EN 14043:2005+A1:2009

(Main)High rise aerial appliances for fire service use - Turntable ladders with combined movements - Safety and performance requirements and test methods

High rise aerial appliances for fire service use - Turntable ladders with combined movements - Safety and performance requirements and test methods

1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with combined movements of classes 18, 24 and 30, as defined in 3.13, under the control of fire-fighters and intended for fire fighting and rescuing people.

Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage.

Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies power required for the operation of the ladder and permits all of the operational movements to be made simultaneously, with no restriction on the angle of the training movement.

1.2 This European Standard deals with the technical safety requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use, the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or his authorised representative.

It also deals with performance requirements.

1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set <= 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user).

NOTE Special designs for use under special climatic conditions are arranged between the manufacturer and the purchaser.

1.4 This European Standard does not deal with the hazards of the standard automotive chassis or due to use as a road vehicle.

1.5 This European Standard is not applicable to turntable ladder vehicles with combined movements which are manufactured before the date of publication of this European Standard by CEN.

Hubrettungsfahrzeuge für die Feuerwehr - Drehleitern mit kombinierten Bewegungen (Automatik-Drehleitern) - Sicherheits- und Leistungsanforderungen sowie Prüfverfahren

1.1 Diese Europäische Norm legt die Sicherheits- und Leistungsanforderungen sowie die Prüfverfahren für

Drehleitern mit kombinierten Bewegungen (Automatik-Drehleitern) der Klassen 18, 24 und 30, entsprechend

der Definition in 3.13, fest. Diese Anforderungen und Prüfverfahren gelten für die Anwendung der Drehleiter

durch die Feuerwehr (Feuerwehrleute). Drehleitern sind zur Rettung von Menschen und zur Brandbekämpfung

bestimmt.

Drehleitern bestehen aus einem Fahrgestell, dem Aufbau und einem kraftbetätigten Ausleger in Form einer

Leiter mit oder ohne Korb.

Die durch diese Europäische Norm abgedeckten Drehleitern verfügen über ein Fahrgestell mit Eigenantrieb,

dessen Motor die für das Betreiben der Leiter erforderliche Energie bereitstellt und alle Einsatzbewegungen

gleichzeitig ohne Winkelbegrenzung der Drehbewegung zulässt (Automatik-Drehleiter).

1.2 Diese Europäische Norm behandelt die technischen Sicherheitsanforderungen zum Minimieren der in

Abschnitt 4 aufgeführten Gefährdungen, die während der Bereitstellung, während des Betriebes sowie

während der routinemäßigen Überprüfungen und Wartung von Drehleitern auftreten können, wenn diese

entsprechend den Festlegungen des Herstellers oder seines befugten Vertreters durchgeführt werden.

Behandelt werden ebenfalls die Leistungsanforderungen.

1.3 Diese Europäische Norm behandelt den Einsatz von Drehleiterfahrzeugen in einem Temperaturbereich

von −15 °C bis +35 °C und mit einer Windlast auf den Ausleger von ≤ 12,5 m/s. Zusätzliche Maßnahmen

können für einen Einsatz außerhalb dieses Bereichs erforderlich sein. Diese sind dann zwischen Hersteller

und Kunden zu vereinbaren.

ANMERKUNG Sonderausführungen für den Einsatz unter besonderen klimatischen Bedingungen werden zwischen

dem Hersteller und dem Kunden vereinbart.

1.4 Diese Europäische Norm behandelt weder die Gefahren des Standard-Fahrgestells noch Gefahren

infolge des Einsatzes als Straßenfahrzeug.

Moyens élévateurs aériens pour la lutte contre l'incendie - Echelles pivotantes à mouvements combinés - Prescriptions de sécurité et de performances et méthodes d'essais

1.1 La présente Norme européenne spécifie les prescriptions de sécurité et de performances, et les méthodes

d'essais applicables aux échelles pivotantes à mouvements combinés de classes 18, 24 et 30, telles que définies

au 3.13 ; manoeuvrées par les sapeurs-pompiers et prévues pour la lutte contre l'incendie et le sauvetage

de personnes.

Les véhicules à échelle pivotante comprennent un châssis, une carrosserie et une structure extensible motorisée,

sous la forme d'une échelle avec ou sans panier.

Les véhicules à échelle pivotante couverts par la présente Norme européenne ont un châssis automoteur dont le

moteur assure la puissance requise pour faire fonctionner l'échelle et permet de faire tous les mouvements

opérationnels simultanément, sans restriction concernant l'angle du mouvement de pivotement.

1.2 La présente Norme européenne traite des prescriptions techniques de sécurité destinées à minimiser les

phénomènes dangereux énumérés à l'Article 4, pouvant survenir pendant la mise en service, le fonctionnement,

la vérification et la maintenance de routine des échelles pivotantes, effectués conformément aux spécifications

données par le fabricant ou son représentant autorisé.

Il traite également des prescriptions de performances.

1.3 La présente Norme européenne traite de l'utilisation des véhicules à échelle pivotante dans une plage

de température de – 15 °C à + 35 °C et avec une vitesse de vent sur la structure extensible ≤ 12,5 m/s.

Des dispositions supplémentaires peuvent être nécessaires pour un usage en dehors de cette plage (à négocier

entre le fabricant et l'utilisateur).

NOTE Les conceptions particulières relatives à un usage dans des conditions climatiques spéciales sont à définir entre

le fabricant et l'acheteur.

1.4 La présente Norme européenne ne traite pas des phénomènes dangereux relatifs au châssis du véhicule

à moteur normalisé ou découlant de son utilisation comme véhicule routier.

Visoke nadzemne naprave za gasilske enote - Avtomatske vrtljive gasilske avtolestve - Zahteve za varnost in obnašanje v uporabi in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 03-Mar-2009

- Withdrawal Date

- 14-Jan-2014

- Technical Committee

- CEN/TC 192 - Fire service equipment

- Drafting Committee

- CEN/TC 192 - Fire service equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Jan-2014

- Completion Date

- 15-Jan-2014

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Jan-2014

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14043:2005+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "High rise aerial appliances for fire service use - Turntable ladders with combined movements - Safety and performance requirements and test methods". This standard covers: 1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with combined movements of classes 18, 24 and 30, as defined in 3.13, under the control of fire-fighters and intended for fire fighting and rescuing people. Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage. Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies power required for the operation of the ladder and permits all of the operational movements to be made simultaneously, with no restriction on the angle of the training movement. 1.2 This European Standard deals with the technical safety requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use, the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also deals with performance requirements. 1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set <= 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user). NOTE Special designs for use under special climatic conditions are arranged between the manufacturer and the purchaser. 1.4 This European Standard does not deal with the hazards of the standard automotive chassis or due to use as a road vehicle. 1.5 This European Standard is not applicable to turntable ladder vehicles with combined movements which are manufactured before the date of publication of this European Standard by CEN.

1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with combined movements of classes 18, 24 and 30, as defined in 3.13, under the control of fire-fighters and intended for fire fighting and rescuing people. Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage. Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies power required for the operation of the ladder and permits all of the operational movements to be made simultaneously, with no restriction on the angle of the training movement. 1.2 This European Standard deals with the technical safety requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use, the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also deals with performance requirements. 1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set <= 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user). NOTE Special designs for use under special climatic conditions are arranged between the manufacturer and the purchaser. 1.4 This European Standard does not deal with the hazards of the standard automotive chassis or due to use as a road vehicle. 1.5 This European Standard is not applicable to turntable ladder vehicles with combined movements which are manufactured before the date of publication of this European Standard by CEN.

EN 14043:2005+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14043:2005+A1:2009 has the following relationships with other standards: It is inter standard links to EN 14043:2005/AC:2006, EN 14043:2005, EN 14043:2005/prA1, EN 14043:2014, EN 60204-1:1997, EN 60529:1991, EN 61310-1:2008, EN 1846-3:2002, EN 13482:2001, EN ISO 4413:2010, EN ISO 12100-1:2003, EN 1050:1996, EN 1846-2:2001, EN ISO 7731:2008, EN 418:1992. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14043:2005+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14043:2005+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Visoke nadzemne naprave za gasilske enote - Avtomatske vrtljive gasilske avtolestve - Zahteve za varnost in obnašanje v uporabi in preskusne metodeHubrettungsfahrzeuge für die Feuerwehr - Drehleitern mit kombinierten Bewegungen (Automatik-Drehleitern) - Sicherheits- und Leistungsanforderungen sowie PrüfverfahrenMoyens élévateurs aériens pour la lutte contre l'incendie - Echelles pivotantes à mouvements combinés - Prescriptions de sécurité et de performances et méthodes d'essaisHigh rise aerial appliances for fire service use - Turntable ladders with combined movements - Safety and performance requirements and test methods97.145LestveLadders13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 14043:2005+A1:2009SIST EN 14043:2005+A1:2009en,fr,de01-junij-2009SIST EN 14043:2005+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14043:2005+A1

March 2009 ICS 13.220.10 Supersedes EN 14043:2005English Version

High rise aerial appliances for fire service use - Turntable ladders with combined movements - Safety and performance requirements and test methods

Moyens élévateurs aériens pour la lutte contre l'incendie - Echelles pivotantes à mouvements combinés - Prescriptions de sécurité et de performances et méthodes d'essais

Hubrettungsfahrzeuge für die Feuerwehr - Drehleitern mit kombinierten Bewegungen (Automatik-Drehleitern) - Sicherheits- und Leistungsanforderungen sowie Prüfverfahren This European Standard was approved by CEN on 1 August 2005 and includes Corrigendum 1 issued by CEN on 6 December 2006 and Amendment 1 approved by CEN on 11 January 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14043:2005+A1:2009: ESIST EN 14043:2005+A1:2009

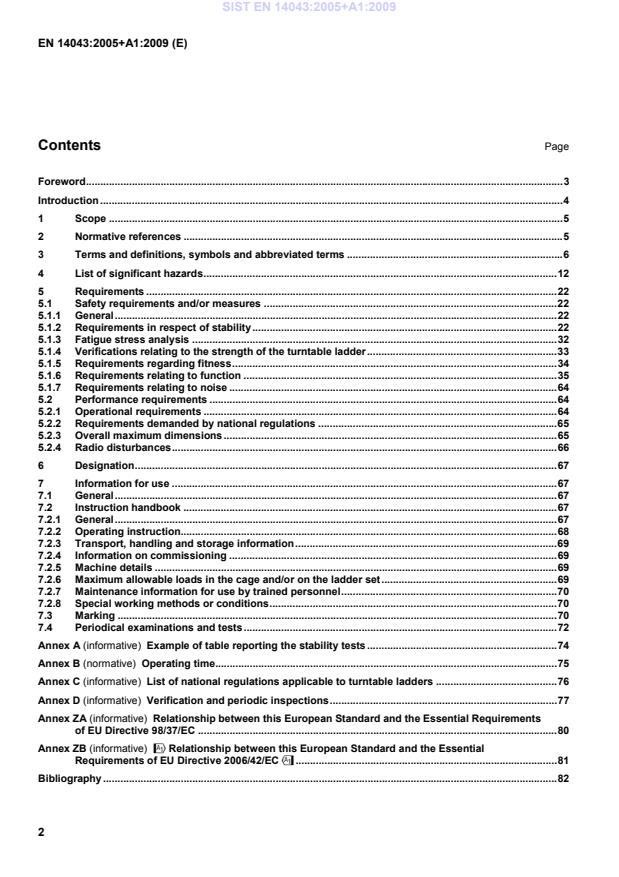

Example of table reporting the stability tests . 74Annex B (normative)

Operating time . 75Annex C (informative)

List of national regulations applicable to turntable ladders . 76Annex D (informative)

Verification and periodic inspections . 77Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 80Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 81Bibliography . 82 SIST EN 14043:2005+A1:2009

1 Scope 1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with combined movements of classes 18, 24 and 30, as defined in 3.13, under the control of fire-fighters and intended for fire fighting and rescuing people. Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage. Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies power required for the operation of the ladder and permits all of the operational movements to be made simultaneously, with no restriction on the angle of the training movement. 1.2 This European Standard deals with the technical safety requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use, the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also deals with performance requirements. 1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set ≤ 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user). NOTE Special designs for use under special climatic conditions are arranged between the manufacturer and the purchaser. 1.4 This European Standard does not deal with the hazards of the standard automotive chassis or due to use as a road vehicle. 1.5 This European Standard is not applicable to turntable ladder vehicles with combined movements which are manufactured before the date of publication of this European Standard by CEN. 2 Normative references The following referenced documents are indispensable for the application of this European Standard. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 418:1992, Safety of machinery — Emergency stop equipment, functional aspects — Principles for design EN 457, Safety of machinery — Auditory danger signals — General requirements, design and testing

(ISO 7731:1986, modified) EN 954-1:1996, Safety of machinery — Safety related parts of control systems — Part 1: General principles for design EN 982, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 1050:1996, Safety of machinery — Risk assessment EN 1846-1:1998, Firefighting and rescue service vehicles — Part 1: Nomenclature and designation SIST EN 14043:2005+A1:2009

EN 1846-1:1998, EN 1846-2:2001 and the following apply. 3.1 turntable ladder with combined movements machine with an extending structure in the form of a ladder set mounted on a self-propelled chassis. The chassis engine supplies the power required for operation. For ladders with combined movements, at least the elevation/depression, extending/housing and the training right/left, are simultaneously possible under the continuous control of the operator. There is no restriction on the angle of the training movement 3.2 turntable ladder equipment entire assembly of the mobile components mounted on the chassis which can carry at its upper extent, fixed or removable rescue equipment NOTE The jacking system is part of the turntable ladder equipment. 3.3 ladder set part of turntable ladder comprising several ladder sections which are connected together so as to extend telescopically 3.4 extended ladder set length L distance, expressed in metres, between the extreme points of the extended ladder 3.5 rescue cage fixed or removable complementary device principally used for firefighting, rescuing people and other operational services SIST EN 14043:2005+A1:2009

2 Special boundary of use, load = 0 + turntable ladder equipment (3.23.3) 3 Supported boundary of use, load + cage = 0 (3.23.2)

Figure 1 — Example of boundary SIST EN 14043:2005+A1:2009

NOTE It is assumed, for this measurement, that the vehicle is standing on a horizontal surface. Figure 2 — Jacking width 3.25 operating time tR time required in order to reach, from the travel position, the maximum rescue height (at 90° to the longitudinal axis of the chassis) NOTE If appropriate the operating time (tR) includes the time for attaching the cage and making it ready for use with the ladder stabilized at maximum jacking width by the vehicle. 3.26 stability test – static verification test of a turntable ladder’s ability to resist tipping or rolling over with the ladder set not being moved under load 3.27 stability test – dynamic verification test of a turntable ladder’s ability to resist tipping or rolling over with the ladder set being permitted to move under load 3.28 static overload test static test of the turntable ladder for permanent deformation NOTE The static overload test is not a stability test. 3.29 test of fitness for purpose test to confirm the correct functioning of all the functions of a turntable ladder and its special equipment SIST EN 14043:2005+A1:2009

Key A First section B Intermediate sections C Last section Figure 3 — Designation of ladder set sections 4 List of significant hazards This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in this European Standard, identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk. SIST EN 14043:2005+A1:2009

Pressure of the jacks on the ground • 5.1.6.5.2 • 5.1.6.2.12 • 5.1.6.2.13 • 5.1.6.2.14 • 7

Uncontrolled movement (lifting on the base plate) • 5.1.6.2.14

Suspensions locking device Re-establishing ground contact with the tyres during return to travel position • 5.1.6.2.15

Defect in the suspension locking device on activation • 5.1.6.2.1 • 7

Cradle/turret Crushing by the training drive mechanism • 5.1.6.7.1

Crushing by the turret in motion • 5.1.6.7.1 • 5.1.6.7.2

Crushing by the cradle in motion • 5.1.6.7.1

Ladder set Crushing between the rounds during extending and housing • 5.1.6.5.3 • 5.1.6.8.1 • 7

Rescue cage Crushing by mobile parts during levelling correction • 5.1.6.4.8 SIST EN 14043:2005+A1:2009

Impact against an obstacle • 5.1.6.4.3 • 5.1.6.4.12 • 5.1.6.4.14 • 5.1.6.5.3 • 5.1.6.5.5 • 7

Fitting/removal of the rescue cage • 5.1.6.4.6

Movement in the rescue cage

• 5.1.6.4.13

Crushing a person outside the cage • 5.1.6.4.12 • 5.1.6.5.3 • 5.1.6.5.4 • 5.1.6.8.1 • 7 1.2 Shearing hazard Cradle/turret Crushing by the cradle in motion • 5.1.6.7.1

Ladder set Crushing between the rounds during extending and housing • 5.1.6.5.3 • 5.1.6.8.1

Rescue cage Crushing by mobile parts during levelling correction • 5.1.6.4.8

Impact against an obstacle • 5.1.6.4.12 • 5.1.6.5.3 • 5.1.6.5.5 1.3 Cutting or severing hazard General

• EN 1846-2

Ladder set Damaged wire ropes • 5.1.6.8.2 1.4 Entanglement hazard General All moving parts • 5.1.6.7.1 • 5.1.6.8.2 • 7

Jacks Movement of the jacks • 5.1.6.2.11 • 5.1.6.2.14 • 5.1.6.2.15 • 5.1.6.5.2 • 7 SIST EN 14043:2005+A1:2009

Cradle/turret Entanglement by pinion/crown • 5.1.6.7.2

Entanglement by the moving turret • 5.1.6.5.3 • 5.1.6.7.1 • 5.1.6.7.2

Rescue cage Cage deployment control • 5.1.6.5.4

Ladder set Entanglement by pulley and chains and entanglement by the winding drum • 5.1.6.8.2 1.5 Drawing-in or trapping hazard General Presence of a person in the working area

• 5.1.6.5.6 1.6 Impact hazard Jacks Movement of the jacks • 5.1.6.5.2 • 5.1.6.2.14 • 7

Put pressure on the ground • 5.1.6.5.2 • 5.1.6.2.14 • 7

Neutralisation suspension Re-establishing ground contact with the tyres during return to travel position • 5.1.6.2.15

Cradle/turret Crushing by the turret in motion • 5.1.6.5.3 • 5.1.6.7.1 • 5.1.6.7.2 • 7

Rescue cage Impact against an obstacle • 5.1.6.4.3 • 5.1.6.4.12 • 5.1.6.4.14 • 5.1.6.5.3 • 5.1.6.5.5 • 7 SIST EN 14043:2005+A1:2009

Couplings, etc. • 5.1.6.9

• Wire ropes • Linkages • All hydraulic components • 7 1.9 High pressure fluid injection or ejection hazard Hydraulic drive systems Injury and/or contamination by leakage or rupture • 5.1.6.9 • 7 2 Electrical hazards 2.1

Contact of persons with live parts (direct contact) Overall design General measures • EN 60204-1 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) Overall design General measures • EN 60204-1 2.3 Approach to live parts under high voltage Ladder set Contact with overhead electrical conductors • 5.1.6.2.10 • 7 2.4 Electrostatic hazard General

• 5.1.6.2.10 4 Hazard generated by noise 4.2 Interference with speech communication, acoustic signals, etc. Communications

• 5.1.6.8.5

Ladder Normal operation • 5.1.6.8.5 • 5.1.7 • Annexes C and F of EN 1846-2:2001SIST EN 14043:2005+A1:2009

cage/ladder • access ladder/chassis deck • access ladder/ground level • Emergency operating system

• 5.1.6.8.4

• 5.1.6.8.3

• 5.1.6.11.2

• 5.1.2.3.6

Rescue cage Fitting/removal • 5.1.6.4.6 8.2 Inadequate consideration of hand-arm or foot-leg anatomy Jack control console Jack control • 5.1.6.5.1 • 5.1.6.5.2

Cradle/turret control console Cradle/turret movement control • 5.1.6.5.1 • 5.1.6.5.3

Ladder set control console Ladder set movement control • 5.1.6.5.1 • 5.1.6.5.3

Ladder set Access • 5.1.6.11.2 • 5.1.6.11.5

Rescue cage control console Ladder/cradle/turret movement • 5.1.6.5.1 • 5.1.6.5.5

Good visibility of the movement • 5.1.6.5.5

Main control console Access • 5.1.6.5.3 8.3 Neglected use of personal protection equipment General

• 7 8.4 Inadequate local lighting Control consoles Use of consoles • 5.1.6.5.1

Access to the main control console Use of consoles • 5.1.6.5.3 8.5 Mental overload and underload, stress All movements Use of controls without error • 5.1.6.5.1 • 5.1.6.5.2 • 5.1.6.5.3 • 5.1.6.5.5 SIST EN 14043:2005+A1:2009

Control consoles

Operating controls/reading of information • 5.1.6.5 • 7 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction)

The whole ladder General operation • 5.1.6

Intentional stop or failure of the main power supply • 5.1.2.3.6 • 5.1.2.3.7 10.3 External influences on electrical equipment Electrical circuits and components General measures • 5.1.6.10 10.5 Errors in the software Software

• 5.1.6.12 13 Failure of the power supply

The whole ladder General operation • 5.1.2.3.6

Intentional stop or failure of the main power supply • 5.1.2.3.6

Jacks Rupture of the power supply of the components • 5.1.6.2.5

Suspension locking Rupture of the power supply of the components • 5.1.6.2.5

Cradle/turret Failure of the power supply of the components • 5.1.6.13.1

Ladder set Rupture of the power supply of the components • 5.1.6.13.1

Rescue cage Rupture of the power supply of the components • 5.1.6.13.1

Software Insufficient supply and/or failure • 5.1.6.12.3 • 5.1.6.12.8 14 Failure of the control circuit

Jacks Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Suspension locking Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Cradle/turret Failure in the control software • 5.1.6.12 SIST EN 14043:2005+A1:2009

Restarting • 5.1.6.5.1

Failure of a drive or load retaining element • 5.1.6.13.1 • 5.1.6.13.2 • 5.1.6.13.3

Ladder set Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Failure of a drive or load retaining element • 5.1.2 • 5.1.6.13.1 • 5.1.6.13.2 • 5.1.6.13.3

Rescue cage Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Failure of a drive or load retaining element • 5.1.6.4.2 • 5.1.6.4.7 • 5.1.6.5.1

Analogical detectors Normal operation • 5.1.6.12.6 • 5.1.6.12.7

Logical detectors Normal operation • 5.1.6.12.3 • 5.1.6.12.5 • 5.1.6.12.7 • 7

Management of the stability Normal operation • 5.1.2.3.9

Operation without safety measures • 5.1.2.3.5 • 5.1.2.3.7 15 Errors of fitting

Rescue cage Fitting of the rescue cage to the tip of the ladder set • 5.1.6.4.6 • 5.1.6.4.7 17 Falling or ejected objects or fluids

General

• 5.1.6.9

• 7

Drive hydraulic systems Injury and/or contamination by leakage or rupture • 5.1.6.9 • 7 SIST EN 14043:2005+A1:2009

Rescue cage Elements falling from the rescue cage • 5.1.6.4.3 • 5.1.6.4.5 • 5.1.6.4.11 18 Loss of stability/overturning of machinery

General All movements • 5.1.1 • 5.1.2

Jacks Unsuitable ground • 5.1.6.2.12 • 7

Movement of the vehicle • 5.1.6.1

Variation of jacking width • 5.1.6.2

Unevenness of the ground • 5.1.6.2.6 • 5.1.6.2.7 • 5.1.6.2.8

Jacking Ground pressure failure • 5.1.6.2.2 • 5.1.6.5.3 • 7

Technical defect • 5.1.1

Inadvertent operation • 5.1.6.2.4

Damage to the jacks due to external action • 5.1.6.2.11

Suspension locking Normal operation • 5.1.6.2.16

Cradle/turret Technical defect • 5.1.1

Exterior impact • 5.1.6.7.2

Ladder set Exceeding the stability limits • 5.1.2 • 5.1.6.3.3 • 5.1.6.3.4

Overload • 5.1.4

External influence by wind load • 5.1.6.6 • 7

Exceeding the limits of free standing use in order to attain the limits of supported use • 5.1.2.3.2 • 7

Rescue cage Overload in the rescue cage • 5.1.6.4.13 SIST EN 14043:2005+A1:2009

Vehicle deck Standing or moving

• 5.1.6.11.1 • 5.1.6.11.3

Ladder set Rounds • 5.1.6.3.1 • 5.1.6.8.6 • 5.1.6.11.4

Rescue cage Defective horizontal alignment of the cage floor • 5.1.6.4.1 • 7

Access rescue cage/ladder • 5.1.6.4.9 21 Hazards linked to the work position 21.1 Fall of persons during access to (or at/from) the work position Vehicle deck Getting up and down • 5.1.6.11.2 • 5.1.6.11.5 • 5.1.6.11.6

Standing or moving on the platform surface • 5.1.6.11.1 • 5.1.6.11.3

Cradle/turret Access to main control console if required • 5.1.6.5.3

Ladder set Access • 5.1.6.8.3 • 5.1.6.8.4 • 7

Rescue cage Access to rescue cage/ladder • 5.1.6.4.9 35 Falling of person from person carrier

Rescue cage Falling from the rescue cage • 5.1.6.4.3 • 5.1.6.4.4 • 7 37 Human error, human behaviour

Control consoles Operating controls • 5.1.6.3 • 5.1.6.5 • 7

Reading of information • 5.1.6.5 • 7 SIST EN 14043:2005+A1:2009

Key 1 Force resulting from wind load, Fw 2 Force resulting from dead weight load, FG and FE ˜3 Force resulting from inertial forces tangential to direction of movement™, FN 4 Force resulting from the working load, FL 5 Force resulting from diverse forces (e.g. jet reaction), Fs 6 Force resulting from residual forces, FR 7 Angle being the combination of camber angle and gradient angle Figure 4 — Example of forces acting on turntable ladder 5.1.2.1.2 Calculation of the working load (see Figure 5) The working load shall be assumed to be a point concentrated on the base of the rescue cage acting at the centre of area of the base. The area of the cage base is the area within the upper handrail and not the area determined in accordance with 5.1.6.4.13. For ladders without rescue cage, the mass shall be applied at the end of the ladder set, in the centre of the last round. The mass corresponding to the supplementary load to be taken into account shall be at least 25 kg. SIST EN 14043:2005+A1:2009

where q is the impact pressure of 100 ˜N/m²™; and

Aproj. is the outside surface of the ladder. SIST EN 14043:2005+A1:2009

Key 1 Overall height of cage 2 Width exposed to the wind Figure 6 — Surface exposed to the wind 5.1.2.1.3.4 The wind force acting on the equipment in the rescue cage is calculated as a force equal to 3 % of dead weight (see Table 1) of the equipment acting at a point 0,5 m above the base of the rescue cage. 5.1.2.1.4 Calculation of manual force The minimum value for the manual force is assumed to be 200 N for turntable ladder vehicles. The manual force acts at a height of 1,1 m over the base of the rescue cage. Any greater permissible force shall be specified by the manufacturer. SIST EN 14043:2005+A1:2009

Symbol Unit Direction of action Factors for use in calculations Speed of movement V m/s - ≤ 0,7 > 0,7 Forces engendered by gravity (dead weight) FG N vertical 1,0 × FG Force engendered by working load (applied load) FL N vertical 1,25 × FL Inertial forces FN N

tangential to direction of movement 0,1 × FE

+ 0,1 × FL 0,2 × FE

+ 0,2 × FL Wind forces FW N horizontal 1,1 × FW Diverse forces FS N Selected angle1,1 × FS Key

FL = PL × g (N) FE is the force engendered by the unloaded ladder set (N) = mE × g mE is the mass of the ladder set (kg) FG = mG × g (N) g = 9,81 (m/s2) mG is the mass (kg) NOTE Pitching inaccuracies (sloping ground): 0,5 (see 5.1.2.1.5.8).

5.1.2.1.5.2 Forces engendered by gravity (FG and FE) which generate a tilting moment and/or righting moment, are multiplied by the factor of 1,0. They are assumed to be acting vertically downwards. 5.1.2.1.5.3 Forces engendered by the gravity of the maximum working load (FL), which create a tilting moment and/or righting moment are multiplied by the factor of 1,25. They are assumed to be acting vertically downwards. 5.1.2.1.5.4 Inertial forces engendered by masses in motion (mass forces FN) are multiplied by a factor of 0,1 for V ≤ 0,7 m/s and by the factor of 0,2 for V > 0,7 m/s. They are assumed to act tangentially to the direction of movement which generates the maximum tilting moment and applied to the centre of gravity of the structure in motion. 5.1.2.1.5.5 Diverse forces (FS) (e.g. manual forces, reaction to a water jet) are multiplied by the factor of 1,1 and assumed to act in the direction of movement which generates the maximum tilting moment. 5.1.2.1.5.6 Wind forces (FW) having an influence on stability are multiplied by the factor of 1,1. They are assumed to act horizontally. 5.1.2.1.5.7 The absolute velocity at the head of the extended ladder set under normal working conditions shall be taken as the speed of movement V. 5.1.2.1.5.8 Forces resulting from 0,5° pitching inaccu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...