EN 12201-2:2011

(Main)Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

This European Standard specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40)

for buried and above ground applications, intended for the conveyance of water for human consumption, raw water

prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes.

NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment

attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and

sewerage may not be suitable for water supply for human consumption.

It also specifies the test parameters for the test methods referred to in this standard.

In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with

components of PE and other materials intended to be used under the following conditions:

a) allowable operating pressure, PFA, up to 25 bar 1);

b) an operating temperature of 20 °C as a reference temperature;

c) buried in the ground;

d) sea outfalls;

e) laid in water;

f) above ground, including pipes suspended below bridges.

NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of EN 12201-

1:2011.

NOTE 3 Pipes constructions including barrier layers are not covered by this document.

EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and

additives.

It covers three types of pipe:

PE pipes (outside diameter dn) including any identification stripes;

PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter

dn) as specified in Annex B, where all layers have the same MRS rating;

PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the

pipe (‘coated pipe’) as specified in Annex C.

NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into

account their particular requirements and any relevant national guidance or regulations and installation practices or codes.

NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products

to this document is required in accordance with Table 2 of EN 12201-1:2011.

Kunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: Rohre

Dieser Teil der EN 12201 legt die Anforderungen an erdverlegte und oberirdisch verlegte Rohre aus Poly¬ethy-len (PE 100, PE 80 und PE 40) fest, die für den Transport von Trinkwasser, des zur Aufbereitung vorgesehenen Rohwassers, für Ent¬wässerungs- und Ab¬wasser¬druckleitungen, Unterdruckentwässerungs-systeme sowie für den Transport von Brauchwasser vorgesehen sind.

ANMERKUNG 1 In Zusammenhang mit Rohrleitungsteilen aus PE für den Transport von Trinkwasser einschließlich des aufzubereitenden Rohwassers wird auf diese Europäische Norm, 5.3 verwiesen. Rohrleitungsteile, die für den Transport von Brauchwasser sowie für Entwässerungs- und Abwasserleitungen gefertigt wurden, sind möglicherweise nicht für die Versorgung mit Trinkwasser geeignet.

Er legt auch die Prüfparameter für die Prüfverfahren fest, auf die in dieser Norm verwiesen wird.

Zusammen mit den Teilen 1 sowie 3 bis 5 der EN 12201 gilt dieser Teil für Rohre aus PE, deren Verbin¬dungen untereinander, mit anderen Rohrleitungsteilen aus PE sowie mit Rohrleitungsteilen aus anderen Werkstoffen, die zur Verwendung unter den folgenden Bedingungen vorgesehen sind:

a) maximal zulässiger Betriebsdruck PFA bis 25 bar );

b) eine Betriebstemperatur von 20 °C als Bezugstemperatur;

c) erdverlegt;

d) Entwässerung ins Meer (Siele);

e) in Gewässern verlegt;

f) oberirdisch verlegt, einschließlich Düker und Brückenleitungen.

ANMERKUNG 2 Für Anwendungsgebiete, in denen konstante Betriebstemperaturen von über 20 °C bis höchstens 40 °C auf¬treten, siehe EN 12201-1:2011, Anhang A.

ANMERKUNG 3 Rohre mit Sperrschichten werden in diesem Dokument nicht behandelt.

EN 12201 enthält Festlegungen über maximal zulässige Betriebsdrücke und legt Anforderungen an die Ein-färbung von Rohrleitungsteilen sowie die Verwendung von Zusatzstoffen fest.

Drei Arten von Rohren werden behandelt:

- PE-Rohre (Außendurchmesser dn), einschließlich Identifizierungsstreifen;

- PE-Rohre mit koextrudierten Schichten auf der Außenseite und/oder der Innenseite des Rohres (Gesamt-Außendurchmesser dn), wie in Anhang B festgelegt, wobei alle Schichten denselben MRS-Wert aufweisen;

- PE-Rohre (Außendurchmesser dn), mit einer abziehbaren, aufliegenden thermoplastischen Zusatz¬schicht auf der Außenseite des Rohres („beschichtetes Rohr“), wie in Anhang C festgelegt.

ANMERKUNG 4 Der Anwender bzw. Auftraggeber ist unter Berücksichtigung der eigenen Anforderungen sowie der geltenden nationalen Empfehlungen oder Festlegungen und Verlegepraktiken für die entsprechende Auswahl dieser Kriterien verantwortlich.

ANMERKUNG 5 Die Bewertung des Widerstandes gegen langsames Risswachstum von PE-Formmassen, die für die Herstellung von Produkten nach diesem Dokument verwendet werden, ist nach EN 12201-1:2011, Tabelle 2 erforderlich.

Systèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2: Tubes

La présente partie de l’EN 12201 spécifie les caractéristiques des tubes en polyéthylène (PE 100, PE 80 et PE 40) pour des applications enterrées et non enterrées prévues pour le transport d'eau destinée à la consommation humaine, y compris l'eau brute avant traitement, les branchements et les collecteurs d'assainissement avec pression, les réseaux d'évacuation des eaux usées sous vide et l'eau destinée à d'autres usages

NOTE 1 Pour les composants en PE prévus pour le transport d'eau destinée à la consommation humaine et d'eau brute avant traitement, l'attention est attirée au 5.3 de la présente Norme européenne. Les composants fabriqués pour l'eau destinée à des usages généraux et pour l'assainissement peuvent s'avérer inaptes pour l'alimentation en eau destinée à la consommation humaine.

Elle spécifie également les paramètres d'essai des méthodes d'essai auxquelles il est fait référence dans la présente norme.

Conjointement avec la Partie 1 et les Parties 3 à 5 de l'EN 12201, elle s'applique aux tubes en PE et à leurs assemblages, ainsi qu’à leurs assemblages avec des composants en PE et autres matières, destinés à être utilisés dans les conditions suivantes :

a) avec une pression de service admissible, PFA, jusqu'à 25 bar ) ;

b) à une température de service de 20 °C comme température de référence ;

c) enterrés dans le sol ;

d) comme émissaires de rejet en mer ;

e) posés dans l'eau ;

f) non enterrés, y compris canalisations suspendues sous des ponts.

NOTE 2 Pour les applications à température de service constante supérieure à 20 °C et jusqu'à 40 °C, voir Annexe A de l’EN 12201 1:2011.

NOTE 3 Les systèmes de canalisations incluant des couches barrières ne sont pas couverts par ce document.

L’EN 12201 couvre une plage de pressions de service admissibles et définit des exigences concernant les couleurs et les additifs.

Elle concerne trois types de tubes :

- les tubes en PE (diamètre extérieur dn) y compris toutes bandes d'identification éventuelles ;

- les tubes en PE comportant des couches co-extrudées soit sur leur surface externe ou interne, soit sur leurs deux surfaces (diamètre extérieur total dn), tel que spécifié dans l'Annexe B, où toutes les couches ont la même classification MRS ;

- les tubes en PE (diamètre extérieur dn) comportant une couche supplémentaire thermoplastique contiguë pelable sur leur surface externe (« tube revêtu »), tel que spécifié dans l’Annexe C.

NOTE 4 Il incombe à l'acheteur ou au prescripteur la responsabilité de réaliser une sélection convenable de ces aspects en prenant en compte les exigences particulières ainsi que les directives ou règles nationales et les pratiques et codes de pose en usage dans son pays.

NOTE 5 L’évaluation de la résistance à la propagation lente de la fissure de la composition pour tube en PE utilisée pour fabriquer des produits correspondant au présent document est nécessaire, conformément au Tableau 2 de l’EN 12201 1:2011.

Cevni sistemi iz polimernih materialov za oskrbo z vodo in za odvodnjavanje in kanalizacijo pod tlakom - Polietilen (PE) - 2. del: Cevi

Ta del EN 12201 določa značilnosti cevi iz polietilena (PE), ki so namenjene prenosu vode za prehrano ljudi, vključno z neobdelano vodo pred obdelavo. Določa tudi preskusne parametre za preskusne metode, navedene v tem standardu. Skupaj z drugimi deli EN 12201 velja za PE-cevi, njihove spoje in spoje s komponentami iz PE in drugih materialov, namenjene uporabi v naslednjih pogojih: a) najvišji obratovalni tlak, MOP, do vključno 25 bar, b) obratovalna temperatura 20 °C kot referenčna temperatura.

General Information

- Status

- Withdrawn

- Publication Date

- 06-Sep-2011

- Withdrawal Date

- 24-Sep-2013

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 25-Sep-2013

- Completion Date

- 25-Sep-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

EN 12201-2:2003 - Plastics piping systems for water supply - Polyethylene (PE) - Part 2: Pipes - Effective Date

- 01-Apr-2009

- Effective Date

- 01-Apr-2009

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12201-2:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes". This standard covers: This European Standard specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40) for buried and above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes. NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and sewerage may not be suitable for water supply for human consumption. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with components of PE and other materials intended to be used under the following conditions: a) allowable operating pressure, PFA, up to 25 bar 1); b) an operating temperature of 20 °C as a reference temperature; c) buried in the ground; d) sea outfalls; e) laid in water; f) above ground, including pipes suspended below bridges. NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of EN 12201- 1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document. EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: PE pipes (outside diameter dn) including any identification stripes; PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

This European Standard specifies the characteristics of pipes made from polyethylene (PE 100, PE 80 and PE 40) for buried and above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes. NOTE 1 For PE components intended for the conveyance of water for human consumption and raw water prior to treatment attention is drawn to 5.3 of this European Standard. Components manufactured for water for general purposes, drainage and sewerage may not be suitable for water supply for human consumption. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Part 1 and Parts 3 to 5 of EN 12201, it is applicable to PE pipes, their joints and to joints with components of PE and other materials intended to be used under the following conditions: a) allowable operating pressure, PFA, up to 25 bar 1); b) an operating temperature of 20 °C as a reference temperature; c) buried in the ground; d) sea outfalls; e) laid in water; f) above ground, including pipes suspended below bridges. NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of EN 12201- 1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document. EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: PE pipes (outside diameter dn) including any identification stripes; PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

EN 12201-2:2011 is classified under the following ICS (International Classification for Standards) categories: 23.040.05 - Pipeline and its parts for external sewage systems; 23.040.20 - Plastics pipes; 91.140.60 - Water supply systems; 93.020 - Earthworks. Excavations. Foundation construction. Underground works; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12201-2:2011 has the following relationships with other standards: It is inter standard links to EN 12201-2:2003, EN 13244-2:2002, EN 12201-2:2011+A1:2013, ISO 11357-6:2008, ISO 6259-3:1997, EN ISO 6259-1:2015, EN ISO 1167-1:2006, EN ISO 13968:2008, EN 3858:2002, EN ISO 2505:2023, EN 15309:2007, EN ISO 9969:2016, EN ISO 3126:2005, EN 12201-5:2024, EN ISO 1133-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12201-2:2011 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12201-2:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Cevni sistemi iz polimernih materialov za oskrbo z vodo in za odvodnjavanje in kanalizacijo pod tlakom - Polietilen (PE) - 2. del: CeviKunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: RohreSystèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2: TubesPlastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes93.030Zunanji sistemi za odpadno vodoExternal sewage systems91.140.60Sistemi za oskrbo z vodoWater supply systems23.040.20Cevi iz polimernih materialovPlastics pipesICS:Ta slovenski standard je istoveten z:EN 12201-2:2011SIST EN 12201-2:2011en,fr,de01-december-2011SIST EN 12201-2:2011SLOVENSKI

STANDARDSIST EN 13244-2:2003SIST EN 12201-2:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12201-2

September 2011 ICS 23.040.20 Supersedes EN 12201-2:2003, EN 13244-2:2002English Version

Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes

Systèmes de canalisations en plastique pour l'alimentation en eau et pour les branchements et les collecteurs d'assainissement avec pression - Polyéthylène (PE) - Partie 2: Tubes

Kunststoff-Rohrleitungssysteme für die Wasserversorgung und für Entwässerungs- und Abwasserdruckleitungen - Polyethylen (PE) - Teil 2: Rohre This European Standard was approved by CEN on 8 July 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12201-2:2011: ESIST EN 12201-2:2011

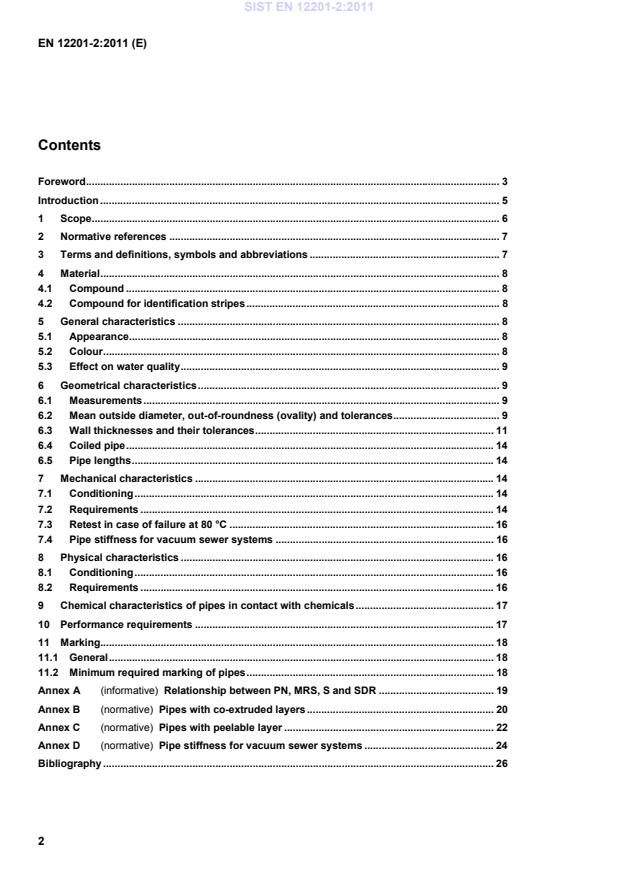

Relationship between PN, MRS, S and SDR . 19Annex B(normative)

Pipes with co-extruded layers . 20Annex C(normative)

Pipes with peelable layer . 22Annex D(normative)

Pipe stiffness for vacuum sewer systems . 24Bibliography . 26 SIST EN 12201-2:2011

System Standards are based on the results of the work being undertaken in ISO/TC 138, "Plastics pipes, fittings and valves for the transport of fluids", which is a Technical Committee of the International Organization for Standardization (ISO). They are supported by separate standards on test methods to which references are made throughout the System Standard.

The System Standards are consistent with general standards on functional requirements and on recommended practice for installation.

EN 12201 consists of the following parts: EN 12201-1:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 1: General; EN 12201-2:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 2: Pipes (this standard); EN 12201-3:, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 3: Fittings; EN 12201-4 , Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 4: Valves for water supply systems; EN 12201-5, Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 5: Fitness for purpose of the system; CEN/TS 12201-7, Plastics piping systems for water supply — Polyethylene (PE) — Part 7: Guidance for the assessment of conformity.

In this revision, the scope of this standard includes two additional types of pipe;- PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe as specified in Annex B, where all layers have the same MRS rating; PE pipes with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. In this revision, pipe diameters specified have been increased to 2500 mm. Test methods have been updated as appropriate and in accordance with other parts of this standard.

EN 12201-1:2011, EN 12201-3:2011 [1] and prEN 12201-4:2011 [2]. Characteristics for fitness of purpose are covered in EN 12201-5:2011 and CEN/TS 12201-7 [3] gives guidance for the assessment of conformity. This Part of EN 12201 covers the characteristics of pipes. SIST EN 12201-2:2011

NOTE 2 For applications operating at constant temperatures greater than 20 °C and up to 40 °C, see Annex A of

EN 12201-1:2011. NOTE 3 Pipes constructions including barrier layers are not covered by this document.

EN 12201 covers a range of allowable operating pressures and gives requirements concerning colours and additives. It covers three types of pipe: PE pipes (outside diameter dn) including any identification stripes; PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe (total outside diameter dn) as specified in Annex B, where all layers have the same MRS rating; PE pipes (outside diameter dn) with a peelable, contiguous thermoplastics additional layer on the outside of the pipe (‘coated pipe’) as specified in Annex C. NOTE 4 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national guidance or regulations and installation practices or codes. NOTE 5 Assessment of the resistance to slow crack growth of the PE pipe compound used for the manufacture of products to this document is required in accordance with Table 2 of EN 12201-1:2011.

1) 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2. SIST EN 12201-2:2011

EN ISO 13968, Plastics piping and ducting systems —Thermoplastics pipes — Determination of ring flexibility (ISO 13968:2008) ISO 4433-1:1997, Thermoplastics pipes — Resistance to liquid chemicals — Classification — Part 1: Immersion test method ISO 4433-2:1997, Thermoplastics pipes — Resistance to liquid chemicals — Classification — Part 2: Polyolefin pipes ISO 6259-3:1997, Thermoplastics pipes — Determination of tensile properties — Part 3: Polyolefin pipes ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) 3 Terms and definitions, symbols and abbreviations For the purposes of this document, the terms and definitions, symbols and abbreviations given in

EN 12201-1 apply. SIST EN 12201-2:2011

The ends of the pipe shall be cut cleanly and square to the axis of the pipe. 5.2 Colour Pipes intended for the conveyance of water for human consumption shall be black or blue. In addition, black pipes may be identified by blue stripes, according to national preference. Blue pipes or black pipes with blue stripes are intended for the conveyance of water for human consumption only.

Pipes intended for other purposes, drainage and sewerage shall be black or black with brown stripes or according to national preference.

The outer coextruded layer of coextruded pipes (see Annex B) or the outer peelable layer of peelable layer pipes (see Annex C) for pipe intended for the conveyance of water for human consumption shall be either black or blue. In addition identification stripes may be used according to national preference for the application. The outer coextruded layer of coextruded pipes (see Annex B) or the outer peelable layer of peelable layer pipes (see Annex C) for pipe intended for other purposes shall be either black or black with brown stripes or brown or according to national preference. In addition identification stripes of a different colour may be used according to national preference for the application.

NOTE 1 In some countries, pipes made from non-pigmented compound in conjunction with an external peelable layer are permitted, providing the compound conforms to the requirements of this standard. If this is allowed in a country, this should be clearly stated in the national foreword. NOTE 2 For above ground installations, all components other than black should be protected from direct UV light. NOTE 3 The national preference for colour should be stated in the National Foreword. SIST EN 12201-2:2011

1 000

1 200 1 400 1 600 1 800 2 000

2 250

2 500 16 20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 1 000 1 200 1 400 1 600 1 800 2 000

2 250

2 500

16,0 20,0 25,0 32,0 40,0 50,0 63,0 75,0 90,0 110,0 125,0 140,0 160,0 180,0 200,0 225,0 250,0 280,0 315,0 355,0 400,0 450,0 500,0 560,0 630,0 710,0 800,0 900,0 1 000,0 1 200,0 1 400,0 1 600,0

1 800,0 2 000,0

2 250,0

2 500,0 16,3 20,3 25,3 32,3 40,4 50,4 63,4 75,5 90,6 110,7 125,8 140,9 161,0 181,1 201,2 226,4 251,5 281,7 316,9 357,2 402,4 452,7 503,0 563,4 633,8 716,4 807,2 908,1 1 009,0 1 210,8 c 1 412,6 c 1 614,4 c 1 816,2 c

2 018,0 c

2270,3 c

2522,5 c

1,2 1,2 1,2 1,3 1,4 1,4 1,5 1,6 1,8 2,2 2,5 2,8 3,2 3,6 4,0 4,5 5,0 9,8 11,1 12,5 14,0 15,6 17,5 19,6 22,1 24,9 28,0 — — — — — —

—

—

—

a

In accordance with ISO 11922-1:1997 [7] grade B for sizes ≤ 630 and grade A for sizes > 710 except for dn 40 and 50. b In accordance with ISO 11922-1:1997 [7] grade N for sizes ≤ 630 and is measured at the point of manufacture. c

Tolerance calculated as 0,009dn and does not conform to grade A in ISO 11922-1:1997 [7]. d For straight lengths of pipe with diameters ≥ 900 the maximum out-of-roundness shall be agreed between the manufacturer and the purchaser.

NOTE 2 Tolerance bands in accordance with ISO 11922-1:1997 [7] are calculated using the following formulae, as applicable. a)

Grade A: 0,009dn rounded to the next greater 0,1 mm with a minimum value of 0,3 mm and a maximum value of 10,0 mm; b)

Grade B: 0,006dn rounded up to the next greater 0,1 mm with a minimum value of 0,3 mm and a maximum value of 4,0 mm; c)

Grade N:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...