EN 12331:2021

(Main)Food processing machinery - Mincing machines - Safety and hygiene requirements

Food processing machinery - Mincing machines - Safety and hygiene requirements

This document specifies requirements for the design and manufacture of mincing machines (see Figure 1).

The mincing machines (hereinafter referred to as machine) covered by this document are used for size reduction of fresh or frozen meat, meat products and fish (hereinafter referred to as product) by cutting in a set of cutting tools.

Household machines are not included in this document. Filling mincers are covered by EN 12463 “Food processing machinery — Filling machines and auxiliary machines — Safety and hygiene requirements”.

This document applies only to machines that are manufactured after the date of issue of this document.

This document covers:

a) professional machines (see Figure 1 a) used for on-demand preparation in shops and/or restaurants characterized by all of the following features (if any of the features is missing the machine is considered an industrial machine):

1) designed as a table-top machine;

2) having a feed tray;

3) the product is only fed manually;

4) is only operated from the ground;

5) is operated by no more than one operator;

6) with full visibility and full accessibility of the entire machine from the operator workstation;

7) having hole plate diameter ≤ 106 mm;

8) a worm casing set which is removable without using any tools;

9) the weight of the worm casing set ≤ 15 kg;

NOTE The table-top machine can be equipped with a frame or base, so no separate table is needed.

b) industrial machines (see Figure 1 b) used for industrial mass production, and which cannot be characterized as a professional machine.

This document does not describe the specific requirements for the control of machines with foot switch.

This document does not describe the specific requirements for additional mixing screws in the feed intake hopper which are covered by EN 13570:2005+A1:2010 “Food processing machinery — Mixing machines — Safety and hygiene requirements”.

Figure 1 - Examples of machines

This document covers the following types of machines:

- machine with feed tray, feed intake and pusher (see Figure 3);

- machine with feed tray, feed intake, restrictor plate and pusher (see Figure 4);

- machine with feed intake hopper, protective cover and feeding screw (see Figure 6);

- machine with feed intake hopper, with or without protective cover, feeding screw, with loading device (continuously or discontinuously).

Machines comprise a machine base, a worm casing with a worm, a feed tray (with feed intake) or a feed intake hopper, a set of cutting tools, a lock nut, a drive motor. They will also have various safeguarding devices as examples in Clause 4.

Machines can be equipped e.g. with:

- an extraction claw;

- an ejector or extractor;

- a protective hood over the discharge outlet;

- a protective cover over the inlet opening of the feed intake hopper;

- a transport carriage for the lock nut, the set of cutting tools, the worm and the feeding screw;

- a lifting device for the lock nut, the set of cutting tools, the worm and the feeding screw;

- a loading device.

The product is fed manually or with a loading device into the machine. The product is fed to the worm either by a pusher or a feeding screw and reduced in size by a set of cutting tools.

This document specifies all significant hazards, hazardous situations and events relevant to machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D).

This document specifies the hazards which can arise during commissioning, operation, cleaning, use, maintenance and decommissioning of the machine.

Nahrungsmittelmaschinen - Wölfe - Sicherheits- und Hygieneanforderungen

Dieses Dokument legt Anforderungen an die Konstruktion und Herstellung von Wölfen (siehe Bild 1) fest.

Die von diesem Dokument erfassten Wölfe (nachfolgend als Maschinen bezeichnet) werden für die Zerkleinerung von frischem oder gefrorenem Fleisch, Fleischprodukten und Fisch (nachfolgend als Produkt bezeichnet) durch Zerschneiden in einem Schneidsatz verwendet.

Haushaltsgeräte sind nicht in diesem Dokument eingeschlossen. Füllwölfe werden in EN 12463 „Nahrungsmittelmaschinen - Füllmaschinen und Vorsatzmaschinen - Sicherheits- und Hygieneanforderungen“ behandelt.

Dieses Dokument gilt nur für Maschinen, die nach dem Ausgabedatum dieses Dokuments hergestellt werden.

Dieses Dokument behandelt:

a) professionelle Maschinen (siehe Bild 1 a), die in Läden oder Restaurants für die Herstellung nach Bedarf verwendet werden und sich durch die folgenden Merkmale auszeichnen (wenn eines der Merkmale nicht erfüllt ist, wird die Maschine als industrielle Maschine betrachtet):

1) konstruiert als Tischmaschine;

2) mit Einfüllschale;

3) das Produkt wird nur manuell eingebracht;

4) wird nur vom Boden aus betrieben;

5) wird von nicht mehr als einem Bediener betrieben;

6) die gesamte Maschine ist vom Arbeitsbereich des Bedieners vollständig einsehbar und vollständig zugänglich;

7) hat einen Lochscheibendurchmesser ≤ 106 mm;

8) ein Schneckengehäusesatz, der ohne Einsatz von Werkzeugen ausbaubar ist;

9) das Gewicht des Schneckengehäusesatzes liegt bei ≤ 15 kg;

ANMERKUNG Die Tischmaschine kann mit einem Rahmen oder einem Sockel ausgestattet sein, sodass kein separater Tisch erforderlich ist.

b) industrielle Maschinen (siehe Bild 1 b), die für industrielle Massenherstellung eingesetzt werden und die sich nicht als professionelle Maschine charakterisieren lassen.

Dieses Dokument beschreibt keine speziellen Anforderungen an die Steuerung von Maschinen mittels Fußschalter.

Dieses Dokument beschreibt keine speziellen Anforderungen an zusätzliche Mengwellen im Einfülltrog, die von EN 13570:2005+A1:2010 „Nahrungsmittelmaschinen - Mischmaschinen - Sicherheits- und Hygieneanforderungen” behandelt werden.

[...]

Machines pour les produits alimentaires - Hachoirs - Prescriptions relatives à la sécurité et l'hygiène

Le présent document spécifie les prescriptions relatives à la conception et à la fabrication des hachoirs (voir Figure 1).

Les hachoirs (ci-après désignés « machines ») couverts par le présent document sont utilisés pour hacher de la viande fraîche ou congelée, des produits à base de viande et du poisson (ci-après désignés « produit »), la coupe étant effectuée dans un jeu d’outils de coupe.

Les machines à usage domestique ne sont pas couvertes par le présent document. Les poussoirs sont couverts par l’EN 12463 « Machines pour les produits alimentaires " Machines à pousser et machines auxiliaires " Prescriptions relatives à la sécurité et à l’hygiène ».

Le présent document ne s’applique qu’aux machines fabriquées après sa date de publication.

Le présent document traite des :

a) machines professionnelles (voir Figure 1 a) utilisées pour la préparation à la demande dans les magasins et/ou les restaurants et caractérisées par toutes les caractéristiques suivantes (si l'une des caractéristiques est manquante, la machine est considérée comme une machine industrielle) :

i) conçues comme machines de table ;

ii) équipées d’un plateau de chargement ;

iii) le produit est uniquement chargé manuellement ;

iv) uniquement utilisées au sol ;

v) n’étant pas exploitées par plus d’un opérateur ;

vi) offrant une visibilité totale et une accessibilité totale de l'ensemble de la machine depuis le poste de travail de l'opérateur ;

vii) dont le diamètre de la grille perforée est ≤ 106 mm ;

viii) avec un corps de hachoir qui est amovible sans outil ;

ix) dont le poids du corps de hachoir est ≤ 15 kg ;

NOTE La machine de table peut être équipée d'un bâti ou d'un socle, de sorte qu'aucune table séparée n'est nécessaire.

b) machines industrielles (voir Figure 1 b) utilisées pour la production industrielle de masse, et qui ne peuvent pas être qualifiées de machines professionnelles.

Le présent document ne décrit pas les exigences spécifiques pour les machines avec commandes aux pieds.

Le présent document ne décrit pas les prescriptions spécifiques pour les vis mélangeuses supplémentaires dans la trémie de chargement qui sont couvertes par l’EN 13570:2005+A1:2010 « Machines pour les produits alimentaires — Malaxeurs — Prescriptions relatives à la sécurité et à l'hygiène ».

Le présent document couvre les types de machines suivants :

- machine avec plateau de chargement, goulotte de chargement et poussoir (voir Figure 3) ;

- machine avec plateau de chargement, goulotte de chargement, grille protectrice et poussoir (voir Figure 4) ;

- machine avec trémie de chargement, capot de protection et vis de chargement (voir Figure 6) ;

- machine avec trémie de chargement, avec ou sans protecteur mobile en sortie de hachoir, vis de chargement, avec dispositif de chargement (en continu ou discontinu).

Les machines comprennent un socle, un corps de hachoir avec une vis d'acheminement, un plateau de chargement (avec goulotte de chargement) ou une trémie de chargement, un jeu d’outils de coupe, un écrou de corps, un moteur d'entraînement et, suivant le type de machine, des composants électriques, hydrauliques et pneumatiques. Elles comprennent également plusieurs dispositifs de sécurité donnés en exemple à l’Article 5.

...

Stroji za predelavo hrane - Stroji za mletje mesa - Varnostne in higienske zahteve

General Information

- Status

- Published

- Publication Date

- 10-Aug-2021

- Withdrawal Date

- 27-Feb-2022

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 2 - Meat processing machinery

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 11-Aug-2021

- Due Date

- 22-Aug-2020

- Completion Date

- 11-Aug-2021

Relations

- Replaces

EN 12331:2015 - Food processing machinery - Mincing machines - Safety and hygiene requirements - Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 1672-2:2005+A1:2009 - Food processing machinery - Basic concepts - Part 2: Hygiene requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12331:2021 - Food processing machinery: Mincing machines - Safety and hygiene requirements is the CEN standard that specifies safety and hygiene requirements for commercial and industrial mincing machines used to reduce the size of fresh or frozen meat, meat products and fish. It replaces EN 12331:2015 and applies to machines manufactured after its issue date. Household machines are excluded; filling mincers are covered separately by EN 12463.

Key topics and technical requirements

- Scope and machine types: Differentiates professional (table‑top, feed tray, manual feed, single operator, hole plate ≤ 106 mm, removable worm casing ≤ 15 kg) and industrial mincers (mass production equipment).

- Hazard coverage: Specifies significant hazards during commissioning, operation, cleaning, maintenance and decommissioning (see Annex D).

- Mechanical safety: Guarding of cutting tools, safe access to feed inlets, lock nuts, worm casing and safe removal/handling of components.

- Electrical safety: Requirements for electrical equipment in line with EN 60204‑1.

- Stability and ergonomics: Machine stability, operator workstation design and manual handling limits.

- Hygiene and cleanability: Materials, surface finish and design principles to allow effective cleaning (see Annex B).

- Noise and acoustic testing: Noise measurement and declaration procedures (Annex A) aligned with EN ISO 3744 / EN ISO 11201.

- Other hazards: Requirements addressing gases (N2, CO2, steam) where applicable and recommendations for safeguarding devices (e.g., protective hoods, feed covers, extractors).

- Verification and documentation: Procedures for verifying safety measures, and user information/marking requirements (Clause 5–6).

Applications and who uses this standard

- Machine manufacturers (design, R&D, compliance teams) use EN 12331:2021 to design and certify mincing machines that meet EU safety and hygiene expectations.

- Food processors, butchers, restaurants and caterers select compliant professional or industrial mincers and verify safe operation and cleaning procedures.

- Maintenance and service providers use it to plan safe maintenance and component handling.

- Regulators, market surveillance and safety bodies reference it for conformity assessment and incident investigation.

Related standards

- EN 12463 - Filling machines (filling mincers)

- EN 13570 - Mixing machines (mixing screws in hoppers)

- EN 60204‑1 - Electrical equipment of machines

- EN 1672‑2 - Food processing machinery - hygiene requirements

- EN ISO 3744 / EN ISO 11201 / EN ISO 4871 - Noise measurement and declaration

- EN ISO 12100 - General machinery risk assessment and design principles

EN 12331:2021 is essential for ensuring safe, hygienic mincing equipment in commercial and industrial food production, supporting compliance, operator safety, and effective cleaning practices.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 12331:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Mincing machines - Safety and hygiene requirements". This standard covers: This document specifies requirements for the design and manufacture of mincing machines (see Figure 1). The mincing machines (hereinafter referred to as machine) covered by this document are used for size reduction of fresh or frozen meat, meat products and fish (hereinafter referred to as product) by cutting in a set of cutting tools. Household machines are not included in this document. Filling mincers are covered by EN 12463 “Food processing machinery — Filling machines and auxiliary machines — Safety and hygiene requirements”. This document applies only to machines that are manufactured after the date of issue of this document. This document covers: a) professional machines (see Figure 1 a) used for on-demand preparation in shops and/or restaurants characterized by all of the following features (if any of the features is missing the machine is considered an industrial machine): 1) designed as a table-top machine; 2) having a feed tray; 3) the product is only fed manually; 4) is only operated from the ground; 5) is operated by no more than one operator; 6) with full visibility and full accessibility of the entire machine from the operator workstation; 7) having hole plate diameter ≤ 106 mm; 8) a worm casing set which is removable without using any tools; 9) the weight of the worm casing set ≤ 15 kg; NOTE The table-top machine can be equipped with a frame or base, so no separate table is needed. b) industrial machines (see Figure 1 b) used for industrial mass production, and which cannot be characterized as a professional machine. This document does not describe the specific requirements for the control of machines with foot switch. This document does not describe the specific requirements for additional mixing screws in the feed intake hopper which are covered by EN 13570:2005+A1:2010 “Food processing machinery — Mixing machines — Safety and hygiene requirements”. Figure 1 - Examples of machines This document covers the following types of machines: - machine with feed tray, feed intake and pusher (see Figure 3); - machine with feed tray, feed intake, restrictor plate and pusher (see Figure 4); - machine with feed intake hopper, protective cover and feeding screw (see Figure 6); - machine with feed intake hopper, with or without protective cover, feeding screw, with loading device (continuously or discontinuously). Machines comprise a machine base, a worm casing with a worm, a feed tray (with feed intake) or a feed intake hopper, a set of cutting tools, a lock nut, a drive motor. They will also have various safeguarding devices as examples in Clause 4. Machines can be equipped e.g. with: - an extraction claw; - an ejector or extractor; - a protective hood over the discharge outlet; - a protective cover over the inlet opening of the feed intake hopper; - a transport carriage for the lock nut, the set of cutting tools, the worm and the feeding screw; - a lifting device for the lock nut, the set of cutting tools, the worm and the feeding screw; - a loading device. The product is fed manually or with a loading device into the machine. The product is fed to the worm either by a pusher or a feeding screw and reduced in size by a set of cutting tools. This document specifies all significant hazards, hazardous situations and events relevant to machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D). This document specifies the hazards which can arise during commissioning, operation, cleaning, use, maintenance and decommissioning of the machine.

This document specifies requirements for the design and manufacture of mincing machines (see Figure 1). The mincing machines (hereinafter referred to as machine) covered by this document are used for size reduction of fresh or frozen meat, meat products and fish (hereinafter referred to as product) by cutting in a set of cutting tools. Household machines are not included in this document. Filling mincers are covered by EN 12463 “Food processing machinery — Filling machines and auxiliary machines — Safety and hygiene requirements”. This document applies only to machines that are manufactured after the date of issue of this document. This document covers: a) professional machines (see Figure 1 a) used for on-demand preparation in shops and/or restaurants characterized by all of the following features (if any of the features is missing the machine is considered an industrial machine): 1) designed as a table-top machine; 2) having a feed tray; 3) the product is only fed manually; 4) is only operated from the ground; 5) is operated by no more than one operator; 6) with full visibility and full accessibility of the entire machine from the operator workstation; 7) having hole plate diameter ≤ 106 mm; 8) a worm casing set which is removable without using any tools; 9) the weight of the worm casing set ≤ 15 kg; NOTE The table-top machine can be equipped with a frame or base, so no separate table is needed. b) industrial machines (see Figure 1 b) used for industrial mass production, and which cannot be characterized as a professional machine. This document does not describe the specific requirements for the control of machines with foot switch. This document does not describe the specific requirements for additional mixing screws in the feed intake hopper which are covered by EN 13570:2005+A1:2010 “Food processing machinery — Mixing machines — Safety and hygiene requirements”. Figure 1 - Examples of machines This document covers the following types of machines: - machine with feed tray, feed intake and pusher (see Figure 3); - machine with feed tray, feed intake, restrictor plate and pusher (see Figure 4); - machine with feed intake hopper, protective cover and feeding screw (see Figure 6); - machine with feed intake hopper, with or without protective cover, feeding screw, with loading device (continuously or discontinuously). Machines comprise a machine base, a worm casing with a worm, a feed tray (with feed intake) or a feed intake hopper, a set of cutting tools, a lock nut, a drive motor. They will also have various safeguarding devices as examples in Clause 4. Machines can be equipped e.g. with: - an extraction claw; - an ejector or extractor; - a protective hood over the discharge outlet; - a protective cover over the inlet opening of the feed intake hopper; - a transport carriage for the lock nut, the set of cutting tools, the worm and the feeding screw; - a lifting device for the lock nut, the set of cutting tools, the worm and the feeding screw; - a loading device. The product is fed manually or with a loading device into the machine. The product is fed to the worm either by a pusher or a feeding screw and reduced in size by a set of cutting tools. This document specifies all significant hazards, hazardous situations and events relevant to machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D). This document specifies the hazards which can arise during commissioning, operation, cleaning, use, maintenance and decommissioning of the machine.

EN 12331:2021 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12331:2021 has the following relationships with other standards: It is inter standard links to EN 12331:2015, EN 60204-1:2018, EN 60529:1991/A1:2000, EN 61496-1:2013, EN 60529:1991/A2:2013, EN 60529:1991, EN 1672-2:2005+A1:2009, EN ISO 4287:1998/A1:2009, EN ISO 4287:1998, EN ISO 13857:2019, EN 1005-2:2003+A1:2008, EN ISO 3746:2010, EN ISO 11688-1:2009, EN ISO 4871:2009, EN ISO 11201:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12331:2021 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12331:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2021

Nadomešča:

SIST EN 12331:2015

Stroji za predelavo hrane - Stroji za mletje mesa - Varnostne in higienske zahteve

Food processing machinery - Mincing machines - Safety and hygiene requirements

Nahrungsmittelmashinen - Wölfe - Sicherheits- und Hygieneanforderungen

Machines pour les produits alimentaires - Hachoirs - Prescriptions relatives à la sécurité

et l'hygiène

Ta slovenski standard je istoveten z: EN 12331:2021

ICS:

67.260 Tovarne in oprema za živilsko Plants and equipment for the

industrijo food industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12331

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2021

EUROPÄISCHE NORM

ICS 67.260 Supersedes EN 12331:2015

English Version

Food processing machinery - Mincing machines - Safety

and hygiene requirements

Machines pour les produits alimentaires - Hachoirs - Nahrungsmittelmaschinen - Wölfe - Sicherheits- und

Prescriptions relatives à la sécurité et l'hygiène Hygieneanforderungen

This European Standard was approved by CEN on 23 May 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12331:2021 E

worldwide for CEN national Members.

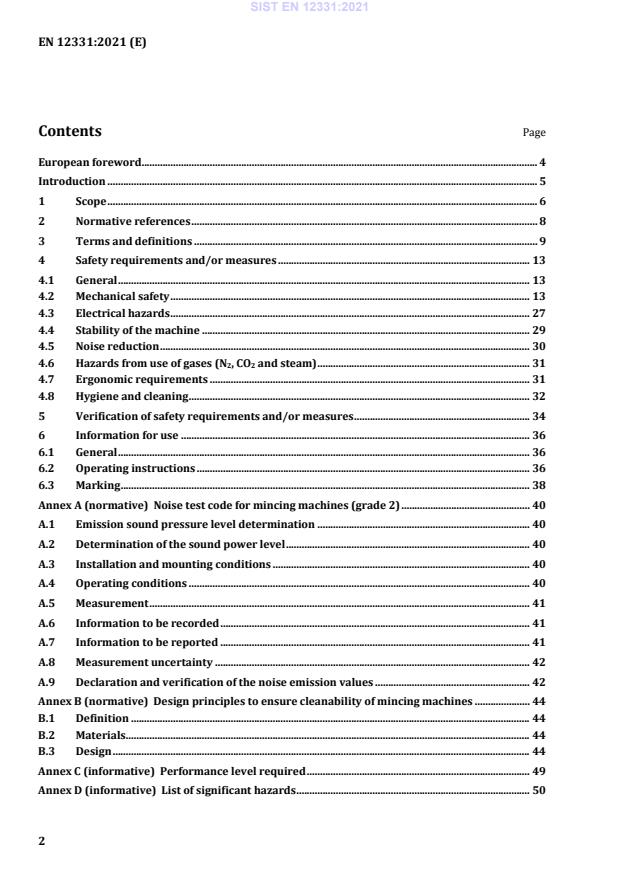

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 8

3 Terms and definitions . 9

4 Safety requirements and/or measures . 13

4.1 General . 13

4.2 Mechanical safety . 13

4.3 Electrical hazards . 27

4.4 Stability of the machine . 29

4.5 Noise reduction . 30

4.6 Hazards from use of gases (N2, CO2 and steam) . 31

4.7 Ergonomic requirements . 31

4.8 Hygiene and cleaning . 32

5 Verification of safety requirements and/or measures . 34

6 Information for use . 36

6.1 General . 36

6.2 Operating instructions . 36

6.3 Marking . 38

Annex A (normative) Noise test code for mincing machines (grade 2) . 40

A.1 Emission sound pressure level determination . 40

A.2 Determination of the sound power level . 40

A.3 Installation and mounting conditions . 40

A.4 Operating conditions . 40

A.5 Measurement . 41

A.6 Information to be recorded . 41

A.7 Information to be reported . 41

A.8 Measurement uncertainty . 42

A.9 Declaration and verification of the noise emission values . 42

Annex B (normative) Design principles to ensure cleanability of mincing machines . 44

B.1 Definition . 44

B.2 Materials . 44

B.3 Design . 44

Annex C (informative) Performance level required . 49

Annex D (informative) List of significant hazards . 50

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 51

Bibliography . 53

European foreword

This document (EN 12331:2021) has been prepared by Technical Committee CEN/TC 153 “Machinery

intended for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2022 and conflicting national standards shall

be withdrawn at the latest by February 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12331:2015.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

The significant changes with respect to the previous edition EN 12331:2015 are listed below:

— for better distinction, two types of mincing machines are defined: professional and industrial;

— the requirements have been specified and revised with regard to the two types of mincing machine

(professional and industrial).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C-standard as stated in EN ISO 12100.

This document is of relevance, in particular for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in the case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type-C-standard are different from those which are stated in type-A- or -B-

standards, the provisions of this type-C-standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type-C-

standard.

1 Scope

This document specifies requirements for the design and manufacture of mincing machines (see

Figure 1).

The mincing machines (hereinafter referred to as machine) covered by this document are used for size

reduction of fresh or frozen meat, meat products and fish (hereinafter referred to as product) by cutting

in a set of cutting tools.

Household machines are not included in this document. Filling mincers are covered by EN 12463 “Food

processing machinery — Filling machines and auxiliary machines — Safety and hygiene requirements”.

This document applies only to machines that are manufactured after the date of issue of this document.

This document covers:

a) professional machines (see Figure 1 a) used for on-demand preparation in shops and/or restaurants

characterized by all of the following features (if any of the features is missing the machine is

considered an industrial machine):

1) designed as a table-top machine;

2) having a feed tray;

3) the product is only fed manually;

4) is only operated from the ground;

5) is operated by no more than one operator;

6) with full visibility and full accessibility of the entire machine from the operator workstation;

7) having hole plate diameter ≤ 106 mm;

8) a worm casing set which is removable without using any tools;

9) the weight of the worm casing set ≤ 15 kg;

NOTE The table-top machine can be equipped with a frame or base, so no separate table is needed.

b) industrial machines (see Figure 1 b) used for industrial mass production, and which cannot be

characterized as a professional machine.

This document does not describe the specific requirements for the control of machines with foot switch.

This document does not describe the specific requirements for additional mixing screws in the feed intake

hopper which are covered by EN 13570:2005+A1:2010 “Food processing machinery — Mixing machines

— Safety and hygiene requirements”.

a) Professional machine with feed tray and b) Industrial machine with feed intake hopper,

restrictor plate protective cover and feeding screw

Key

1 lock nut 6 feed intake 11 feed intake hopper 16 protective hood

2 hole plate 7 pusher 12 feeding screw 17 worm

3 blade 8 restrictor plate 13 protective cover 18 machine rack

4 worm 9 feed tray 14 on-/off-switch with 19 loading device

protective hood

5 worm casing 10 on-/off-switch 15 lock nut 20 floor

21 table 22 table-top

Figure 1 — Examples of machines

This document covers the following types of machines:

— machine with feed tray, feed intake and pusher (see Figure 3);

— machine with feed tray, feed intake, restrictor plate and pusher (see Figure 4);

— machine with feed intake hopper, protective cover and feeding screw (see Figure 6);

— machine with feed intake hopper, with or without protective cover, feeding screw, with loading

device (continuously or discontinuously).

Machines comprise a machine base, a worm casing with a worm, a feed tray (with feed intake) or a feed

intake hopper, a set of cutting tools, a lock nut, a drive motor. They will also have various safeguarding

devices as examples in Clause 4.

Machines can be equipped e.g. with:

— an extraction claw;

— an ejector or extractor;

— a protective hood over the discharge outlet;

— a protective cover over the inlet opening of the feed intake hopper;

— a transport carriage for the lock nut, the set of cutting tools, the worm and the feeding screw;

— a lifting device for the lock nut, the set of cutting tools, the worm and the feeding screw;

— a loading device.

The product is fed manually or with a loading device into the machine. The product is fed to the worm

either by a pusher or a feeding screw and reduced in size by a set of cutting tools.

This document specifies all significant hazards, hazardous situations and events relevant to machines,

when they are used as intended and under conditions of misuse which are reasonably foreseeable by the

manufacturer (see Annex D).

This document specifies the hazards which can arise during commissioning, operation, cleaning, use,

maintenance and decommissioning of the machine.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 1005-1:2001+A1:2008, Safety of machinery — Human physical performance — Part 1: Terms and

definitions

EN 1005-2:2003+A1:2008, Safety of machinery — Human physical performance — Part 2: Manual

handling of machinery and component parts of machinery

EN 1005-3:2002+A1:2008, Safety of machinery — Human physical performance — Part 3: Recommended

force limits for machinery operation

EN 1672-2:2005+A1:2009, Food processing machinery — Basic concepts — Part 2: Hygiene requirements

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2016, modified)

1)

EN 60529:1991 , Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 61496-1:2013, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:2012)

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

1) As impacted by EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting

plane (ISO 3746:2010)

2)

EN ISO 4287:1998 , Geometrical product specifications (GPS) — Surface texture: Profile method — Terms,

definitions and surface texture parameters (ISO 4287:1997)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 7010:2020, Graphical symbols — Safety colours and safety signs — Registered safety signs

(ISO 7010:2019, Corrected version 2020-06)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a workstation and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13854:2019, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

(ISO 13854:2017)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

2) As impacted by EN ISO 4287:1998/AC:2008 and EN ISO 4287:1998/A1:2009.

3.1

platform

accessible workstation

3.2

worm

rotating screw-shaped component in the worm casing for product transport to the set of cutting tools

3.3

ejector/extractor

device for detaching the set of cutting tools and the worm

3.4

extraction claw

tool for detaching the set of cutting tools and the worm

3.5

loading device

device for the lifting and tilting of transport cars and containers

3.6

container

device for holding processed and/or unprocessed product

3.7

protective cover

device with safety function

3.8

feed intake

housing between the feed tray and the worm casing

3.9

feed intake hopper

device for holding the unprocessed product

3.10

locking device

device for locking the trolley or container in the load bearing device

3.11

trolley

movable container

3.12

design dimension

sum of dimensions measured as tight string length from the workstation (floor, steps, intermediate steps

or platforms) to the hopper edge (inclusively additional safety measures) and from the hopper edge

(inclusively additional safety measures) to the first danger point in the feed intake hopper (see Figure 7

and Figure 8)

3.13

cooling mincer

machine with a cooling device for the feed intake and the worm casing

3.14

workstation

every location at the machine from which the operator interacts with the machine

3.15

hole plate

plate with bores

Note 1 to entry: A hole plate is shown in Figure 1 a).

3.16

end hole plate

last hole plate towards the outlet

3.17

blade

element for cutting the product

3.18

feed tray

device for receiving the product to be processed to feed the feed intake by hand

3.19

mechanical trip bar

movable device with a safety function

3.20

worm casing

element for holding the worm and the set of cutting tools

3.21

worm casing set

arrangement consisting of a worm casing, a worm, a set of cutting tools and a lock nut

3.22

set of cutting tools

arrangement of blades and hole plates for size reduction of product

Note 1 to entry: The number and type of cutting tools used is selected depending on the desired quality of the

minced product.

3.23

protective grid

device on the feed intake hopper mouth with a safety function

3.24

protective hood

device on the discharge outlet with a safety function

3.25

restrictor plate

device above the feed intake

3.26

pusher

device used to push the product further in the feed intake

3.27

feeding screw

rotating screw-shaped component in the feed intake hopper for product transport to the worm

3.28

transport carriage

movable device for holding the lock nut, set of cutting tools, worm and feeding screw

3.29

lock nut

device for locking the set of cutting tools in the worm casing

3.30

professional machine

machine used for on-demand preparation in shops or restaurants

Note 1 to entry: A professional machines used for on-demand preparation in shops and/or restaurants is

characterized by all of the following features (if any of the features is missing the machine is considered an industrial

machine):

— designed as a table-top machine;

— having a feed tray;

— the product is only feed manually;

— is only operated from the ground;

— is operated by no more than one operator;

— with full visibility and full accessibility of the entire machine from the operator workstation;

— having hole plate diameter ≤ 106 mm;

— a worm casing set which is removable without using any tools;

— the weight of the worm casing set ≤ 15 kg.

Note 2 to entry: The table-top machine can be equipped with a frame or base, so no separate table is needed.

3.31

industrial machine

machine used for industrial mass production or which cannot be characterized as a professional machine

3.32

easily cleanable

designed and constructed to be cleanable by a simple cleaning methode, where necessary after removing

easily dismantled parts

4 Safety requirements and/or measures

4.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause. In

addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for relevant,

but not significant hazards which are not dealt with by this document.

Where the means of reducing the risk is by the arrangement or positioning of the installed machine, the

manufacturer shall include in the Information for use a reference to the reduction means to be provided,

and to any limiting value of the requirement, and, if appropriate, to the means of verification.

Where the means of reducing the risk is by a safe system of work, the manufacturer shall include in the

information for use details of the system and of the elements of training required by the operating

personnel.

Machine safety functions are implemented and assured through Safety-Related Parts of the Control

System (SRP/CS) that shall achieve a required Performance Level (PL ). This requirement is given for

r

each safety function in the relevant subclauses of Clause 4. Table C.1 summarizes PL for each safety

r

function; however, the provisions of Clause 4 remain the sole and complete normative set of

requirements and explanations.

Figure 2 shows the significant hazard zones of machines.

a) Machine with feed intake b) Machine with feed intake hopper

Key

1 zone 1 4 zone 4 7 zone 7

2 zone 2 5 zone 5 8 zone 8

3 zone 3 6 zone 6 9 zone 9

10 zone 10

Figure 2 — Hazard zones

4.2 Mechanical safety

4.2.1 General

The machines shall be designed and constructed in accordance with the conditions mentioned below.

The interlocking systems of guards shall comply with EN ISO 14119:2013, 4.2, and the safety-related

parts of the control system shall comply with EN ISO 13849-1:2015.

In addition, interlocking systems shall be designed to comply with the following features:

— fulfil hygienic requirements;

— protected against mechanical damages;

— protected against the effects of cleaning and disinfecting materials;

— protected against the effects of cleaning fluids (water);

— not be easy to by-pass or render non-operational;

— be contained in the machine casing and comply with EN ISO 14119:2013, 7.2 a) 1).

The manufacturer shall indicate in the instruction handbook that the interlocking device shall be checked

every day (see 6.2 d)). Fixing systems of fixed guards shall remain attached to these guards or to the

machine when the guards are removed.

4.2.2 Zone 1 – Requirements for machines with feed intake and worm

Access to the worm in the feed intake shall be prevented, e.g. by the following measures:

1) On machines with diameter of feed intake D ≤ 52 mm (see Figure 3), the distance L between the upper

feed intake edge and the worm shall be:

a) L ≥ 100 mm on machines with diameter of feed intake D ≤ 46 mm;

b) L ≥ 120 mm on machines with diameter of feed intake 46 mm < D ≤ 52 mm.

a) Fixed feed tray b) Removable feed tray c) Removable feed tray

Key

D inlet diameter of feed intake

L distance from inlet of feed intake to worm

1 feed tray

2 feed intake

3 worm

Where the inlet is not a circle, D shall be considered as the maximum dimension.

Figure 3 — Feed intake without restrictor plate – Safety dimensions

2) On machines with a diameter of feed intake D > 52mm, a restrictor plate (see Figure 4) shall be

provided by the following measures:

a) the restrictor plate shall be provided with an interlocking device unless it is permanentally fixed

(e.g. by welding; a fixation by means of screws is not regarded as permanent);

b) when a force between the mass of the machine and ≤ 150 N is applied in any position and any

direction on the restrictor plate, the restrictor plate shall not permanentally raise the distance S

more than 2 mm if the requirements of Table 1 are met;

c) the inlet of the restrictor plate shall have a diameter C ≤ 52 mm;

d) the horizontal distance from outer edge of restrictor plate to feed intake edge shall be E ≥ 40 mm;

e) the dimensions S, L, L and L and the arrangement of the restrictor plate shall be in accordance

1 2

with Figure 4 and Table 1;

A pusher shall be supplied with the machine (see Figure 1 a)). The functional length of the pusher L shall

p

be 0,9 × (L + S) ≤ L < (L + S), and the diameter of the functional length C shall be 0,9 × C ≤ C < C and shall

p p p

have a mechanical stop with a dimension D ≥ 1,1 × C. Additionally, the handle shall have a shape and

p

dimensions that prevent from reaching the worm. The machine should be equipped with a holder for the

pusher, which will take the pusher during non-use.

The interlocking system of the removable feed tray or restrictor plate shall comply with 4.2.1 and the

safety-related parts of the control system shall present at least a Performance Level “d” defined with an

MTTF “high” according to EN ISO 13849-1:2015.

d

After removal of the feed tray or the restrictor plate the worm shall come to a standstill within 2 s, tested

on a machine which is running empty.

Table 1 — Safety dimensions on feed intake with restrictor plate

Dimension 52 mm < D ≤ 85 mm 85 mm < D ≤ 200 mm

C ≤ 52 mm

a

E ≥ 40 mm

S ≤ 40 mm ≤ 120 mm

L ≥ 120 mm L + L

1 2

L not applicable ≥ 230 mm

b

L not applicable to be calculated

a

Usually the restrictor plate is attached to the rim of the feed tray and reaches over the feed intake by at least E > 40 mm.

b

With a dimension S ≤ 40 mm, the hand can penetrate up to the wrist and the kinked fingers get into the feed intake, so

that the dimension L ≥ 120 mm prevents reaching the worm. From a dimension S > 40 mm, the forearm can also penetrate,

and the complete hand can get into the feed intake, considered by the dimension L ≥ 230 mm. To prevent reaching the

worm, however, dimension L is required. Here a dimension L2 shall be added to the dimension L1 as a function of the

intervention angle, which is determined by the dimensions E, S and D with an assumed forearm and wrist diameter

H = 40 mm.

a) 52 mm < D ≤ 85 mm b) 85 mm < D ≤ 200 mm

Key

penetration by hand, wrist, forearm

C inlet diameter of restrictor plate

D inlet diameter of feed intake

E horizontal distance from outer edge of restrictor plate to feed intake edge

H diameter of forearm and wrist

S distance between feed tray and lower edge of restrictor plate

L distance from inlet of feed intake to worm

L distance from wrist to worm

Figure 4 — Feed intake with restrictor plate – Safety dimensions

Key

L functional length of the pusher (0,9 × (L + S) ≤ L < (L + S))

p p

Cp diameter of the functional length (0,9 × C ≤ Cp < C)

Dp dimension of the mechanical stop (Dp ≥ 1,1 × C)

C inlet diameter of restrictor plate (see Figure 4)

S distance between feed tray and lower edge of restrictor plate (see Figure 4)

L distance from inlet of feed intake to worm (see Figure 4)

Figure 5 — Example of a pusher

4.2.3 Zone 2 – Requirements for machines with feed intake hopper and feeding screw

4.2.3.1 General

Access to the danger zones at the feeding screw in the feed intake hopper shall be prevented by one of

the following measures:

— the design (e.g. closed feed intake hoppers) including a closed loading device for products (e.g. feed

screw, pipeline with pump) (see 4.2.3.2);

— the use of guards (e.g. a protective cover) (see 4.2.3.3);

— the use of electro-sensitive protective devices (e.g. light barrier, see 4.2.3.5.3);

— the use of fixed guards (e.g. fence) (see 4.2.8.2.4);

— the use of adequate safety distances, design and additional measures (see 4.2.3.5).

4.2.3.2 Machines with closed feed intake hopper

The feed intake hopper and the loading device shall be designed to be completely closed (connection of

machines), or the openings shall comply with EN ISO 13857:2019, Table 4.

Where the loading device can be disconnected from the feed intake hopper, it shall be fitted with an

interlocking device complying with EN ISO 14119:2013 in a circuit that ensures that machine can only

run if the loading device is correctly fitted. This circuit shall comply with at least a Performance Level “c”

according to EN ISO 13849-1:2015.

The manufacturer shall indicate in the instruction handbook that the protective cover of the hopper

opening shall not be walked on (see 6.2 d)).

4.2.3.3 Machines with a protective cover over feed intake hopper

At the feed intake hopper, there shall be a protective cover. The protective cover shall be interlocked. The

slamming of the protective cover shall be avoided (see 4.2.7.1). Depending on the distance to the first

danger point E in the feed intake hopper, the feeding screw has to come to a standstill by the opening

distance H (see Figure 6) within 4 s (machine is running empty) after raising the front edge of the

protective cover.

The interlocking device of the movable protective cover shall comply with 4.2.1, and the safety-related

parts of the control system shall present at least a Performance Level “c” according to

EN ISO 13849-1:2015.

Openings in the protective cover shall be designed in accordance with EN ISO 13857:2019, Table 4.

Dimensions in millimetres

E H

≥ 100 ≤ 12

≥ 120 ≤ 20

≥ 200 ≤ 30

≥ 300 ≤ 40

≥ 550 ≤ 50

Key

H opening distance

E distance to the first danger point

Figure 6 — Machine with feed intake hopper and protective cover — Safety dimensions

4.2.3.4 Access to the feeding screw

Access to the feeding screw shall be prevented by an interlocking movable guard in accordance with

EN ISO 14120:2015 under one of the following conditions:

— the feeding screw shall come to a standstill within 2 s after activation of the protective device;

— dismantling of the guard takes longer than 4 s;

— interlocking guard with guard locking.

4.2.3.5 Machines with continuous operation

4.2.3.5.1 General

On machines which cannot use an interlocked protective cover or an electro-sensitive protective device

because they need to operate continuously, the following measures are necessary:

4.2.3.5.2 Safety distances

The design dimension (see 3.12) shall be ≥ 2 250 mm. This is only possible in connection with additional

measures in 4.2.3.5.3. There the distance from floor to upper edge of a mechanical trip bar or an electro-

sensitive protective device shall be H > 1 600 mm. The distance from the workstation on steps and

platforms up to the hopper edge shall be > 1 100 mm (see Figure 8).

4.2.3.5.3 Additional measures

With a height of > 1 500 mm, a view into the feed intake hopper (e.g. by means of a mirror, fill level

indication) shall be possible.

The machine shall be designed (e.g. vertical and smooth) to prevent the operator climbing on the

machine. This also applies to movable steps in its upper position and the surrounding of mechanical trip

bar/electro-sensitive protective device or movable protective grid at hopper edge.

Additional measures for:

a) steps or platforms

If danger points in the feed intake hopper can be reached from a workstation on step or platform (the

design dimension (see 3.12) does not reach 2 250 mm, see Figure 7) the step or platform shall be

interlocked. When the machine is running empty, the feeding screw shall come to a standstill within 4 s

after the interlocking system has been actuated. The actuation shall be triggered when an ascendable

position of a movable step is reached or the workstation on a step or platform is entered.

The interlocking system of the workstation on a step or platform shall comply with 4.2.1 and the safety-

related parts of the control system shall present at least a Performance Level “c” according to

EN ISO 13849-1:2015.

The workstation of steps shall have a width ≥ 500 mm and a length ≥ 400 mm and a toe rail of a height of

15 mm. If the workstation is < 500 mm above ground, an area of a width ≥ 400 mm and a length ≥ 350 mm

is sufficient. The workstation shall be of the non-slip type.

Platforms shall have an accessible area of a width ≥ 500 mm. The length of the platform shall correspond

to the length of the hopper.

Platforms which are located > 500 mm above ground shall be fitted with e.g. railings to prevent falls.

Intermediate steps, stairs or step ladders and grab handles shall be provided if the step-up height to the

step or to the platform is H > 500 mm. The workstations and treads shall be sufficiently large and of the

non-slip type and arranged at identical distances from one another.

The workstation of the intermediate step shall have a width of ≥ 300 mm and a length of ≥ 200 mm.

Treads of step ladders shall have a length of ≥ 500 mm and a width of ≥ 80 mm. A step ladder shall be

arranged at an angle of < 75° to the horizontal.

Key

1 mechanical trip bar

2 interlocked workstation (step)

H distance between floor and upper edge of safeguard when there is no workstation

H distance between interlocked workstation and upper edge of safeguard

H3 distance between floor and interlocked workstation

D width of safeguard when there is no workstation

D width of safeguard when there is a interlocked workstation

E distance between worm at S and upper edge of hopper when there is no workstation

E1 distance between worm at S1 and upper edge of hopper when there is a interlocked workstation

S1 distance between worm and hopper

S distance between and hopper and safeguard

H1 + D + E design dimension for a workstation on the floor ≥ 2 250 mm

Figure 7 — Machine with open feed intake hopper and interlocked workstation with mechanical

trip bar – Safety dimensions

b) Mechanical trip bar/Electro-sensitive protective device or movable protective grid at hopper edge.

At the hopper edge, running around all sides, shall be a mechanical trip bar, or an electro-sensitive

protective device, or a protective grid with a trip function (see Figure 7 and Figure 8). The design

dimension (see 3.12) shall be ≥ 2 250 mm.

The following requirements additionally apply depending on the safeguard selected:

— mechanical trip bar: the distance between the mechanical trip bar and the edge of the hopper shall

be S ≤ 50 mm and the mechanical trip bar shall be triggered within that range and the actuating

force shall be ≤ 50 N;

— electro-sensitive protective device:

— one beam light barrier: the distance between the one-beam light barrier and the edge of the

hopper shall be S ≤ 8 mm;

— all others: the distance between the electro-sensitive protective device and the edge of the

hopper shall be S ≤ 20 mm and the sensor detection capability of the electro-sensitive

protective device shall be ≤ 14 mm.

The dangerous equipment in the hopper shall, if the machines is running empty, come to a standstill

within 3 s by using hole plates < 160 mm Ø and 4 s by using hole plates ≥ 160 mm Ø.

The interlocking of the mechanical trip bar or the movable protective grid shall comply with 4.2.1, and

the safety-related parts of the control system shall present at least a Performance Level “c” according to

EN ISO 13849-1:2015.

The design of the light barrier shall be in accordance with ESPE type 2 of EN 61496-1:2013.

Key

1 light barrier or movable protective grid

2 workstation, not interlocked (step)

H1 ≥ 1 600 mm H4 ≥ 1 600 mm

H ≥ 1 100 mm H + D + E ≥ 2 250 mm

2 1

H ≥ 500 mm H + D + E ≥ 2 250 mm

3 4 1 1

H1 distance between floor and upper edge of safeguard when there is no workstation

D width of safeguard when there is no workstation

E distance between worm and upper edge of safeguard when there is no workstation

H2 distance between workstation (not interlocked) and upper edge of hopper

D1 width of safeguard when there is a workstation (not interlocked)

E1 distance between worm and upper edge of safeguard when there is a workstation (not interlocked)

H distance between workstation (not interlocked) and upper edge of safeguard

H3 distance between floor and workstation (not interlocked)

Design dimension for a workstation on the floor H1 + D + E

Design dimension for a workstation, not interlocked H + D + E

4 1 1

Figure 8 — Machine with open feed intake hopper and workstation (not interlocked) with

electro-sensitive protective device or protective grid – Safety dimensions

4.2.4 Zone 3 – Discharge outlet on machines

4.2.4.1 General

Access to the blade behind the end hole plate through the holes of the end hole plate shall be prevented,

e.g. by one of the following measures:

— the design of the end hole plate without protective hood (see 4.2.4.2);

— using a protective hood (see 4.2.4.3).

4.2.4.2 Design of the end hole plate without protective hood

The diameter of the holes in the end hole plate shall be ≤ 8 mm. The thickness of the end hole plate shall

be ≥ 5 mm.

The end hole plate and the worm casing shall be designed so that only a plate as described above can be

put into the worm casing at the outlet side.

The manufacturer has to indicate in the instruction handbook, that the end hole plate is not allowed to be

ground thinner than 5 mm thickness (see 6.2 d)).

4.2.4.3 Design of the protective hood

If it is intended to use end hole plates with holes > 8 mm diameter, a protective hood shall be fitted to the

outlet. The protective hood shall have a projecting length in working direction L ≥ 1,8 × D or L ≥ 550 mm

1 1

(D = diameter of the hole plate in mm) and a lateral projecting length of L ≥ 1,2 × D or L ≥ 300 mm.

2 2

Where L is the shortest distance from outer rim in front of the protective hood to the first danger point

at the end hole plate, and L is the shortest distance from outer rim at the side of the protective hood to

the first danger point at the end hole plate (see Figure 9).

The manufacturer has to indicate in the instruction handbook (see 6.2 d)), that the distance U between

the trolley, container or conveying system and the protective hood shall be ≤ 50 mm (see Figure 9). The

knife shall come to a standstill within 2 s after opening the protective hood by 50 mm at the point of

maximum movement. The protective hood shall be movable and interlocked.

Key

1 protective hood

2 end hole plate

3 locking nut

L1 ≥ 1,8 × D or ≥ 550 mm

L ≥ 1,2 × D or ≥ 300 mm

U ≤ 50 mm

Figure 9 — Discharge outlet on machines – Protective hood

The interlocking of the protective hood shall comply with 4.2.1 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...