EN 12732:2021

(Main)Gas infrastructure - Welding steel pipework - Functional requirements

Gas infrastructure - Welding steel pipework - Functional requirements

This document contains requirements for the production and testing of weld joints for the installation and modification, including in-service welding, of onshore steel pipelines and pipework used in gas infrastructure. This includes all pressure ranges and processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 and non-conventional gases such as (injected) biomethane and hydrogen, where:

- the pipeline elements are made of unalloyed or low-alloyed carbon steel;

- the pipeline is not located within commercial or industrial premises as integral part of the industrial process on those premises except for any pipelines and facilities delivering gas to such premises;

- the pipework is not located within households or industrial installations according to EN 1775 or EN 15001;

- the design temperature of the system is between −40 °C up to and including 120 °C.

For injected biomethane or hydrogen a detailed technical evaluation of the functional requirements is required, ensuring there are no other constituents or properties of the gases that can affect the integrity of the pipeline.

This document is not applicable to welds produced prior to the publication of this document.

This document specifies common basic principles for gas infrastructure. Users of this document are expected to be aware that there can exist more detailed national standards and/or codes of practice in the CEN member countries.

This document is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles.

In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this document, the national legislation/regulation takes precedence as illustrated in CEN/TR 13737 (all parts).

NOTE CEN/TR 13737 (all parts) contains:

- clarification of relevant legislation/regulations applicable in a country;

- if appropriate, more restrictive national requirements;

- national contact point for the latest information.

Gasinfrastruktur - Schweißen an Rohrleitungen aus Stahl - Funktionale Anforderungen

Dieses Dokument enthält Anforderungen für die Herstellung und Prüfung von Schweißverbindungen für die Errichtung und Änderungen (einschließlich Schweißen an in Betrieb befindlichen Leitungen) von landverlegten Stahlrohrleitungen und Anlagen, die in der Gasinfrastruktur verwendet werden. Dazu gehören alle Druckbereiche und aufbereitetes, ungiftiges und nicht korrosives Erdgas nach EN ISO 13686 und nichtkonventionelle Gase wie (eingespeistes) Biomethan und Wasserstoff, wo:

— die Rohrleitungsteile aus nicht legiertem oder niedrig legiertem Kohlenstoffstahl bestehen;

— alle Leitungen und Anlagen, die sich auf Gewerbe- oder Werksgelände befinden, ausschließlich der Versorgung solcher Grundstücke dienen und kein wesentlicher Bestandteil der Anlagen für Betriebsabläufe auf diesem Gelände sind;

— es sich nicht um Leitungen innerhalb von Haus- oder Industrieinstallationen nach EN 1775 oder EN 15001 handelt;

— die Auslegungstemperatur zwischen −40 °C bis einschließlich 120 °C liegt.

Für eingespeistes Biomethan oder Wasserstoff ist eine detaillierte technische Bewertung der funktionellen Anforderungen erforderlich, um sicherzustellen, dass es keine anderen Bestandteile oder Eigenschaften der Gase gibt, die die Integrität der Leitung beeinträchtigen können.

Dieses Dokument ist nicht auf Schweißnähte anwendbar, die vor der Veröffentlichung dieses Dokuments erstellt wurden.

Dieses Dokument legt gemeinsame Grundprinzipien für die Gasinfrastruktur fest. Es wird erwartet, dass Anwender dieses Dokuments sich dessen bewusst sind, dass detailliertere nationale Normen bzw. Technische Regeln in den CEN-Mitgliedsländern existieren können.

Dieses Dokument ist für die Anwendung in Verbindung mit diesen nationalen Normen und/oder Verfahrensregeln vorgesehen, welche die vorstehend genannten Grundsätze darlegen.

Beim Auftreten von Widersprüchen aufgrund restriktiver Anforderungen in nationalen Gesetzen/Vorschriften als in diesem Dokument gefordert, haben nationale Gesetze/Vorschriften Vorrang wie in CEN/TR 13737 (alle Teile) dargestellt.

ANMERKUNG CEN/TR 13737 (alle Teile) enthält:

— Klärung relevanter in einem Land anwendbarer Rechtsvorschriften/Regelungen;

— gegebenenfalls restriktivere nationale Anforderungen;

— nationale Anlaufstelle für die neusten Informationen.

Infrastructures gazières - Soudage des tuyauteries en acier - Prescriptions fonctionnelles

Le présent document contient des prescriptions relatives à l’exécution et au contrôle des assemblages soudés pour l’installation et la modification, y compris les activités de soudage en service, des tuyauteries et canalisations terrestres en acier utilisées dans les infrastructures gazières. Cela inclut toutes les plages de pression pour le transport de gaz naturel non toxique et non corrosif conformément à l’EN ISO 13686, ainsi que les gaz non conventionnels tels que le biométhane et l’hydrogène (injectés) lorsque :

- les éléments de canalisations sont réalisés en acier au carbone non ou faiblement allié ;

- la canalisation n’est pas située dans des sites commerciaux ou industriels comme partie intégrante du procès industriel réalisé sur ces sites, à l’exception des canalisations et installations servant à alimenter ces derniers ;

- la tuyauterie n’est pas située à l’intérieur d’installations domestiques conformément à l’EN 1775 ou à l'EN 15001 ;

- la température de conception du système est comprise entre –40 °C et 120 °C inclus.

Pour le biométhane ou l'hydrogène injecté, une évaluation technique détaillée des prescriptions fonctionnelles est nécessaire afin de s'assurer qu'aucun autre composant ou propriété des gaz peut nuire à l'intégrité de la canalisation.

Le présent document ne s’applique pas aux assemblages soudés préexistant à sa publication.

Le présent document spécifie les principes de base communs pour les infrastructures gazières. Il convient que les utilisateurs du présent document gardent à l’esprit l’existence éventuelle, dans les pays membres du CEN, de codes de pratique et/ou de normes nationales plus détaillés.

Le présent document est destiné à être appliqué conjointement avec ces Normes nationales et/ou codes de pratique, qui détaillent les principes de base précités.

En cas de conflits liés à des exigences législatives/réglementaires plus restrictives que les prescriptions du présent document, la législation/réglementation nationale doit prévaloir, comme illustré dans le CEN/TR 13737 (toutes parties).

NOTE Le CEN/TR 13737 (toutes parties) contient :

- la clarification de la législation/réglementation pertinente applicable dans un pays ;

- si approprié, les exigences nationales plus restrictives ;

- le contact national pour les dernières informations.

Infrastruktura za plin - Varjenje jeklenih cevovodov - Funkcionalne zahteve

Ta evropski standard vsebuje zahteve za izdelavo in preskušanje zvarnih spojev za namestitev in spremembe kopenskih jeklenih cevovodov in cevovodnih sistemov, ki se uporabljajo v infrastrukturi za plin, vključno z obratovalnimi cevovodi, za vse razpone tlakov za prenos obdelanega, nestrupenega in nekorozivnega zemeljskega plina v skladu s standardom EN ISO 13686 ter za prenos nekonvencionalnih plinov, kot je vbrizgani biometan, vključno z vodikom,

pri čemer:

– so elementi cevovoda izdelani iz nelegiranega ali malo legiranega ogljikovega jekla;

– cevovod ni nameščen znotraj poslovnih ali industrijskih območij kot sestavni del industrijskega postopka na teh območjih, razen cevovodov in opreme za dostavo plina na ta območja;

– cevovod ni nameščen znotraj gospodinjskih inštalacij v skladu s standardom EN 1775;

– je načrtovana temperatura sistema od –40 °C do vključno 120 °C.

Kopenski jekleni cevovodi in cevovodni sistemi, ki se uporabljajo v infrastrukturi za plin, vključujejo obratovalne cevovode in so namenjeni za vse razpone tlakov za prenos obdelanega, nestrupenega in nekorozivnega zemeljskega plina v skladu s standardom EN ISO 13686 ter za prenos nekonvencionalnih plinov v skladu s standardom EN ISO 13686, pri čemer se zanje izvede podrobno tehnično vrednotenje funkcionalnih zahtev (kot npr. za vbrizgani biometan, vodik), ki zagotavlja, da plini nimajo drugih sestavin ali lastnosti, ki lahko vplivajo na neoporečnost cevovoda.

Ta standard se ne uporablja za zvare, izdelane pred objavo tega evropskega standarda.

Preglednica 1 določa področja uporabe za kakovostne kategorije kot funkcijo delovnega tlaka in materialov, uporabljenih za cevi.

Dodatne zahteve so lahko določene, če je na primer:

– obremenitev cevovodov in cevnih sistemov,

– materialov,

– usmerjanje povezav,

– zasnova ali tehnika varjenja

nujna.

General Information

- Status

- Published

- Publication Date

- 16-Nov-2021

- Withdrawal Date

- 30-May-2022

- Technical Committee

- CEN/TC 234 - Gas infrastructure

- Drafting Committee

- CEN/TC 234/WG 3 - Gas Transportation

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 17-Nov-2021

- Due Date

- 30-Oct-2021

- Completion Date

- 17-Nov-2021

Relations

- Replaces

EN 12732:2013+A1:2014 - Gas infrastructure - Welding steel pipework - Functional requirements - Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12732:2021 (EN 12732:2021) defines functional requirements for welding steel pipework used in gas infrastructure. It covers production, inspection and testing of weld joints for installation, modification and in-service welding of onshore steel pipelines and pipework carrying processed, non-toxic and non‑corrosive natural gas (per EN ISO 13686), and non‑conventional gases such as injected biomethane and hydrogen (subject to detailed technical evaluation). The standard applies to pipelines made from unalloyed or low‑alloy carbon steel with design temperatures from −40 °C to 120 °C and to all pressure ranges, while excluding certain in‑building and household pipework per EN 1775 / EN 15001. It is intended to be used alongside national standards and codes of practice; national legislation takes precedence where more restrictive.

Key topics and technical requirements

- Scope & applicability: Onshore gas transmission and distribution pipelines (exclusions noted); not retroactive to welds produced before publication.

- Quality system requirements: Expectations for documented processes and traceability for welding operations.

- Welding contractors & procedures: Qualification and control of contractors, welding procedure specifications (WPS), preheat/post‑weld rules.

- Welder and operator qualifications: Criteria and additional requirements (see Annex A) for manual and mechanized welding personnel.

- Production welding: Joint types, preparation, tack welding, repair rules and destructive testing thresholds (e.g., DP over 16 bar).

- Attachment & in‑service welding: Hot‑tapping, cathodic protection connections and safety/supervision for live repairs (Annex D).

- Inspection & testing: Non‑destructive testing (NDT) methods, destructive testing (DT), acceptance levels (including AUT, UT, TOFD, RT) and documentation requirements (Annexes C, E, F, J).

- Specific acceptance criteria: Visual, radiographic and other NDT acceptance criteria (Annexes G, H, I).

- Ancillary guidance: Topics such as brazing, stud welding for cathodic protection and differences from previous editions (Annexes K, L).

Practical applications and users

This standard is essential for:

- Pipeline owners and operators (asset integrity, construction, maintenance)

- Welding contractors and fabrication shops (WPS, qualifications)

- Inspection and NDT providers (AUT, UT, TOFD, RT procedures)

- Design engineers, project managers and safety officers (hot‑tap and in‑service welding)

- Regulators and auditors ensuring compliance with gas infrastructure safety practices

Use EN 12732 to establish consistent welding controls, ensure qualified personnel, specify appropriate NDT/acceptance criteria, and document welded joint integrity for gas pipeline projects.

Related standards and notes

- Intended to be applied with relevant national standards/codes of practice; national legislation supersedes where more restrictive (see CEN/TR 13737).

- Referenced international standards include EN ISO 13686, EN 1775, EN 15001 and various EN/ISO welding and NDT standards cited in the normative references.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 12732:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas infrastructure - Welding steel pipework - Functional requirements". This standard covers: This document contains requirements for the production and testing of weld joints for the installation and modification, including in-service welding, of onshore steel pipelines and pipework used in gas infrastructure. This includes all pressure ranges and processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 and non-conventional gases such as (injected) biomethane and hydrogen, where: - the pipeline elements are made of unalloyed or low-alloyed carbon steel; - the pipeline is not located within commercial or industrial premises as integral part of the industrial process on those premises except for any pipelines and facilities delivering gas to such premises; - the pipework is not located within households or industrial installations according to EN 1775 or EN 15001; - the design temperature of the system is between −40 °C up to and including 120 °C. For injected biomethane or hydrogen a detailed technical evaluation of the functional requirements is required, ensuring there are no other constituents or properties of the gases that can affect the integrity of the pipeline. This document is not applicable to welds produced prior to the publication of this document. This document specifies common basic principles for gas infrastructure. Users of this document are expected to be aware that there can exist more detailed national standards and/or codes of practice in the CEN member countries. This document is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles. In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this document, the national legislation/regulation takes precedence as illustrated in CEN/TR 13737 (all parts). NOTE CEN/TR 13737 (all parts) contains: - clarification of relevant legislation/regulations applicable in a country; - if appropriate, more restrictive national requirements; - national contact point for the latest information.

This document contains requirements for the production and testing of weld joints for the installation and modification, including in-service welding, of onshore steel pipelines and pipework used in gas infrastructure. This includes all pressure ranges and processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 and non-conventional gases such as (injected) biomethane and hydrogen, where: - the pipeline elements are made of unalloyed or low-alloyed carbon steel; - the pipeline is not located within commercial or industrial premises as integral part of the industrial process on those premises except for any pipelines and facilities delivering gas to such premises; - the pipework is not located within households or industrial installations according to EN 1775 or EN 15001; - the design temperature of the system is between −40 °C up to and including 120 °C. For injected biomethane or hydrogen a detailed technical evaluation of the functional requirements is required, ensuring there are no other constituents or properties of the gases that can affect the integrity of the pipeline. This document is not applicable to welds produced prior to the publication of this document. This document specifies common basic principles for gas infrastructure. Users of this document are expected to be aware that there can exist more detailed national standards and/or codes of practice in the CEN member countries. This document is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles. In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this document, the national legislation/regulation takes precedence as illustrated in CEN/TR 13737 (all parts). NOTE CEN/TR 13737 (all parts) contains: - clarification of relevant legislation/regulations applicable in a country; - if appropriate, more restrictive national requirements; - national contact point for the latest information.

EN 12732:2021 is classified under the following ICS (International Classification for Standards) categories: 25.160.40 - Welded joints and welds. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12732:2021 has the following relationships with other standards: It is inter standard links to EN 12732:2013+A1:2014, EN ISO 15614-1:2017, EN ISO 20378:2018, EN ISO 18275:2018, EN ISO 17637:2016, EN ISO 5817:2023, EN 10204:2004, EN ISO 23279:2017, EN ISO 11666:2018, EN ISO 9606-1:2017, EN ISO 14341:2020, EN ISO 6520-1:2007, EN ISO 9692-1:2013, EN ISO 19285:2017, EN ISO 14171:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12732:2021 is associated with the following European legislation: Standardization Mandates: M/017. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12732:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Nadomešča:

SIST EN 12732:2013+A1:2014

Infrastruktura za plin - Varjenje jeklenih cevovodov - Funkcionalne zahteve

Gas infrastructure - Welding steel pipework - Functional requirements

Gasinfrastruktur - Schweißen an Rohrleitungen aus Stahl - Funktionale Anforderungen

Infrastructures gazières - Soudage des tuyauteries en acier - Prescriptions fonctionnelles

Ta slovenski standard je istoveten z: EN 12732:2021

ICS:

25.160.40 Varjeni spoji in vari Welded joints and welds

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12732

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2021

EUROPÄISCHE NORM

ICS 25.160.40 Supersedes EN 12732:2013+A1:2014

English Version

Gas infrastructure - Welding steel pipework - Functional

requirements

Infrastructures gazières - Soudage des tuyauteries en Gasinfrastruktur - Schweißen an Rohrleitungen aus

acier - Prescriptions fonctionnelles Stahl - Funktionale Anforderungen

This European Standard was approved by CEN on 3 October 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12732:2021 E

worldwide for CEN national Members.

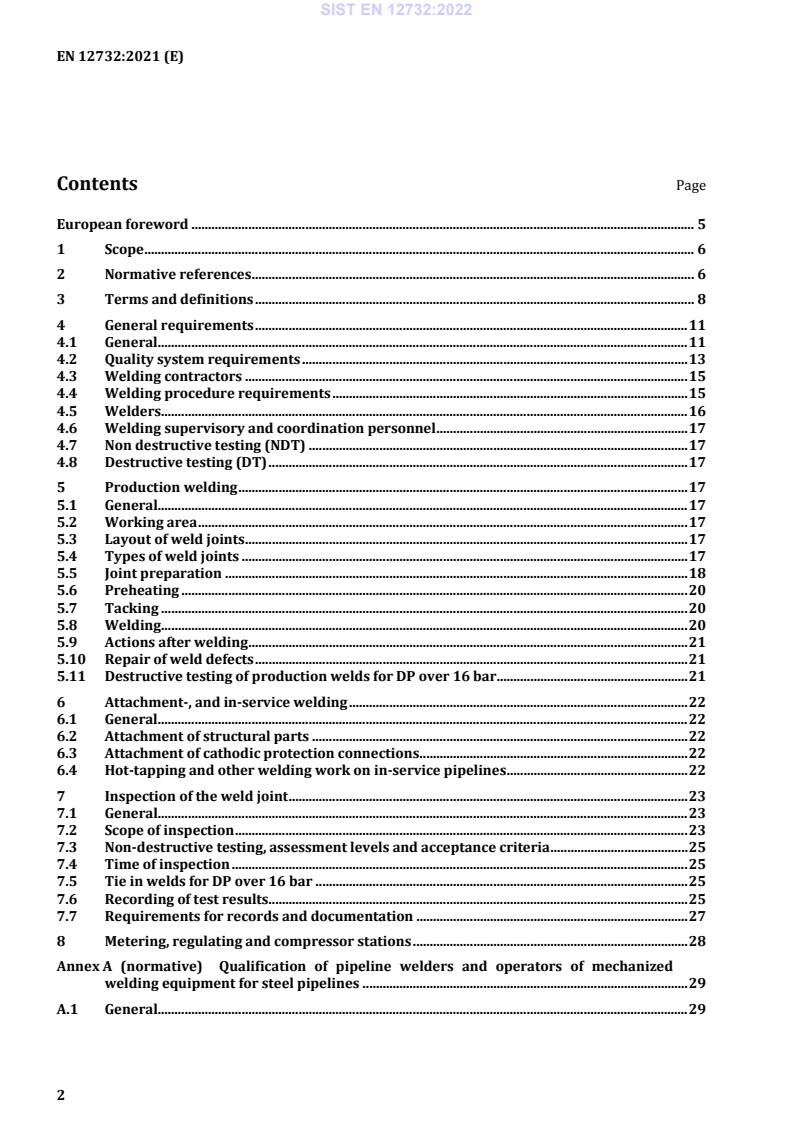

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 General requirements . 11

4.1 General. 11

4.2 Quality system requirements . 13

4.3 Welding contractors . 15

4.4 Welding procedure requirements . 15

4.5 Welders. 16

4.6 Welding supervisory and coordination personnel . 17

4.7 Non destructive testing (NDT) . 17

4.8 Destructive testing (DT) . 17

5 Production welding . 17

5.1 General. 17

5.2 Working area . 17

5.3 Layout of weld joints . 17

5.4 Types of weld joints . 17

5.5 Joint preparation . 18

5.6 Preheating . 20

5.7 Tacking . 20

5.8 Welding . 20

5.9 Actions after welding . 21

5.10 Repair of weld defects . 21

5.11 Destructive testing of production welds for DP over 16 bar . 21

6 Attachment-, and in-service welding . 22

6.1 General. 22

6.2 Attachment of structural parts . 22

6.3 Attachment of cathodic protection connections . 22

6.4 Hot-tapping and other welding work on in-service pipelines . 22

7 Inspection of the weld joint . 23

7.1 General. 23

7.2 Scope of inspection . 23

7.3 Non-destructive testing, assessment levels and acceptance criteria . 25

7.4 Time of inspection . 25

7.5 Tie in welds for DP over 16 bar . 25

7.6 Recording of test results. 25

7.7 Requirements for records and documentation . 27

8 Metering, regulating and compressor stations . 28

Annex A (normative) Qualification of pipeline welders and operators of mechanized

welding equipment for steel pipelines . 29

A.1 General. 29

A.2 Additional requirements to EN ISO 9606-1:2017 and EN ISO 14732:2013 . 29

A.3 Additional requirements for operators of mechanized welding equipment . 30

Annex B (informative) Testing on lamination defects . 31

Annex C (informative) Time-of-flight diffraction technique (TOFD) . 32

C.1 General . 32

C.2 Additional and substitutional requirements to EN ISO 10863:2011 . 32

Annex D (normative) Critical aspects for hot-tap welding or welding on in-service pipelines . 41

D.1 General . 41

D.2 procedural requirements . 41

D.3 Supervision . 42

D.4 Safety precautions . 42

D.5 Welding consumables . 42

D.6 Welding procedure specification (WPS) . 43

D.7 Welding procedure qualification for in-service welding . 43

D.8 Qualification of the welder . 43

D.9 Weld preparation long seam . 43

D.10 Weld preparation circular seam . 43

D.11 Repairs . 44

D.12 Non-destructive testing . 44

D.13 Pressure test . 44

D.14 Documentation . 44

Annex E (normative) AUT examination of joints . 45

E.1 Extent of this annex . 45

E.2 General Requirements . 45

E.3 Field Inspection . 52

E.4 Adjustments of the AUT system . 54

E.5 Acceptance criteria tier 1 . 54

E.6 Acceptance criteria tier 2 . 56

Annex F (informative) Manual ultrasonic testing of weld joints for wall thickness between

approximately 6 mm and 8 mm . 60

F.1 General . 60

F.2 Setting of range . 60

F.3 Sensitivity adjustment when using the Distance Gain Size method . 60

Annex G (normative) EPRG acceptance criteria . 64

G.1 General . 64

G.2 EPRG defect acceptance levels and defect limits . 64

G.3 Requirements . 65

Annex H (normative) Visual acceptance criteria according to EN ISO 5817:2014 . 71

Annex I (normative) RT acceptance criteria according to EN ISO 10675 and

EN ISO 5817:2014 . 73

Annex J (normative) Alternative method and acceptance criteria for UT inspection . 75

J.1 Distance Gain Size method . 75

J.2 Comparative Element method. 75

J.3 General. 75

Annex K (informative) Brazing and stud welding of connections for cathodic protection

systems . 77

K.1 Joining techniques . 77

K.2 Procedure qualification . 77

K.3 Operation qualification . 78

K.4 Production joints . 78

Annex L (informative) Significant technical changes between this European Standard and

the previous edition . 79

Bibliography . 80

European foreword

This document (EN 12732:2021) has been prepared by Technical Committee CEN/TC 234 “Gas

infrastructure”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2022, and conflicting national standards shall be

withdrawn at the latest by May 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12732:2013+A1:2014.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

Annex L provides details of significant technical changes between this document and the previous

edition.

There is a complete suite of functional standards prepared by CEN/TC 234 “Gas infrastructure” to cover

all parts from the input of gas to the transmission system up to the inlet connection of the gas

appliances, whether for domestic, commercial or industrial purposes.

In preparing this document, a basic understanding of gas infrastructure by the user has been assumed.

Gas infrastructure is complex and the importance on safety of its construction and use has led to the

development of very detailed codes of practice and operating manuals in the member countries. These

detailed statements embrace recognized standards of gas engineering and the specific requirements

imposed by the legal structures of the member countries.

CEN/TC 234 will continue its work updating this standard to the latest developments at regular

intervals.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document contains requirements for the production and testing of weld joints for the installation

and modification, including in-service welding, of onshore steel pipelines and pipework used in gas

infrastructure. This includes all pressure ranges and processed, non-toxic and non-corrosive natural gas

according to EN ISO 13686 and non-conventional gases such as (injected) biomethane and hydrogen,

where:

• the pipeline elements are made of unalloyed or low-alloyed carbon steel;

• the pipeline is not located within commercial or industrial premises as integral part of the industrial

process on those premises except for any pipelines and facilities delivering gas to such premises;

• the pipework is not located within households or industrial installations according to EN 1775 or

EN 15001;

• the design temperature of the system is between −40 °C up to and including 120 °C.

For injected biomethane or hydrogen a detailed technical evaluation of the functional requirements is

required, ensuring there are no other constituents or properties of the gases that can affect the integrity

of the pipeline.

This document is not applicable to welds produced prior to the publication of this document.

This document specifies common basic principles for gas infrastructure. Users of this document are

expected to be aware that there can exist more detailed national standards and/or codes of practice in

the CEN member countries.

This document is intended to be applied in association with these national standards and/or codes of

practice setting out the above-mentioned basic principles.

In the event of conflicts in terms of more restrictive requirements in national legislation/regulation

with the requirements of this document, the national legislation/regulation takes precedence as

illustrated in CEN/TR 13737 (all parts).

NOTE CEN/TR 13737 (all parts) contains:

• clarification of relevant legislation/regulations applicable in a country;

• if appropriate, more restrictive national requirements;

• national contact point for the latest information.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1708-1, Welding - Basic welded joint details in steel - Part 1: Pressurized components

EN 10204, Metallic products - Types of inspection documents

EN ISO 636, Welding consumables - Rods, wires and deposits for tungsten inert gas welding of non-alloy

and fine-grain steels - Classification (ISO 636)

EN ISO 2560, Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and

fine grain steels - Classification (ISO 2560)

EN ISO 3834-2, Quality requirements for fusion welding of metallic materials - Part 2: Comprehensive

quality requirements (ISO 3834-2)

EN ISO 5817, Welding - Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) - Quality levels for imperfections (ISO 5817)

EN ISO 6520-1, Welding and allied processes - Classification of geometric imperfections in metallic

materials - Part 1: Fusion welding (ISO 6520-1)

EN ISO 9606-1:2017, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1:2017)

EN ISO 9692-1, Welding and allied processes - Types of joint preparation - Part 1: Manual metal arc

welding, gas-shielded metal arc welding, gas welding, TIG welding and beam welding of steels (ISO 9692-

1)

EN ISO 9712, Non-destructive testing - Qualification and certification of NDT personnel (ISO 9712)

EN ISO 10675-1:2016, Non-destructive testing of welds - Acceptance levels for radiographic testing - Part

1: Steel, nickel, titanium and their alloys (ISO 10675-1:2016)

EN ISO 10863:2011, Non-destructive testing of welds - Ultrasonic testing - Use of time-of-flight diffraction

technique (TOFD) (ISO 10863:2011)

EN ISO 10893-8, Non-destructive testing of steel tubes - Part 8: Automated ultrasonic testing of seamless

and welded steel tubes for the detection of laminar imperfections (ISO 10893-8)

EN ISO 11666, Non-destructive testing of welds - Ultrasonic testing - Acceptance levels (ISO 11666)

EN ISO 13588, Non-destructive testing of welds - Ultrasonic testing - Use of automated phased array

technology (ISO 13588)

EN ISO 14171, Welding consumables - Solid wire electrodes, tubular cored electrodes and electrode/flux

combinations for submerged arc welding of non alloy and fine grain steels - Classification (ISO 14171)

EN ISO 14174, Welding consumables - Fluxes for submerged arc welding and electroslag welding -

Classification (ISO 14174)

EN ISO 14175, Welding consumables - Gases and gas mixtures for fusion welding and allied processes (ISO

14175)

EN ISO 14341, Welding consumables - Wire electrodes and weld deposits for gas shielded metal arc

welding of non alloy and fine grain steels - Classification (ISO 14341)

EN ISO 14732:2013, Welding personnel - Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2013)

EN ISO 15609-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure specification - Part 1: Arc welding (ISO 15609-1)

EN ISO 15614-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys (ISO

15614-1)

EN ISO 17636-1, Non-destructive testing of welds - Radiographic testing - Part 1: X- and gamma-ray

techniques with film (ISO 17636-1)

EN ISO 17636-2, Non-destructive testing of welds - Radiographic testing - Part 2: X- and gamma-ray

techniques with digital detectors (ISO 17636-2)

EN ISO 17637, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO 17637)

EN ISO 17638, Non-destructive testing of welds - Magnetic particle testing (ISO 17638)

EN ISO 17640, Non-destructive testing of welds - Ultrasonic testing - Techniques, testing levels, and

assessment (ISO 17640)

EN ISO 18275, Welding consumables - Covered electrodes for manual metal arc welding of high-strength

steels - Classification (ISO 18275)

EN ISO 19285, Non-destructive testing of welds - Phased array ultrasonic testing (PAUT) - Acceptance

levels (ISO 19285)

EN ISO 20378, Welding consumables - Rods for gas welding of non-alloy and creep-resisting steels -

Classification (ISO 20378)

EN ISO 23279, Non-destructive testing of welds - Ultrasonic testing - Characterization of discontinuities in

welds (ISO 23279)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

3.1

design pressure

DP

pressure on which design calculations are based

3.2

design temperature

DT

temperature on which the design calculations are based

3.3

round porosity

gas pore in a weld where the length is less as three times the width

3.4

elongated porosity

gas pore in a weld where the length is more than three times the width

3.5

gas

gaseous fuel which is in a gaseous state at a temperature of 15 °C under atmospheric pressure

(1,013 25 bar absolute)

3.6

gas infrastructure

all pipelines, stations and installations from the input of gas to the transmission system up to the inlet

connection of the gas appliances, whether for domestic, commercial or industrial purposes

3.7

gas compressor station

installation used for:

• transporting gas in pipelines;

• compressing gas from a pipeline to a gas storage facility or vice versa

Note 1 to entry: More than one of the above functions could be performed simultaneously or alternately.

3.8

gas distribution system

pipeline system including piping above and below ground and all other equipment necessary to deliver

the gas to the consumer

3.9

gas transmission

activity intended to convey gas from one place to another through pipelines in order to deliver gas to

distribution systems or to industrial consumers

3.10

hot pass

second pass for a cellulosic welded pipe girth weld

3.11

installation

equipment and facilities for the extraction, production, chemical treatment, measurement, control,

storage or off-take of the transported gas

3.12

national requirements

requirements following from applicable national legislation or national standards

3.13

onshore pipeline

buried and/or above ground pipeline including those sections laid in or across inland lakes or water

courses

3.14

pipeline

system of pipework with all associated equipment and stations up to the point of delivery

Note 1 to entry: This pipework is mainly below ground but also includes above ground parts.

3.15

pipeline components

elements from which a pipeline is constructed. The following are distinct pipeline elements: pipe

including cold-formed bends, fittings

Note 1 to entry: Reducers, tees, factory-made elbows and bends, flanges, caps, welding stubs, mechanical joints,

fabrications, manufactured from elements referred above.

Note 2 to entry: Manifolds, slug catchers, pig launching/receiving stations, metering and control runs, equipment.

Note 3 to entry: Valves, expansion joints, insulating joints, pressure regulators, pumps, compressors, dedicated

pressure vessels.

3.16

pipeline operator

private or public organisation authorised to design, construct, and/or operate and maintain the gas

infrastructure, i.e. gas transmission operators (TSO) and gas distribution operators (DSO)

3.17

pipework

assembly of pipes and fittings

3.18

pressure

gauge pressure of the fluid inside the system, measured in static conditions

3.19

root pass

first pass in a single sided pipe girth weld

3.20

station

plant or facility for the operation and/or processing of gas infrastructure

3.21

test pressure

TP

pressure to which a part of the gas infrastructure is subjected to, to ensure safe operation

Note 1 to entry: The test pressure can be different for the different parts of the infrastructure to be tested.

3.22

weld repair

process of repairing a defect that is discovered after the weld has been completed, by additional

welding

Note 1 to entry: The repair can involve complete removal of a cylinder of pipe or removal of a localized area by

grinding or other means followed by additional welding.

3.23

welder

person who holds and manipulates the electrode holder, welding torch or blow pipe by hand

3.24

weld operator

person who operates a mechanized welding system

3.25

welding procedure specification

WPS

document that has been qualified and provides the required variables of the welding procedure to

ensure repeatability during production welding

3.26

temper bead method

weld sequence where the heat-affected zone of the base material is softened as much as possible

3.27

hydrogen dissolved in metal, HDM

amount in ml of diffusible hydrogen in 100 mg of weld metal

4 General requirements

4.1 General

Table 1 assigns the application areas to quality requirement categories as a function of the design

pressure and pipe materials used.

When using this document the following shall be defined by the pipeline operator, the applicable

paragraph is given in brackets:

a) applicable quality requirement category. (scope);

b) applicable quality requirements as defined in Table 2 (4.2);

c) are there specific requirements on visual testing (VT) personnel, and/or qualification (4.2);

d) applicable welding qualification standards (4.2);

e) are all weld metal tensile tests required (4.4);

f) for category B and C, are batch certificates required for welding consumables, when required the

pipeline operator has to define the contents of the certificate (4.4.2);

g) for filler materials not in accordance with listed European standards, is batch qualification with

WPQR allowed (4.4.2);

h) if overmatching weld material is required (4.4.2);

i) if hot deformation for misalignment compensation is allowed for materials of R ≤ 360 MPa (6.2);

t 0,5

j) is the weld always to be covered after completion of welding (5.9);

k) for category D, requirements for repair welding procedures (5.10);

l) extent of NDT techniques (7.2);

m) choice of acceptance criteria (7.3);

n) if the data of NDT need to be delivered to the pipeline operator (7.7);

o) for in-service welds, method, extend and acceptance criteria (D.12).

Additional requirements can be specified when, for example:

• the strain on pipelines and systems;

• the materials;

• the line routing;

• the design or the welding technique;

• local regulations, are considered critical.

Table 1 — Allocation to quality requirement categories

Quality

requirement Area of activity applies to

category

≤ 5 bar

a

Materials used from group 1.1, 1.2 and 1.4 according to CEN ISO/TR 15608 Yield

strength of materials used, R ≤ 360 MPa

B

t 0,5

Examples of use: Mains and service pipes in gas distribution systems, pipework in

stations

> 5 bar ≤ 16 bar

a

Materials used from group 1.1, 1.2 and 1.4 according to CEN ISO/TR 15608 Yield

C strength of materials used, R ≤ 360 MPa

t 0,5

Examples of use: Pipelines including pipework in stations and gas distribution

systems

b

> 16 bar

Materials used from group 1, 2 and 3 according to CEN ISO/TR 15608

D

Examples of use: Pipelines including pipework in stations and gas transmission

systems

Key

R 0,5 is the specified minimum yield strength according to EN ISO 3183

t

NOTE 1 “Category A” for pipework up to and including 100 mbar, as mentioned in the previous version

EN 12732:2000, has been incorporated in the pressure range of “Category B” and has been deleted from this

table.

NOTE 2 Gas infrastructure with a MOP up to and including 16 bar is generally dedicated to gas distribution.

a

When the materials used are outside this range the operator shall review the applicability of the

requirements of this standard or apply Quality requirement category D.

b

Pipelines having hoop stresses at design pressure up to 30 % of specified minimum yield strength (R )

t 0,5

and operated at a pressure up to 24 bar can be allocated to quality requirement Category C by the pipeline

operator.

4.2 Quality system requirements

If required by the pipeline operator, a quality system shall be applied to pipeline welding. A set of

recommended quality requirements according to EN ISO 3834 (all parts) is provided in Table 2, which

specifies the requirements of EN ISO 3834 (all parts) for the different categories as defined in Table 1.

Table 2 — Recommended quality requirements

Quality requirement category in accordance

with Table 1

Requirement relating to:

B C D

Quality system according to:

• EN ISO 3834-1 and EN ISO 3834-2 (complete) + • •

• EN ISO 3834-1 and EN ISO 3834-3 (standard) + • •

• EN ISO 3834-1 and EN ISO 3834-4 (elementary) • – –

Welding coordination personnel:

• Personnel according to EN ISO 14731:2006

• welding engineer + + •

• welding technologist + • +b

• welding specialist • • +b

• welding practitioner as defined in IIW-IAB-

• + –

252-07

a

NDT

• Independent NDT company accredited to

• • •

EN ISO/IEC 17020 or EN ISO/IEC 17025.

• personnel performing NDT to EN ISO 9712 • • •

• personnel performing Visual Testing; VT level 2,

+ + •

or qualification as welding practitioner or over.

Welding procedure specification (WPS):

• According to EN ISO 15609-1 • • •

• According to EN ISO 15609-2 (up to 100 mbar) • – –

Approval of welding procedures according to

one of the following standards:

• EN ISO 15614-1 level 2 (welding procedure test) + • •

• EN ISO 15610 (using approved welding

• – –

consumables)

• EN ISO 15611 (previous experience) – – –

b

+ + –

• EN ISO 15612 (standard welding procedures)

• EN ISO 15613 (pre-production welding test) + + +

Key: • recommended + optional – not recommended

a

testing personal can be employed by either the pipeline operator, the contractor or the NDT company.

b

This can also be applicable in Category D for small projects or for materials with R ≤ 360 MPa.

t 0,5

4.3 Welding contractors

If required by the pipeline operator, contractors shall demonstrate their ability to perform the work.

Reference can be made to EN ISO 3834.

4.4 Welding procedure requirements

4.4.1 General

Welding procedures shall be qualified in accordance with the standards as specified by the pipeline

operator, for guidance see Table 2 recommended quality requirements. For welding process 311 the

maximum design pressure for which this process is allowed is 100 mbar.

The welding procedure specification shall be in accordance with EN ISO 15609-1 and be submitted to

the pipeline operator for approval prior to commencement of welding.

4.4.2 Welding consumables

Welding consumables shall be in accordance with:

• EN ISO 2560 and EN ISO 18275 for shielded metal arc welding (process no. 111);

• EN ISO 14341 and EN ISO 636 for gas metal arc welding (process nos. 135, 141);

• EN ISO 17632 for flux-cored arc welding (process nos. 114, 136);

• EN ISO 14175 for shielding gases;

• EN ISO 14171 for submerged arc welding (process no. 12X);

• EN ISO 14174 for fluxes for submerged arc welding (process no. 12X);

• EN ISO 20378 for autogenous welds (process no. 311).

The numbering of the processes given in brackets is in accordance with EN ISO 4063.

If the filler material to be used in production welding is not listed in these European Standards,

applicable measures shall be set by pipeline operator.

Batch testing of the filler materials can be required by the pipeline operator. In this case the certificates

shall be in accordance with EN 10204, type 3.1. The certificate shall at least contain the chemical

composition and the as welded mechanical properties.

For DP over 16 bar

Welding consumables shall be certified minimum as 3.1 according to EN 10204. The chemical

composition and mechanical tests as specified in the applicable standard for the welding consumable

shall be listed in the certificate.

The use of overmatched consumables is recommended. Weld metal overmatching can be a welding

procedure qualification requirement of the pipeline operator, for example when using the EPRG girth

defect acceptance criteria (Annex G). Unless otherwise agreed, matching weld metal for girth welds

shall be required.

The chemical composition of the deposited weld metal shall be compatible with the base metal, taking

into account any specific property requirements.

For wall thicknesses > 8 mm a lower strength consumable can be used for the root and hot pass.

After filler material has been removed from its original package, it shall be protected or stored in

accordance with the manufacturer's requirements, so that its characteristics or welding properties are

not affected.

4.4.3 Impact testing requirements

For DP over 16 bar

In addition to EN ISO 15614-1, charpy impact testing is required for weld and heat affected zone for a

wall thickness of 5 mm and over. When extracting the charpy impact specimens the thickness shall be

as large as possible. The test temperature is to be taken at the minimum design temperature of the

pipeline, unless otherwise specified by the pipeline operator.

The minimum required values are listed below:

a) steel grades with specified minimum yield strength less or equal to 360 MPa average: 27 joules (J),

individual: 20 J;

b) steel grades with specified minimum yield strength greater than 360 MPa average: 40 J, individual:

30 J;

c) if the EPRG weld defect acceptance rules are specified by the pipeline operator see Annex G:

average: 40 J, individual: 30 J;

d) for sub-size specimens the measured energy shall be converted to the full-size impact energy C (in

joules) using the formula:

8 mm××10 mm C

m

C=

A

m

where

C is the impact energy for the full-size specimen, in joules;

is the measured impact energy, in joules;

C

m

is the cross-section measured under the notch, in square millimetres.

A

m

If an all-weld-metal tensile test is specified, the test specimen and the tests shall be in accordance with

the appropriate European Standard. Yield strength shall be equal to or higher than the specified

minimum yield strength of the parent metal.

For welds made in pipes using a lower strength weld consumable in the root and with a deposited weld

metal thickness in the qualification test piece of 5 mm or less no separate impact tests are required.

When this separate testing, as required by EN ISO 15614-1 is not performed, the PQR has the following

limitations:

• the PQR is only used with the same sequence of processes;

• the maximum qualified thickness of the root layer is 1,5 the deposited weld metal thickness of the

weld process or filler material used for the root.

4.5 Welders

All welders shall be qualified in accordance with Annex A for the work they are required to undertake.

4.6 Welding supervisory and coordination personnel

If a quality system is required by the pipeline operator, the supervisory and the coordination personnel

should be qualified as indicated in Table 2.

Welding tasks and responsibilities for welding shall be clearly assigned to personnel with the

appropriate experience and technical knowledge. The supervisory and coordination personnel can be

employed by the operator or contractor.

The monitoring of welding work on site can be delegated from the welding coordinator in charge to a

welding engineer, welding specialist, welding technologist or a welding practitioner when listed as

recommended or optional for the categories as per Table 2.

4.7 Non destructive testing (NDT)

NDT Personnel performing testing in accordance with this document shall be qualified to an

appropriate level in accordance with EN ISO 9712 or equivalent in the relevant industrial sector. For

direct VT by welding practitioners and over they should be qualified to EN ISO 14731:2006. An

independent NDT company should be accredited to EN ISO/IEC 17020 or EN ISO/IEC 17025.

NOTE For digital radiography to EN ISO 17636-2 additional qualification can be required for technique and

personnel.

4.8 Destructive testing (DT)

The DT company should be accredited to EN ISO/IEC 17025.

5 Production welding

5.1 General

All welding shall comply with the approved welding procedure specifications.

5.2 Working area

The working space shall enable adequate access to the working area in order to provide a safe

environment and to allow satisfactory production and testing of a weld joint. If feasible, working pits or

bell holes should be constructed in the pipe trench. They should have a minimum free length of 3,0 m

(±0,1 m) at the weld area. The distance from pipe to bell hole bottom should be not less than 0,4 m

(±0,1 m) and from pipe to trench wall not less than 0,6 m (±0,1 m).

Bell holes shall be kept free of water during welding and welding related work.

5.3 Layout of weld joints

Weld joints, in particular tie-ins, shall be arranged and designed in a way suited to the planned welding

and testing technique. The placement of tie-in welds is particularly important.

5.4 Types of weld joints

5.4.1 General

Unless otherwise agreed, pipes and pipeline fittings shall be connected using butt-welded joints.

5.4.2 Weld fit-up

Weld fit-up shall be sufficient to ensure a good penetration of the joint. In ar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...