EN 9200:2004

(Main)Aerospace series - Programme management - Guidelines for project management specification

Aerospace series - Programme management - Guidelines for project management specification

For a given aerospace project, the present document is intended to be used as a reference to current best practices. These can be used as a guideline for the creation and negotiation of the project management specification between a customer and a supplier, and hence lead to the creation of the project management plan.

It may be used for any project utilising several actors at different levels. In particular in the case of large projects it presents provisions recommended for the management of a project according to (see Figure 1):

- project organisation,

- work breakdown structure,

- phasing and scheduling,

- risk management,

- configuration management,

- documentation management,

- interfaces with other disciplines,

- project monitoring and control,

- technical performance control,

- cost control,

- schedule control,

- resource management,

- quality assurance,

- project closure.

Luft- und Raumfahrt - Programm-Management - Richtlinie für eine Projektmanagement-Spezifikation

Série aérospatiale - Management de programme - Recommandation pour une spécification de management de projet

Le présent document est destiné à servir de référence en matière de meilleures pratiques courantes, pour un

projet aérospatial donné. Celles-ci peuvent servir de guide pour la création et la négociation de la spécification

de management de projet entre un client et un fournisseur, et entraînent donc la création d'un plan de

management de projet.

Ce document est utilisable pour tout projet faisant intervenir plusieurs acteurs à des niveaux différents.

Notamment dans le cas de grands projets, il présente les dispositions recommandées pour le management

d�un projet, suivant (voir Figure 1) :

¾ l�organisation du projet ;

¾ l�organigramme des tâches ;

¾ la logique de déroulement ;

¾ le management des risques ;

¾ le management de la configuration ;

¾ le management de la documentation ;

¾ les interfaces avec les autres disciplines ;

¾ la conduite et la maîtrise du projet :

¾ maîtrise des performances techniques ;

¾ maîtrise des coûts ;

¾ maîtrise des délais.

¾ le management des ressources ;

¾ l�assurance de la qualité ;

¾ la clôture du projet.

Aeronavtika - Vodenje programov - Smernice za specifikacijo vodenja projekta

General Information

- Status

- Published

- Publication Date

- 09-Nov-2004

- Withdrawal Date

- 30-May-2005

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 1 - General

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 21-Jan-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 9200:2004 (Aerospace series)

EN 9200:2004 is a CEN (AECMA-STAN) European standard that provides guidelines for project management specification in aerospace projects. It is intended as a reference to current best practices for creating and negotiating a project management specification between a customer and a supplier, and to support the development of the supplier’s project management plan. The standard is applicable to single projects or large multi-actor programmes where several organisations interact across tiers.

Key topics and technical requirements

EN 9200:2004 outlines recommended provisions and topics to be addressed in a project management specification. Key areas include:

- Project organisation - roles, responsibilities and contractual hierarchy

- Work breakdown structure (WBS) - logical decomposition of tasks and deliverables

- Phasing and scheduling - project phases, milestones and critical path identification

- Risk management - risk identification, assessment and mitigation provisions

- Configuration management - baselines, configuration items and change control (aligned with ISO 10007)

- Documentation management - document control, approvals and traceability

- Interfaces with other disciplines - systems engineering and multidisciplinary coordination

- Project monitoring and control - techniques for technical performance, cost and schedule control

- Resource management - personnel, facilities and material planning

- Quality assurance - alignment with EN ISO 9001/EN 9100 quality system expectations

- Project closure - acceptance, handover and lessons-learned

The standard defines terms and concepts (drawing from EN ISO 9000) and is descriptive rather than prescriptive - it recommends what should be included in the specification and notes that suppliers may use internal procedures provided they meet the recommendations.

Practical applications - who uses EN 9200:2004

- Customers / prime contractors - to prepare a clear project management specification prior to contract award

- Suppliers and subcontractors - to develop compliant project management plans and execution plans

- Programme and project managers - as a checklist of required management disciplines for complex aerospace projects

- Systems engineers, quality managers and contracts teams - to align technical, quality and contractual controls across the supply chain

- Procurement and compliance officers - to assess management obligations and associated cost impacts

EN 9200 is especially useful for large, multi-partner aerospace programmes where consistent management practices reduce risk and improve coordination.

Related standards

EN 9200 references and aligns with established quality and systems standards, including:

- EN ISO 9000:2000 / EN ISO 9001:2000

- ISO 10006:2003 (project quality management)

- ISO 10007:2003 (configuration management)

- EN 9100:2003, EN 9130:2001

- IEEE 1220:1998 (systems engineering process)

Use EN 9200:2004 as a practical blueprint to define project management requirements, ensure supplier alignment, and improve project governance in aerospace programmes.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 9200:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Programme management - Guidelines for project management specification". This standard covers: For a given aerospace project, the present document is intended to be used as a reference to current best practices. These can be used as a guideline for the creation and negotiation of the project management specification between a customer and a supplier, and hence lead to the creation of the project management plan. It may be used for any project utilising several actors at different levels. In particular in the case of large projects it presents provisions recommended for the management of a project according to (see Figure 1): - project organisation, - work breakdown structure, - phasing and scheduling, - risk management, - configuration management, - documentation management, - interfaces with other disciplines, - project monitoring and control, - technical performance control, - cost control, - schedule control, - resource management, - quality assurance, - project closure.

For a given aerospace project, the present document is intended to be used as a reference to current best practices. These can be used as a guideline for the creation and negotiation of the project management specification between a customer and a supplier, and hence lead to the creation of the project management plan. It may be used for any project utilising several actors at different levels. In particular in the case of large projects it presents provisions recommended for the management of a project according to (see Figure 1): - project organisation, - work breakdown structure, - phasing and scheduling, - risk management, - configuration management, - documentation management, - interfaces with other disciplines, - project monitoring and control, - technical performance control, - cost control, - schedule control, - resource management, - quality assurance, - project closure.

EN 9200:2004 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 9200:2004 has the following relationships with other standards: It is inter standard links to EN 9100:2018, EN 15595:2009+A1:2011, EN ISO 9000:2015, EN 14535-1:2005+A1:2011, EN ISO 9001:2015, EN 9223-102:2018, EN 9208:2021, EN 9227-1:2025, EN 9277:2015, EN 9239:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 9200:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2005

Aeronavtika - Vodenje programov - Smernice za specifikacijo vodenja projekta

Aerospace series - Programme management - Guidelines for project management

specification

Luft- und Raumfahrt - Programm-Management - Richtlinie für eine Projektmanagement-

Spezifikation

Série aérospatiale - Management de programme - Recommandation pour une

spécification de management de projet

Ta slovenski standard je istoveten z: EN 9200:2004

ICS:

03.100.40 Raziskave in razvoj Research and development

49.020 Letala in vesoljska vozila na Aircraft and space vehicles in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 9200

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2004

ICS 49.140

English version

Aerospace series - Programme management - Guidelines for

project management specification

Série aérospatiale - Management de programme - Luft- und Raumfahrt - Programm-Management - Richtlinie

Recommandation pour une spécification de management für eine Projektmanagement-Spezifikation

de projet

This European Standard was approved by CEN on 4 June 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 9200:2004: E

worldwide for CEN national Members.

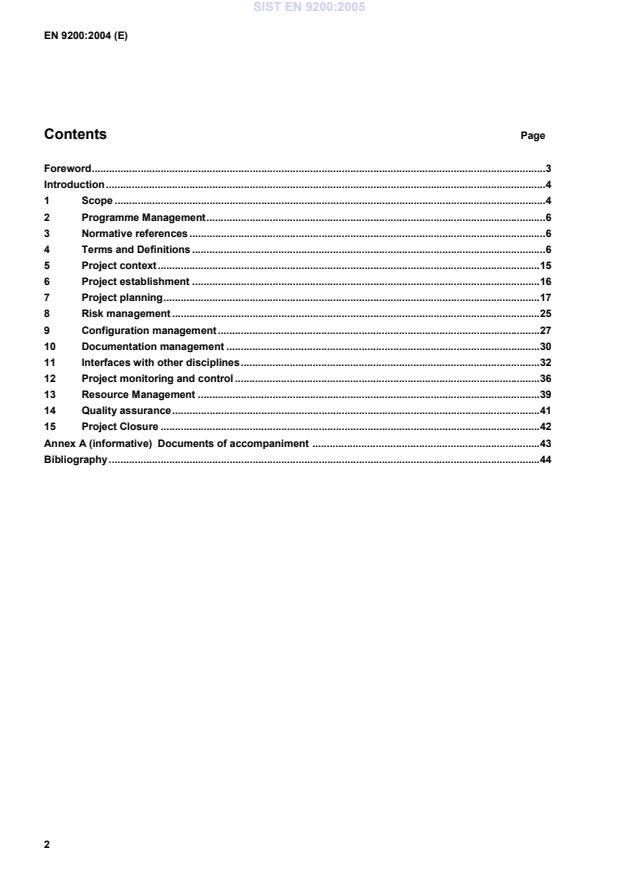

Contents Page

Foreword.3

Introduction.4

1 Scope .4

2 Programme Management.6

3 Normative references .6

4 Terms and Definitions .6

5 Project context.15

6 Project establishment .16

7 Project planning.17

8 Risk management .25

9 Configuration management.27

10 Documentation management .30

11 Interfaces with other disciplines.32

12 Project monitoring and control .36

13 Resource Management .39

14 Quality assurance.41

15 Project Closure .42

Annex A (informative) Documents of accompaniment .43

Bibliography.44

Foreword

This document (EN 9200:2004) has been prepared by the European Association of Aerospace

Manufacturers - Standardization (AECMA-STAN).

After enquiries and votes carried out in accordance with the rules of this Association, this Standard has

received the approval of the National Associations and the Official Services of the member countries of

AECMA, prior to its presentation to CEN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by May 2005, and conflicting national standards shall be withdrawn at

the latest by May 2005.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and the United Kingdom.

Annex A is informative.

Introduction

Project management aims at planning, monitoring and control of all aspects of a project, and the motivation

of all those involved in it, to achieve the project objectives, on time and to the specified cost, quality and

performance.

It requires:

the definition of the activities,

the roles and the responsibilities for the various actors,

consistency between their activities,

capacity for communication between them,

a stable and rigorous project organisation.

To achieve these objectives, the present document describes the key best practices for the management of

an aerospace project, to be adapted specifically for each particular project to be managed.

In this standard, the customer is either an external identified customer, or an internal entity within the

organisation, in charge of receiving or accepting the product. Additionally, this standard may also be used as

a basis for the relationship between customers and suppliers at any level of the supply chain.

Prior to contract negotiations, the customer will issue a management specification, against which a supplier

will submit a management plan. This document will assist in that process by indicating the major issues

presented in both documents.

The customers in charge of the establishment of the project management specification should be aware that

any management requirement has an impact on the costs and that, as in the case of the requirements for a

product, the minimum acceptable requirements should be an objective.

The project management specification is to be established with the objective of achieving the highest

effectiveness in this discipline. In particular, attention is drawn to the possibility for suppliers to use, to the

maximum extent, their own internal methods and procedures, in order to obtain quality, reliability and

limitation of costs, provided internal procedures meet this recommendation.

1 Scope

For a given aerospace project, the present document is intended to be used as a reference to current best

practices. These can be used as a guideline for the creation and negotiation of the project management

specification between a customer and a supplier, and hence lead to the creation of the project management

plan.

It may be used for any project utilising several actors at different levels. In particular in the case of large

projects it presents provisions recommended for the management of a project according to (see Figure 1):

project organisation,

work breakdown structure,

phasing and scheduling,

risk management,

configuration management,

documentation management,

interfaces with other disciplines,

project monitoring and control,

- technical performance control,

- cost control,

- schedule control,

resource management,

quality assurance,

project closure.

PROJECT MANAGEMENT

Project

Risk management Quality assurance

establishment

(clause 8) (clause 14)

(clause 6)

Configuration

Project planning

management

(clause 7)

(clause 9)

Documentation

management

(clause 10)

Interfaces with

other disciplines

(clause 11)

Project monitoring and control

(clause 12)

Technical performance

Cost control Schedule control

control

(subclause 12.2) (subclause 12.3)

(subclause 12.1)

Resource

management

(clause 13)

Figure 1 – Document organisation

The terminology employed is explained in clause 4. It is limited to specifying the context in which potentially

ambiguous terms are employed. As far as possible, this terminology includes definitions already appearing in

various normative documents, preferably international standards.

2 Programme Management

Referring to the definitions of project and project management as given in clause "0 Foreword", programme

management may be considered as the directing of a portfolio of projects which benefit from a consolidated

approach or towards one specific objective.

The common element of the projects in a portfolio is that they run simultaneously, or at least overlap with

one another, they share a number of common resources and are supposed to generate some income.

Under this definition, Programme Management is typically concerned with activities at a much higher level

within the organisation.

This standard will only focus on project management.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

This document is consistent with the quality management requirements as considered in normative

references:

EN ISO 9000:2000, Quality management systems – Fundamentals and vocabulary (ISO 9000:2000)

EN ISO 9001:2000, Quality management systems – Requirements (ISO 9001:2000)

ISO 10006:2003, Quality management systems – Guidelines for quality management in project

ISO 10007:2003, Quality management systems – Guidelines for configuration management

EN 9100:2003, Aerospace series – Quality management systems – Requirements (based on

ISO 9001:2000) and Quality systems – Model for quality assurance in design,

development, production, installation and servicing (based on ISO 9001:1994)

EN 9130: 2001, Aerospace series – Quality management systems – Record retention

IEEE 1220:1998, Standard for Application and Management of the Systems Engineering Process IEEE

1)

Computer Society Document

4 Terms and Definitions

For the purposes of this European Standard, the terms and definitions given in EN ISO 9000:2000 and the

following apply.

4.1

acceptance (of a product or a document)

decision pronounced by the customer, acknowledging that the product or the document is in conformity with

the contractual commitments

NOTE The acceptance of a document does not involve the responsibility from the authority which accepts

it, on the use of the document.

4.2

acquisition strategy

set of principles defined by a customer as regards technologies, performances, costs, schedules,

co-operations to lead the project, …

1) Published by Institute of Electrical and Electronics Engineers Inc – 445 Hoes Lane – P.O.Box 1331 – Piscataway,

NJ 08855-1331 - USA

4.3

anomaly

gap between a current situation and an expected one

NOTE An anomaly justifies an investigation which might lead to the discovery of a nonconformity or a defect.

4.4

applicable configuration

configuration of a product identified by its changes from the configuration baseline

At a given moment, a product may have several applicable configurations.

4.5

approval

formal agreement allowing the use or the application of a document

NOTE The approving authority commits its own responsibility on the use of the document contents.

4.6

as built configuration

configuration of one product item identified by its gaps of conformity with respect to its applicable

configuration

4.7

audit

systematic and objective activity undertaken to determine to what extent the requirements related to the

agreed topic are satisfied

This audit is carried out by one or more persons independent from what is being audited.

4.8

change

changes to document content submitted to configuration control (Technical specification, Design data file, …)

and characterised by their impact on their use

4.9

configuration

functional and physical characteristics of a product as defined in technical documents and achieved in the

product

[ISO 10007:2003]

4.10

configuration baseline

configuration of a product formally established at a specific point in time, which serves as reference for

further activities

[ISO 10007:2003]

4.11

configuration item

aggregation of hardware, software, processed materials, services, or any of its discrete portions, that is

designated for configuration management and treated as a single entity in the configuration management

process

[ISO 10007:2003]

4.12

contractual hierarchy

stacking customer/supplier such as the supplier of level N becomes customer of the level N+1

4.13

corrective action

action to eliminate the cause of a detected nonconformity, or other undesirable situation

[EN ISO 9000:2000]

4.14

critical path

sequence of tasks where any delay affects the final date

4.15

design (of a product or a system)

set of technical output data of the design process describing the functional and physical characteristics of a

product or a system

NOTE The data is structured in the design data file.

4.16

design data file

a structured set of documents constituting the response of the product designer to the technical

requirements of the applicant

All the verifiable product characteristics (including the acceptance criteria) could be expressed in this

document, and the prescribed processes to produce it are indicated. This file allows identification of the

product, in order to prepare its manufacturing and inspection file and its operating documentation.

4.17

design justification data file

document gathering the whole set of information on studies and tests showing that a product is compliant

with its design data file and meets the specification expressing the need which this product shall satisfy

4.18

design justification plan

document established by the supplier describing the set of needed works in order to demonstrate that a

product compliant with its Design data file, meets the specification expressing the need which this product

shall satisfy

4.19

deviation permit

permission to depart from the originally specified requirements of a product prior to realisation

[EN ISO 9000:2000]

NOTE A deviation permit is generally given for a limited quantity of products or period of time, and for a

specific use.

4.20

execution plan

document established by every supplier which:

describes:

- the main tasks and their logic (it ensures the consistency and integrates work of the different

disciplines such as management, systems engineering, integrated logistics support and RAMS, .),

- the resources (hardware and software) needed for their realisation;

presents the schedule of works and in particular the critical paths of the project and the particular

actions to be carried out.

4.21

function

actions of a product or one of its components expressed exclusively in terms of finality

4.22

functional analysis

approach which consists in defining, ordering, characterising, prioritising and/or giving value to the functions

NOTE 1 The Functional analysis applies to creation or improvement of a product, it is in this case the

fundamental base of value analysis. Applied to the need only, it is the base for the establishment of the

functional performance specification.

NOTE 2 Ordering aims at classifying the operating functions (sometimes technical functions in the event of

redesign) in a logical way and allowing the identification of their interrelationships.

The characterisation consists in defining the evaluation criteria, in specifying their levels and in indicating their

flexibility.

Prioritising allows evaluation of the order of importance of the functions.

giving value to the functions prioritises their relative or absolute contributions, independently of the solutions

4.23

functional architecture

structured breakdown of the system in functions and sub-functions (internal and external interfaces and data

flow) which complies with a need

4.24

functional performance specification

document by which the applicant expresses his need (or the one which he is in charge to express) in terms

of operating and constraints functions

For each of them, evaluation criteria and corresponding levels are defined. To each of these levels, flexibility

must be associated.

NOTE 1 The establishment of a functional performance specification implies that a study allowed the precise

definition of the user’s needs.

NOTE 2 As an answer, the objective is to obtain the product proposal able to meet the expected service,

under the intended conditions, at minimum cost ; for this purpose a functional performance specification

expresses only results requirements and, in principle, no resources requirements.

NOTE 3 An evaluation criterion (of a qualitative nature) is accompanied by a scale allowing the location of its

level (of a quantitative nature).

NOTE 4 Obtaining the totality of the expected advantages of a functional performance specification implies

use of flexibility.

4.25

function-tree

representation of the product or the system showing the breakdown in functions and sub-functions which

must be fulfilled by successive products levels

4.26

integrated logistics support

co-ordinated and iterative set of technical and management tasks whose objectives are the following:

to express the need in logistics support and the environmental constraints of use in the expression of

operational need;

to contribute to obtaining a system design including the support elements:

- allowing to optimise and maintain its effectiveness for all its life time, in consistency with the user

resources,

- allowing total optimisation « performances/costs/schedules »;

to realise, set up and to renew the support elements, according to the exploitation and the

maintenance needs.

4.27

integrated logistics support plan

document established by the supplier describing the organisation, the resources, the methods and the key

events set up to achieve the specified goals as regards logistics support

4.28

in use configuration

configuration of one product item identified by its as-built configuration and complemented by the

consequences of any in-service event on its functional and physical characteristics

NOTE Technical events, consumption of life potential, repairs etc. are examples of in-service events.

4.29

key-events

events considered as representative of the project progress and selected because of:

their character as an outstanding task start/end,

their interface character,

their criticality, (technical, economical, schedule risks, etc),

their contractual aspect (payment milestone).

4.30

lessons learnt

collection and exploitation, by all the actors of information concerning the events which have occurred

throughout the project

4.31

life cycle

this describes the whole series of developments of the product throughout its life starting from the expression

of its need until the disposal, whatever the form is

4.32

life cycle cost

total expenses for the whole life of the product for a given use

For a user, the life cycle cost includes the acquisition cost, the in service cost, the maintenance cost (spares,

etc.). Possibly the cost of modification, the cost of destruction, etc.

4.33

life profile

chronological description of the situations in which a product will be utilised from its delivery to its disposal

NOTE “situations” correspond to the different uses of the product and events in its life (e.g. transport,

handling, storage, maintenance, different missions.) with the respective duration and occurrences.

4.34

life time

duration, under a given set of conditions, of an interval of time, starting at a given moment and finishing

when the failure rate becomes unacceptable, or when the product is regarded as non repairable following a

failure

4.35

logistics support

set of tasks carried out on a system and including:

maintaining or recovery of the system availability,

providing the user and the various repairers, the supply items, the documentation, the tools, logistic

resources and the infrastructure needed to carry out the assigned tasks,

users training,

technical follow-up of the system in service.

4.36

logistics support analysis (LSA)

method contributing to the optimisation of the expected system design, starting from the expressed need and

the considered operational concepts

Then to define and optimise the products and the services necessary to implement, use and maintain the

availability of the system.

4.37

management plan

document established by the supplier to describe how he answers the set of requirements of the

management specification, according to its quality system

4.38

manufacturing and inspection file

document or set of documents detailing in a structured way the data necessary, in a given industrial context, for

the manufacturing and the inspection of a product compliant with its design described in the design data file

4.39

nonconformity

non-fulfilment of a requirement

[EN ISO 9000:2000]

4.40

operational need

need to be satisfied to fulfil a mission

4.41

phasing and scheduling

logical sequence of all the tasks of the project taking into account the requirements resulting from the

acquisition strategies and the execution plans declined in the stacking of customer/supplier

4.42

physical architecture

arrangement of physical elements which define a solution (products and operating processes) designed to

satisfy a need expressed by a functional architecture

[according to IEEE 1220]

4.43

preventive action

action to eliminate the cause of a potential nonconformity, or other undesirable potential situation

[EN ISO 9000:2000]

NOTE 1 There can be more than one cause for a potential nonconformity.

NOTE 2 Preventive action is taken to prevent occurrence whereas corrective action is taken to prevent

recurrence.

4.44

procedure

specified way to carry out an activity or a process

[EN ISO 9000:2000]

NOTE 1 Procedures can be documented or not.

NOTE 2 When a procedure is documented, the term "written procedure" or "documented procedure" is

frequently used. The document that contains a procedure can be called a "procedure document".

4.45

process

set of interrelated or interacting activities which transforms inputs into outputs

[according to EN ISO 9000:2000]

NOTE 1 Inputs to a process are generally outputs of others processes.

NOTE 2 Processes in a organisation are generally planned and carried out under controlled conditions to

add value.

NOTE 3 A process where the conformity of the resulting product cannot be readily or economically verified

is frequently referred to as a "special process".

4.46

product

result of a process

[according to EN ISO 9000:2000]

NOTE 1 There are four generic product categories, as follows:

- services (e.g. transport);

- software (e.g. computer programme, dictionary);

- hardware (e.g. mechanical parts);

- processed materials (e.g. lubricant).

Many products comprise elements belonging to different generic product categories. Whether the product is

then called service, software, hardware or processed material depends on the dominant element. For example,

the offered product "automobile" consists of hardware (e.g. tyres), processed materials (e.g. fuel, cooling

liquid), software (e.g. engine control software driver's manual), and service (e.g. operating explanations given

by the salesman).

NOTE 2 Service is the result of at least one activity necessarily performed at the interface between the

supplier and customer and is generally intangible. Provision of service can involve, for example, the following:

- an activity performed on a customer-supplied tangible product (e.g. automobile to be repaired);

- an activity performed on a customer-supplied intangible product (e.g. the income statement needed to

prepare a tax return);

- the delivery of an intangible product (e.g. the delivery of information in the context of knowledge

transmission);

- the creation of ambience for the customer (e.g. in hotels and restaurants).

Software consists of information and is generally intangible and can be in the form of approaches, transactions

or procedures.

Hardware is generally tangible and its amount is a countable characteristic. Processed materials are generally

tangible and their amount is a continuous characteristic. Hardware and processed materials often are referred

to as goods.

NOTE 3 Quality assurance is mainly focused on intended product.

4.47

product-tree

representation of the product or the system showing the physical breakdown in successive products levels

4.48

project

unique process, consisting of a set of co-ordinated and controlled activities with start and finish dates,

undertaken to achieve an objective conforming to specific requirements, including constraints of time, cost

and resources

[ISO 10006:2003]

4.49

project management specification

contractual document established by a customer prescribing the requirements to which his suppliers shall be

compliant for the activities of leading, organising and managing the project

4.50

project phase

part of a project during which a set of consistent and ordered necessary tasks is carried out to achieve a

predetermined goal

4.51

qualification

set of tasks contributing to provide proofs, while basing on theoretical and experimental justifications, that the

defined product satisfies the specified need and can be produced

The qualification decision is the act by which the customer, at the origin of the technical specification, attests

on the basis of theoretical and experimental justifications, that the defined product, identified by the design

data file, meets all the requirements of the Technical specification and can be produced.

4.52

quality assurance plan

supplier document which defines the quality assurance provisions specific to the project

4.53

RAMS

all aptitudes (Reliability, Availability Maintainability, Safety) of a product which enable it to have the specified

functional performances, at the requested time, for the considered duration and without damage for itself and

its environment

4.54

repair

action on a nonconforming product to make it acceptable for the intended use

[EN ISO 9000:2000]

NOTE 1 Repair includes remedial action taken on a previously conforming product to restore it for use, for

example as part of maintenance.

NOTE 2 Unlike rework, repair can affect or change parts of the nonconforming product.

4.55

requirement

need or expectation that is stated, generally implied or obligatory

[EN ISO 9000:2000]

NOTE 1 "generally implied" means that it is custom or common practice for the organisation, its customers

and other interested parties, that the need or expectation under consideration is implied.

NOTE 2 A qualifier can be used to denote a specific type of requirements, e.g. product requirements, quality

management requirement, customer requirement.

NOTE 3 A specified requirement is one which is stated, for example, in a document.

NOTE 4 Requirements can be generated by different interested parties.

4.56

review

activity undertaken to determine the suitability, adequacy and effectiveness of the subject matter to achieve

established objectives

[EN ISO 9000:2000]

NOTE Review can also include the determination of efficiency.

EXAMPLE Management review, design and development review, review of customer requirements and

nonconformity review.

4.57

rework

action on a nonconforming product to make it conform to the requirements

[EN ISO 9000:2000]

NOTE Unlike rework, repair can affect or change parts of the nonconforming product.

4.58

risk

feared event for the correct progress and obtaining of the project expected results

4.59

scrap

action on a nonconforming product to preclude its originally intended use

[EN ISO 9000:2000]

EXAMPLE Recycling, destruction.

NOTE In a nonconforming service situation, use is precluded by discontinuing the service.

4.60

support element

product or service implemented for the support of the system

4.61

system

set of complex hardware, software, personnel and operating processes, organised in a way to satisfy the

needs and to fulfil the expected services, in a given environment

NOTE A system when it constitutes a supply is a product.

4.62

systems engineering

engineering, implying the convergence of different technical disciplines, which allows the customer and the

supplier to co-ordinate the various technical processes (e.g. analysis need, design, …) concurring in an

iterative and exhaustive way to the adequacy of the solution throughout the product or system life cycle

4.63

task

action to be achieved, under fixed conditions, to obtain an expected and identified result

4.64

technical event

any significant technical event, predicted or not, arising during the life cycle of a product

4.65

technical specification

contractual document established by the product applicant, for the designer, and expressing his need (or the

one he is charged to express) in terms of technical requirements

The technical specification also defines the verification conditions of the requirements respect.

4.66

traceability

ability to trace the history, application or location of that which is under consideration

[according to EN ISO 9000:2000]

NOTE 1 When considering product traceability can relate to:

- the origin of materials and parts,

- the processing history, and

- the distribution and location of the product after delivery.

NOTE 2 In the field of metrology the definition in VIM: 1993, 6.10, is the accepted definition.

4.67

validation

confirmation, through the provision of objective evidence, that the requirements for a specific intended use or

application have been fulfilled

[EN ISO 9000:2000]

NOTE 1 The term "validated" is used to designate the corresponding status.

NOTE 2 The use conditions for validation can be real or simulated.

4.68

verification

confirmation, through the provision of objective evidence, that specified requirements have been fulfilled

[EN ISO 9000:2000]

NOTE 1 The term "verified" is use to designate the corresponding status.

NOTE 2 Confirmation can comprise activities such as:

- performing alternative calculations,

- comparing a new design specification with a similar proven design specification,

- undertaking tests and demonstrations, and

- reviewing documents prior to issue.

4.69

waiver (concession)

written authorisation to use a specimen or a batch of specimens of the product presenting a variation

between the as-built configuration and the applicable configuration

The waivers (concessions) are given for explicit uses.

4.70

work breakdown structure

global and structured breakdown of all the project, based on the product-tree or the function-tree, identifying

the tasks and the main resources required to perform the project

4.71

work packages

grouping of tasks related to the same product and the same supplier

5 Project context

Each project takes place in an overall environment, or context, which influences its implementation and

provides key features for defining its objectives.

It is essential that the various issues arising from inside or outside the company where the project will take

place are identified, understood and resolved before discussing and/or specifying the project management

requirements.

As far as the internal context is concerned, the following issues should be identified and understood:

Business Issues: this deals with aspects such as target price, margins, generated cash flow, time to

market, exportability, etc.

Strategic Issues: this deals with aspects such as business development opportunities, positioning

versus competitors, strategic partnerships, etc.

Industrial Issues: the project may be an opportunity for developing new/strategic industrial capabilities

internally and/or with strategic partners or suppliers

Technical/Technological Issues: aspects regarding the availability and mastering of key technical or

technological capabilities are essential to be considered when planning or resourcing the project

Skills/Competencies Issues: key skills and competencies needed to successfully achieve the project

must be considered and understood

Lessons learnt from previous projects

The external context should also be taken into account; this could deal with issues such as:

Customer issues, as far as relationships, requirements, standards, regulations, reporting, agreements,

offsets, etc. are concerned

Partners/Suppliers issues as far as their involvement, technical/financial/industrial capabilities are

concerned

and any other stakeholders, such as involved public agencies, governments, lobbies, etc.

Once these issues are identified and understood, the project should consider the total picture and conduct

trade-off studies to derive the most appropriate compromise to set up the project objectives upon.

Project management specifications/requirements could be built upon these objectives. Of course, during the

life of the project, any significant change to identified issues (or new issue) should lead to a reassessment of

its consequences and a deriving of modified project objectives.

6 Project establishment

6.1 General

The project establishment should be prepared as a formal document based on project objectives,

external/internal context, available resources and the project business case.

6.2 Project objectives

Project objectives should be defined as a set of quantified targets in respect of performance / functionality,

phasing and scheduling, cost and quality.

Validation and confirmation should be sought through the project internal or external customer.

The project schedule should be defined by using major milestones which should be precisely defined. An

indication of deadlines for preliminary and/or critical project reviews should also be given.

The project objectives should be detailed and formalised during the project concept phase and should

contain Top Level Requirements, i.e.

Top Level Product Requirements

Top Level Project Management Requirements

Top Level Marketing Requirements

Top Level Business Requirements

Top Level Procurement Requirements

Top Level Product Support Requirements

etc.

The assessment of project objectives should be checked throughout the whole project lifecycle.

6.3 Management of project external context

The sensitivity factors should be known and laid down in the business case and risk analysis. Depending on

the gravity of these factors, measures should be taken to reduce their possible impact.

Within the company, measures of establishing credibility for the project should be taken into account.

6.4 Management of project interactions

Possible synergies from/to other projects, or parts of them, should be taken into account.

6.5 Resource assessment

An estimate of required resources (personnel as well as infrastructure) for the whole project should be

undertaken.

Possible conflicts with resource availability should be highlighted within the risk analysis. If needed,

appropriate actions for an early resource prioritisation should be launched.

Any resource assessment should take into account the full supply chain including strategic alliances.

6.6 Project business case

The business case should contain as a minimum:

Strategic interest;

Market assessment;

This should contain all market conditions which render the projects necessary, and should include

Market environment, market potential, market requirements, and the investigation of main competitors;

Brief economic description;

The indication of main economical parameters should be described, and should include the financing

model, funding sources, currencies, prices, etc.;

Brief technical description;

A technical description of the project objectives, including main technical features which determine

performance for a given cost, should be given and should include risks and opportunities, required

technologies, maturity of technology candidates, etc.

For the overall project viability assessment the following should be established in line with the Top Level

Requirements: Pricing policy, target cost, business case objectives, cash flow.

7 Project planning

7.1 Management specification and management plan

7.1.1 Purpose

The project management specification is a contractual document prescribing the requirements to which the

first level suppliers should conform for the activities of control, organisation and management of the project.

During the progress of the project, the suppliers may be subject to distinct and successive contracts

including, if necessary, a management specification which reflects the requirements of the customer.

The goal of the project management specification is to gather in the same document, the management

requirements. It should be established as soon as possible in the progress of the project (and in particular at

the stage of the invitation to tender), because it determines much of the project success.

The management specification and hence the management plans (see 7.1.3) constitute the project

management rules. These rules could be adapted to each project phase.

7.1.2 Application to all the actors of a project

Each actor at a given level has the role of customer in relation to his suppliers.

With respect to the management specification received from his customer, the actor located at a given level

adapts the management requirements for his suppliers in a way such as they satisfy his own requirements

and those of his customer.

The tailoring of the management requirements should be appropriate to the level of the supplier’s

participation, whilst ensuring the continuity and the stability of the project rules.

In all the customer/supplier relationships, the management requirements should be contractual.

7.1.3 Management plan

The management plan may be established by the supplier to describe how he answers the set of

requirements of the management specification, according to its quality system.

The management plan should be based upon and makes reference to company basis and standards The

level of document access to the customer should be defined within the contractual negotiations.

The management plan and the executive plans are different documents with different purposes (see Figure 2):

Contract

Customer

Management Technical

Specification Specification

Management Plan Execution Plans

Supplier

- Organisation - Development Plan

- … - Production Plan

- Configuration - …

Management Plan

- Quality Assurance Plan

- RAMS Plan, …

Figure 2 – Management and executive plans purposes

7.1.3.1 Setting-up

The management plan may refer to specific plans fulfilling the corresponding requirements of the

management specification (examples: quality assurance plan, integrated logistic support plan, etc.).

Each supplier should establish the relationship between the content of its management plan and the

requirements of the specification which it answers. Any possible variations are noted.

7.1.3.2 Acceptance

The supplier may submit to his customer, for acceptance, the management plan which he has prepared,

including the successive changes.

After acceptance, the management plan constitutes a supplier commitment.

7.1.3.3 Consistency of the management plans

When there are several suppliers at the same level, the customer may be led either to impose a set of common

rules, or to establish consistency between the management plans proposed by the various suppliers.

A customer may require, to ensure consistency, some management plans beyond his direct suppliers to be

supplied to him.

7.2 Project organisation

7.2.1 Purpose

The implementation of a project organisation is necessary to ensure the execution and the control of the

project. It should be the responsibility of each actor to ensure his ability to fulfil the project requirements

(contract review).

The organisation to be set up takes in account the considered project phases, the nature of the tasks to be

carried out and the specified required competencies. The project organisation should be consistent with

contractual and technical commitments.

Project peculiarities should dictate the most effective and the simplest mode of management and of

contractual relationships.

The managing and contracting responsibilities should be defined in order to evaluate the contractual and

legal commitments.

If the project has links with other projects, the responsibilities relating to the interface definition and

management may be specified and taken into account while setting up the project organisation.

7.2.2 Organisation requirements

The preparation, definition and setting up of the project organisation should be carried out consistently with

the project objectives.

At every level, the customer exp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...