diameter of flange [mm], Figures 6 to 14 d5, d5t, d5e Diameter of bolt hole, pierced, blind, effective [mm], Figures 6 to 14, Formulae (4), (5)

d6 Inside diameter of loose flange [mm], Figures 12, 14 d7 Diameter of position of reaction between loose flange and stub or collar [mm], Figure 1, Formulae

(61) and (84) to (89). d8 Outside diameter of collar [mm], Figure 12 d9 Diameter of a central hole in a blank flange [mm], Figure 11 dB0, dBe, dBs Diameter of bolt: nominal diameter, effective diameter, shank diameter [mm], Figure 3, Table A.1 dB2, dB3 Basic pitch diameter, basic minor diameter of thread [mm], see Figure 3 dB4 Maximum possible outside contact diameter between bolt head or nut and flange or washer [mm], Formula (47)

dGi,dGe, dGt Diameter of gasket, interim, effective, theoretical [mm], Figure 4, Formula (56), Table 1 dK1, dK2 Extreme contact diameters (inside, outside) [mm], Formulae (46) and (47) dG0, dG1, dG2 Real, theoretical inside, theoretical outside contact diameters [mm], Figure 4 dE, dF, dL dS, dX, dw Average diameter of part or section designated by the subscript [mm], Figures 1 and 6 to 14 dw1, dw2 Inside, Outside diameter of washer [mm], Figure 1, 2 e0 Wall thickness of central plate of blank flange within diameter d0 [mm], Figure 11 SIST EN 1591-1:2014

eP, eQ Part of flange thickness with (eP), without (eQ) radial pressure loading [mm], Figures 6 to 14, such that eP+eQ = eF eS Thickness of connected shell [mm], Figures 6 to 10, 12 to 14 eW Washer thickness [mm], Figure 1, 2 eX Flange thickness at weak section [mm], Figure 11 fB, fE, fF, fL, fS, fW Nominal design stress [MPa] of the part designated by the subscript, at design temperature [°C] or [K], as defined and used in pressure vessel codes (see Formulae (123), (127), (130) to (133), (140), (145), (146), (148), (150) and (151)) hG, hH, hL Lever arms [mm], Figure 1, Formulae (81) to (83) and (87) to (89) hP, hQ, hR, hS, hT

Lever arm corrections [mm], Formulae (77), (79) and (80), (31) and (37), (29), (30) jM, jS Sign number for moment, shear force (+1 or 1), Formulae (136) and (137) kQ, kR, kM, kS Correction factors, Formulae (32), (33), (138), (139) lB, ls Bolt axial dimensions [mm], Figure 2, Formulae (98) and (42) le le = lB - lS lH Length of hub [mm], Figures 6, 7, 13, 14, Formulae (17), (18) m tightness factor for subsequent conditions ( I>0 ) [-], (Annex G) nB Number of bolts, Formulae (3), (6), (41), (42) pB Pitch between bolts [mm], Formula (3) pt Pitch of bolt thread [mm], Table A.1 SIST EN 1591-1:2014

Load ratio of flange ring due to radial force, Formula (140) Z Formula (130), Table 2 B, F, G, L, X,

Load ratio of part and/or cross-section designated by the subscript, to be calculated for all load conditions, Formulae (123), (129), (145), (151), (128), (149), (147)

.B, .F, .G, .L, .W Thermal expansion coefficient of the part designated by the subscript, averaged between T0 and TB, TF, TG, TL, TS, TW [K-1], Formula (97) , , /, , , , x Intermediate variables, Formulae (19), (25) to (27), (62), (132), (133) 01+, 01- Scatter of initial bolt load of a single bolt, above nominal value, below nominal value, Annex B 0+, 0– Scatter for the global load of all the bolts above nominal value, below nominal value, Annex B µ Friction factor for bolting, see Annex B µG Friction factor between the gasket and the flange facing, Table (E.1) and Formula (104) π Numerical constant (π = 3,141593) ρ Diameter ratio as given in Formula (36) 3G Angle of inclination of a sealing face [rad or deg], Figure 4, Table 1 3S Angle of inclination of connected shell wall [rad or deg], Figures 8, 9 SIST EN 1591-1:2014

Figure 1 — Loads and lever arms

Figure 2 — Washer or spacer

sBelll−= Figure 3 — Bolts SIST EN 1591-1:2014

Figure 4 — Gaskets

Key 1 male flange (tongue) 2 female flange (groove) 3 gasket Figure 5 — Details for tongue and groove facing SIST EN 1591-1:2014

Key 1 shell 2 hub 3 ring Figure 6 — Weld-neck flanges with cylindrical shells (example 1)

Key 1 shell 2 hub 3 ring Figure 7 — Weld-neck flanges with cylindrical shells (example 2) SIST EN 1591-1:2014

Key 1 shell 2 ring Figure 8 — Flanges welded to conical shells

Key 1 shell 2 ring Figure 9 — Flanges welded to spherical shells SIST EN 1591-1:2014

Key 1 shell 2 ring Figure 10 — Weld-on plate flange

Key 1 plate 2 ring Figure 11 — Blank flange SIST EN 1591-1:2014

Key 1 shell 2 collar 3 loose flange Figure 12 — Loose flanges with collar

Figure 13 — Hubbed slip-on welded flange SIST EN 1591-1:2014

Figure 14 — Hubbed threaded flange

4 Requirements for use of the calculation method 4.1 General Where permitted, the calculation method is an alternative to design validation by other means, e.g.: special testing; proven practice; use of standard flanges within permitted conditions. The calculation method can also be used to assess the behaviour and admissibility of a bolted flange connection for a specified initial bolt force (see Clause 5). 4.2 Geometry The calculation method is applicable to the configurations having: a) flanges whose section is given or may be assimilated to those given in Figure 6 to Figure 14; b) four or more identical bolts uniformly distributed; c) gasket whose section and configuration after loading can be assimilated by one of those given in Figure 4 and Figure 5; d) flange dimension which meet the following conditions: 1) ;0,5/2,0;0,5/2,0LLFF≤≤≤≤ebeb 2) )01,01/(1cosssed+≥ϕ. SIST EN 1591-1:2014

5 Checking the assembly for a specified initial tightening bolt force (or torque) The details of calculation method as the calculation process are detailed in Annex D. SIST EN 1591-1:2014

Then the calculation shall be performed in the usual way from Formula (55) to Formula (110). From the required initial bolt force calculated in Formula (110) two cases shall be considered: If the value FG0req given by Formula (110) is higher than the initial value FG0 given by Formula (1), the value of FB0,specified is not sufficient to insure the tightness criteria. So the value of FB0, specified shall be increased to meet the tightness criteria. The calculation procedure from Formula (55) to Formula (110) shall be applied again. If the value FG0req given by Formula (110) is lower than the initial value FG0 given by Formula (1), the value of FB0,specified is sufficient to insure the tightness criteria and therefore the calculation can be continued using the value of FG0 calculated by Formula (1) as the gasket force in assembly condition (I=0). In that case, the initial bolt force at assembly can be very much greater than the required one, and the Formula (119) shall be replaced by Formula (2), taking into account the lower bound of the applied initial bolt force at assembly phase. {}R0B0maxRR0B0mindG0)/101()3/2(;maxFFNFFF−×−×−= (2) 6 Calculation parameters 6.1 General The parameters defined in this clause are effective dimensions, areas and stiffness parameters. 6.2 Flange parameters 6.2.1 General The formulae given in 6.2 shall be used for each of the two flanges and whe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...