EN 12923-1:2006

(Main)Advanced technical ceramics - Monolithic ceramics - Part 1: General practice for undertaking corrosion tests

Advanced technical ceramics - Monolithic ceramics - Part 1: General practice for undertaking corrosion tests

This part of EN 12923 specifies guidelines to be employed when undertaking corrosion tests on advanced technical ceramics. The mechanisms of chemical attack on advanced ceramics are widely varied and depend on the chemical and phase composition and the phase morphology of the material, as well as the corrosive conditions imposed. For any particular engineering application it is usually necessary to model expected conditions of use in order to obtain quantitative data on the ability to withstand the proposed end-use conditions.

This European Standard is not restricted to specific material types, nor does it prescribe particular test conditions or a test duration. The actual testing requirements might be very specific, for example, in order to investigate the suitability of a range of materials for a given application in which certain specified conditions occur. This European Standard provides recommended methods for undertaking the assessment of the effect of corrosion and provides guidance on practical issues related to undertaking the tests.

Hochleistungskeramik - Monolithische Keramik - Teil 1: Allgemeines zur Durchführung von Korrosionsprüfungen

Céramiques techniques avancées - Céramiques monolithiques - Partie 1 : Pratique générale en matière d'essais de corrosion

La présente partie de l’EN 12923 spécifie des lignes directrices à employer lors de la réalisation d’essais de corrosion sur les céramiques techniques avancées. Les mécanismes d’attaque chimique des céramiques avancées sont extrêmement variés et dépendent de la composition chimique et de la composition de la phase, de la morphologie de la phase du matériau, ainsi que des conditions de corrosion imposées. Dans le cas d’une application d’ingénierie particulière, il est généralement nécessaire de modéliser les conditions d’utilisation escomptées, afin d’obtenir des données quantitatives sur l’aptitude à résister aux conditions prévues lors de l’utilisation finale.

La présente Norme européenne ne se limite pas à des types de matériaux spécifiques et ne prescrit ni conditions d’essai particulières, ni durée d’essai. Les exigences relatives aux essais réels peuvent être très spécifiques, afin de rechercher, par exemple, l’adéquation d’une gamme de matériaux à une application donnée pour laquelle certaines conditions sont spécifiées. La présente Norme européenne indique les méthodes recommandées pour évaluer les effets de la corrosion et constitue un guide des opérations pratiques liées à la réalisation des essais.

Sodobna tehnična keramika - Monolitna keramika – 1. del: Splošni postopki za izvajanje korozijskih preskusov

General Information

- Status

- Withdrawn

- Publication Date

- 19-Dec-2006

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 184 - Advanced technical ceramics

- Drafting Committee

- CEN/TC 184/WG 3 - Monolithic ceramics

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Mar-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 03-Aug-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 12923-1:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Advanced technical ceramics - Monolithic ceramics - Part 1: General practice for undertaking corrosion tests". This standard covers: This part of EN 12923 specifies guidelines to be employed when undertaking corrosion tests on advanced technical ceramics. The mechanisms of chemical attack on advanced ceramics are widely varied and depend on the chemical and phase composition and the phase morphology of the material, as well as the corrosive conditions imposed. For any particular engineering application it is usually necessary to model expected conditions of use in order to obtain quantitative data on the ability to withstand the proposed end-use conditions. This European Standard is not restricted to specific material types, nor does it prescribe particular test conditions or a test duration. The actual testing requirements might be very specific, for example, in order to investigate the suitability of a range of materials for a given application in which certain specified conditions occur. This European Standard provides recommended methods for undertaking the assessment of the effect of corrosion and provides guidance on practical issues related to undertaking the tests.

This part of EN 12923 specifies guidelines to be employed when undertaking corrosion tests on advanced technical ceramics. The mechanisms of chemical attack on advanced ceramics are widely varied and depend on the chemical and phase composition and the phase morphology of the material, as well as the corrosive conditions imposed. For any particular engineering application it is usually necessary to model expected conditions of use in order to obtain quantitative data on the ability to withstand the proposed end-use conditions. This European Standard is not restricted to specific material types, nor does it prescribe particular test conditions or a test duration. The actual testing requirements might be very specific, for example, in order to investigate the suitability of a range of materials for a given application in which certain specified conditions occur. This European Standard provides recommended methods for undertaking the assessment of the effect of corrosion and provides guidance on practical issues related to undertaking the tests.

EN 12923-1:2006 is classified under the following ICS (International Classification for Standards) categories: 81.060.99 - Other standards related to ceramics. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12923-1:2006 has the following relationships with other standards: It is inter standard links to ENV 12923-1:1997, EN ISO 17092:2023, EN 60584-1:2013, ISO 6906:1984, EN 843-1:2006, EN 623-4:2004, EN 1006:2009, ENV 1186-12:1995, EN 843-4:2005, EN 623-1:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12923-1:2006 is associated with the following European legislation: Standardization Mandates: M/076. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12923-1:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Advanced technical ceramics - Monolithic ceramics - Part 1: General practice for undertaking corrosion testsCéramiques techniques avancées - Céramiques monolithiques - Partie 1: Pratique générale destinée aux essais de corrosionHochleistungskeramik - Monolithische Keramik - Teil 1: Allgemeines zur Durchführung von KorrosionsprüfungenTa slovenski standard je istoveten z:EN 12923-1:2006SIST EN 12923-1:2007en81.060.30Sodobna keramikaAdvanced ceramicsICS:SIST ENV 12923-1:20001DGRPHãþDSLOVENSKI

STANDARDSIST EN 12923-1:200701-maj-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12923-1December 2006ICS 81.060.99Supersedes ENV 12923-1:1997

English VersionAdvanced technical ceramics - Monolithic ceramics - Part 1:General practice for undertaking corrosion testsCéramiques techniques avancées - Céramiquesmonolithiques - Partie 1: Pratique générale destinée auxessais de corrosionHochleistungskeramik - Monolithische Keramik - Teil 1:Allgemeines zur Durchführung von KorrosionsprüfungenThis European Standard was approved by CEN on 25 November 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12923-1:2006: E

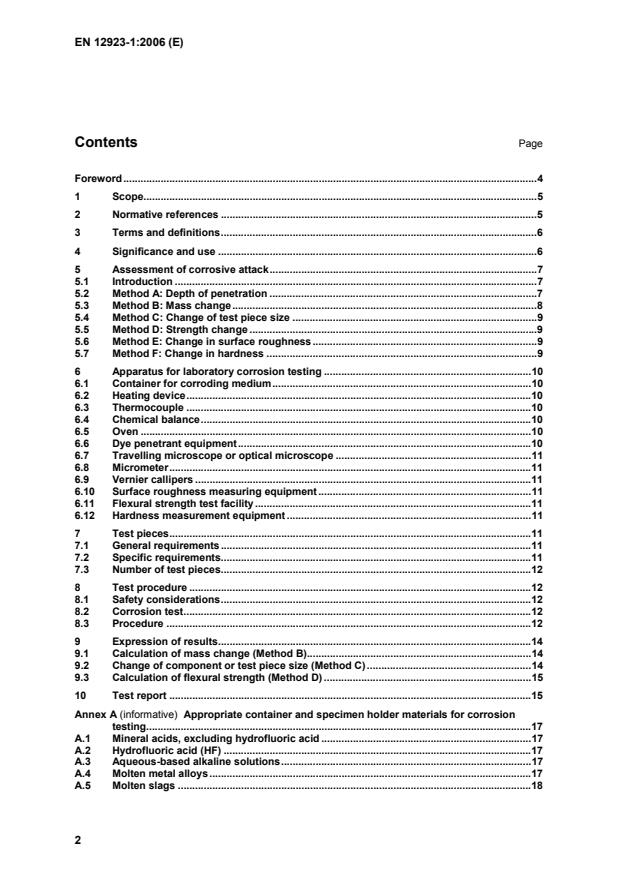

Appropriate container and specimen holder materials for corrosion testing.17 A.1 Mineral acids, excluding hydrofluoric acid.17 A.2 Hydrofluoric acid (HF).17 A.3 Aqueous-based alkaline solutions.17 A.4 Molten metal alloys.17 A.5 Molten slags.18

Part 1: General practice for undertaking corrosion tests

Part 2: Oxidation test At the time of publication of this edition of Part 1, Part 2 was a European Prestandard. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Appropriate in some

appropriate cases

B. Change of mass Appropriate, but Inappropriate Appropriate if non-

sometimes inadequate

slagging

C. Change of cross- Not always appropriate Appropriate Appropriate section when change is small

D. Change of strength Appropriate Might be

Appropriate if non-

appropriate if adherent

slagging; might be

material is removed appropriate if adherent

material is removed

E. Change of surface Appropriate for slight Usually inappropriate Usually inappropriate roughness corrosion

F. Change of hardness Appropriate Usually inappropriate Might be

appropriate if

non-slagging G. Change of Appropriate Usually inappropriate Appropriate corrodent composition

5.3 Method B: Mass change 5.3.1 Accurate determination of change in dry mass might not properly reflect the extent of attack as a result of either the adherence of solid surface deposits or the retention of corrosion products within porosity generated by corrodent penetration. A change in mass therefore indicates that some attack might have occurred, but other criteria need to be employed to quantify its overall effect on performance. 5.3.2 Assuming that the process of mass gain or mass loss is attributable to the test piece behaviour, accurate determination of change in dry mass relies on being able to minimize contact between the test piece and the apparatus in which it is housed for the duration of the corrosion test. If strong reaction occurs between the test piece surface and its support, a significant error in registered mass change might result. NOTE 1 It might be necessary to perform some preliminary tests to ensure that the supporting material is sufficiently non-reactive with the test material before conducting the required tests. In some atmospheres, for example in low oxygen content atmospheres at high temperatures, the evolution of volatile species from one test piece can interact with or contaminate adjacent test pieces. Cases of this type necessitate separately exposing each test piece to the corroding medium. NOTE 2 For the particular case of high temperature oxidation tests, further information is given in

ENV 12923-2 [1]. 5.3.3 Free circulation of corrodent around the test piece is required. If this is for any reason significantly reduced by the geometrical arrangement of test pieces and supporting apparatus, rates of corrosion might be reduced as the corroding species become consumed. A very high velocity of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...