EN 9208:2021

(Main)Aerospace series - Programme management - Expression of need - Guidance on and format for (Need) Technical Specification

Aerospace series - Programme management - Expression of need - Guidance on and format for (Need) Technical Specification

This document belongs to the documents going along with EN 9200 relating to Project Management Specification.

The aims of this document are as follows:

- to specify/remind the concept of (Need) Technical Specification (N)TS;

- to define the principles and conditions for drawing up, approving, using and updating a (N)TS;

- to propose a template of (N)TS.

The template identifies topics and types of related requirements to be covered in a (N)TS without being completely exhaustive or mandatory. It is due to be analysed like a check-list and tailored according to the type of the product of interest, the context of the bodies involved and the contractual details.

The principle of drawing up a (N)TS applies to both tangible and intangible products (e.g. services).

The customer/supplier relationship addressed by these principles may also apply within a single organization. The concepts of customer and supplier are discussed in this document without distinction between internal or external relationship.

This document implements and adapts EN 16271 to the context, in order to meet the specific needs of the aeronautical field and more generally the needs of other fields.

This document is more explicit about certain aspects of ISO/IEC/IEEE 29148 dedicated to requirements engineering, such as the responsibility for drawing up a (N)TS on a contractual basis and also the process of drawing it up within a programme (stages and milestones). It also supplements the technical specification framework proposed by ISO/IEC/IEEE 29148, in particular with requirements relating to safety of operation and result assurance.

The relationships existing between Functional Performance Specification (FPS) and (N)TS for expression of needs are given in Annex A.

Luft- und Raumfahrt - Programm-Management - Bedarfsbekundung - Anleitung und Format für die (Bedarfs-)Technische Lieferbedingung

Dieses Dokument gehört zu den Dokumenten, die in Bezug auf die Projektmanagement-Spezifikation mit EN 9200 einhergehen.

Die Ziele dieses Dokuments sind wie folgt:

— Festlegung des Begriffs der (Bedarfs-)Technischen Lieferbedingung (N)TS bzw. Erinnerung daran;

— Festlegung der Grundsätze und Bedingungen für die Erstellung, Genehmigung, Verwendung und Aktualisierung einer (N)TS;

— Vorschlag einer Vorlage für (N)TS.

Die Vorlage identifiziert Themen und Arten von zugehörigen Anforderungen, die in einer (N)TS zu erfassen sind, ohne vollständig erschöpfend oder verbindlich zu sein. Sie wird wie eine Checkliste analysiert und auf die Art des interessierenden Produkts, den Kontext der beteiligten Stellen und die vertragsrechtlichen Einzelheiten abgestimmt.

Der Grundsatz der Erstellung einer (N)TS ist anwendbar sowohl für materielle als auch für immaterielle Produkte (z. B. Dienstleistungen).

Das Kunden-Lieferanten-Verhältnis, das Gegenstand dieser Grundsätze ist, kann auch innerhalb einer einzelnen Organisation angewendet werden. Die Begriffe von „Kunde“ und „Lieferant“ werden in diesem Dokument ohne Unterscheidung zwischen internen und externen Beziehungen erörtert.

Dieses Dokument setzt die Norm EN 16271 um und passt sie an den Kontext an, um den spezifischen Bedürfnissen des Bereichs von Luft- und Raumfahrt und ganz allgemein den Bedürfnissen anderer Bereiche gerecht zu werden.

In diesem Dokument werden bestimmte Aspekte des Dokuments ISO/IEC/IEEE 29148, die dem Requirements Engineering gewidmet sind, wie z. B. die Verantwortung für die Erstellung einer (N)TS auf vertraglicher Grundlage und auch der Prozess der Erstellung innerhalb eines Programms (Etappen und Meilensteine), ausführlicher behandelt. Es ergänzt auch das von ISO/IEC/IEEE 29148 vorgeschlagene Rahmenwerk für technische Spezifikationen, insbesondere durch Anforderungen an die Betriebssicherheit und die Ergebnissicherung.

Die zwischen einer funktionalen Leistungsbeschreibung (FLB) und einer (N)TS zur Bedarfsbekundung bestehenden Zusammenhänge sind in Anhang A aufgeführt.

Série aérospatiale - Management de programme - Expression du besoin - Guide pour l'élaboration de la spécification technique de besoin

Le présent document fait partie des documents d'accompagnement de l’EN 9200 relative à la Spécification de Management de Programme.

Le présent document a pour objet de :

- préciser/rappeler le concept de Spécification Technique de Besoin (STB) ;

- définir les principes et les conditions d'élaboration, d'approbation, d'utilisation et d'évolution d'une STB ;

- proposer un plan type de STB.

Le plan type identifie un certain nombre de thèmes et des types d’exigences associées à aborder dans une STB sans être totalement exhaustif et sans présenter un caractère obligatoire. Il est à analyser comme un aide-mémoire (check-list) et à adapter en fonction du type de produit envisagé, du contexte des organismes en présence et des données contractuelles.

Le principe d’élaboration d’une STB s’applique aux produits tangibles et intangibles (par exemple : services).

Ces principes peuvent même être étendus à des relations de type client/fournisseur internes à un organisme donné. Les notions de client et fournisseur sont abordées dans ce document de façon indifférenciée au sens interne ou externe.

Le présent document permet de mettre en oeuvre et d’adapter au contexte la norme NF EN 16271, pour répondre aux besoins spécifiques du domaine aéronautique et plus largement aux besoins d'autres domaines.

Le présent document précise certains aspects du document ISO/IEC/IEEE 29148 consacré à l’ingénierie des exigences, tels que la responsabilité d’établissement de la STB sur un plan contractuel ainsi que son processus d’élaboration au sein d’un programme (phases et jalons). Elle complète également le canevas de spécification technique proposé par l’ISO/IEC/IEEE 29148 avec notamment les exigences relatives à la sûreté de fonctionnement et celles sur l’assurance de résultat.

Les relations existantes entre le Cahier des Charges Fonctionnel (CdCF) et la STB pour l'expression du besoin sont présentées dans l'Annexe A.

Aeronavtika - Vodenje programov - Izražanje potreb - Navodilo in oblika za (potrebe) tehnične specifikacije

General Information

- Status

- Published

- Publication Date

- 12-Oct-2021

- Withdrawal Date

- 29-Apr-2022

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 1/S 6 - Engineering

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 13-Oct-2021

- Completion Date

- 13-Oct-2021

Relations

- Effective Date

- 28-Jan-2026

Overview

EN 9208:2021 - Aerospace series: Programme management - Expression of need - Guidance on and format for (Need) Technical Specification ((N)TS) provides guidance and a template for drafting, approving, using and updating a customer’s expression of need in the form of a (Need) Technical Specification. It is part of the EN 9200 project management specification suite and adapts EN 16271 and aspects of ISO/IEC/IEEE 29148 to the aeronautical context. The document applies to both tangible and intangible products (including services) and is intended for internal or external customer–supplier relationships.

Key topics and technical requirements

- Purpose and scope of a (N)TS: clarifies contractual role, responsibilities and the expression of need as a programme artefact.

- Process and lifecycle: stages, milestones and responsibilities for preparing and updating the (N)TS across programme phasing.

- Requirement quality and format: rules for requirement expression, traceability, flexibility and breakdown by product structure.

- Core content areas (template/check‑list approach):

- Product concept, scope and operational context (missions, scenarios, life profile)

- Functional requirements and Functional Performance Specification (FPS) relationships (Annex A)

- Lifetime, RAMS (Reliability, Availability, Maintainability, Safety) and safety‑of‑operation requirements

- Product protection, human factors and external interfaces

- Logistic support, in‑service operations, obsolescence and supply chain requirements

- Environmental resistance, design constraints and imposed solutions

- Requirements for result assurance, acceptance and qualification of specimens

- Updating and tailoring: guidance to adapt the template by product type, contractual details and organisational context.

- Informative annexes: mapping to CMMI models, NATO Architecture Framework (NAF), human factors views, ILS references and suggested (N)TS contents.

Practical applications and users

Who uses EN 9208:2021:

- Programme and project managers in aerospace and defence

- Systems and requirements engineers drafting or reviewing technical specifications

- Procurement and contract managers translating needs into contractual requirements

- Safety, RAMS and logistics/ILS specialists defining assurance and support requirements

- Suppliers and prime contractors aligning deliverables, acceptance criteria and lifecycle support

Typical uses:

- Producing a contractually binding (Need) Technical Specification for hardware, software or services

- Ensuring requirement quality, traceability and alignment with FPS documents

- Embedding safety and result assurance criteria into procurement and acceptance processes

- Tailoring specification content to programme phase, operational scenarios and support strategy

Related standards

- EN 9200 (Programme management - Project management specification)

- EN 16271 (Expression of needs)

- ISO/IEC/IEEE 29148 (Requirements engineering)

Keywords: EN 9208:2021, (Need) Technical Specification, NTS, aerospace programme management, requirements engineering, RAMS, logistic support, FPS, EN 9200.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 9208:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Programme management - Expression of need - Guidance on and format for (Need) Technical Specification". This standard covers: This document belongs to the documents going along with EN 9200 relating to Project Management Specification. The aims of this document are as follows: - to specify/remind the concept of (Need) Technical Specification (N)TS; - to define the principles and conditions for drawing up, approving, using and updating a (N)TS; - to propose a template of (N)TS. The template identifies topics and types of related requirements to be covered in a (N)TS without being completely exhaustive or mandatory. It is due to be analysed like a check-list and tailored according to the type of the product of interest, the context of the bodies involved and the contractual details. The principle of drawing up a (N)TS applies to both tangible and intangible products (e.g. services). The customer/supplier relationship addressed by these principles may also apply within a single organization. The concepts of customer and supplier are discussed in this document without distinction between internal or external relationship. This document implements and adapts EN 16271 to the context, in order to meet the specific needs of the aeronautical field and more generally the needs of other fields. This document is more explicit about certain aspects of ISO/IEC/IEEE 29148 dedicated to requirements engineering, such as the responsibility for drawing up a (N)TS on a contractual basis and also the process of drawing it up within a programme (stages and milestones). It also supplements the technical specification framework proposed by ISO/IEC/IEEE 29148, in particular with requirements relating to safety of operation and result assurance. The relationships existing between Functional Performance Specification (FPS) and (N)TS for expression of needs are given in Annex A.

This document belongs to the documents going along with EN 9200 relating to Project Management Specification. The aims of this document are as follows: - to specify/remind the concept of (Need) Technical Specification (N)TS; - to define the principles and conditions for drawing up, approving, using and updating a (N)TS; - to propose a template of (N)TS. The template identifies topics and types of related requirements to be covered in a (N)TS without being completely exhaustive or mandatory. It is due to be analysed like a check-list and tailored according to the type of the product of interest, the context of the bodies involved and the contractual details. The principle of drawing up a (N)TS applies to both tangible and intangible products (e.g. services). The customer/supplier relationship addressed by these principles may also apply within a single organization. The concepts of customer and supplier are discussed in this document without distinction between internal or external relationship. This document implements and adapts EN 16271 to the context, in order to meet the specific needs of the aeronautical field and more generally the needs of other fields. This document is more explicit about certain aspects of ISO/IEC/IEEE 29148 dedicated to requirements engineering, such as the responsibility for drawing up a (N)TS on a contractual basis and also the process of drawing it up within a programme (stages and milestones). It also supplements the technical specification framework proposed by ISO/IEC/IEEE 29148, in particular with requirements relating to safety of operation and result assurance. The relationships existing between Functional Performance Specification (FPS) and (N)TS for expression of needs are given in Annex A.

EN 9208:2021 is classified under the following ICS (International Classification for Standards) categories: 03.100.01 - Company organization and management in general; 49.020 - Aircraft and space vehicles in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 9208:2021 has the following relationships with other standards: It is inter standard links to EN 9200:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 9208:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Aeronavtika - Vodenje programov - Izražanje potreb - Navodilo in oblika za

(potrebe) tehnične specifikacije

Aerospace series - Programme management - Expression of need - Guidance on and

format for (Need) Technical Specification

Luft- und Raumfahrt - Programm-Management - Bedarfsbekundung - Anleitung und

Format für die (Bedarfs-)Technische Lieferbedingung

Série aérospatiale - Management de programme - Expression du besoin - Guide pour

l'élaboration de la spécification technique de besoin

Ta slovenski standard je istoveten z: EN 9208:2021

ICS:

03.100.01 Organizacija in vodenje Company organization and

podjetja na splošno management in general

49.020 Letala in vesoljska vozila na Aircraft and space vehicles in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 9208

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2021

EUROPÄISCHE NORM

ICS 49.020

English Version

Aerospace series - Programme management - Expression

of need - Guidance on and format for (Need) Technical

Specification

Série aérospatiale - Management de programme - Luft- und Raumfahrt - Programm-Management -

Expression du besoin - Guide pour l'élaboration de la Bedarfsbekundung - Anleitung und Format für die

spécification technique de besoin (Bedarfs-)Technische Lieferbedingung

This European Standard was approved by CEN on 23 August 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 9208:2021 E

worldwide for CEN national Members.

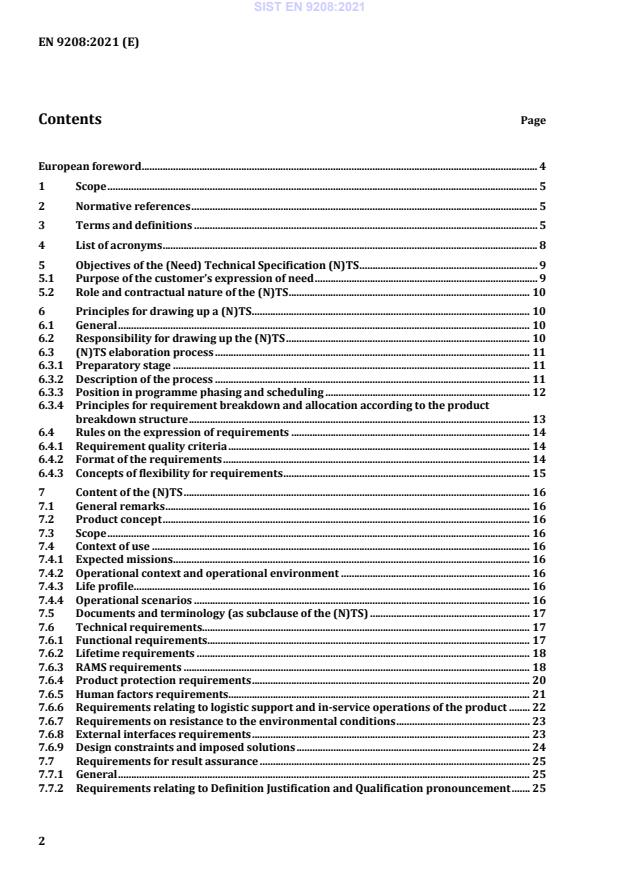

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 List of acronyms . 8

5 Objectives of the (Need) Technical Specification (N)TS . 9

5.1 Purpose of the customer’s expression of need . 9

5.2 Role and contractual nature of the (N)TS . 10

6 Principles for drawing up a (N)TS . 10

6.1 General . 10

6.2 Responsibility for drawing up the (N)TS . 10

6.3 (N)TS elaboration process . 11

6.3.1 Preparatory stage . 11

6.3.2 Description of the process . 11

6.3.3 Position in programme phasing and scheduling . 12

6.3.4 Principles for requirement breakdown and allocation according to the product

breakdown structure . 13

6.4 Rules on the expression of requirements . 14

6.4.1 Requirement quality criteria . 14

6.4.2 Format of the requirements . 14

6.4.3 Concepts of flexibility for requirements . 15

7 Content of the (N)TS . 16

7.1 General remarks . 16

7.2 Product concept . 16

7.3 Scope . 16

7.4 Context of use . 16

7.4.1 Expected missions . 16

7.4.2 Operational context and operational environment . 16

7.4.3 Life profile . 16

7.4.4 Operational scenarios . 16

7.5 Documents and terminology (as subclause of the (N)TS) . 17

7.6 Technical requirements. 17

7.6.1 Functional requirements. 17

7.6.2 Lifetime requirements . 18

7.6.3 RAMS requirements . 18

7.6.4 Product protection requirements . 20

7.6.5 Human factors requirements. 21

7.6.6 Requirements relating to logistic support and in-service operations of the product . 22

7.6.7 Requirements on resistance to the environmental conditions . 23

7.6.8 External interfaces requirements . 23

7.6.9 Design constraints and imposed solutions . 24

7.7 Requirements for result assurance . 25

7.7.1 General . 25

7.7.2 Requirements relating to Definition Justification and Qualification pronouncement . 25

7.7.3 Requirements relating to the conditions of acceptance of specimens of the product . 25

8 Updating of a (N)TS . 26

Annex A (informative) Relations between FPS and (N)TS . 27

Annex B (informative) Mapping with CMMI-Acquisition and CMMI-Development models . 28

Annex C (informative) Overview of the NATO Architecture Framework (NAF) . 29

Annex D (informative) Architecture views for human factors . 32

Annex E (informative) Contents suggested for a (N)TS . 33

Annex F (informative) Standards or guides for safety studies . 34

Annex G (informative) Detailed requirements relating to logistic support and in-service

operations of the product . 35

G.1 User support . 35

G.1.1 Requirements relating to user technical documentation (UTD) . 35

G.1.2 Requirements relating to user training and learning . 35

G.1.3 Requirements relating to user support (Helpdesk Service) . 35

G.2 Customer support . 35

G.2.1 Requirements relating to asset management on behalf of the customer . 35

G.2.2 Requirements relating to technical support or service provision. 36

G.3 Operational services . 36

G.3.1 Requirements relating to product deployment . 36

G.3.2 Requirements relating to product operation . 36

G.3.3 Requirements relating to operation incident treatment . 36

G.3.4 Requirements relating to availability and service continuity follow-up . 36

G.4 Analysis of logistic support, logistics and maintenance in operational condition . 36

G.4.1 Requirements relating to logistic support analysis . 36

G.4.2 Requirements relating to logistics . 37

G.4.2.1 Requirements relating to the product supply chain . 37

G.4.2.2 Requirements relating to packaging, handling, storage and transport (EMST) . 37

G.4.2.3 Requirements relating to spare, consumable and ingredient management . 37

G.4.2.4 Requirements relating to support means (test means and platform tooling, except

training platform) . 37

G.4.3 Requirements relating to maintenance in operational condition . 38

G.4.3.1 Requirements on in-use product observability and data collection . 38

G.4.3.2 Requirements relating to product maintenance (repair, spare, change, etc.) . 38

G.4.3.3 Requirements relating to obsolescence management . 38

Annex H (informative) Standards and guides related to integrated logistic support (ILS)

requirements . 39

Bibliography . 40

European foreword

This document (EN 9208:2021) has been prepared by the Aerospace and Defence Industries

Association of Europe - Standardization (ASD-STAN).

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2022, and conflicting national standards shall be

withdrawn at the latest by April 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document belongs to the documents going along with the EN 9200 relating to Project Management

Specification.

The aims of this document are as follows:

— to specify/remind the concept of (Need) Technical Specification (N)TS;

— to define the principles and conditions for drawing up, approving, using and updating a (N)TS;

— to propose a template of (N)TS.

The template identifies topics and types of related requirements to be covered in a (N)TS without being

completely exhaustive or mandatory. It is analysed like a check-list and tailored according to the type of

the product of interest, the context of the bodies involved and the contractual details.

The principle of drawing up a (N)TS applies to both tangible and intangible products (e.g. services).

The customer/supplier relationship addressed by these principles may also apply within a single

organization. The concepts of customer and supplier are discussed in this document without distinction

between internal or external relationship.

This document implements and adapts to the context the EN 16271 standard, in order to meet the

specific needs of the aeronautical field and more generally the needs of other fields.

This document is more explicit about certain aspects of the ISO/IEC/IEEE 29148 document dedicated to

requirements engineering, such as the responsibility for drawing up a (N)TS on a contractual basis and

also the process of drawing it up within a programme (stages and milestones). It also supplements the

technical specification framework proposed by ISO/IEC/IEEE 29148, in particular with requirements

relating to safety of operation and result assurance.

The relationships existing between Functional Performance Specification (FPS) and (N)TS for

expression of needs are given in Annex A.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 9200, Aerospace series - Programme management - Guidelines for project management specification

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 9200 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

environmental agent

one of the physical, chemical, biological, etc. phenomena that may have direct or indirect, immediate or

delayed, effect on living beings, human activities and systems or their operation

[SOURCE: NF X 50-144-1]

3.2

need

what is necessary for, or desired by, the user

Note 1 to entry: A need may be explicit or implicit; it may be existing or potential.

Note 2 to entry: “Implicit” means that it is usual or a common practice for all the parties concerned.

[SOURCE: Adapted from EN 16271]

3.3

functional performance specification

FPS

document in which the needs are listed in terms of service functions and constraints

Note 1 to entry: Drawing up a FPS implies that a functional analysis has been able to clearly define the users’

needs.

Note 2 to entry: Assessment criteria and their performance levels are defined for each of these functions, when

relevant and possible. Each performance level is expressed with a certain degree of flexibility.

[SOURCE: Adapted from EN 16271]

3.4

constraint

externally imposed limitation on requirements, design, or implementation or on the process used to

develop or modify a product or on any other provision

Note 1 to entry: A constraint is a factor that is imposed on the solution by force or compulsion and may limit or

modify the choice of solution.

Note 2 to entry: Constraints may come from authoritative texts (laws, regulations, standards, market

demand, etc.).

[SOURCE: Adapted from ISO/IEC/IEEE 29148]

3.5

life cycle

set of phases in the life of a product, from the expression of need until disposal

Note 1 to entry: The product can be firstly conceptual then physical.

Note 2 to entry: The life cycle typically includes the following phases:

— Initial expression of need;

— feasibility;

— definition;

— development;

— production;

— operation;

— disposal.

Note 3 to entry: Notion not to be confused with life profile.

3.6

requirement

statement that translates or expresses a need and its associated constraints and conditions

[SOURCE: ISO/IEC/IEEE 29148]

3.7

special requirements

those requirements identified by the customer, or determined by the organisation, which have high

risks of not being met, thus requiring their inclusion in the operational risk management process

Note 1 to entry: Factors used in the determination of special requirements include product or process

complexity, past experience, and product or process maturity.

EXAMPLE performance requirements imposed by the customer that are at the limit of the industry’s

capability, or requirements determined by the organization to be at the limit of its technical or process capabilities

[SOURCE: Adapted from EN 9100]

3.8

interface

boundary shared between two products, or two product parts, which has physical and/or functional

exchanges

3.9

performance

measurable characteristic(s) of a product

3.10

life profile

chronological description of the use situations in which a physical product is expected to be found, from

ex-factory to disposal

Note 1 to entry: By situation, we mean: transport, handling, storage, maintenance, operational use., with all

environmental conditions, durations and respective occurrences.

Note 2 to entry: The life profile is described for product/customer or product/job couples. For a given product,

there may be several life profiles depending on the considered concepts of use or deployments.

Note 3 to entry: Not to be confused with life cycle.

3.11

operational scenario

description of an imagined sequence of events that includes the interaction of the product or service

with its environment and users, as well as interaction among its product or service components

Note 1 to entry: Operational scenarios are used to evaluate the requirements and design of the product and to

verify and validate the product.

[SOURCE: Adapted from ISO/IEC/IEEE 24765]

3.12

(need) technical specification

(N)TS

contractual document drawn up by the customer, intended for the supplier, in which the customer

expresses his needs (or the needs he has been instructed to convey) in terms of technical requirements

Note 1 to entry: The (Need) Technical Specification may also establish the conditions to ensure that these

requirements are met.

4 List of acronyms

AIS Analogue Interface Sheet

ARINC Aeronautical Radio INCorporated

BIT Built In Test

CMMI Capability Maturity Model Integration

DIS Digital Interface Sheet

EBIOS (Expression des Besoins et Identification des Objectifs de Sécurité) — Expression of need and

Identification of Safety Objectives

EMST (Emballage Manutention Stockage Transport) — Packaging Handling Storage Transport

FEROS (Fiche d’Expression Rationnelle des Objectifs de Sécurité) — Rational expression of Security

Objectives Statement

FPS Functional Performance Specification

HUMS Health and Usage Monitoring System

ICD Interface Control Document

ILS Integrated Logistics Support

IRS Interface Requirement Specification

LRU Line Replaceable Unit

MEHARI (Méthode Harmonisée d’Analyse des Risques) — Harmonized Risk Assessment Methodology

MTBF Mean Time Between Failures

MTTR Mean Time To Repair

NAF NATO Architecture Framework

NATO North Atlantic Treaty Organization

(N)TS (Need) Technical Specification

NRBC Nuclear, Radiological, Bacteriological, Chemical

PTS Product Technical Specification

QoS Quality of Service

RAMS Reliability, Availability, Maintainability and Safety

REACh Registration Evaluation and Authorization of Chemicals

RFID Radio-Frequency IDentification

RoHS Restrictions of Hazardous Substances

SLA Service Level Agreement

TRL Technology Readiness Level

UTD User Technical Documentation

5 Objectives of the (Need) Technical Specification (N)TS

5.1 Purpose of the customer’s expression of need

The (N)TS is drawn up under the customer’s responsibility (see 6.2) and its purpose is to formalize the

needs in technical terms. A (N)TS attached to a contract results from negotiations between the

customer and the supplier. It reflects the compromise between technological feasibility, performance,

imposed solutions, total cost, realization duration and risks.

NOTE 1 The total cost includes non-recurring costs (related to design, development, etc.) and recurring costs

(related to manufacturing, purchasing, operation, support, etc.) over the entire life cycle of the product.

It expresses the technical requirements over the entire life cycle of the product:

— functional and performance requirements;

— lifetime requirements;

— RAMS requirements (reliability, availability, maintainability, safety);

— product protection requirements including information security;

— human factors requirements;

— requirements relating to logistic support and in-service operations of the product;

— requirements on resistance to the environmental conditions;

— external interfaces requirements;

— design constraints and imposed solutions.

It can also express the requirements regarding result assurance:

— relating to definition justification and qualification pronouncement;

— relating to the conditions of acceptance of specimens of the product.

NOTE 2 The expression of need may change according to the phases of the life cycle. It could be considered

compared to expected intermediate supplies, which may be a model, prototype, document, etc. up to the

operational product. Thus mock-ups, prototypes and different versions of the product, which are to be supplied

under contract and which differ from the operational product due to special requirements or tolerances, may be

the subject of a separate (N)TS or a document showing the deviations compared with the (N)TS of the operational

product.

The (N)TS requirements are those necessary and sufficient for a supplier to be able to draw up, if

necessary, its own Product Technical Specification (PTS) and establish a product definition that fulfils

the need.

These requirements are mainly formalized in terms of functions and performance expected from the

product to be designed and defined, bearing in mind the identified risks accepted by the parties

(see 6.1).

It is recommended to take into account the general requirements expressed in the higher-level (N)TS

for each level of the product breakdown structure (see 6.3.4). These general requirements may be:

component policy, marking rule, documentation, etc.

To understand the origin of the requirement, and also how the (N)TS of the product can be integrated in

a larger system (“Where does this need come from? What about this restriction? Why this

requirement?”), the customer should ensure traceability of the requirements from the top-level

(including the case where the product belongs to a larger system, as in the case of systems of systems)

down to the (N)TS appended to the contract. It may also be wise to establish traceability links between

decisions (emails, report, etc.) and the (N)TS requirements, in a requirement justification file for

example.

The Aeronautical Quality Management System standards (EN 9100 and EN 9110) introduce the concept

of “special requirements” for certain requirements (see definition). This concept emphasizes the high

risk of not being able to meet a requirement.

This kind of requirements (“special requirements”) may be determined either by the customer (in the

(N)TS) or by the supplier (in the PTS) and implies these requirements to be dealt with via the risk

management process of the customer and/or supplier.

In order to answer the various questions such as “is this requirement the right one?” it is recommended,

where applicable, to ensure validation of the requirements (using ARP4754A/ED-79A) against the

different expressions of need regarding the context where the product will take place.

5.2 Role and contractual nature of the (N)TS

The (N)TS serves as a contractual basis between a customer and its supplier. The (N)TS allows the

supplier to design and define the product. This product can be developed, modified or selected from a

portfolio of existing products, as long as it fulfils the requirements expressed by the customer.

Based on the customer/supplier relationship, the (N)TS is the reference document that enables the

customer to

— express his need for the supplier in terms of results and not solution,

— pronounce the decision concerning qualification of the product definition and, reciprocally, enables

the supplier to justify the product definition by means of analyses or tests,

— process the technical changes in the product definition; the (N)TS is therefore an element of the

reference configuration of the product (see EN 9223-100 and its accompanying documents) and

— decide on requests for waivers or deviation (see EN 9223-105) if elements of the Definition Data

File are not sufficient to decide on this request.

The (N)TS is a part of the contract; the contract also specifies other types of requirements (means to be

implemented, work packages, programme management requirements, etc.).

NOTE For organisations which follow CMMI models, Annex B shows how CMMI models map to the (N)TS.

6 Principles for drawing up a (N)TS

6.1 General

(N)TS requirements are the result of iterative and, as far as possible, collaborative work based among

other considerations on risk analysis (see EN 9239), performed by both the customer and the supplier.

The goal is to reach a compromise between the customer requirements and industry ability to meet

them, via different proposals of candidate suppliers (performance, costs and deadlines).

6.2 Responsibility for drawing up the (N)TS

Within the customer/supplier relationship, (N)TS requirement elaboration is under customer

responsibility.

NOTE Even if the customer delegates the task of drawing up the (N)TS to a supplier (often under a specific

contract), the document will remain the customer responsibility.

The supplier in turn may translate the customer requirements in a designer (supplier) language and

supplement them with derived requirements related to the chosen solution and the supplier constraints

(product policy, re-use, etc.). In this case the resulting document is the Product Technical Specification

(PTS). This document is the entry point of the product design process which leads to the establishment

of its Definition Data File (DDF).

In all cases, the product definition shall be justified against the Customer (N)TS.

6.3 (N)TS elaboration process

6.3.1 Preparatory stage

It is recommended that a functional analysis of need, possibly supplemented by an architecture

description, be carried out before drawing up a (N)TS. This is to identify the various expected functions

and to express the quantitative and qualitative requirements for each of the functions, for example in a

Functional Performance Specification (FPS).

It is also recommended that information from other programmes be considered before drawing up the

(N)TS, in order to encourage reuse of proven solutions, lessons learned and technology selection based

on readiness levels with regards to the specific programme.

Within a given programme, the preliminary work products (studies results, mock-ups, etc.) resulting

from upstream studies (ILS study, RAMS study, operational concept development and

experimentation, etc.), shall be planned and specified in dedicated (N)TS with the right level of detail,

for reuse in the scope of the final product.

In all cases, the reused solution should meet the requirements of the new programme. It should be

checked that the features of the reused solution not specified in the (N)TS do not lead to negative

consequences (in terms of costs, deadlines, performance, reliability, etc.).

6.3.2 Description of the process

The result of the elaboration process of a (N)TS is a set of technical requirements intended to be

included in the development contract.

The essential stages of this process are (see Figure 1)

— the definition of the requirements, with identification of the special requirements (see 3.7 and 5.1),

— their analysis and negotiation with the potential supplier(s) and

— incorporation of the (N)TS into a contract.

Key

Documents under customer’s responsibility

Documents under supplier’s responsibility

Figure 1 — Fundamental steps of a (N)TS elaboration process

6.3.3 Position in programme phasing and scheduling

6.3.3.1 General

A (N)TS is drawn up progressively with several editions linked to the programme’s milestones (see

Figure 2). This process is performed at each level of the product breakdown structure. The main

editions are the preliminary (N)TS and the reference (N)TS, described below.

6.3.3.2 Preliminary (N)TS

The preliminary (N)TS sets out the initial need as requirements that are usable by designers. The

preliminary (N)TS is baselined at the end of the feasibility phase. Its purpose is to be used by potential

suppliers to draw up bids for the customer. The preliminary (N)TS allows the customer to evaluate the

different bids.

The ability to convert the need expressed in the preliminary (N)TS into an achievable solution concept

(with regards to the technical aspect, cost, deadlines and organization) is generally evaluated in a

Feasibility Review. This review enables the definition phase to be launched.

6.3.3.3 Reference (N)TS

The reference (N)TS is elaborated from the preliminary (N)TS, supplemented with requirements issued

from more detailed studies and resulting from trade-offs performed with candidate supplier(s). It is

baselined at the end of the definition phase (preliminary design process) and is incorporated in a

contract at the latest before the development phase (i.e. before the start of the detailed design process).

NOTE Detailed studies performed during the (N)TS elaboration may concern environmental conditions

(adaptation of the product to its environment), information required for the interfaces, logistical support analysis

studies, qualification requirements, ability to meet performance requirements bearing in mind tolerance margins,

RAMS studies, etc.

The product (N)TS edition presented at the Preliminary Design Review (see RG.Aéro 000 67) is linked

to the preliminary (N)TS documents of its components within the chosen concept of architecture. At the

end of the review, it is approved as reference for development of the product and becomes the

reference (N)TS.

The reference (N)TS should be managed in configuration in accordance with the methods described in

Clause 8 of this document.

Figure 2 — Positioning of (N)TS editions according to project phasing and scheduling

6.3.4 Principles for requirement breakdown and allocation according to the product breakdown

structure

All the (N)TS of the product components are established according to the product breakdown structure,

so that every component needing to be obtained from a third party has a (N)TS. This principle applies

whatever the component level in the product breakdown structure.

The decomposition process of the product involves breakdown and allocation of the requirements

expressed in the product (N)TS into necessary and sufficient requirements for its components.

The requirement allocation results from arbitrations requiring suitable analyses (risks analyses, cost

analyses, feasibility analyses, availability analyses, etc.).

The requirements allocated to a given level of the product breakdown structure should be traced to the

higher-level requirements.

However, some requirements at a given level may be a result of a design choice at that level of the

breakdown structure and consequently not traceable to the higher level. These are called derived

requirements. In this case, the assumptions related to these requirements need to be made explicit.

This is particularly the case when the breakdown process creates new interfaces with generation of

associated requirements assigned to the concerned components. See documents DO-178C or

ARP4754A/ED-79A for more information on the concept of derived requirements.

6.4 Rules on the expression of requirements

6.4.1 Requirement quality criteria

As the (N)TS is the expression of the requirements which shall be fulfilled by the product, these

requirements should be

— identified (marked by a unique identifier),

— atomic (avoid grouping together several requirements in the same statement),

— non-redundant (do not express the same requirement several times, possibly with different

statements),

— non-ambiguous (avoid multiple interpretations of the statements),

— verifiable, either theoretically (calculation, modelling, etc.) or experimentally (tests, set of

tests, etc.),

— complete (address all the requirements in the product (N)TS, including references to other

separate documents) and

— justifiable (in a separate document).

The scope of validity of the requirements should be specified, stating the conditions of application and

cases of exclusion as far as possible.

Any quantified performance requirement should have a tolerance range around the target value. This

range represents uncertainties relating to knowledge of the product or its actual environment, to means

of design, manufacture, measurement, etc.

For a full list of quality criteria in the expression of a requirement, refer to the ISO/IEC/IEEE 29148

standard about requirement engineering.

The main pitfalls to be avoided are over-specification, under-specification, confusion between needs

and solution, insufficient maturity of the expression of needs, lack of customer/supplier agreement, etc.

Only the applicable and relevant subclauses of reference standards, should be quoted.

6.4.2 Format of the requirements

A requirement may be expressed in text or graphic form, within a document or model (e.g. a chart,

digital mock-up or simulation model).

Architectural frameworks (see Annex C) can help formalizing part of requirements with viewpoints

which reflect stakeholder concerns:

— user viewpoint: the operational view (describes operational activities and concept of use of the

solution described with scenarios);

— acquirer viewpoint: the programmatic view (describes activities and supplies in accordance with

the phasing and scheduling of the programme) and capability view (functionalities of the product to

be acquired in accordance with the phasing and scheduling of the programme).

The following architectural views may also be used to formalize the constraints on solutions, processes

and procedures that are imposed or to be reused, especially in the case of renovation, transformation or

work reassignment contracts:

— designer viewpoint on the initial product: the system view (functional and structural

representation;

— manufacturer viewpoint on the initial product: the technical view (taking account of constraints in

terms of standards to be applied or mandatory solutions).

The list of views identified as being relevant in (N)TS elaboration is provided in Annex C and Annex D.

6.4.3 Concepts of flexibility for requirements

6.4.3.1 In the preliminary (N)TS

During the supplier consultation stage, it is recommended that a degree of flexibility be assigned to each

requirement, so that the requirements may be put in hierarchical order in terms of obligation to be met.

This ranges from the lowest level in terms of imperativeness, i.e. “optional”, “desirable” or “nice to have”

up to the highest level, i.e. “mandatory”, “essential“, “guaranteed”, etc. Intermediate levels will be

determined, e.g. “important”, “significant”.

This concept of flexibility allows to keep proper candidates who meet a at least the mandatory

requirements.

It also enables to discriminate between bids which are equivalent in terms of mandatory requirements.

NOTE Degrees of flexibility such as the following may be introduced:

— mandatory;

— important;

— nice to have.

This concept of flexibility disappears in the reference (N)TS in which all the requirements shall be

fulfilled by the supplier.

6.4.3.2 In the reference (N)TS

In the particular case of performance, another concept of flexibility may lead to the specification of two

levels of expected performance for the same requirement:

— a performance level required by contract (which requires a result achievement);

— a target level of performance (which requires a commitment on means and best-effort).

NOTE For commitment on means, the supplier has to implement all possible means to reach the required

objectives.

7 Content of the (N)TS

7.1 General remarks

The suggested contents of a (N)TS are given in Annex E. If necessary, the structure may be tailored to fit

in with the formalism of the architectural frameworks.

Depending on the needs, some of the following subclauses may be split in dedicated documents

(e.g. integrated logistic support, result assurance, information security, interfaces, etc.).

7.2 Product concept

This subclause presents the concept and purpose of the product required by the contract.

7.3 Scope

This subclause defines the scope of application of the (N)TS of considered product with its concerned

included and excluded versions (in terms of Configuration Management). This subclause is particularly

important in the case of large programmes which involve many changes over a long period.

7.4 Context of use

7.4.1 Expected missions

This subclause describes the expected missions of the product required by the contract.

7.4.2 Operational context and operational environment

This subclause defines the scope of use that the product will have to fit in (context and period of

operational use, limits, criticality, location of use, place of the product in the operational environment

where it will be integrated, etc.). This enables the requirements to be considered into the context of use

of the product, and so to be better understood.

The other products which interface directly with the product concerned will be identified in this part.

NOTE Information on general use is necessary in case of sensitive products (in terms of export control of the

products, the national interest and the interest of the (N)TS issuer, etc.), so that the product supplier:

— is sure to obtaining authorization to develop and export the product and

— can use technologies and components compatible with product usage and purpose.

For example, some commercially-available software packages are prohibited in some export products.

The same is true for some hardware components such as “wideband” or high-power components.

7.4.3 Life profile

This subclause defines the different situations that the product will face during its usage (transport,

handling, storage, maintenance, operational use).

The relative duration of exposure of the product to each identified situation should be quantified for a

standard period of use.

As a reminder, the definition of “life profile” is given in Clause 3.

7.4.4 Operational scenarios

This subclause defines the design-critical operational scenarios applicable during the expected

missions, in the context identified in 7.4.2. I.e. as all the scenarios

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...