EN 13450:2002

(Main)Aggregates for railway ballast

Aggregates for railway ballast

This European Standard specifies requirements for natural crushed unbound aggregates for use in construction of railway track. For the purposes of this standard the aggregate is referred to as railway ballast. The necessity for testing for all properties specified in this standard is limited, depending upon the end use of the railway ballast.

Gesteinskörnungen für Gleisschotter

Die vorliegende Europäische Norm legt die Eigenschaften von Gesteinskörnungen für die Verwendung beim Bau von Bahnkörpern fest, die durch Aufbereitung natürlicher oder industriell hergestellter Materialien oder gebrochener ungebundener rezyklierter Gesteinskörnungen gewonnen werden. Für die Zwecke dieser Norm werden die Gesteinskörnungen als Gleisschotter bezeichnet.

Sie enthält Festlegungen für die Bewertung der Konformität von Produkten nach dieser Europäischen Norm.

ANMERKUNG Die Anforderungen dieser Europäischen Norm basieren auf Erfahrungen mit Gesteinskörnungsarten, die sich in der Anwendung bewährt haben. Die Verwendung von Gesteinskörnungen aus Bezugsquellen ohne eine derartige Bewährung, wie z. B. von rezyklierten oder in einem industriellen Prozess entstandenen Gesteinskörnungen, sollte sorgfältig geprüft werden. Derartige Gesteinskörnungen könnten trotz Übereinstimmung mit sämtlichen Anforderungen dieser Europäischen Norm Eigenschaften besitzen, die nicht im Mandat M 125 (in der geänderten Fassung) erfasst sind und die nicht für die Gesamtheit der Gesteinskörnungsarten mit einer bewährten Anwendung gelten. Falls erforderlich, können für die Beurteilung ihrer Eignung die am jeweiligen Verwendungsort geltenden Vorschriften herangezogen werden.

Granulats pour ballasts de voies ferrées

La présente Norme européenne spécifie les caractéristiques des granulats obtenus par traitement de matériaux naturels ou artificiels ou de granulats recyclés concassés utilisés dans la construction de voies ferrées. Pour les besoins de la présente norme, les granulats sont appelés ballasts de voies ferrées.

Elle fournit l'évaluation de conformité des produits.

NOTE Les exigences de la présente Norme européenne sont basées sur l'expérience acquise avec des types de granulats disposant d'un mode d'utilisation établi. Il convient de prêter une attention particulière à l'utilisation de granulats provenant de sources ne présentant pas ce mode d'utilisation, par exemple, les granulats recyclés ou les granulats issus de certains produits industriels dérivés. Il est possible que de tels granulats, dont il convient qu'ils soient conformes à toutes les exigences de la présente Norme européenne, possèdent d'autres caractéristiques non incluses dans le mandat M 125 (selon amendement) et qui ne s'appliquent pas à la totalité des types de granulats dotés d'un modèle établi d'utilisation. Le cas échéant, les dispositions en vigueur sur le lieu d'utilisation peuvent être adoptées pour évaluer leur aptitude à l'emploi.

Agregati za grede železniških prog

General Information

- Status

- Published

- Publication Date

- 17-Dec-2002

- Withdrawal Date

- 29-Jun-2004

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 4 - Hydraulic bound and unbound aggregates

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 05-Oct-2007

- Completion Date

- 05-Oct-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-May-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16730:2016 - Railway applications - Track - Concrete sleepers and bearers with under sleeper pads - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13450:2002 - "Aggregates for railway ballast" (CEN) defines properties and conformity procedures for natural, manufactured or recycled crushed unbound aggregates used as railway ballast. The standard covers sampling, production, geometrical and physical requirements, durability tests, harmful components, factory production control and marking. Testing is required only as necessary for the intended end use; many clauses reference existing test methods (EN 932, EN 933, EN 1097, EN 1367, etc.).

Key topics and technical requirements

- Scope and terminology: Defines railway ballast, natural/manufactured/recycled ballast and size designation (typical designations: lower sieve d = 31.5 mm; upper sieve D = 50 mm or 63 mm).

- Sampling and sample reduction: Referenced to EN 932 series; annexes provide guidance for sampling from wagons or tracks (Annex A) and interpreting site samples (Annex B).

- Geometrical requirements:

- Grading categories (A–F) for particle size distribution as determined by EN 933-1.

- Fine particles (passes 0.5 mm) and fines (passes 0.063 mm) classification and maximum content categories.

- Particle shape: Flakiness index (EN 933-3) is the reference; shape index (EN 933-4) also covered. Categories (FI15, FI20, FI35, etc.) are specified.

- Particle length categories to control long particles.

- Mechanical and wear resistance:

- Resistance to fragmentation (Los Angeles coefficient, LARB) per EN 1097-2 with conditions in Annex C (categories LARB 12–24).

- Impact value (SZRB) as alternative fragmentation assessment (Annex D).

- Resistance to wear (micro‑Deval, MDE RB) per EN 1097-1 with conditions in Annex E (categories MDE RB 5–15).

- Durability:

- Freeze/thaw resistance (EN 1367-1, Annex F) and magnesium sulfate soundness (EN 1367-2, Annex G). Informative guidance in Annex H.

- Conformity, designation and marking: Procedures for evaluating conformity and for product designation/labeling, plus factory production control (Annex I).

Practical applications and users

- Who uses EN 13450:

- Railway engineers and track designers specifying ballast for new construction or renewal.

- Aggregate producers and suppliers setting production and quality control.

- Testing laboratories performing conformity and performance tests.

- Contractors, infrastructure owners and asset managers assessing material suitability.

- Why it matters:

- Ensures mechanical stability, drainage and track geometry retention.

- Provides harmonized test methods and categories to support procurement, compliance and lifecycle performance of track ballast.

- Facilitates cross-border supply and regulatory compliance within CEN member states.

Related standards

EN 13450 references and aligns with other aggregate standards relevant to construction materials, for example:

- EN 932 (sampling and sample reduction), EN 933 (geometrical tests), EN 1097 (mechanical tests), EN 1367 (durability tests).

- Complementary CEN standards for other aggregate uses: EN 12620 (concrete), EN 13043 (bituminous mixtures), EN 13242 (unbound materials).

Keywords: EN 13450:2002, railway ballast, aggregates, CEN, ballast grading, Los Angeles coefficient, micro‑Deval, flakiness index, sampling, freeze/thaw.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13450:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aggregates for railway ballast". This standard covers: This European Standard specifies requirements for natural crushed unbound aggregates for use in construction of railway track. For the purposes of this standard the aggregate is referred to as railway ballast. The necessity for testing for all properties specified in this standard is limited, depending upon the end use of the railway ballast.

This European Standard specifies requirements for natural crushed unbound aggregates for use in construction of railway track. For the purposes of this standard the aggregate is referred to as railway ballast. The necessity for testing for all properties specified in this standard is limited, depending upon the end use of the railway ballast.

EN 13450:2002 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13450:2002 has the following relationships with other standards: It is inter standard links to EN 13450:2013, EN 933-1:1997, EN 932-3:2022, EN 1097-6:2000, EN 1367-3:2001, EN 933-3:2012, EN 932-1:1996, EN 1097-2:1998, EN 1367-1:1999, EN 1367-2:1998, EN 932-5:2012, EN 1097-1:1996, EN 933-4:2008, EN 16730:2016, EN ISO 3815-2:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13450:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13450:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Aggregates for railway ballastAgregati za grede železniških progGranulats pour ballasts de voies ferréesGesteinskörnungen für Gleisschotter91.100.15Mineralni materiali in izdelkiMineral materials and productsICS:SIST EN 13450:2003enTa slovenski standard je istoveten z:EN 13450:200201-marec-2003SIST EN 13450:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13450December 2002ICS 91.100.15English versionAggregates for railway ballastGranulats pour ballasts de voies ferréesGesteinskörnungen für GleisschotterThis European Standard was approved by CEN on 7 November 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13450:2002 E

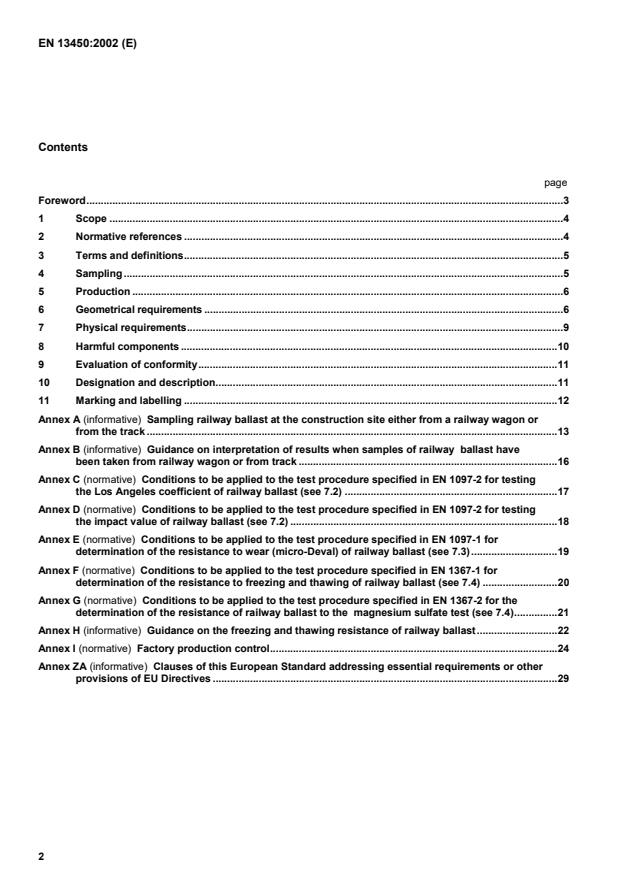

Sampling railway ballast at the construction site either from a railway wagon orfrom the track.13Annex B (informative)

Guidance on interpretation of results when samples of railway

ballast havebeen taken from railway wagon or from track.16Annex C (normative)

Conditions to be applied to the test procedure specified in EN 1097-2 for testingthe Los Angeles coefficient of railway ballast (see 7.2).17Annex D (normative)

Conditions to be applied to the test procedure specified in EN 1097-2 for testingthe impact value of railway ballast (see 7.2).18Annex E (normative)

Conditions to be applied to the test procedure specified in EN 1097-1 fordetermination of the resistance to wear (micro-Deval) of railway ballast (see 7.3).19Annex F (normative)

Conditions to be applied to the test procedure specified in EN 1367-1 fordetermination of the resistance to freezing and thawing of railway ballast (see 7.4).20Annex G (normative)

Conditions to be applied to the test procedure specified in EN 1367-2 for thedetermination of the resistance of railway ballast to the

magnesium sulfate test (see 7.4).21Annex H (informative)

Guidance on the freezing and thawing resistance of railway ballast.22Annex I (normative)

Factory production control.24Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of EU Directives.29

treatments and for bound and unbound applications, excluding concrete, mortar and grout.EN 13139Aggregates for mortar.EN 13242Aggregates for unbound and hydraulically bound materials for use in civil engineeringwork and road construction.EN 13383-1Armourstone - Part 1: specification.Annexes A, B and H are informative and annexes C, D, E, F, G and I are normative.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the followingcountries are bound to implement this European Standard : Austria, Belgium, Czech Republic, Denmark, Finland,France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain,Sweden, Switzerland and the United Kingdom.

For the purposes of thisstandard, the aggregate is referred to as railway ballast.It provides for the evaluation of conformity of the products to this European Standard.NOTE The requirements in this European Standard are based upon experience with aggregate types with an establishedpattern of use.

Care should be taken when considering the use of aggregates from sources with no such pattern of use, e.g.,recycled aggregates and aggregates arising from certain industrial by-products.

Such aggregates, that should comply with allthe requirements of this European Standard, could have other characteristics not included in Mandate M 125 (as amended) thatdo not apply to the generality of aggregate types with an established pattern of use and when required, provisions valid at theplace of use can be used to assess their suitability.2 Normative referencesThis European Standard incorporates by dated or undated reference, provisions from other publications. Thesenormative references are cited at the appropriate places in the text, and the publications are listed hereafter. Fordated references, subsequent amendments to or revisions of any of these publications apply to this EuropeanStandard only when incorporated in it by amendment or revision.

For undated references the latest edition of thepublication referred to applies (including amendments).EN 932-1:1996,Tests for general properties of aggregates — Part 1: Methods for sampling.EN 932-2,Tests for general properties of aggregates — Part 2: Methods for reducing laboratory samples.EN 932-3,Tests for general properties of aggregates — Part 3: Procedure and terminology for simplifiedpetrographic description.EN 932-5,Tests for general properties of aggregates — Part 5: Common equipment and calibration.EN 933-1:1997,Tests for geometrical properties of aggregates — Part 1: Determination of particle sizedistribution - Sieving method.EN 933-3,Tests for geometrical properties of aggregates — Part 3: Determination of particle shape- Flakiness index.EN 933-4,Tests for geometrical properties of aggregates — Part 4: Determination of particle shape- Shape index.EN 1097-1:1996,Tests for mechanical and physical properties of aggregates - Part 1: Determination of theresistance to wear (micro-Deval).EN 1097-2:1998,Tests for mechanical and physical properties of aggregates — Part 2: Methods for thedetermination of resistance to fragmentation.EN 1097-6:2000,Tests for mechanical and physical properties of aggregates — Part 6: Determination of particledensity and water absorption.EN 1367-1:1999,Tests for thermal and weathering properties of aggregates — Part 1: Determination of resistanceto freezing and thawing.EN 1367-2:1998,Tests for thermal and weathering properties of aggregates — Part 2: Magnesium sulfate test.EN 1367-3,Tests for thermal and weathering properties of aggregates — Part 3: Boiling test for“Sonnenbrand basalt”.

When required, the tests specified shall be carried out to determineappropriate properties.NOTE 1When the value of a property is required but not defined by specified limits the value should be declared by theproducer as an XXDeclared category, e.g., in Table 4 a value of flakiness index of say 40 corresponds to FI40 (Declared value).NOTE 2When a property is not required, a “No requirement” category can be used.NOTE 3Guidance on selection of appropriate categories for specific applications can be found in national provisions in theplace of use of the railway ballast.6.2 Railway ballast sizeRailway ballast size shall be designated by a pair of sieve sizes in millimetre with d as the lower limit designationsieve and D as the upper limit designation sieve between which most of the particle size distribution lies.For railway ballast D is 50 mm or 63 mm and d is 31,5 mm.6.3 GradingThe grading of the railway ballast determined in accordance with EN 933-1 shall be declared in accordance withthe relevant category specified in Table 1.Table 1 — Categories for gradingRailway ballast size 31,5 mm to 50 mmRailway ballast size 31,5 mm to 63 mmPercentage passing by massGrading categorySieve sizemmABCDEF8063504031,522,431,5 to 5031,5 to 6310010070 to 9930 to 651 to 250 to 3 50-10097 to 10070 to 9930 to 701 to 250 to 3 50-10095 to 10070 to 9925 to 751 to 250 to 3 50-10097 to 9965 to 9930 to 651 to 250 to 3- 5010095 to 9955 to 9925 to 751 to 250 to 3- 5010093 to 9945 to 7015 to 400 to 70 to 7-³ 85NOTE 1

The requirement for passing the 22,4 mm sieve applies to railway ballast sampled at the place of production.NOTE 2

In certain circumstances a 25 mm sieve may be used as an alternative to the 22,4 mm sieve when a tolerance of0 to 5 would apply (0 to 7 for category F).6.4 Fine particlesThe content of fine particles determined in accordance with EN 933-1 shall be declared in accordance with therelevant category specified in Table 2.

The requirement applies to railway ballast sampled at the place of production.6.5 FinesThe fines content determined in accordance with EN 933-1 shall be declared in accordance with the relevantcategory specified in Table 3.When required cleanliness shall be assessed from the fines content. Fines shall be considered non-harmful if thetotal fines content is less than the relevant category specified in Table 3 in accordance with the provisions valid inthe place of use of the aggregate.Table 3 — Categories for fines contentMaximum percentage passing by massSievesizeFines content categorymmABCDeclaredD0,0630,51,01,5> 1,5No requirementNOTE

The requirement applies to railway ballast sampled at the place of production.6.6 Particle shape6.6.1 Flakiness indexWhen required the shape of coarse railway ballast shall be determined in terms of the flakiness index as specifiedin EN 933-3.Flakiness index shall be the reference test for the determination of shape of railway ballast. The Flakiness indexshall be declared in accordance with the relevant category specified in Table 4.

SIDeclaredNo requirementSINR6.7 Particle lengthParticle length shall be assessed by measuring with an appropriate gauge or calipers.NOTELimits should be selected from the specified range until such a time as there is more data available on aggregateproperties related to performance.When required, the particle length shall be declared in accordance with the relevant category specified in Table 6.Table 6 — Categories for particle lengthPercentage by mass with length

100 mm in agreater than 40 kg sampleParticle length categoryABCDDeclaredE46812> 12No requirement

LARB DeclaredNo requirementLARB NRWhere required, the impact value of railway ballast (SZRB, using the conditions as specified in annex D),determined in accordance with EN 1097-2:1998, clause 6, shall be declared in accordance with the relevantcategory specified in Table 8.Table 8 — Categories for maximum values of resistance to impactImpact value%CategorySZRB 14 18 22> 22SZRB 14SZRB 18SZRB 22

SZRB DeclaredNo requirementSZRB NR

MDE RB DeclaredNo requirementMDE RB NR7.4 Durability7.4.1 Resistance to freezing and thawingWhen required, the durability of railway ballast in terms of freeze/thaw resistance, shall be assessed by either thefreeze/thaw test in accordance with EN 1367-1, using the conditions as specified in annex F, or the magnesium sulphatesoundness test in accordance with EN 1367-2, using the conditions as specified in annex G and the results declared.NOTEThere is limited experience of the use of either of these tests for assessing the durability of railway ballast.

Advice onthe applicability of the test methods and of using water absorption as a screening test is given in annex H.7.4.2 Particle densityWhen required the particle density shall be determined in accordance with EN 1097-6:2000, annex B and the resultsdeclared.7.4.3 Water absorptionWhen required the water absorption shall be determined in accordance with EN 1097-6:2000 annex B and the resultsdeclared.7.5 SonnenbrandIf signs of "Sonnenbrand" are known from a quarry of basalt or closely related rocks qualitative testing shall be carriedout in accordance with EN 1367-3 and the results declared.NOTE"Sonnenbrand" is a type of rock decay that can be present in some basalts and manifests itself under the influenceof atmospheric conditions. It starts with the appearance of grey/white coloured spots.

Usually hairline cracks are generatedradiating out from the spots and interconnecting them.

This reduces the strength of the mineral fabric, and as a result the rockdecays to small particles.

Depending on the source this process can take place within months of extraction or extend overseveral decades.

In exceptional cases a rapid decay results in the formation of large cracks and the breaking of aggregateparticles.8 Harmful componentsRailway ballast shall not contain other components or matter than specified in this standard.

a new source of aggregates is to be used.b)

there is a major change in the nature of the raw materials or in the processing conditions which may affect

the properties of the aggregates.The results of the initial tests shall be documented as the starting point of the factory production control for thatmaterial.

This shall particularly include the identification of any components likely to emit radiation above normalbackground levels, any components likely to release polyaromatic carbons or other dangerous substances.

If thecontent of any of these components exceeds the limits in force according to the provisions valid in the place of useof the railway ballast, the results of the initial tests shall be declared9.3 Factory production controlThe producer shall have in place a system of factory production control that complies with the requirements ofannex I.The records held by the producer shall indicate what quality control procedures are in operation during theproduction of the aggregate.NOTE 1The form of control applied to any aggregate depends upon its intended use and the regulations relating to that use.NOTE 2For inspection purposes only, railway ballast can be sampled from the track in accordance with annex A.10 Designation and description10.1 DesignationRailway ballast shall be identified in the following terms:a) source - if the material has been re-handled in a depot both source and depot shall be given;b) a simple indication of the petrographic type (see EN 932-3);c) railway ballast size;d) where required a producer's code to relate the designation to the description;e) any additional information needed to identify the particular railway ballast aggregate.10.2 Essential information for the description of a railway ballast aggregateOnly the items a) to c) in 10.1 are essential descriptions of a railway ballast aggregate.

The necessity for otherinformation depends on the situation and end use.NOTEThe purchaser should inform the supplier at the time of order of any special requirements associated with a particularend use.

Thespecification limits contained within this standard are based on the testing of samples taken at this location.

Themethod of sampling should be as specified in EN 932-1.However there will be occasions when it will be necessary to take a sample of railway ballast at the time of deliveryor from the track. Reasons can include to check if degradation has occurred during transport or to investigate aparticular track problem. In such situations one of the following sampling procedures should be adopted.A.2 Sampling railway ballast from a railway wagonA.2.1

Sampling of railway ballast at a construction site should be carried out in accordance with the principles anddefinitions specified in EN 932-1.A.2.2

Sampling should only be carried from a fully loaded wagon by use of a sampling box (see EN 932-1:1996,Figure 5) of inner dimensions length 700 mm, width 450 mm and height 250 mm.A.2.3

All the increments for one bulk sample should be taken from one wagon and from one discharge opening(slide or conveyor belt) of that wagon.A.2.4

A minimum of four increments should be taken.A.2.5

The first increment should be taken about 10 s after the commencement of unloading, the last increment about10 s before the end of unloading and intermediate increments at regular intervals in between the first and last.A.2.6

The discharge opening should be completely open at the time of sampling.A.2.7

The wagon should move at walking pace (about 3 km/h) over the sampling box.A.2.8

The contents of one sample box should constitute one increment.A.2.9

The increments should be mixed together to form a bulk sample on a clean flat surface or on a thick tearresistant plastic sheet.A.2.10

The bulk sample should be split into the required number of subsamples in accordance with EN 932-1.A.3 Sampling railway ballast from track without use of a steel frameA.3.1

The bulk sample should consist of one or more spaces between sleepers.A.3.2

If it is required to sample railway ballast from more than one space between sleepers then the first, fourth andthen every third space should be sampled.A.3.3 The railway ballast should be removed completely first by using a ballast fork and then a small shovel or similar.A.3.4

The railway ballast should be removed down to the bottom of the railway ballast layer. Care should be taken toensure that no damage is caused to the formation or the protective layer and that no particles originating from themare included in the sample.

The increments should be mixed together to form a bulk sample on clean, flat surface or on thick tear-resistant plastic sheet.A.3.6

The bulk sample should be split into the required number of subsamples, in accordance with EN 932-1.A.4 Sampling railway ballast from track using a steel frameA.4.1

A steel frame serrated at its lower edge, as shown in Figure A.1, can be used for railway ballast samplingfrom the track.Dimensions in millimetres83003201005502020A-AAA122020Key1Welding seam2Steel plateFigure A.1 - Frame for sampling railway ballastA.4.2

The sampling procedure should be as described in A.3 except that at each space between sleepers fromwhich it is required to take a sample, the steel frame should be driven into the railway ballast using a sledgehammer.

The steel frame should be driven between concrete sleepers without damaging the sleepers.

Railway ballast should be removed first with a ballast fork and the frame then driven deeper into the railwayballast. Removal of the bottom layer of railway ballast should be with a small shovel or similar. Care should be takento ensure that no damage is caused to the formation or the protective layer and that no particles originating fromthem are included in the sample.A.4.4

The increments should be mixed together to form a bulk sample on a clean, flat surface or thick tear-resistantplastic sheet.A.4.5

The bulk sample should be split into the required number of subsamples, in accordance with EN 932-1.

Wash each fraction separately, in accordance withEN 933-1:1997, 7.1, and dry them in the oven at (110 ± 5) °C to constant mass. Allow the fractions to cool to ambienttemperature.Reduce the mass of each size fraction as specified in EN 932-2 so that each has a mass of (5 000 ± 50) g. Combinethe two reduced fractions to produce a test portion with a total dry mass of (10 000 ± 100) g.C.5 Test procedureUnder EN 1097-2:1998, 5.3, the machine shall be rotated for 1000 revolutions instead of 500 revolutions at aspeed of 31 min-1 to 33 min-1.C.6 Calculation and expression of resultsUnder EN 1097-2:1998, 5.4, replace the equation:500005mLA-=by the following equation:100m00010RB-=C.7 Test reportReport that the test procedure was carried out in accordance with EN 1097-2:1998, clauses 4 and 5, applying theconditions of use as specified in this annex.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...