EN 13001-1:2015

(Main)Cranes - General design - Part 1: General principles and requirements

Cranes - General design - Part 1: General principles and requirements

This European Standard specifies general principles and requirements to be used together with EN 13001 2 and the EN 13001 3 series of standards, and as such they specify conditions and requirements on design to prevent mechanical hazards of cranes, and a method of verification of those requirements.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 of this European Standard is necessary to reduce or eliminate the risks associated with the following hazards:

a) instability of the crane or its parts (tilting);

b) exceeding the limits of strength (yield, ultimate, fatigue);

c) elastic instability of the crane or its parts (buckling, bulging);

d) exceeding temperature limits of material or components;

e) exceeding the deformation limits.

This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

Krane - Konstruktion allgemein - Teil 1: Allgemeine Prinzipien und Anforderungen

Diese Europäische Norm legt die allgemeinen Grundlagen und Anforderungen fest, die zusammen mit EN 13001 2 und der Normenreihe EN 13001 3 anzuwenden sind und spezifiziert die Bedingungen und Anforderungen an die Konstruktion zur Vermeidung von mechanischen Gefährdungen bei Kranen sowie eine Methode der Überprüfung dieser Anforderungen.

ANMERKUNG Besondere Anforderungen für spezielle Krantypen sind in der zutreffenden Europäischen Norm für den speziellen Krantyp angegeben.

Im Folgenden ist eine Auflistung von signifikanten Gefährdungssituationen und Gefährdungsereignissen gegeben, die Risiken für Personen während des normalen Gebrauchs und vorhersehbarem Missbrauch (des Krans) zur Folge haben könnten. Abschnitt 4 dieser Europäischen Norm wird zur Reduzierung oder Eliminierung der mit den folgenden Gefährdungen verbundenen Risiken benötigt:

a) Instabilität des Krans oder seiner Teile (Kippen);

b) Überschreitung der Festigkeitsgrenzwerte (Fließgrenze, Bruch-, Ermüdungsfestigkeit);

c) elastische Instabilität des Krans oder seiner Teile (Knicken, Ausbeulen);

d) Überschreitung von Temperaturgrenzwerten des Werkstoffs oder der Komponenten;

e) Überschreitung der Verformungsgrenzwerte.

Diese Europäische Norm gilt für Krane, die nach dem Datum der Genehmigung dieser Norm durch CEN hergestellt werden und dient als Referenzgrundlage für die Europäischen Normen für spezielle Krantypen.

Appareils de levage à charge suspendue - Conception générale - Partie 1 : Principes généraux et prescriptions

La présente Norme européenne spécifie les principes généraux et les prescriptions à utiliser conjointement avec l’EN 13001-2 et la série des EN 13001-3, et dans ce cadre elles spécifient les conditions et les prescriptions de conception visant à prévenir les dangers mécaniques liés aux appareils de levage à charge suspendue, et elles spécifient une méthode de vérification de ces prescriptions.

NOTE Des prescriptions spécifiques relatives aux types particuliers d’appareil de levage à charge suspendue sont données dans la norme européenne appropriée au type particulier de grue.

La liste suivante spécifie les situations et les événements dangereux significatifs, susceptibles d'entraîner des risques pour les personnes lors d'une utilisation normale et d'une mauvaise utilisation prévisible. L'Article 4 de la présente Norme européenne est nécessaire pour réduire ou éliminer les risques associés à ces phénomènes dangereux :

a) instabilité de l’appareil de levage à charge suspendue ou de ses éléments (basculement) ;

b) dépassement des limites de résistance (élasticité, rupture, fatigue) ;

c) instabilité élastique de l’appareil de levage ou de ses éléments (flambage, voilement) ;

d) dépassement des limites de température du matériau ou des composants ;

e) dépassement des limites de déformation.

La présente Norme européenne s'applique aux appareils de levage à charge suspendue construits après sa date d'approbation par le CEN et sert de base de référence pour les normes européennes pour des types de grues particuliers.

Žerjavi - Konstruiranje, splošno - 1. del: Splošna načela in zahteve

General Information

- Status

- Published

- Publication Date

- 07-Apr-2015

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 2 - Design - General

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 15-Jan-2021

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 13001-1:2004+A1:2009 - Cranes - General design - Part 1: General principles and requirements - Effective Date

- 08-Jun-2022

- Effective Date

- 15-Apr-2015

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13001-1:2015 - published by CEN - is the European standard for the general design of cranes, titled "Cranes - General design - Part 1: General principles and requirements." It provides the high-level design principles, verification methods and safety requirements to prevent mechanical hazards in cranes. EN 13001-1:2015 is intended to be used together with EN 13001-2 (Load actions) and the EN 13001-3 series (Limit states and proof of competence) as the reference base for crane design and verification across Europe.

Key topics and technical requirements

- Scope and purpose: Establishes general principles and requirements for mechanical safety of cranes and a method for theoretical verification (proof calculation).

- Hazard reduction: Addresses significant hazardous situations including:

- instability/tilting,

- exceeding strength limits (yield, ultimate, fatigue),

- elastic instability (buckling, bulging),

- excessive temperatures of materials/components,

- excessive deformations.

- Proof calculation: Sets out objectives and methods to demonstrate that a crane design meets safety requirements under agreed service conditions (including erection, dismantling, transport).

- Uses the limit state method and, where applicable, the allowable stress method.

- Requires modelling of crane and loads, simulation of load actions, load combinations and evaluation of limit states.

- Load histories and classification: Requires analysis of representative load histories to reflect realistic operational sequences, fatigue assessment and stress cycle classification.

- Verification practices: Defines models, partial safety factors, stress spectra, and methods for proof of competence consistent with recognized state of the art.

- Normative and informative material: Includes references to EN ISO 12100 (risk assessment), ISO 2394, and Annexes (e.g., selection of suitable crane standards, relationship to Machinery Directive).

Practical applications

- Use EN 13001-1:2015 to:

- Design and verify the structural and mechanical components of cranes for safety against instability, strength failure and fatigue.

- Prepare engineering calculations and documentation to demonstrate conformity with the Machinery Directive.

- Define interfaces between purchaser, designer and component manufacturers for specification and selection.

- Typical deliverables: proof calculations, design reports, fatigue assessments, load modelling and verification records.

Who should use this standard

- Crane designers and structural/mechanical engineers

- Crane manufacturers and component suppliers

- Safety engineers, conformity assessors and notified bodies

- Purchasers/specifiers of cranes and end‑users responsible for safe operation

- Inspectors and maintenance planners involved in lifecycle safety

Related standards

- EN 13001-2 - Load actions

- EN 13001-3 series - Limit states and proof of competence (steel structure, wire ropes, wheel/rail, machinery, hooks)

- EN ISO 12100 - Risk assessment and risk reduction

Keywords: EN 13001-1:2015, crane design standard, crane safety, proof calculation, limit state method, load actions, fatigue, CEN.

Frequently Asked Questions

EN 13001-1:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Cranes - General design - Part 1: General principles and requirements". This standard covers: This European Standard specifies general principles and requirements to be used together with EN 13001 2 and the EN 13001 3 series of standards, and as such they specify conditions and requirements on design to prevent mechanical hazards of cranes, and a method of verification of those requirements. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 of this European Standard is necessary to reduce or eliminate the risks associated with the following hazards: a) instability of the crane or its parts (tilting); b) exceeding the limits of strength (yield, ultimate, fatigue); c) elastic instability of the crane or its parts (buckling, bulging); d) exceeding temperature limits of material or components; e) exceeding the deformation limits. This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

This European Standard specifies general principles and requirements to be used together with EN 13001 2 and the EN 13001 3 series of standards, and as such they specify conditions and requirements on design to prevent mechanical hazards of cranes, and a method of verification of those requirements. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 of this European Standard is necessary to reduce or eliminate the risks associated with the following hazards: a) instability of the crane or its parts (tilting); b) exceeding the limits of strength (yield, ultimate, fatigue); c) elastic instability of the crane or its parts (buckling, bulging); d) exceeding temperature limits of material or components; e) exceeding the deformation limits. This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

EN 13001-1:2015 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13001-1:2015 has the following relationships with other standards: It is inter standard links to EN 13001-1:2004+A1:2009, EN 13001-1:2004+A1:2009/AC:2009, ISO 2394:2015, EN 840-3:2012, EN ISO 12100:2010, EN 13001-2:2021, EN 13001-3-1:2012, EN 13001-3-1:2012+A2:2018, CEN/TS 13001-3-2:2008, EN 15955-2:2025, EN 13852-1:2025, EN 13852-3:2021, EN 1570-2:2016, EN 1991-3:2006, EN 15011:2011+A1:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13001-1:2015 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13001-1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2015

Nadomešča:

SIST EN 13001-1:2005+A1:2009

SIST EN 13001-1:2005+A1:2009/AC:2010

Žerjavi - Konstruiranje, splošno - 1. del: Splošna načela in zahteve

Cranes - General design - Part 1: General principles and requirements

Krane - Konstruktion allgemein - Teil 1: Allgemeine Prinzipien und Anforderungen

Appareils de levage à charge suspendue - Conception générale - Partie 1: Principes

généraux et prescriptions

Ta slovenski standard je istoveten z: EN 13001-1:2015

ICS:

53.020.20 Dvigala Cranes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 13001-1

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2015

ICS 53.020.20 Supersedes EN 13001-1:2004+A1:2009

English Version

Cranes - General design - Part 1: General principles and

requirements

Appareils de levage à charge suspendue - Conception Krane - Konstruktion allgemein - Teil 1: Allgemeine

générale - Partie 1 : Principes généraux et prescriptions Prinzipien und Anforderungen

This European Standard was approved by CEN on 16 February 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13001-1:2015 E

worldwide for CEN national Members.

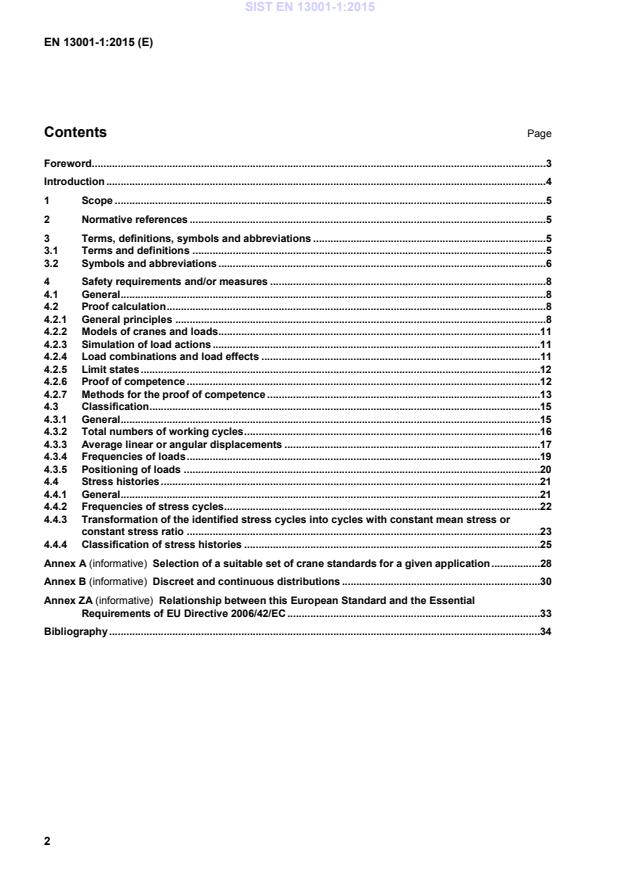

Contents Page

Foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms, definitions, symbols and abbreviations . 5

3.1 Terms and definitions . 5

3.2 Symbols and abbreviations . 6

4 Safety requirements and/or measures . 8

4.1 General . 8

4.2 Proof calculation . 8

4.2.1 General principles . 8

4.2.2 Models of cranes and loads .11

4.2.3 Simulation of load actions .11

4.2.4 Load combinations and load effects .11

4.2.5 Limit states .12

4.2.6 Proof of competence .12

4.2.7 Methods for the proof of competence .13

4.3 Classification.15

4.3.1 General .15

4.3.2 Total numbers of working cycles .16

4.3.3 Average linear or angular displacements .17

4.3.4 Frequencies of loads .19

4.3.5 Positioning of loads .20

4.4 Stress histories .21

4.4.1 General .21

4.4.2 Frequencies of stress cycles .22

4.4.3 Transformation of the identified stress cycles into cycles with constant mean stress or

constant stress ratio .23

4.4.4 Classification of stress histories .25

Annex A (informative) Selection of a suitable set of crane standards for a given application .28

Annex B (informative) Discreet and continuous distributions .30

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC .33

Bibliography .34

Foreword

This document (EN 13001-1:2015) has been prepared by Technical Committee CEN/TC 147 “Cranes -

Safety”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by October 2015, and conflicting national standards shall be withdrawn at

the latest by October 2015.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13001-1:2004+A1:2009.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

The major changes in this revision are in 4.2.7.2, 4.3.3 and 4.4.4. Annex B has been added.

This European Standard is one part of EN 13001. The parts are the following ones:

— Part 1: General principles and requirements;

— Part 2: Load actions;

— Part 3-1: Limit States and proof competence of steel structure;

— Part 3-2: Limit states and proof of competence of wire ropes in reeving systems;

— Part 3-3: Limit states and proof of competence of wheel/rail contacts;

— Part 3-4: Limit states and proof of competence of machinery [currently at Enquiry stage];

— Part 3-5: Limit states and proof of competence of forged hooks [Technical Specification].

For the relationship with other European Standards for cranes, see Annex A.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Introduction

This European Standard has been prepared to be a harmonized standard to provide one means for the

mechanical design and theoretical verification of cranes to conform to the essential health and safety

requirements of the Machinery Directive, as amended. This standard also establishes interfaces between the

user (purchaser) of the crane and the designer, as well as between the designer and the component

manufacturer, in order to form a basis for selecting cranes and components.

This European Standard is a type C standard as stated in EN ISO 12100.

The crane parts, components or machinery concerned and the extent to which hazards are covered are

indicated in the scope of this standard.

When provisions of this type C standard are different from those, which are stated in type A or B standards,

the provisions of this type C standard take precedence over the provisions of the other standards, for

machines that have been designed and built according to the provisions of this type C standard.

1 Scope

This European Standard specifies general principles and requirements to be used together with EN 13001-2

and the EN 13001-3 series of standards, and as such they specify conditions and requirements on design to

prevent mechanical hazards of cranes, and a method of verification of those requirements.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the

particular crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to

persons during normal use and foreseeable misuse. Clause 4 of this European Standard is necessary to

reduce or eliminate the risks associated with the following hazards:

a) instability of the crane or its parts (tilting);

b) exceeding the limits of strength (yield, ultimate, fatigue);

c) elastic instability of the crane or its parts (buckling, bulging);

d) exceeding temperature limits of material or components;

e) exceeding the deformation limits.

This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of

this standard and serves as reference base for the European Standards for particular crane types.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 13001-2, Crane safety — General design — Part 2: Load actions

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

ISO 2394, General principles on reliability for structures

ISO 4306-1:2007, Cranes — Vocabulary — Part 1: General

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and, for the

definitions of loads, in ISO 4306-1:2007, Clause 6, and the following apply.

3.2 Symbols and abbreviations

The symbols and abbreviations used in this part of EN 13001 are given in Table 1.

Table 1 — Symbols and abbreviations

Symbols,

Description

abbreviations

admσ Allowable (admissible) stress

C Total number of working cycles

C Number of working cycles where a load i is handled

i

C Number of working cycles of task r

r

Dh0 to Dh9

Classes of average linear displacement X for hoisting

lin

Dt0 to Dt9

Classes of average linear displacement X for traversing (trolley)

lin

Dc0 to Dc9

Classes of average linear displacement X for travelling (crane)

lin

Da0 to Da5 Classes of average angular displacement X

ang

f

Characteristic loads including dynamic factors

i

F

Combined loads from load combination j (limit state method)

j

Combined loads from load combination j (allowable stress method)

F

j

k Stress spectrum factor, based on m of detail under consideration

m

kQ

Load spectrum factor

kQ Load spectrum factor for task r

r

Limit in damage calculation

lim D

limσ Limit design stress

m Inverse slope of the log σ /log N curve

a

nˆ Total number of stress cycles

n

Number of stress cycles of class ij

ij

(r)

Number of stress cycles of class ij occurring each time task r is carried out

n

ij

nn,

Service frequency of position i or j

ri rj

n ( R or σ ) Number of stress cycles with stress amplitude σ ( R or σ )

m a m

Number of stress cycles with amplitude σ ( R or σ )

n ( R or σ )

a,i m

i m

Number of stress cycles to failure by fatigue

N

N Number of cycles at reference point

D

Symbols,

Description

abbreviations

p

Average number of accelerations

Classes of average numbers of accelerations p

to P

P , P

to Q Classes of load spectrum factors kQ

Q

Q Maximum value of Q for all tasks r

r

Q Magnitude of load i

i

Q Maximum load for task r

r

R Characteristic resistance of material, connection or component

d

Stress ratio

R

s

Stress history parameter

S to S Classes of stress history parameters

s

02 9

S

Load effect in section k of a member (limit state method)

k

Load effect in section k of a member (allowable stress method)

S

k

to U

Classes of total numbers of working cycles C

UU,

xx,

Displacement of the drive under consideration to serve position i or j

ri rj

Average displacement during task r

x

r

Average linear or angular displacement

X , X

lin ang

αα,,α Angles between horizontal line and lines of constant N in the σσ− plane

12 am

α

Relative number of working cycles for task r

r

γ

Overall safety factor

f

γ

Resistance coefficient

m

γ

Risk coefficient

n

γ

Partial safety factor

p

γ Reduced partial safety factor

p

ν Relative total number of stress cycles

σ Stress amplitude

a

σ (R), σ (R)

ˆ Stress amplitude, maximum stress amplitude for constant stress ratio R

a

a

σ (σ ), σ (σ )

ˆ Stress amplitude, maximum stress amplitude for constant mean stress σ

a m m m

a

σ Stress amplitude of range i

a,i

Symbols,

Description

abbreviations

σ Lower extreme value of stress cycle

b

σ

Design stress in element l (limit state method)

l

σ

Design stress in element l (allowable stress method)

l

σ

Stresses in element l resulting from S (limit state method)

k

1l

σ

Stresses in element l resulting from S (allowable stress method)

1l

k

σ

Stresses in element l arising from local effects (limit state method)

2l

σ

Stresses in element l arising from local effects (allowable stress method)

2l

σ

Mean stress

m

σ Mean stress of range j

m,j

σ Upper extreme value of stress cycle

u

ϕ Dynamic factors

i

4 Safety requirements and/or measures

4.1 General

Cranes shall conform to the safety requirements and/or measures of this clause. Hazards not covered in

EN 13001 (all parts) may be covered by other general requirements for all types of cranes and/or by specific

requirements for particular types of cranes, as given in the standards listed in Annex A. In addition, the

machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant

which are not dealt with by the above mentioned standards.

4.2 Proof calculation

4.2.1 General principles

The objective of this calculation is to prove theoretically that a crane, taking into account the service conditions

agreed between the user, designer and/or manufacturer, as well as the states during erection, dismantling and

transport, has been designed in conformance to the safety requirements to prevent mechanical hazards.

The proof of competence according to the EN 13001 series shall be carried out by using the general principles

and methods appropriate for this purpose and corresponding with the recognized state of the art in crane

design.

Alternatively, advanced and recognized theoretical or experimental methods may be used in general, provided

that they conform to the principles of this standard.

Hazards can occur if extreme values of load effects or their histories exceed the corresponding limit states. To

prevent these hazards with a margin of safety, it shall be shown that the calculated extreme values of load

effects from all loads acting simultaneously on a crane and multiplied with an adequate partial safety

coefficient, as well as the estimated histories of load effects, do not exceed their corresponding limit states at

any critical point of the crane. For this purpose the limit state method, and where applicable the allowable

stress method, is used in accordance with international and European design codes.

The analysis of load actions from individual events or representative use of a crane (representative load

histories) is required to reflect realistic unfavourable operational conditions and sequences of actions of the

crane.

Figure 1 illustrates the general layout of a proof calculation for cranes.

Key

a) models of crane and loads

b) load actions

c) limit states

d) proof

Figure 1 — Layout of the proof calculation

4.2.2 Models of cranes and loads

For the calculation of the movements, inner forces (torques in gears, rope forces, etc.) and losses of the crane

or its parts, rigid body kinetic models are used.

The loads acting on this model are the motor torques and/or brake torques, which shall balance any of the

loads acting on the moved parts as losses, mass forces caused by gravity, movement of the crane or parts

thereof, and wind forces.

From this rigid body kinetic model of the crane and the load models, any variation of displacement, speed,

acceleration and/or inner forces as well as the corresponding instantaneous values of acceleration and/or

inner forces can be derived.

These variations, if calculated in conformity with the agreed service conditions, are the base for estimating the

histories of load effects (e.g. heat equivalents) and the stress histories. Since the variations and instantaneous

values of accelerations and inner forces calculated by using a rigid body kinetic model only represent mean

values of the real process, loads caused by sudden alterations of these mean values shall be amplified by

dynamic factors ϕ to estimate their real values (see EN 13001-2).

i

For cranes or crane configurations where all the loads from different drives acting simultaneously do not affect

each other because they are acting at right angles to each other (i.e. orthogonal), load actions from drives can

be considered independently. In cases where the loads from simultaneous actions of different drives affect

each other (dependent, non-orthogonal), this shall be taken into account.

The calculation of nominal stresses in any mechanical and/or structural component of a crane or its parts can

commonly be based on appropriate elasto-static models, built up by beam or more sophisticated elements,

such as plane stress, plate or shell elements.

A nominal stress is a stress calculated in accordance with simple elastic strength of materials theory,

excluding local stress concentration effects.

4.2.3 Simulation of load actions

For the simulation of the time varying process of load actions on a crane or its parts, static equivalent loads

from independent events occurring during the intended use of a crane shall be applied to elasto-static models,

which correspond with the configuration and supporting conditions of the crane or its parts under

consideration.

NOTE In this context the term “load” or “load action” means any action or circumstance, which causes load effects in

the crane or its parts, for example: forces, intended and non-intended displacements and/or movements, temperature,

wind pressure.

Static equivalent loads are given in EN 13001-2. These static equivalent loads are considered as deterministic

actions, which have been adjusted in such a way that they represent load actions during the use of the crane

from the actions or circumstances under consideration.

The limit state method (see 4.2.7.1) does take into account the probabilistic nature of the loads, whereas the

allowable stress method (see 4.2.7.2) does not.

If a higher level of safety is required in some instance, a risk factor γ may be agreed upon and applied

n

(see EN 13001-2).

4.2.4 Load combinations and load effects

The loads shall be superimposed in such a way that the resulting load effects attain their instantaneous

extreme values for the considered situation of use. Such superimpositions are called load combinations. Basic

load combinations are given in EN 13001-2.

When establishing the load combinations, consideration shall be given to the use of the crane, taking into

account its control systems, its normative instructions for use, and any other inherent conditions, where they

relate to the specific aim of the proof of competence.

Magnitude, position and direction of all loads which act simultaneously in the sense of a load combination,

shall be chosen in such a way that extreme load effects occur in the component or design detail under

consideration. Consequently, in order to establish the extreme stresses in all the design critical points, several

loading events or crane configurations shall be studied within the same load combination, e.g. different

positions of a crab in a bridge or gantry crane.

The upper and lower extreme values of the load effects, in terms of inner forces or nominal stresses, shall be

used for a static proof calculation to avoid the hazards described in the scope. In combination with the agreed

service conditions and the kinematic properties of the crane or its parts, these values limit the histories of

inner forces or nominal stresses for the proof of fatigue strength.

For the proof of fatigue strength, the number and magnitude of significant stress cycles shall be specified.

4.2.5 Limit states

For the purposes of this standard limit states are states of the crane, its components or materials which, if

exceeded, can result in the loss of the operational characteristics of the crane. There is a distinction between

ultimate limit states and serviceability limit states as follows:

a) Ultimate limit states, given by:

1) plastic deformations from the effect of nominal stresses or sliding of frictional connections;

2) failure of components or connections (e.g. static failure, failure by fatigue or formation of critical

cracks);

3) elastic instability of the crane or its parts (e.g. buckling, bulging);

4) rigid body instability of the crane or its parts (e.g. tilting, shifting).

b) Serviceability limit states, examples of which are:

1) deformations which impair the intended utilization of the crane (e.g. function of moving components,

clearances of parts);

2) vibrations that cause damage to the crane driver or cause damage to the crane structure or restrict

the ability to operate;

3) exceeding temperature limits (e.g. overheating of motors and brakes).

4.2.6 Proof of competence

The limit states applicable to the combination of material selection, manufacturing techniques and the

specified service conditions shall be stated in the proof of competence.

For the verification that the ultimate limit states are not exceeded, the following proofs shall be established:

a) proof of strength of members, connections and components:

1) under static and quasi-static loading;

2) under cyclic loading (fatigue);

b) proof of elastic stability of the crane and its parts;

c) proof of crane stability.

For the verification that the serviceability limit states are not exceeded, the following aspects shall be

considered, and a proof be established where appropriate:

d) proof of deformation;

e) vibration;

f) thermal performance.

4.2.7 Methods for the proof of competence

4.2.7.1 Limit state method

For a general description of the limit state method, see ISO 2394. For all crane systems, the limit state method

is applicable without any restriction.

Individual characteristic loads f shall be calculated and amplified where necessary using the factors ϕ ,

i i

γ

p

multiplied by the appropriate partial safety factors γ or reduced partial safety factors and combined into F

p j

according to the load combination under consideration. When agreed upon F shall also be multiplied by an

j

appropriate risk coefficient γ The result γ ⋅ F shall be used to determine the resulting load effects S , i.e. the

n. n j k

inner forces in structural or mechanical components or the forces in articulations and supports.

For proof that yielding and elastic instability will not occur, the nominal design stresses σ due to the action of

1 l

the loads on a particular component are calculated and combined with any stresses σ resulting from local

2 l

effects, calculated using the appropriate partial safety factors γ and where agreed upon the risk coefficient γ .

p n

The resulting design stress σ shall be compared with the limit design stress lim σ. It is derived from the

l

specific strength or characteristic resistance R of material, connection or component with at least 95 %

d

probability of survival, divided by the resistance coefficient γ = 1,10.

m

For the proof of crane stability it shall be shown that under the combined action of the loads multiplied by their

partial safety factors no rigid body movement occurs. All supports, where given limits are exceeded, i.e.

wheel/rail under tension or rope under compression, shall be neglected. This means that in the sense of the

elasto-static model, the corresponding restraints shall be set “inactive”. The remaining positive and/or frictional

support forces shall be sufficient to ensure the crane stability.

A flow chart illustrating the limit state method for the proof calculation based on stresses is shown in Figure 2.

For the proof based on forces, moments, deflections the limit state method shall be applied by analogy.

Key

1 see EN 13001–2

f characteristic load i on the element component including dynamic factors

i

F combined load from load combination

j

S load effects in section k of members or supporting parts, such as inner forces and moments, resulting from

k

load combination F

j

σ stresses in the particular element l as a result of load effects S

1 l k

σ stresses in the particular element l arising from local effects

2 l

σ resulting design stress in the particular element l

l

R specified strength or characteristic resistance of the material, particular element or connection, such as the

d

stress corresponding to the yield point, limit of elastic stability or fatigue

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...