EN 453:2000+A1:2009

(Main)Food processing machinery - Dough mixers - Safety and hygiene requirements

Food processing machinery - Dough mixers - Safety and hygiene requirements

This standard specifies safety and hygiene requirements for the design and manufacture of dough mixers with rotating bowls of capacity greater than or equal to 5 l ) and less than or equal to 500 l.

These dough mixers are used to process various ingredients e.g. flour, sugar, fat, salt, water and other ingredients in food manufacturers and shops. These machines are sometimes used in other industries (e.g. pharmaceutical industry, chemical industry, printing), but hazards related to these uses are not considered in this standard.

The following machines are excluded:

- planetary mixers (EN 454);

- continuously fed machines;

- mixers with stationary vertical bowls;

- experimental and testing machines under development by the manufacturer;

- domestic appliances;

- automatic loading and unloading devices.

The intended use of the machine, as defined in 3.12 of EN 292-1:1991 and as given in the manufacturer’s instruction handbook, is the loading of various ingredients, processing them by means of a kneading tool, unloading and cleaning. The operation is usually carried out in cycles of variable duration. Manual operations are sometimes necessary to take samples, to scrape the bowl or add ingredients.

The significant hazards covered by the standard are mechanical (crushing, shearing, trapping, impact and loss of stability), electrical, ergonomic and also those resulting from noise, inhalation of flour dust and lack of hygiene.

This standard does not deal with noise reduction.

It applies only to machines manufactured after the date of issue of this standard.

Nahrungsmittelmaschinen - Teigknetmaschinen - Sicherheits- und Hygieneanforderungen

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, die durch Risikobeurteilung (siehe

EN 1050) ermittelt und in Abschnitt 4 dieser Europäischen Norm aufgeführt werden, die sich bei Zentrifugen

zur Verarbeitung von essbaren Ölen und Fetten ergeben, wenn diese bestimmungsgemäß und unter den vom

Hersteller vorgesehenen Bedingungen verwendet werden.

Sie legt die Sicherheits- und Hygieneanforderungen für die Gestaltung, die Herstellung, den Gebrauch, die

Instandhaltung und die Reinigung von Zentrifugen fest.

Der übliche Betriebsablauf wird in 3.2 beschrieben.

Diese Norm gilt nicht für Maschinen, bei denen Extraktion durch Lösungsmittel erfolgt und

Zusatzeinrichtungen (z.B. Förderbänder, Trichter usw.) zum Einsatz kommen.

Sie gilt nicht für Korbzentrifugen.

Diese Norm gilt in erster Linie für Maschinen, die nach dem Datum der Annahme durch CEN hergestellt

werden.

Machines pour les produits alimentaires - Pétrins - Prescriptions relatives à la sécurité et l'hygiène

La présente norme européenne spécifie les prescriptions de sécurité et d'hygiène relatives à la conception et à la

construction des pétrins de boulangerie et de pâtisserie à cuve tournante d'un volume supérieur ou égal à 5 l 1)

et inférieur ou égal à 500 l.

Ces pétrins sont utilisés pour travailler différents ingrédients comme la farine, le sucre, les matières grasses, le sel,

l'eau, etc. dans l'industrie alimentaire et les commerces de l'alimentation. Ces machines sont parfois utilisées

dans d'autres industries (par exemple : industrie pharmaceutique, chimique, imprimerie) mais les risques relatifs

à ces utilisations ne sont pas pris en compte dans cette norme.

Les machines suivantes sont exclues :

- les batteurs-mélangeurs (EN 454) ;

- les machines travaillant en alimentation continue ;

- les mélangeurs à cuve verticale fixe ;

- les machines expérimentales ou d'essais en cours de mise au point par le fabricant ;

- les appareils domestiques ;

- les appareils automatiques de chargement et de déchargement.

L'utilisation normale d'une machine, telle que définie en 3.12 de l'EN 292-1:1991 et dans le manuel d'instructions

du fabricant, comprend les opérations de chargement des divers ingrédients, le travail de ceux-ci à l'aide de l'outil

de pétrissage, le déchargement et le nettoyage. Le fonctionnement s'effectue généralement par cycles de durée

variable. Des opérations manuelles sont quelquefois nécessaires pour prélever des échantillons, racler la cuve ou

ajouter des ingrédients.

Les phénomènes dangereux significatifs couverts par la norme sont mécaniques (écrasement, cisaillement,

entraînement, choc et perte de stabilité), électriques, ergonomiques et aussi ceux résultant du bruit, de l'inhalation

de poussière de farine et du manque d'hygiène.

!texte supprimé"

Elle s'applique seulement aux machines fabriquées après sa date de publication.

Stroji za predelavo hrane - Mešalniki testa - Varnostne in higienske zahteve

Ta standard določa varnostne in higienske zahteve za načrtovanje in izdelavo mešalnikov testa z vrtečimi se skledami prostornine, večje ali enake 5 ter manjše ali enake 500 l. Ti mešalniki testa se uporabljajo za obdelavo raznih sestavin, t.j. moke, sladkorja, maščobe, soli, vode in ostalih sestavin za proizvajalce živil in trgovin. Te stroje se včasih uporablja tudi v drugih industrijah (t.j. farmacevtski industriji, kemični industriji, tiskanje), vendar nevarnosti, povezane s tovrstno uporabo, v tem standardu niso upoštevane. Izvzeti so naslednji stroji: - planetarni mešalniki (EN 454); - stroji z neprekinjenim podajanjem; - mešalniki s stalnimi navpičnimi posodami; - eksperimentalni in preskusni stroji v razvoju z strani proizvajalca; - gospodinjski aparati; - naprave z samodejnim nakladanjem in razkladanjem. Predvidena uporaba stroja, kot je določeno v 3.12 EN 292-1:1991 in podano v proizvajalčevem priročniku z navodili, je nakladanje raznih sestavin, obdelava le-teh z orodjem za gnetenje, razkladanje in čiščenje. Postopek se običajno izvaja v ciklih z različnim trajanjem. Včasih je za odvzem vzorcev, postrganje posode ali dodajanje sestavin potrebno ročno posredovanje. Velike nevarnosti, zajete z tem standardom, so mehanske (zdrobitev, ureznine, ujetje, udarci in izguba stabilnosti), električne, ergonomske in prav tako tiste, ki so posledica hrupa, vdihavanja prahu moke in pomanjkanja higiene. Velja samo za stroje, izdelane po datumu objave tega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 22-Dec-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 1 - Bakery equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Oct-2014

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 136, C 136, C 136, C 136, C 136, C 136, C 136, C OJ Date: 26-May-2010

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 12-Feb-2011

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 453:2000+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Dough mixers - Safety and hygiene requirements". This standard covers: This standard specifies safety and hygiene requirements for the design and manufacture of dough mixers with rotating bowls of capacity greater than or equal to 5 l ) and less than or equal to 500 l. These dough mixers are used to process various ingredients e.g. flour, sugar, fat, salt, water and other ingredients in food manufacturers and shops. These machines are sometimes used in other industries (e.g. pharmaceutical industry, chemical industry, printing), but hazards related to these uses are not considered in this standard. The following machines are excluded: - planetary mixers (EN 454); - continuously fed machines; - mixers with stationary vertical bowls; - experimental and testing machines under development by the manufacturer; - domestic appliances; - automatic loading and unloading devices. The intended use of the machine, as defined in 3.12 of EN 292-1:1991 and as given in the manufacturer’s instruction handbook, is the loading of various ingredients, processing them by means of a kneading tool, unloading and cleaning. The operation is usually carried out in cycles of variable duration. Manual operations are sometimes necessary to take samples, to scrape the bowl or add ingredients. The significant hazards covered by the standard are mechanical (crushing, shearing, trapping, impact and loss of stability), electrical, ergonomic and also those resulting from noise, inhalation of flour dust and lack of hygiene. This standard does not deal with noise reduction. It applies only to machines manufactured after the date of issue of this standard.

This standard specifies safety and hygiene requirements for the design and manufacture of dough mixers with rotating bowls of capacity greater than or equal to 5 l ) and less than or equal to 500 l. These dough mixers are used to process various ingredients e.g. flour, sugar, fat, salt, water and other ingredients in food manufacturers and shops. These machines are sometimes used in other industries (e.g. pharmaceutical industry, chemical industry, printing), but hazards related to these uses are not considered in this standard. The following machines are excluded: - planetary mixers (EN 454); - continuously fed machines; - mixers with stationary vertical bowls; - experimental and testing machines under development by the manufacturer; - domestic appliances; - automatic loading and unloading devices. The intended use of the machine, as defined in 3.12 of EN 292-1:1991 and as given in the manufacturer’s instruction handbook, is the loading of various ingredients, processing them by means of a kneading tool, unloading and cleaning. The operation is usually carried out in cycles of variable duration. Manual operations are sometimes necessary to take samples, to scrape the bowl or add ingredients. The significant hazards covered by the standard are mechanical (crushing, shearing, trapping, impact and loss of stability), electrical, ergonomic and also those resulting from noise, inhalation of flour dust and lack of hygiene. This standard does not deal with noise reduction. It applies only to machines manufactured after the date of issue of this standard.

EN 453:2000+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 453:2000+A1:2009 has the following relationships with other standards: It is inter standard links to EN 453:2000, EN 453:2014, EN 60651:1994, EN 60204-1:1997, EN 60529:1991, EN ISO 4871:1996, EN 292-2:1991/A1:1995, EN 663:1994, EN 294:1992, EN 1050:1996, EN 954-1:1996, EN 1672-2:1997, EN ISO 3744:1995, EN 292-2:1991, EN ISO 11201:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 453:2000+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 453:2000+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Mešalniki testa - Varnostne in higienske zahteveNahrungsmittelmaschinen - Teigknetmaschinen - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Pétrins - Prescriptions relatives à la sécurité et l'hygièneFood processing machinery - Dough mixers - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 453:2000+A1:2009SIST EN 453:2001+A1:2010en,fr01-marec-2010SIST EN 453:2001+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 453:2000+A1

December 2009 ICS 67.260 Supersedes EN 453:2000English Version

Food processing machinery - Dough mixers - Safety and hygiene requirements

Machines pour les produits alimentaires - Pétrins - Prescriptions relatives à la sécurité et l'hygiène

Nahrungsmittelmaschinen - Teigknetmaschinen - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 2 January 2000 and includes Amendment 1 approved by CEN on 24 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 453:2000+A1:2009: ESIST EN 453:2001+A1:2010

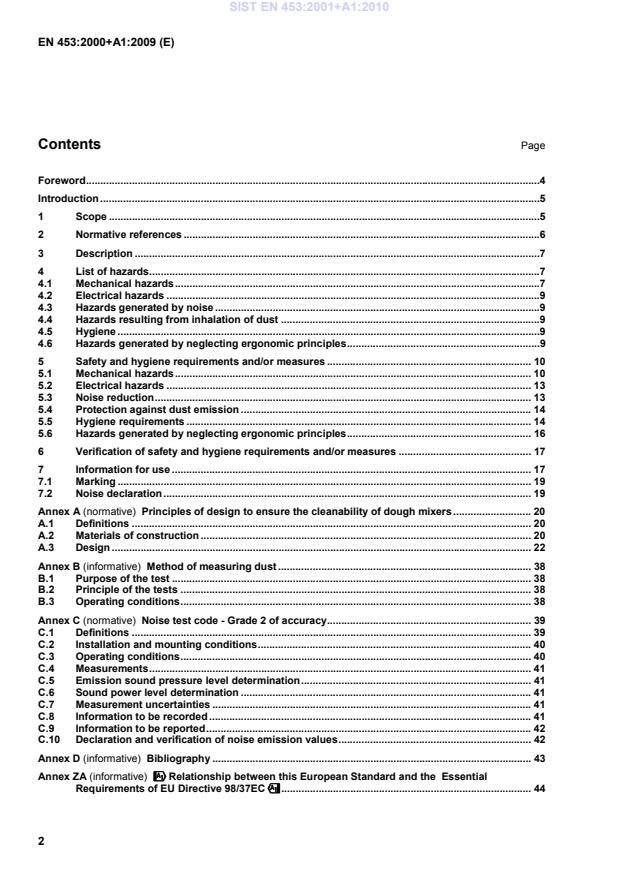

Principles of design to ensure the cleanability of dough mixers . 20A.1Definitions . 20A.2Materials of construction . 20A.3Design . 22Annex B (informative)

Method of measuring dust . 38B.1Purpose of the test . 38B.2Principle of the tests . 38B.3Operating conditions . 38Annex C (normative)

Noise test code - Grade 2 of accuracy. 39C.1Definitions . 39C.2Installation and mounting conditions . 40C.3Operating conditions . 40C.4Measurements . 41C.5Emission sound pressure level determination . 41C.6Sound power level determination . 41C.7Measurement uncertainties . 41C.8Information to be recorded . 41C.9Information to be reported . 42C.10Declaration and verification of noise emission values . 42Annex D (informative)

Bibliography . 43Annex ZA (informative)

!!!!Relationship between this European Standard and the

Essential Requirements of EU Directive 98/37EC"""" . 44SIST EN 453:2001+A1:2010

!!!!Relationship between this European Standard and the

Essential Requirements of EU Directive 2006/42/EC"""" . 45 SIST EN 453:2001+A1:2010

1) Below 5 l, EN 60335-1 and 60335-2 are applicable. SIST EN 453:2001+A1:2010

Figure 1 a)

Figure 2 b)

Figure 3 c) Figure 4 — Danger zones of a dough mixer

4.2 Electrical hazards Hazard of electric shock from direct or indirect contact with live components. Hazard of external influences on electrical equipment (e.g. cleaning with water). 4.3 Hazards generated by noise Especially large dough mixers generate airborne noise which can result in hearing damage, in accidents due to interference with speech communication and interference with the perception of acoustic signals. 4.4 Hazards resulting from inhalation of dust Use of dough mixers exposes operators to dust including flour and ingredients which may be harmful to their health, causing rhinitis (running noses), watering eyes and possibly occupational asthma. 4.5 Hygiene Lack of hygiene can create a risk to human health and unacceptable modification of foodstuff e.g. contamination by microbial growth or foreign materials. 4.6 Hazards generated by neglecting ergonomic principles During operation, cleaning and maintenance, there is a risk of injury or chronic damage to the body resulting from awkward body postures. SIST EN 453:2001+A1:2010

Figure 2 a)

Figure 2 b) Key: (1) volume covered by the kneading tool a distance between the internal rim of the bowl and the external part of the guard b horizontal distance between the external part of the guard and the nearest point of the danger zone

i.e. the volume covered by the movement of the kneading tool (s) c distance between the bowl guard and the rotating bowl rim d distance between the upper rim of the bowl and the position of the outer edge of the guard when the

interlocking device is actuated Figure 2 — Dimensions of the guard

Table 1 — Dimensions of the guard Dimensions in millimetres b

a

c

d b ≤ 120 a = 0 c ≤ 25 d < 25 120 < b ≤ 230 a ≤ 100 c ≤ 25 d < 50 b > 230 a ≤ 140 c ≤ 25 d < 75

5.1.1.2 In order to facilitate dough discharge from dough mixers with non-removable bowls,

movement of the kneading tool and bowl motions at low speed is permitted with the guard opened, by operation of a hold-to-run control. This allows the operator to turn the bowl for unloading the bowl in different positions. 5.1.1.3 Stopping time Guard actuated stopping devices shall stop the dough mixer with the bowl empty within 4 s of opening the guard. SIST EN 453:2001+A1:2010

Food area

Splash area

Non food area Figure 3 a)

Food area

Splash area

Non food area Figure 3 b)

Food area

Splash area

Non food area Figure 3 c) Figure 3 — Hygiene areas (with guards removed) 5.6 Hazards generated by neglecting ergonomic principles Awkward body postures during maintenance and cleaning as well as filling and emptying the bowl and other operations, shall be avoided. Suitably positioned lifting devices and/or transport carriages shall be provided for installation, removal and transport of any part of the dough mixer weighing more than 25 kg. If the mass of the filled removable bowl exceeds 25 kg, a handling device shall be fitted, for example wheels on the bowl or a separate trolley. Pushing and pulling with excessive effort shall be avoided e.g. by use of low -friction castor wheels or by the design of the bowl coupling mechanism. If tilting of the bowl is manual, it shall require a force not more than 250 N. When lowering of the kneading tool is manual, lowering or lifting with the bowl empty shall require a force not more than 250 N in normal operating conditions. Control devices shall be placed within proper reach for the operator as stated in annex A of EN 614-1:1995. SIST EN 453:2001+A1:2010

Tests relating to electromagnetic compatibility may be limited where the supplier of the electric/electronic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...