EN ISO 16101:2004

(Main)Packaging - Transport packaging for dangerous goods - Plastics compatibility testing (ISO 16101:2004)

Packaging - Transport packaging for dangerous goods - Plastics compatibility testing (ISO 16101:2004)

ISO 16101:2004 specifies the requirements and test methods for compatibility testing of polyethylene based plastics packagings and composite packagings with plastic inners containing liquids. The testing involves storage with the packaged substance, or with a standard liquid as defined in Annex A. Annex B describes small scale laboratory tests which may be used to determine the assimilation of those products to be carried with the standard liquids.

Verpackung - Verpackungen zur Beförderung gefährlicher Güter - Verträglicheitsprüfung für Kunststoffverpackungen (ISO 16101:2004)

Diese Europäische Norm enthält Anforderungen und Prüfverfahren für die chemische Verträglichkeitsprüfung von Kunststoffverpackungen und Kombinationsverpackungen mit Innenverpackungen aus Polyethylen, die für Flüssigkeiten vorgesehen sind. Die Prüfung schließt die Vorlagerung mit dem zu verpackenden Füllgut oder mit einer Standardflüssigkeit, wie sie in Anhang B definiert wird, ein. Anhang C beschreibt Labormethoden, die für die Zuordnung von zu befördernden Produkten und Standardflüssigkeiten verwendet werden können.

Emballages - Emballages pour le transport des marchandises dangereuses - Essais de compatibilité des matières plastiques (ISO 16101:2004)

L'ISO:16101:2004 spécifie les exigences et les méthodes d'essai pour vérifier la compatibilité des emballages en plastique à base de polyéthylène et des emballages composites dont les récipients intérieurs en plastique contiennent des liquides. L'essai implique le stockage avec la substance emballée ou avec un liquide standard tel que défini dans l'Annexe A. L'Annexe B décrit des essais en laboratoire sur éprouvettes qui peuvent être utilisés pour déterminer l'assimilation de ces produits aux liquides standard.

NOTE Il convient d'utiliser conjointement la présente norme avec une ou plusieurs des réglementations internationales présentées dans la bibliographie.

Embalaža - Transportna embalaža za nevarno blago - Preskušanje združljivosti plastike (ISO 16101:2004)

General Information

- Status

- Withdrawn

- Publication Date

- 14-Sep-2004

- Withdrawal Date

- 20-Aug-2013

- Technical Committee

- CEN/TC 261 - Packaging

- Drafting Committee

- CEN/TC 261/SC 5/WG 16 - Packaging of dangerous goods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Aug-2013

- Completion Date

- 21-Aug-2013

Relations

- Effective Date

- 11-Sep-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

BRCGS (Brand Reputation Compliance Global Standards)

Global food safety and quality standards owner.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Sponsored listings

Frequently Asked Questions

EN ISO 16101:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Packaging - Transport packaging for dangerous goods - Plastics compatibility testing (ISO 16101:2004)". This standard covers: ISO 16101:2004 specifies the requirements and test methods for compatibility testing of polyethylene based plastics packagings and composite packagings with plastic inners containing liquids. The testing involves storage with the packaged substance, or with a standard liquid as defined in Annex A. Annex B describes small scale laboratory tests which may be used to determine the assimilation of those products to be carried with the standard liquids.

ISO 16101:2004 specifies the requirements and test methods for compatibility testing of polyethylene based plastics packagings and composite packagings with plastic inners containing liquids. The testing involves storage with the packaged substance, or with a standard liquid as defined in Annex A. Annex B describes small scale laboratory tests which may be used to determine the assimilation of those products to be carried with the standard liquids.

EN ISO 16101:2004 is classified under the following ICS (International Classification for Standards) categories: 13.300 - Protection against dangerous goods; 55.140 - Barrels. Drums. Canisters. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 16101:2004 has the following relationships with other standards: It is inter standard links to EN ISO 13274:2013, EN ISO 1628-3:2010, CEN/TS 16157-1:2011, EN ISO 2818:2019, EN ISO 11542-2:1998, EN ISO 1183-1:2025, EN ISO/IEC 17025:2017, EN ISO 1133-2:2011, EN ISO 527-2:2025, EN ISO 11403-3:2021, EN ISO 291:2008, EN ISO 16104:2003, EN ISO 17855-2:2024, EN 15507:2008, EN 14487-1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 16101:2004 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 16101:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2005

Embalaža - Transportna embalaža za nevarno blago - Preskušanje združljivosti

plastike (ISO 16101:2004)

Packaging - Transport packaging for dangerous goods - Plastics compatibility testing

(ISO 16101:2004)

Verpackung - Verpackungen zur Beförderung gefährlicher Güter - Verträglicheitsprüfung

für Kunststoffverpackungen (ISO 16101:2004)

Emballages - Emballages pour le transport des marchandises dangereuses - Essais de

compatibilité des matieres plastiques (ISO 16101:2004)

Ta slovenski standard je istoveten z: EN ISO 16101:2004

ICS:

13.300 Varstvo pred nevarnimi Protection against dangerous

izdelki goods

55.180.99 Drugi standardi v zvezi z Other standards related to

distribucijo blaga s prevozom freight distribution of goods

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN ISO 16101

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2004

ICS 13.300; 55.140

English version

Packaging - Transport packaging for dangerous goods - Plastics

compatibility testing (ISO 16101:2004)

Emballages - Emballages pour le transport des Verpackung - Verpackungen zur Beförderung gefährlicher

marchandises dangereuses - Essais de compatibilité des Güter - Verträglicheitsprüfung für Kunststoffverpackungen

matières plastiques (ISO 16101:2004) (ISO 16101:2004)

This European Standard was approved by CEN on 27 February 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 16101:2004: E

worldwide for CEN national Members.

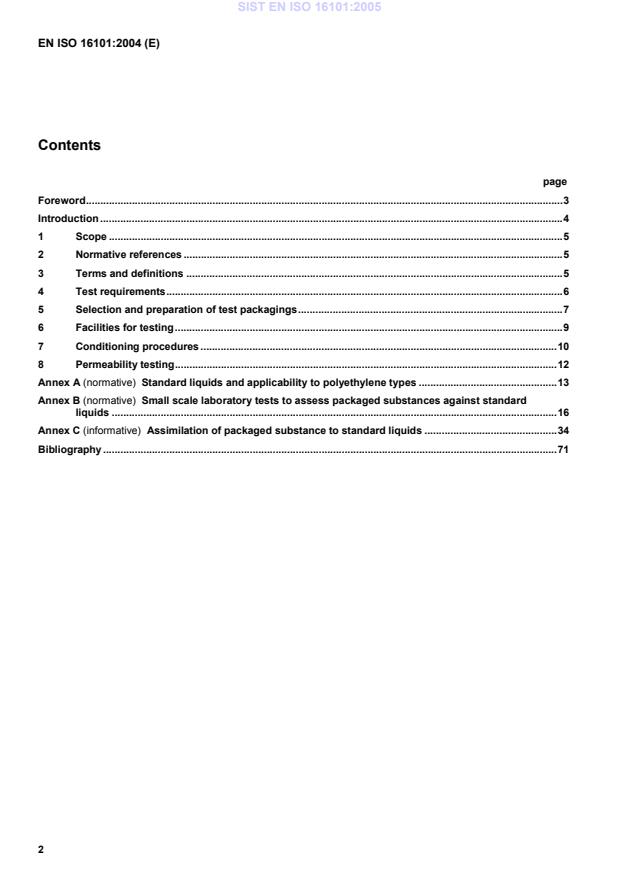

Contents

page

Foreword.3

Introduction .4

1 Scope.5

2 Normative references.5

3 Terms and definitions .5

4 Test requirements.6

5 Selection and preparation of test packagings.7

6 Facilities for testing.9

7 Conditioning procedures.10

8 Permeability testing.12

Annex A (normative) Standard liquids and applicability to polyethylene types .13

Annex B (normative) Small scale laboratory tests to assess packaged substances against standard

liquids .16

Annex C (informative) Assimilation of packaged substance to standard liquids .34

Bibliography .71

Foreword

This document (EN ISO 16101:2004) has been prepared by CEN /TC 261, "Packaging", the secretariat of which is

held by AFNOR, in collaboration with ISO/TC 122 "Packaging".

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by March 2005, and conflicting national standards shall be withdrawn at the latest by

March 2005.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports the objectives of the framework Directives on Transport of Dangerous Goods.

This European Standard has been submitted for reference into the RID and/or in the technical annexes of the ADR.

Therefore in this context the standards listed in the normative references and covering basic requirements of the

RID/ADR not addressed within the present standard are normative only when the standards themselves are

referred to in the RID and/or in the technical annexes of the ADR.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Introduction

This standard was developed to provide requirements and test procedures to meet the compatibility provisions for

plastics packagings to contain liquids as set out in:

The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR)

(covering most of Europe) [2] and

Regulations concerning the International Carriage of Dangerous Goods by Rail (RID) (covering most of Europe,

parts of North Africa and the Middle East) [5].

This procedure is an alternative option to that set out in the UN Recommendations on the Transport of Dangerous

Goods [1].

Plastics packaging material can be attacked by the chemical contents of the package. Such effects are caused by

different mechanisms such as environmental stress cracking (ESC) chemical degradation and swelling.

The UN Recommendations and the associated modal regulations require that all packagings shall be assessed for

compatibility with the substances which they are to contain. The UN text makes special reference to plastics

packagings for liquids. The procedure therein contains details of testing for six months at ambient temperature with

the liquid to be carried. RID/ADR permits as an alternative the use of standard liquids to which this document refers.

The UN Recommendations are given legal entity not only to ADR and RID but also to:

The International Civil Aviation Organisations Technical Instructions for the SafeTransport of Dangerous

Goods by Air (ICAO Tis) (worldwide) [3] and

The International Maritime Dangerous Goods Code (IMDG Code) (worldwide) [4].

These two modal rules do not refer to the standard liquid tests but they may still be acceptable as the UN

provisions do not make the six month test a mandatory requirement.

The application of this standard will need to take account of the requirements of these international agreements

and the relevant national regulations [6] [7] for domestic transport of dangerous goods.

Although not stipulated in the UN Recommendations or the modal regulations, these tests may be applied, where

deemed appropriate, to inner packagings of combination packagings. However, for this purpose, the standard liquid

tests may not be applicable to all types of plastics materials, since the tests were originally created for high

molecular weight high density polyethylene (PE-HD-HMW).

WARNING — The use of this International Standard may involve hazardous materials and equipment. This

International Standard does not purport to address all of the safety problems associated with its use. It is

the responsibility of the user of this International Standard to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to use.

1 Scope

This standard specifies the requirements and test methods for compatibility testing of polyethylene based plastics

packagings and composite packagings with plastic inners containing liquids. The testing involves storage with the

packaged substance, or with a standard liquid as defined in annex A. Annex B describes small scale laboratory

tests, which may be used to determine the assimilation of those products to be carried with the standard liquids.

NOTE This standard should be used in conjunction with one or more of the International Regulations set out in the

Bibliography

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN ISO 291, Plastics - Standard atmospheres for conditioning and testing

EN ISO 527-2, Plastics - Determination of tensile properties - Part 2: Test conditions for moulding and extrusion

plastics (ISO 527-2:1993)

EN ISO 1133, Plastics - Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of

thermoplastics (ISO 1133:1997)

EN ISO 1183-1, Plastics - Methods for determining the density of non-cellular plastics – Part 1: Immersion method,

liquid pyknometer method and titration method (ISO 1183-1:2004)

EN ISO 1628-3, Plastics - Determination of the viscosity of polymers in dilute solution using capillary viscometers -

Part 3: Polyethylenes and polypropylenes (ISO 1628-3:2001)

EN ISO 1872-2, Plastics — Polyethylene (PE) moulding and extrusion materials — Part 2: Preparation of test

specimens and determination of properties (ISO 1872-2:1997)

EN ISO 2818, Plastics – Preparation of test specimens by machining (ISO 2818:1994)

EN ISO 11403-3 Plastics - Acquisition and presentation of comparable multipoint data - Part 3: Environmental

influences on properties (ISO 11403-3:1999)

EN ISO 11542-2:1998, Plastics - Ultra-high-molecular-weight polyethylene (PE-UHMW) moulding and extrusion

materials - Part 2: Preparation of test specimens and determination of properties (ISO 11542-2:1998)

EN ISO 16104:2003, Packaging – Transport packaging for dangerous goods – Test methods (ISO 16104:2002)

EN ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories (ISO/IEC

17025:1999)

ISO 16770, Plastics - Determination of environmental stress crack (ESC ) of polyethylene – Full-notch creep test

(FNCT)

3 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1

competent authority

any national regulatory body or authority designated or otherwise recognised as such for any purpose in connection

with the regulations specified in the Bibliography

3.2

plastics packagings

drums, jerricans and composite packagings with inner plastics receptacle made from certain types of plastics

NOTE Certain types of polyethylene are listed in A.3.

3.3

packaged substance (chemical product)

dangerous liquid with which the packaging is to be filled for transport

NOTE Packagings used for solid packaged substances, which can become liquid at temperatures encountered during

transport, should also meet the requirements of packagings for liquids.

3.4

standard liquids

defined liquids that are representative in their effect for a specific kind of interaction between a packaged substance

and the plastics packaging

NOTE A full description of the standard liquids can be found in A.2.

4 Test requirements

4.1 General

Plastics packagings selected in accordance with clause 5 shall be conditioned with the packaged substance or a

standard liquid with which it is to be assimilated. Annex C contains a list of substances assigned to standard liquids

For other chemicals not listed in annex C, small scale laboratory tests (see annex B) shall be used to prove

assimilation with standard liquids. The standard liquid chosen shall be at least as aggressive as the substance to

be transported. Where the packaged substance to be filled cannot be assimilated with one of the standard liquids,

the packaged substance itself shall be used and its specification recorded. In the event that the effect is more

aggressive than that of the standard liquids, the six month procedure shall be followed, as given in 7.2, or

alternatively, and with the exception of nitric acid > 55%, the accelerated procedure, as given in 7.3.

NOTE When the standard liquid is water, proof of chemical compatibility is not required.

4.2 Conditioning

Plastics packagings shall be conditioned in accordance with clause 7 of this standard.

4.3 Post-conditioning inspection

At the end of the conditioning period the packagings shall be inspected for leakage. Where no leakage is apparent

testing in accordance with clause 7 of EN ISO 16104:2003 shall commence within 21 days of the end of the

conditioning period (see 7.4).

4.4 Drop test

When tested in accordance with 7.1 of EN ISO 16104:2003, the plastics packaging:

a) shall be leakproof, subsequent to any slight discharge that may be apparent at the moment of impact and

subsequent to the equalization of internal and external pressures (except for inner packagings of combination

packagings, when it is not necessary for the pressure to be equalized);

b) shall not exhibit any damage liable to affect safety during transport, for example if the package cannot be used

without leaking.

4.5 Stacking test

When tested in accordance with 7.2 of EN ISO 16104:2003, the packaging shall not:

a) show any sign of leakage ;

b) show any deterioration which could adversely affect transport safety, nor any distortion liable to reduce its

strength or stability in stacks of packages.

4.6 Leakproofness test

When tested in accordance with 7.3 of EN ISO 16104:2003, plastics packagings shall be leakproof.

4.7 Hydraulic pressure test

When tested in accordance with 7.4 of EN ISO 16104:2003, plastics packagings shall be leakproof.

4.8 Permeability testing

With the exception of composite packagings having a plastics receptacle with outer steel drum, when tested in

accordance with 8 of this standard, plastics packaging shall have a permeability not exceeding 0,008 g/l.h.

4.9 Equivalent testing

The test methods described in this standard shall be considered to be the reference test methods.

NOTE Alternative methods may be used to demonstrate compliance with relevant regulations provided that:

- their equivalency to the reference test method can be demonstrated;

- their use is recorded in the test report;

- prior approval is obtained from the competent authority.

4.10 Test report

All packaging tests in conformity with this standard shall be the subject of a test report prepared in accordance with

annex E of EN ISO 16104:2003. It shall be possible to specifically identify the packaging relative to each test report,

either by the retention of uniquely numbered specimens or by inclusion of sufficient photographs and/or drawings

with unique references.

5 Selection and preparation of test packagings

5.1 Selection of packagings

A minimum of 15 packagings of each design type (or 18 in the case of a requirement to carry out the tests in 8), for

each chemical to be tested, shall be selected at random from normal production and submitted for testing.

NOTE 1 For box shaped composite packagings a different number of samples, 14 or 17, may be required.

Packagings shall be:

a) at least 48 h old;

b) marked with a test reference number which shall also be entered on the test record and later used on the test

report;

c) individually weighed to establish the tare or the filled mass;

NOTE 2 The form of such weighing may be varied to fit in with whether the packagings have been supplied full or empty to

the test station. Where the masses of individual empty packagings are recorded, it is necessary to record only a typical filled

mass (or vice-versa).

d) examined for damage etc. which might invalidate the tests;

NOTE 3 The tests set out below should be applied to every design type of packaging, by polymer type and grade.

NOTE 4 For selective testing see EN ISO 16104:2003, annex F.

NOTE 5 For testing with a lesser number of packagings see EN ISO 16104:2003, 4.1 NOTE.

5.2 Information to be provided with packagings

Each packaging type shall be accompanied by specification(s) for that design type (in the appropriate format set

out in annex G of EN ISO 16104:2003 and by the following additional information as relevant.

The packaging user (with the assistance, where appropriate, of the packaging manufacturer and the test

laboratory) shall identify the packaged substance. In the first instance this process shall consist of identifying the

plastics material concerned and its possible interactions, such as swelling, environmental stress cracking (ESC),

and molecular degradation.

NOTE 1 The specification forms for plastics packagings should identify the material by polymer type and grade.

NOTE 2 Where tests are carried out using the packaged substance the test report may be applicable for other substances

having equivalent or lesser chemical effects.

5.3 Filling of packaging prior to testing

5.3.1 Determination of brimful capacity

A packaging intended to contain liquids shall be filled to not less than 98% of the brimful capacity. The brimful

(overflow) capacity is determined for example by:

weighing the empty packaging including closures (mass empty = m kg) and

weighing the packaging full (mass m kgs brimful = W kg ).

The packaging shall be filled with water until the water just overflows and then fitting the closure and any surplus

mopped up. No steps shall be taken, e.g. by tilting or tapping the packaging, to enable water to penetrate into a

hollow handle or other design feature above the closure.

W - m

b =

d

where

b is the brimful capacity in litres

W is the mass of the packaging when brimful with water in kilograms (kg)

m is the mass of the empty packaging in kilograms (kg)

d is the density of water (1,0 kg/l)

NOTE When the brimful capacity has already been determined by testing to EN ISO 16104:2003, this procedure is not

necessary.

5.3.2 Filling of packaging

Filling of packagings shall be carried out in accordance with the following:

a) The packaging shall be filled to not less than 98 % of the brimful capacity (see 5.3.1).

b) When filling test packagings, at least one packaging shall have its capacity and filling level determined as in c).

Further specimens of that design type may be filled using a dipstick calibrated on the first specimen or, in the

case of small packagings, by mass or volume. When test specimens are filled by mass with a liquid other than

water (e.g. anti-freeze solution), the density of that liquid shall be taken into account, in order to obtain the

correct volume of fill (≥ 98 %). Determination shall be made of the total empty packaging mass including the

closure(s). This facilitates calculation of stacking loads.

c) The calculation of required volume for testing shall be:

(W − m)x98

C =

100d

where

C is the required volume of water in litres (l)

W is the mass of packaging when brimful with water in kilograms (kg)

m is the mass of the empty packaging in kilograms (kg)

d is the relative density of water (1,0 kg/l)

5.4 Closing packagings

Screw type closures shall be tightened to the torque recommended by the applicant where appropriate, which shall

be recorded in the test report.

Closure torque shall not differ from one test to another in the test report. If it is necessary to revise a closure torque

following a failure in one test, then all tests shall be completed using that torque setting.

All tests for a particular liquid shall be carried out at the same torque.

NOTE 1 The closure torque may vary for different seals.

NOTE 2 It is not necessary to apply the specified torque during the conditioning period if this affects the subsequent

performance of the seal during the packaging testing.

Where vented closures are intended for use in the packaging they shall be fitted for testing. Packagings fitted with

vented closures shall be inverted after closing and observed for leakage for a period of 5 min. Leakage from the

closure vent shall be regarded as a failure. An alternative method of test instead of inversion is shown in Figure 1,

clause 7.1.

6 Facilities for testing

6.1 General requirements

Tests shall be carried out at a testing facility capable of meeting the operational provisions of EN ISO/IEC 17025.

NOTE 1 This does not imply a requirement for the test laboratory to have attained third party certification or accreditation, but

if appropriate such external approval may be obtained from either a national accreditation body or from the competent authority.

NOTE 2 Testing staff should have a knowledge of the principles of the dangerous goods regulations, as set out in the UN

Recommendations.

6.2 Accuracy of measurement equipment

The accuracy of measuring equipment shall be more precise than the accuracy of the measurements in testing, as

specified in 6.3, unless otherwise approved by the competent authority. The measuring equipment shall be

calibrated in accordance with the relevant provisions of EN ISO/IEC 17025.

6.3 Accuracy of measurements in testing

Measurement equipment shall be selected such that individual measurement results including errors in reading and

calibration shall not exceed the following tolerances:

Mass in kilograms (kg): ± 2 %

Pressure in kilopascals (kPa): ± 3 %

Distance / length in millimetres (mm): ± 2 %

Temperature in degrees Celsius (ºC): ± 1 °C

Humidity in percentage (%): tolerances are as specified in particular

test methods

Time in minutes (min): ± 3 %

Torque in newton·metres (N·m): ± 3 N m or 10 %, whichever is the greater

NOTE For some measurements, the tolerances may be lower in order to have meaningful measurements e.g. when

measuring masses or dimensions of empty packagings.

Where only maximum or minimum values are specified in the text, tolerances are one sided e.g. in 7.3 the

conditioning temperature may exceed 40°C, but shall not be less.

6.4 Climatic conditions

There shall be adequate climatic facilities to meet the requirements in Table 1 of EN ISO 16104:2003.

6.5 Impact surfaces for drop tests

The drop test area shall be horizontal and flat, massive enough to be immovable and rigid enough to be non-

deformable under test conditions and sufficiently large to ensure that the test package falls entirely on the surface.

7 Conditioning procedures

7.1 General

After filling, the packagings shall be inverted for 24 h (unless fitted with a vented closure, see following), and then

restored to the normal standing position. For the last 24 h of the conditioning period as defined in 7.2 and 7.3, the

packagings shall be inverted again.

For packagings that have vented closures, invert the packagings for a period of 5 min after filling and then restore

the packagings to their normal standing position. At the end of the conditioning period, invert the packagings again

for a period of 5 min.

NOTE As an alternative to complete inversion the packaging may be laid on its side such that all closures are below the

level of the substance being tested (see Figure 1).

Acceptable Unacceptable

Key

1 Liquid level

2 Closure

Figure 1 — Explanatory diagram of alternative inversion method

7.2 Six months ambient conditioning

This test shall be carried out at ambient temperature for a period of 6 months.

For the purposes of this standard, ambient temperature, which shall be monitored and recorded, is considered to

be not less than 15 °C.

NOTE The competent authority may, however, allow an extended period of test for temperatures below 15 °C.

7.3 Accelerated conditioning procedure

The packagings for test shall be conditioned for 21 days at a minimum of 40 °C with each standard liquid required.

The procedure shall be applied for polyethylene types as defined in the A.3.1 and A.3.2. For other types of

polyethylene such as those defined in A 3.3 and A.3.4, the approval of the competent authority shall be obtained

7.4 Procedure at the end of the conditioning period

At the end of the conditioning period, all packagings, except those intended to withstand the stack test, shall be

emptied, rinsed, inspected for damage and prepared for test in accordance with the test procedures for plastics

packagings for liquids (EN ISO 16104). Testing shall commence within 21 days of the end of the conditioning

period. If emptied the packaging shall be kept closed until testing commences.

Packagings which have been conditioned with standard liquid, n-butyl acetate, shall be emptied and refilled with a

mixture of 1 %–10 % aqueous wetting agent solution and 2 % of n-butyl acetate for the stacking test.

NOTE 1 Where the closure elements (for example heat or induction seals) would have to be destroyed to empty the

packaging after conditioning; the packaging should be emptied through an additional opening drilled into the package. Such an

opening should not affect the results of the other tests (drop, hydraulic pressure and leakproofness tests).

NOTE 2 This does not apply to composite packagings where the outer non-plastics packaging withstands the stacking load,

e.g. steel.

NOTE 3 For substances presenting a danger at 40°C it may be necessary to replace the filling substance by another

substance where at least the same chemical interaction has been demonstrated and the agreement of the competent authority

has been obtained.

The same closures and gaskets used during the conditioning of the packagings shall be used for the rest of the

tests; i.e. gaskets and closures shall not be replaced.

7.5 Reuse of standard liquids

The standard liquids shall be checked periodically in accordance with Table 1 as their effectiveness can be reduced

over a period of time.

Table 1 — Reuse of standard liquids

Standard Liquid Specification

Wetting solution New solution for each test or check surface

tension (see annex A )

Acetic acid Concentration 99 ± 1%

a)

Normal butyl acetate

≥ 98 %

a)

Mixture of hydrocarbons 16%–21% aromatic content

Nitric acid

Concentration ≥ 55 %

a)

It is recommended that the absorption of these standard liquids is periodically checked with a control

specimen of polyethylene of defined type and grade, in accordance with B.4.1 The used standard liquid is no

longer fit for purpose when the determined absorption deviates by more than 5 % from the original determined

value.

Tests to monitor the quality of the standard liquids shall be done by appropriate means at intervals according to the

frequency of usage.

8 Permeability testing

8.1 Applicability

This test is required only for packagings for benzene, toluene, xylene or mixtures and preparations containing those

substances.

8.2 Test preparation

Three packagings shall be preconditioned according to 7.2 of this standard for original filling substance or

according to 7.3 of this standard for the standard liquid mixture of hydrocarbons (white spirit).

8.3 Test procedure

The test specimens shall be filled with the packaged substance or standard liquid mixture of hydrocarbons (white

spirit) and weighed before and after storage for 28 days at 23°C and 50% relative atmospheric humidity.

NOTE Equivalent procedure at 40°C - this test may be done in conjunction with the accelerated conditioning procedure 7.3

with standard liquid mixture of hydrocarbons (white spirit).

Annex A

(normative)

Standard liquids and applicability to polyethylene types

A.1 Introduction

The standard liquid system has been developed for the investigation of the compatibility of high molecular weight

high density polyethylene, but it can also be applied to medium molecular weight polyethylene and to packagings

produced from the above polyethylene types where the surface or surfaces have been fluorinated.

NOTE When closures or closure elements are manufactured from materials other than those referred to in A.3, alternative

suitable methods to investigate compatibility may be employed.

A.2 Definitions and applicability of standard liquids

A.2.1 Wetting solution

Wetting solution shall be used for substances causing severe cracking in polyethylene under stress, in particular for

all solutions and preparations containing wetting agents.

An aqueous solution of (1–10)% of a wetting agent shall be used. The surface tension of this solution shall be (31–

35) mN/m at 23 °C.

The stacking test shall be carried out on the basis of a relative density of not less than 1,2.

If adequate chemical compatibility is proved with a wetting solution, a compatibility test with acetic acid is not

required.

NOTE In the case of filling substances, however, which cause polyethylene to stress crack more than wetting solution,

adequate chemical compatibility may be proved after preliminary storage for 21 days at 40 °C in accordance with 7.3 of this

standard, using the original filling matter.

A.2.2 Acetic acid

Acetic acid shall be used for substances and preparations causing cracking in polyethylene under stress, in

particular for monocarboxylic acids and monovalent alcohol, acetic acid of (98–100) % concentration shall be used

with a relative density = 1,05.

The stacking test shall be carried out on the basis of a relative density not less than 1,1.

NOTE In the case of filling substances causing polyethylene to swell more than acetic acid and to such an extent that the

polyethylene mass is increased by up to 4 %, adequate chemical compatibility may be proved after preliminary storage for 21

days at 40 °C, in accordance with 7.3, using the original filling matter.

A.2.3 Normal butyl acetate

Normal butyl acetate and normal butyl acetate-saturated wetting solution shall be used for substances and

preparations that cause polyethylene to swell to such an extent that the polyethylene mass is increased by up to

4 % and at the same time causes cracking under stress, in particular for phyto-sanitary products, liquid paints and

esters.

Normal butyl acetate of (98–100) % concentration shall be used for preliminary storage in accordance with 7.3.

For the stacking test, in accordance with 4.5 of this standard, a test liquid consisting of a (1–10) % aqueous wetting

solution conforming to A.2.1 shall be used mixed with 2 % normal butyl acetate.

The stacking test shall be carried out on the basis of a relative density not less than 1,0.

NOTE In the case of filling substances causing polyethylene to swell more than normal butyl acetate and to such an extent

that the polyethylene mass is increased by up to 7,5 %, adequate chemical compatibility may be proved after preliminary

storage for 21 days at 40 °C, in accordance with 7.3 using the original filling matter.

A.2.4 Mixture of hydrocarbons (white spirit)

Mixture of hydrocarbons (white spirit) shall be used for substances and preparations causing polyethylene to swell,

in particular for hydrocarbons, esters and ketones.

A mixture of hydrocarbons having a boiling range of (160–220) °C, a relative density of 0,78–0,80, a flash point

above 50 °C and an aromatics content of (16–21) % shall be used.

The stacking test shall be carried out on the basis of a relative density of not less than 1,0.

NOTE In the case of filling substances causing polyethylene to swell to such an extent that the polyethylene mass is

increased by more than 7,5 %, adequate chemical compatibility may be proved after preliminary storage for 21 days at 40 °C, in

accordance with 7.3 using the original filling matter.

A.2.5 Nitric acid

Nitric acid shall be used for all substances and preparations having an oxidizing effect on polyethylene and causing

molecular degradation identical to or less than 55 % nitric acid.

Nitric acid in a concentration of not less than 55 % shall be used.

The stacking test shall be carried out on the basis of a relative density of not less than 1,4.

In the case of filling substances more strongly oxidizing than 55 % nitric acid or causing degradation of the

molecular mass, proceed in accordance with 7.2.

A.2.6 Water

Water for substances which do not attack polyethylene in any of the cases referred to under A 2.1 to A 2.5, in

particular for inorganic acids and lyes, aqueous saline solutions, polyvalent alcohols and organic substances in

aqueous solution.

The stacking test shall be carried out on the basis of a relative density of not less than 1,2.

If the testing has been carried out satisfactorily with at least one of the aqueous based standard liquids, wetting

solution or 55 % nitric acid, it is not necessary to carry out the testing with water, for the same test levels

(Packaging Group, relative density, hydraulic pressure).

A.3 Definitions of polyethylene types

A.3.1 High molecular weight high density polyethylene (PE-HD-HMW)

The natural relative (non-pigmented) density at 23 °C after annealing at 100 °C for 1 h shall be ≥ 0,940 g/cm in

accordance with EN ISO 1183-1.

The melt flow rate at 190 °C per 21,6 kg load shall be ≤ 12 g per 10 min in accordance with EN ISO 1133.

A.3.2 Medium molecular weight high density polyethylene (PE-HD-MMW)

The natural relative (non-pigmented) density at 23 °C after annealing at 100 °C for 1 h shall be ≥ 0,940 g/cm in

accordance with EN ISO 1183-1.

The melt flow rate at 190 °C per 2,16 kg load shall be ≤ 0,5 g per 10 min and ≥ 0,1 g per 10 min in accordance with

EN ISO 1133.

or

The melt flow rate at 190°C per 5 kg load shall be ≤ 3,0 g per 10 min and ≥ 0,5 g per 10 min in accordance with EN

ISO 1133.

A.3.3 Cross-linked polyethylene (PE-X)

PE-X is polyethylene having a changed chemical structure in which the major proportion of polymer chains are

chemically connected with each other to form a three-dimensional network.

A.3.4 Linear medium density polyethylene

The natural relative (non-pigmented) density at 23° after annealing at 100°C for 1 h shall be ≥ 0,927 g/cm and

≤ 0,937 g/cm in accordance with EN ISO 1183-1.

The melt flow rate at 190°C per 2,16 kg load shall be ≥ 5,0 g per 10 min and ≤ 10,0 g per 10 min in accordance with

EN ISO 1133

Annex B

(normative)

Small scale laboratory tests to assess packaged substances against

standard liquids

B.1 Introduction

The small scale laboratory tests listed as follows shall be used to assess whether a packaged substance can be

assimilated to a standard liquid for specific grades of polyethylene (high molecular weight high density polyethylene

and medium molecular weight high density polyethylene, additionally cross-linked polyethylene and linear medium

density polyethylene ).

For the cross linked polyethylene and linear medium density polyethylene the prior agreement of the competent

authority shall be obtained.

Three tests cover specific interactions between the packaged substance and the plastics material. These are:

Method A: absorption (one procedure);

Method B: environmental stress cracking ( three procedures);

Method C: molecular degradation (three procedures).

NOTE Where alternative procedures are described each procedure may be regarded as equivalent.

B.2 Requirements

B.2.1 Resistance to absorption (swelling)

For Method A (B.4.1) the percentage weight increase when tested with the packaged substance to be carried shall

be equal or less than that figure obtained when tested with the applicable standard liquid.

B.2.2 Resistance to environmental stress cracking

For Procedure B1 (B.4.2.2), the results shall demonstrate that with the packaged substance there is a lesser or

equal effect than with the standard liquid used as a control.

For Procedure B2 (B.4.2.3) and Procedure B3 (B.4.2.4) the results shall demonstrate that with the packaged

substance there is a time interval to failure equal to or greater than with the standard liquid used as a control.

B.2.3 Resistance to molecular degradation

For Procedure C1 (B.4.3.3) the melt flow rate of the specimen of the material in contact with the packaged

substance shall not exceed that of the same material in contact with 55% nitric acid.

For Procedure C2 (B.4.3.4) the viscosity number of the sample of the material in contact with the packaged

substance shall not be less than that of the same material in contact with 55 % nitric acid.

For Procedure C3 (B.4.3.5) the elongation at break of the sample in contact with the packaged substance shall not

be less than that with the same material with 55 % nitric acid.

B.2.4 Test report

A test report shall be prepared. The report shall include a full description of the packaged substance under test and

the plastics material.

B.3 Selection and preparation of test specimens

B.3.1 A representative complete packaging (at least 48 h old) shall be supplied to the testing laboratory. Test

specimens shall be prepared from material cut from this packaging.

NOTE By agreement with the competent authority the tests may also be carried out on test specimens prepared from

compression moulded or extruded sheet produced from a specific polymer grade and specified thickness.

B.3.2 Each test specimen shall have a means of identification.

B.3.3 Each test specimen shall be examined for damage etc. which could invalidate the tests, e.g. surface

imperfection or contamination.

B.3.4 For cross linked polyethylene, only test specimens taken from the packagings shall be used.

B.4 Test procedures

B.4.1 Resistance to absorption (Method A)

B.4.1.1 Principle

This method details the determination of the resistance to absorption of the plastics packaging when in contact with

a packaged substance (See Figure B.1)

Key

1 Increase in mass due to swelling %

2 Mixture of hydrocarbons (white spirit)

3 Normal butyl acetate

4 Acetic acid

5 Storage period d

Figure B.1 — Determination of the absorption (increase in mass) of the samples immersed in the product at

40° C

B.4.1.2 At least three test specimens of area not less than 450 mm shall be cut from the centre of the

container side wall or from a compression moulded or extruded sheet.

B.4.1.3 The initial mass of each of the test specimens (W ) shall be recorded.

o

B.4.1.4 The test specimens shall be kept fully immersed in the packaged substance in a suitable receptacle.

B.4.1.5 Test specimens shall be immersed until absorption is complete, i.e. constant mass is reached. For

normal test conditions with specimen thickness 2,0 mm or less and test temperature 40°C, this is typically achieved

within a test period of 28 days.

B.4.1.6 At the end of the test period or at appropriate test intervals remove the test pieces, remove all traces of

surface liquid, and record the mass of each test piece (W ).

B.4.1.7 Test specimens shall only be used once.

B.4.1.8 Results

The mean of three results to two significant figures shall be recorded.

100 (W1 - Wo)

% mass increase ∆ W =

Wo

W = initial mass;

W = mass at end of test period.

B.4.1.9 Criteria for assessment

The percentage mass increase, when tested with the packaged substance, shall be less than or equal to that

obtained when tested with the appropriate standard liquid.

NOTE This can be expected to be:

up to 1 % for water, wetting agent solution, acetic acid, or nitric acid;

approximately 4 % for n-butyl acetate;

approximately 7,5 % for mixture of hydrocarbons (white spirit).

B.4.2 Resistance to environmental stress cracking (method B)

B.4.2.1 General

One of the following three alternative procedures shall be used to determine environmental stress cracking:

i) pin impression test (see B.4.2.2)

ii) bent strip test (see B4.2.3)

iii) full notch creep test ( see B.4.2.4)

B.4.2.2 Pin impression test (Procedure B1)

B.4.2.2.1 Special equipment required for test

i) Polished pins, made from material resistant to the product under test, e.g. stainless steel, glass, as specified in

Figure B.2.

ii) Tool, for notching specimen to the required dimensions, as shown in Figure B 3. The notch radius shall be

≤ 0,05 mm.

Dimensions in millimetres

Key

1 Gradient approximately 1: 10

2 Polished

Figure B.2 — Polished pins for Pin Impression Test

B.4.2.2.2 Preparation of test specimens

Cut at least 70 specimens from a packaging, a compression moulded or extruded sheet. Each test specimen shall

not be less than 50 mm long, 30 mm wide and 2 mm or greater in thickness. The test specimen shall be notched

and a hole drilled (3 mm in diameter) in accordance with Figure B.3.

The distance between the bottom of the notch and the edge of the hole shall be (5 ± 0,1) mm or (4 ± 0,1) mm, the

latter being used to shorten the testing time with certain grades of polyethylene.

Dimensions in millimetres

Key

1 Direction of extrusion

2 The 5 mm dimension may be 4 mm where appropriate, in which case the 1,5 mm dimension is increased to

2,5 mm

Figure B.3 — Test specimen for Pin Impression Test

B.4.2.2.3 Preconditioning procedure

Test specimens shall be immersed in both the packaged substance and the standard liquid for a period of 21 days

at either (4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...