EN 933-5:2022

(Main)Tests for geometrical properties of aggregates - Part 5: Determination of percentage of crushed particles in coarse and all-in natural aggregates

Tests for geometrical properties of aggregates - Part 5: Determination of percentage of crushed particles in coarse and all-in natural aggregates

This document specifies the reference method, used for type testing and in case of dispute, for the determination of the percentages of crushed particles, totally crushed particles and totally rounded particles in coarse and all-in natural aggregates. Other methods can be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established.

NOTE 1 Examples of advanced test methods can be found in the Bibliography.

This document applies to coarse aggregates comprising particles within size fraction 4/63 mm. It does not apply to lightweight aggregates.

NOTE 2 For coarse aggregate between 4 mm and 20 mm the percentages of crushed surfaces are linked to the flow coefficient and can therefore be used in association with the test method specified in EN 933 6.

Clause 7.1 specifies the procedure for test portions consisting of one size fraction and Clause 7.2 specifies the procedure for test portions consisting of two or more size fractions.

Guidance for the estimated mass of various size fractions with about 100 particles is given in informative Annex A.

Examples of application of the test procedure and an example of a test data sheet are given in informative Annexes B and C.

Prüfverfahren für geometrische Eigenschaften von Gesteinskörnungen - Teil 5: Bestimmung des prozentualen Anteils an gebrochenen Körnern in groben Gesteinskörnungen und Gesteinskörnungsgemischen

Dieses Dokument legt das für die Erstprüfung und im Streitfall anzuwendende Referenzverfahren für die Bestimmung des prozentualen Anteils an gebrochenen Körnern, vollständig gebrochenen Körnern und vollständig gerundeten Körnern in groben Gesteinskörnungen und natürlichen Gesteinskörnungsgemischen fest. Für andere Zwecke, speziell im Rahmen der werkseigenen Produktionskontrolle, können andere Verfahren angewendet werden, sofern ein ausreichender Zusammenhang mit dem Referenzverfahren nachgewiesen wurde.

ANMERKUNG 1 Beispiele für erweiterte Prüfverfahren können in den Literaturhinweisen gefunden werden.

Das vorliegende Dokument ist anzuwenden für grobe Gesteinskörnungen mit Körnern in der Kornklasse 4/63 mm. Es ist nicht anzuwenden für leichte Gesteinskörnungen.

ANMERKUNG 2 Bei einer groben Gesteinskörnung zwischen 4 mm und 20 mm hängt der Prozentsatz an gebrochenen Oberflächen mit dem Fließkoeffizienten zusammen und kann deshalb als alternatives Prüfverfahren zu dem in EN 933 6 beschriebenen Verfahren angewendet werden.

In 7.1 wird das Verfahren für Messproben, die aus einer Kornklasse bestehen, und in 7.2 das Verfahren für Messproben, die aus zwei oder mehr Kornklassen bestehen, festgelegt.

Leitlinien für die geschätzte Masse unterschiedlicher Kornklassen mit ungefähr 100 Körnern sind im informativen Anhang A aufgeführt.

Beispiele für die Anwendung des Prüfverfahrens und ein Beispiel eines Prüf-Datenblattes werden im informativen Anhang B und im informativen Anhang C aufgeführt.

Essais pour déterminer les caractéristiques géométriques des granulats - Partie 5 : Détermination du pourcentage de surfaces cassées dans les gravillons et graves naturelles

Le présent document spécifie la méthode de référence, utilisée pour les essais de type et en cas de litige, pour la détermination des pourcentages de grains semi-concassés, de grains entièrement concassés et de grains entièrement roulés de gravillons et de graves naturels. D’autres méthodes peuvent être utilisées à d’autres fins, telles que le contrôle de la production en usine, à condition qu’une relation de travail appropriée ait été établie avec la méthode de référence.

NOTE 1 Des exemples de méthodes d’essai avancées sont présentés dans la Bibliographie.

Le présent document s’applique aux gravillons dont la taille est comprise dans la fraction 4/63 mm. Il ne s’applique pas aux granulats légers.

NOTE 2 Pour les gravillons de taille comprise entre 4 mm et 20 mm, les pourcentages de surfaces cassées sont liés au coefficient d’écoulement et peuvent donc être utilisés en association avec la méthode d’essai spécifiée dans l’EN 933-6.

L’article 7.1 spécifie le mode opératoire pour les prises d’essai constituées d’une fraction granulaire et l’article 7.2 spécifie le mode opératoire pour les prises d’essai constituées d’au moins deux fractions granulaires.

Des indications sur la masse estimée de différentes fractions granulaires contenant environ 100 particules sont données dans l’Annexe A informative.

Des exemples d’application du mode opératoire d’essai et un exemple de feuille d’essai sont donnés dans les Annexes B et C informatives.

Preskusi geometričnih lastnosti agregatov - 5. del: Določevanje odstotka lomljenih površin zrn grobega in mešanega agregata

Ta dokument določa referenčno metodo, ki se uporablja za tipsko preskušanje in v primeru spora za določanje odstotka lomljenih zrn, popolnoma zdrobljenih zrn ter popolnoma zaobljenih zrn v vzorcu naravnega grobega in mešanega agregata. Za druge namene, na primer za kontrolo proizvodnje v obratu, je mogoče uporabiti druge metode, če obstaja primerna delovna povezava z referenčno metodo.

OPOMBA 1: Primeri naprednih preskusnih metod so opisani v bibliografiji.

Ta dokument velja za gramoz ali mešanico naravnih grobih agregatov, ki vsebujejo gramoz. Preskusna metoda se uporablja za zrna velikosti od 4 do 63 mm.

OPOMBA 2: Pri grobem agregatu velikosti od 4 do 20 mm so odstotki zdrobljenih površin povezani s koeficientom pretoka in se zato lahko uporabljajo v povezavi s preskusno metodo, določeno v standardu EN 933-6.

Podtočka 7.1 določa postopek za preskusne deleže, sestavljene iz enega velikostnega razreda zrn, podtočka 7.2 pa določa postopek za preskusne deleže, ki so sestavljeni iz dveh ali več velikostnih razredov zrn.

Smernice za ocenjevanje mase preskusnega deleža so na voljo v informativnem dodatku A.

Primeri uporabe preskusnega postopka in primer preskusnega lista so podani v informativnih dodatkih B in C.

General Information

- Status

- Published

- Publication Date

- 01-Nov-2022

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 6/WG 2 - Physical Testing

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 02-Nov-2022

- Due Date

- 30-Sep-2022

- Completion Date

- 02-Nov-2022

Relations

- Effective Date

- 09-Nov-2022

- Effective Date

- 09-Nov-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 933-5:2022 - Tests for geometrical properties of aggregates, Part 5 specifies the reference method for determining the percentage of crushed particles, totally crushed particles and totally rounded particles in coarse and all‑in natural aggregates. It applies to size fractions within 4/63 mm and excludes lightweight aggregates. The method is intended for type testing and dispute resolution; alternative methods may be used for factory production control provided they are correlated with this reference method.

Key topics and technical requirements

- Scope and purpose

- Reference method for coarse/all‑in natural aggregates (4/63 mm).

- Not applicable to lightweight aggregates.

- Definitions

- Crushed surface: angular fractured planar faces with distinct edges.

- Crushed particle (c): >50% of particle surface crushed.

- Totally crushed particle (tc): >90% crushed.

- Totally rounded particle (tr): >90% rounded.

- Test principle

- Manual sorting of a dried test portion into c, tc and tr categories; mass of each category expressed as percentage of the test portion mass.

- Test portion preparation

- Size fraction selected from the laboratory sample (if d < 4 mm then d = 4 mm; if D > 63 mm then D = 63 mm).

- Samples reduced per EN 932-2; sieving per EN 933-1/EN 933-2.

- Oven drying to constant mass at (110 ± 5) °C.

- Procedure notes

- Clause 7.1: procedure for single size fraction where D ≤ 2d (test portion should contain at least 100 particles).

- Clause 7.2: procedure for test portions with two or more size fractions.

- Informative Annex A gives guidance on estimated mass for ~100 particles; Annexes B and C provide worked examples and a data sheet template.

- Apparatus

- Test sieves (EN 933-2), ventilated oven (110 ± 5 °C), balance accurate to 0.1 %, trays, brushes; coloured pencil optional to mark surfaces.

Applications and users

- Who uses EN 933-5:2022

- Aggregate producers, independent testing laboratories, construction material specifiers, concrete/asphalt mix designers, and regulatory authorities.

- Practical uses

- Type testing and acceptance testing of coarse aggregates.

- Resolving contractual disputes over aggregate shape and processing quality.

- Correlating factory production control methods with a standardized reference test.

- Supporting specification compliance for concrete, asphalt and base layers where particle shape affects performance.

Related standards

- EN 933 series (Parts 1–11) - particle size, shape indices, flow coefficient, shells, fines

- EN 932 series - sample reduction and common equipment

- EN 1097 series - mechanical and physical tests for aggregates

Keywords: EN 933-5:2022, crushed particles, coarse aggregates, all-in natural aggregates, geometrical properties of aggregates, reference test method, aggregate testing, particle shape.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 933-5:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tests for geometrical properties of aggregates - Part 5: Determination of percentage of crushed particles in coarse and all-in natural aggregates". This standard covers: This document specifies the reference method, used for type testing and in case of dispute, for the determination of the percentages of crushed particles, totally crushed particles and totally rounded particles in coarse and all-in natural aggregates. Other methods can be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established. NOTE 1 Examples of advanced test methods can be found in the Bibliography. This document applies to coarse aggregates comprising particles within size fraction 4/63 mm. It does not apply to lightweight aggregates. NOTE 2 For coarse aggregate between 4 mm and 20 mm the percentages of crushed surfaces are linked to the flow coefficient and can therefore be used in association with the test method specified in EN 933 6. Clause 7.1 specifies the procedure for test portions consisting of one size fraction and Clause 7.2 specifies the procedure for test portions consisting of two or more size fractions. Guidance for the estimated mass of various size fractions with about 100 particles is given in informative Annex A. Examples of application of the test procedure and an example of a test data sheet are given in informative Annexes B and C.

This document specifies the reference method, used for type testing and in case of dispute, for the determination of the percentages of crushed particles, totally crushed particles and totally rounded particles in coarse and all-in natural aggregates. Other methods can be used for other purposes, such as factory production control, provided that an appropriate working relationship with the reference method has been established. NOTE 1 Examples of advanced test methods can be found in the Bibliography. This document applies to coarse aggregates comprising particles within size fraction 4/63 mm. It does not apply to lightweight aggregates. NOTE 2 For coarse aggregate between 4 mm and 20 mm the percentages of crushed surfaces are linked to the flow coefficient and can therefore be used in association with the test method specified in EN 933 6. Clause 7.1 specifies the procedure for test portions consisting of one size fraction and Clause 7.2 specifies the procedure for test portions consisting of two or more size fractions. Guidance for the estimated mass of various size fractions with about 100 particles is given in informative Annex A. Examples of application of the test procedure and an example of a test data sheet are given in informative Annexes B and C.

EN 933-5:2022 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 933-5:2022 has the following relationships with other standards: It is inter standard links to EN 933-5:1998/A1:2004, EN 933-5:1998, EN 13043:2002, EN 13055-1:2002, EN 16236:2018, EN 13055-2:2004, EN 13242:2013, EN 13242:2002+A1:2007, EN 13043:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 933-5:2022 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/124, M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 933-5:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2023

Nadomešča:

SIST EN 933-5:1999

SIST EN 933-5:1999/A1:2005

Preskusi geometričnih lastnosti agregatov - 5. del: Določevanje odstotka lomljenih

površin zrn grobega in mešanega agregata

Tests for geometrical properties of aggregates - Part 5: Determination of percentage of

crushed particles in coarse and all-in natural aggregates

Prüfverfahren für geometrische Eigenschaften von Gesteinskörnungen - Teil 5:

Bestimmung des prozentualen Anteils an gebrochenen Körnern in groben

Gesteinskörnungen und Gesteinskörnungsgemischen

Essais pour déterminer les caractéristiques géométriques des granulats - Partie 5 :

Détermination du pourcentage de surfaces cassées dans les gravillons et graves

naturelles

Ta slovenski standard je istoveten z: EN 933-5:2022

ICS:

91.100.15 Mineralni materiali in izdelki Mineral materials and

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 933-5

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2022

EUROPÄISCHE NORM

ICS 91.100.15 Supersedes EN 933-5:1998

English Version

Tests for geometrical properties of aggregates - Part 5:

Determination of percentage of crushed particles in coarse

and all-in natural aggregates

Essais pour déterminer les caractéristiques Prüfverfahren für geometrische Eigenschaften von

géométriques des granulats - Partie 5 : Détermination Gesteinskörnungen - Teil 5: Bestimmung des

du pourcentage de surfaces cassées dans les gravillons prozentualen Anteils an gebrochenen Körnern in

et cailloux groben Gesteinskörnungen und

Gesteinskörnungsgemischen

This European Standard was approved by CEN on 26 September 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 933-5:2022 E

worldwide for CEN national Members.

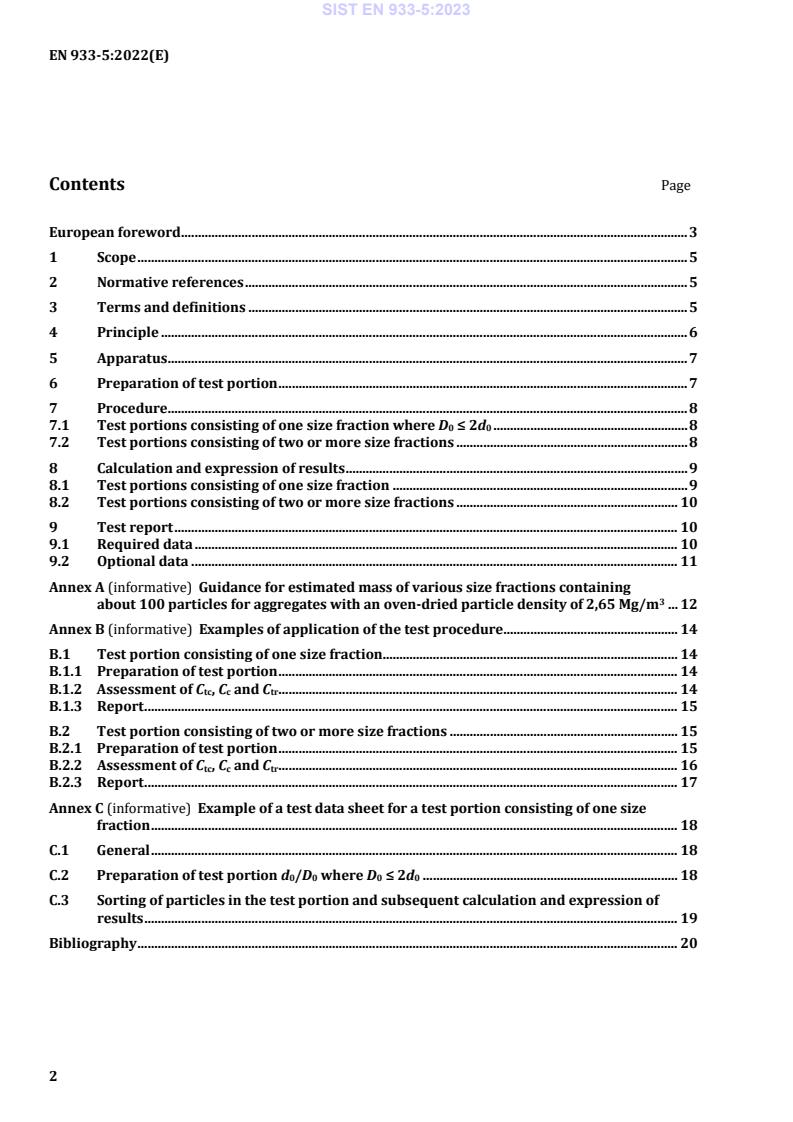

Contents Page

European foreword . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 6

5 Apparatus . 7

6 Preparation of test portion . 7

7 Procedure. 8

7.1 Test portions consisting of one size fraction where D ≤ 2d . 8

0 0

7.2 Test portions consisting of two or more size fractions . 8

8 Calculation and expression of results . 9

8.1 Test portions consisting of one size fraction . 9

8.2 Test portions consisting of two or more size fractions . 10

9 Test report . 10

9.1 Required data . 10

9.2 Optional data . 11

Annex A (informative) Guidance for estimated mass of various size fractions containing

about 100 particles for aggregates with an oven-dried particle density of 2,65 Mg/m . 12

Annex B (informative) Examples of application of the test procedure . 14

B.1 Test portion consisting of one size fraction. 14

B.1.1 Preparation of test portion . 14

B.1.2 Assessment of C , C and C . 14

tc c tr

B.1.3 Report . 15

B.2 Test portion consisting of two or more size fractions . 15

B.2.1 Preparation of test portion . 15

B.2.2 Assessment of C , C and C . 16

tc c tr

B.2.3 Report . 17

Annex C (informative) Example of a test data sheet for a test portion consisting of one size

fraction . 18

C.1 General . 18

C.2 Preparation of test portion d /D where D ≤ 2d . 18

0 0 0 0

C.3 Sorting of particles in the test portion and subsequent calculation and expression of

results . 19

Bibliography . 20

European foreword

This document (EN 933-5:2022) has been prepared by Technical Committee CEN/TC 154 “Aggregates”,

the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2023, and conflicting national standards shall be

withdrawn at the latest by May 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 933-5:1998.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

In comparison with the previous edition, the following technical modifications have been made:

a) The title has been revised to better reflect the scope;

b) Clause 1: Scope has been clarified to show that the standard applies to coarse and all-in natural

aggregates, but not to lightweight aggregates.

c) Clause 3: The definition of a crushed surface has been changed. The definitions of aggregate size and

a rounded particle have been deleted. The definition of a rounded surface has been added;

d) Clause 4: Principle has been amended;

e) Clause 5: Coloured pencil has been added as optional apparatus to facilitate the procedure of

estimating crushed and rounded parts of a particle surface;

f) Clause 6: Preparation of test portion has been revised;

g) Clause 7: Procedure has been amended and an illustrating figure has been added;

h) Clause 8: Calculation and expression of results has been amended;

i) Clause 9: The lists of required and optional data have been updated;

j) New informative Annex A, with guidance for estimated mass of various size fractions with about 100

particles, has been added;

k) New informative Annex B, with example of application of the test procedure, has been added;

l) Previous Annex A, with example of a test data sheet, has been revised and moved to Annex C.

This document forms part of a series of tests for geometrical properties of aggregates. Test methods for

other properties of aggregates are covered by the following European Standards:

— EN 932 (all parts), Tests for general properties of aggregates

— EN 1097 (all parts), Tests for mechanical and physical properties of aggregates

— EN 1367 (all parts), Tests for thermal and weathering properties of aggregates

— EN 1744 (all parts), Tests for chemical properties of aggregates

— EN 13179 (all parts), Tests for filler aggregate used in bituminous mixtures

The other parts of the EN 933 series include:

— Part 1: Determination of particle size distribution - Sieving method

— Part 2: Determination of particle size distribution - Test sieves, nominal size of apertures

— Part 3: Determination of particle shape - Flakiness index

— Part 4: Determination of particle shape - Shape index

— Part 6: Assessment of surface characteristics - Flow coefficient of aggregates

— Part 7: Determination of shell content - Percentage of shells in coarse aggregates

— Part 8: Assessment of fines - Sand equivalent test

— Part 9: Assessment of fines - Methylene blue test

— Part 10: Assessment of fines - Grading of filler aggregates (air jet sieving)

— Part 11: Classification test for the constituents of coarse recycled aggregate

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies the reference method, used for type testing and in case of dispute, for the

determination of the percentages of crushed particles, totally crushed particles and totally rounded

particles in coarse and all-in natural aggregates. Other methods can be used for other purposes, such as

factory production control, provided that an appropriate working relationship with the reference method

has been established.

NOTE 1 Examples of advanced test methods can be found in the Bibliography.

This document applies to coarse aggregates comprising particles within size fraction 4/63 mm. It does

not apply to lightweight aggregates.

NOTE 2 For coarse aggregate between 4 mm and 20 mm the percentages of crushed surfaces are linked to the

flow coefficient and can therefore be used in association with the test method specified in EN 933-6.

Clause 7.1 specifies the procedure for test portions consisting of one size fraction and Clause 7.2 specifies

the procedure for test portions consisting of two or more size fractions.

Guidance for the estimated mass of various size fractions with about 100 particles is given in informative

Annex A.

Examples of application of the test procedure and an example of a test data sheet are given in informative

Annexes B and C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 932-2, Tests for general properties of aggregates - Part 2: Methods for reducing laboratory samples

EN 932-5, Tests for general properties of aggregates - Part 5: Common equipment and calibration

EN 933-1, Tests for geometrical properties of aggregates - Part 1: Determination of particle size

distribution - Sieving method

EN 933-2, Tests for geometrical properties of aggregates - Part 2: Determination of particle size

distribution - Test sieves, nominal size of apertures

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

— IEC Electropedia: available at https://www.electropedia.org/

3.1

size fraction

d /D

i i

fraction of an aggregate passing the larger (D ) of two sieves and retained on the smaller (d )

i i

3.2

test portion

d /D

0 0

sample used as a whole in a single test

3.3

constant mass

mass determined after successive weighings at least 1 h apart not differing by more than 0,1 %

Note 1 to entry: In many cases constant mass can be achieved after a test portion has been dried for a pre-

determined period in a specified oven at (110 ± 5) °C. Test laboratories can determine the time required to achieve

constant mass for specific types and sizes of sample dependent upon the drying capacity of the oven used.

3.4

crushed surface

surface of a particle with angular fractured planar faces and often distinct corners and edges

Note 1 to entry: The crushed surface is usually produced by mechanical processing, but it can also consist of the

original surface of a gravel particle, formed by geological action (breaking without any subsequent significant wear

and weathering of the gravel particle).

3.5

totally crushed particle

particle with more than 90 % of its surface crushed (tc)

3.6

crushed particle

particle with more than 50 % of its surface crushed (c)

3.7

rounded surface

surface of a particle which does not conform to the definition of crushed surface in 3.5

3.8

totally rounded particle

particle with more than 90 % of its surface rounded (tr)

4 Principle

The test consists of sorting by hand a coarse test portion of natural aggregates into crushed particles,

totally crushed particles and totally rounded particles.

The masses of crushed particles, totally crushed particles and totally rounded particles are determined

and expressed as percentages of the test portion mass.

5 Apparatus

Unless otherwise stated, all apparatus shall conform to the general requirements of EN 932-5.

5.1 Test sieves, of nominal size of apertures conforming with EN 933-2.

5.2 Tightly fitting pan and lid, for the sieves.

5.3 Ventilated oven, capable of maintaining a temperature of (110 ± 5) °C, or equipment for drying

the aggregate which does not cause any particle size breakdown.

5.4 Balance or scale, accurate to 0,1 % of the mass to be weighed.

5.5 Trays.

5.6 Brushes.

5.7 Sieving machine, optional.

5.8 Coloured pencil, optional.

6 Preparation of test portion

The test portion shall consist of size fraction d /D , where d and D are determined from the aggregate

0 0 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...