EN 13055-2:2004

(Main)Lightweight aggregates - Part 2: Lightweight aggregates for bituminous mixtures and surface treatments and for unbound and bound applications

Lightweight aggregates - Part 2: Lightweight aggregates for bituminous mixtures and surface treatments and for unbound and bound applications

This European Standard specifies the properties of lightweight aggregates and fillers derived thereof obtained by processing natural, manufactured or recycled materials and mixtures of these aggregates for bituminous mixtures and surface treatments and for unbound and hydraulically bound applications other than concrete, mortar and grout.

This European Standard covers lightweight aggregates of mineral origin having particle densities not exceeding 2000 kg/m3 (2,00 Mg/m3) or loose bulk densities not exceeding 1200 kg/m3 (1,20 Mg/m3) including:

a) natural aggregates;

b) aggregates manufactured from natural materials and/or from by-products of industrial processes;

c) by-products of industrial processes;

d) recycled aggregates.

It provides for the evaluation of conformity of the products to this European Standard.

The requirements specified in this standard may not be relevant to all types of lightweight aggregates. For particular applications the requirements and tolerances can be adapted for the end use.

NOTE Aggregates used in construction should comply with all the requirements of this European Standard. As well as familiar and traditional natural and manufactured aggregates Mandate M/125 "Aggregates" included recycled aggregates and some materials from new or unfamiliar sources. Recycled aggregates are included in the standards and new test methods for them are at an advanced stage of preparation. For unfamiliar materials from secondary sources, however, the work on standardization has only started recently and more time is needed to define clearly the origins and characteristics of these materials. In the meantime such unfamiliar materials when placed on the market as aggregates should comply fully with this standard and national regulations for dangerous substances (see annex ZA) depending upon their intended use. Additional characteristics and requirements can be specified on a case by case basis depending upon experience of use of the product, and defi

Leichte Gesteinskörnungen - Teil 2: Leichte Gesteinskörnungen für Asphalte und Oberflächenbehandlungen sowie für ungebundene und gebundene Verwendung

Diese Europäische Norm legt die Eigenschaften von leichten Gesteinskörnungen und daraus hergestelltem Füller fest, die durch Aufbereitung natürlicher, künstlicher oder recycelter Materialien und deren Mischungen gewonnen und für Asphalt und Oberflächenbehandlungen sowie für ungebundene und hydraulisch gebundene Anwendungen außer Beton, Mörtel und Einpressmörtel verwendet werden.

Diese Europäische Norm gilt für leichte Gesteinskörnungen mineralischen Ursprungs mit Rohdichten von nicht mehr als 2 000 kg/m3 (2,00 Mg/m3) oder Schüttdichten von nicht mehr als 1 200 kg/m3 (1,20 Mg/m3) und schließt ein:

a) natürliche Gesteinskörnungen;

b) aus natürlichen Rohstoffen und/oder aus industriellen Nebenprodukten hergestellte Gesteinskörnungen;

c) industrielle Nebenprodukte;

d) rezyklierte Gesteinskörnungen.

Sie enthält Festlegungen für die Bewertung der Konformität von Produkten nach dieser Europäischen Norm.

Die in dieser Norm festgelegten Anforderungen sind unter Umständen nicht auf jede Art von leichten Gesteinskörnungen anwendbar. Für besondere Anwendungen dürfen die Anforderungen und Toleranzen dem jeweiligen Verwendungszweck angepasst werden.

ANMERKUNG Gesteinskörnungen, die im Bauwesen verwendet werden, sollten alle Anforderungen dieser Europäischen Norm erfüllen. Das Mandat M/125 "Gesteinskörnungen" umfasst neben den bekannten und traditionsgemäß verwendeten natürlichen und industriell hergestellten Gesteinskörnungen auch Recycling-Gesteinskörnungen und einige Baustoffe aus neuen oder noch nicht genau bekannten Bezugsquellen. Die Recycling-Gesteinskörnungen wurden schon in die Normen aufgenommen, und neue Prüfverfahren für sie sind bereits in einem fortgeschrittenen Entwicklungsstadium.

Granulats légers - Partie 2 : Granulats légers pour mélanges hydrocarbonés, enduits superficiels et pour utilisation en couches traitées et non traitées

La présente Norme européenne spécifie les exigences techniques relatives aux granulats légers et aux fillers qui en sont issus, élaborés à partir de matériaux naturels, artificiels ou recyclés et des mélanges de ces granulats qui sont utilisés dans les mélanges hydrocarbonés et les enduits superficiels ainsi qu'en couches traitées ou non traitées, à l'exclusion des bétons, mortiers et coulis.

La présente Norme européenne traite des granulats légers d'origine minérale ayant une masse volumique réelle maximale de 2 000 kg/m3 (2,00 Mg/m3) ou une masse volumique en vrac maximale de 1 200 kg/m3 (1,20 Mg/m3), y compris :

a) les granulats naturels ;

b) les granulats artificiels issus de matériaux naturels et/ou de résidus de processus industriels ;

c) les résidus de processus industriels (à l'exclusion des résidus d'incinération) ;

d) les granulats recyclés.

Elle permet d'évaluer la conformité des produits à la présente Norme européenne.

Les exigences de la présente norme peuvent ne pas être applicables à tous les types de granulats légers. Les exigences et tolérances peuvent être adaptées à l'usage final dans l'application particulière considérée.

NOTE Les granulats utilisés dans la construction doivent respecter toutes les exigences de la présente Norme européenne. Le mandat granulats M/125 "Granulats" couvre aussi bien des granulats naturels usuels et traditionnels, ou des granulats artificiels que des granulats recyclés ou de source nouvelle ou inhabituelle. Les granulats recyclés sont inclus dans les normes et de nouvelles méthodes d'essais les concernant sont à un stade avancé de leur préparation. Pour les granulats inhabituels de source secondaire, le travail de normalisation a commencé récemment et plus de temps est nécessaire pour définir clairement les origines et les caractéristiques de ces matériaux.

Lahki agregati – 2. del: Lahki agregati za bitumenske zmesi in površinske prevleke ter za uporabo v nevezanih in vezanih mešanicah

General Information

- Status

- Withdrawn

- Publication Date

- 06-Jul-2004

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 5 - Lightweight aggregates

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-May-2016

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Replaced By

EN 13055:2016 - Lightweight aggregates - Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13055-2:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Lightweight aggregates - Part 2: Lightweight aggregates for bituminous mixtures and surface treatments and for unbound and bound applications". This standard covers: This European Standard specifies the properties of lightweight aggregates and fillers derived thereof obtained by processing natural, manufactured or recycled materials and mixtures of these aggregates for bituminous mixtures and surface treatments and for unbound and hydraulically bound applications other than concrete, mortar and grout. This European Standard covers lightweight aggregates of mineral origin having particle densities not exceeding 2000 kg/m3 (2,00 Mg/m3) or loose bulk densities not exceeding 1200 kg/m3 (1,20 Mg/m3) including: a) natural aggregates; b) aggregates manufactured from natural materials and/or from by-products of industrial processes; c) by-products of industrial processes; d) recycled aggregates. It provides for the evaluation of conformity of the products to this European Standard. The requirements specified in this standard may not be relevant to all types of lightweight aggregates. For particular applications the requirements and tolerances can be adapted for the end use. NOTE Aggregates used in construction should comply with all the requirements of this European Standard. As well as familiar and traditional natural and manufactured aggregates Mandate M/125 "Aggregates" included recycled aggregates and some materials from new or unfamiliar sources. Recycled aggregates are included in the standards and new test methods for them are at an advanced stage of preparation. For unfamiliar materials from secondary sources, however, the work on standardization has only started recently and more time is needed to define clearly the origins and characteristics of these materials. In the meantime such unfamiliar materials when placed on the market as aggregates should comply fully with this standard and national regulations for dangerous substances (see annex ZA) depending upon their intended use. Additional characteristics and requirements can be specified on a case by case basis depending upon experience of use of the product, and defi

This European Standard specifies the properties of lightweight aggregates and fillers derived thereof obtained by processing natural, manufactured or recycled materials and mixtures of these aggregates for bituminous mixtures and surface treatments and for unbound and hydraulically bound applications other than concrete, mortar and grout. This European Standard covers lightweight aggregates of mineral origin having particle densities not exceeding 2000 kg/m3 (2,00 Mg/m3) or loose bulk densities not exceeding 1200 kg/m3 (1,20 Mg/m3) including: a) natural aggregates; b) aggregates manufactured from natural materials and/or from by-products of industrial processes; c) by-products of industrial processes; d) recycled aggregates. It provides for the evaluation of conformity of the products to this European Standard. The requirements specified in this standard may not be relevant to all types of lightweight aggregates. For particular applications the requirements and tolerances can be adapted for the end use. NOTE Aggregates used in construction should comply with all the requirements of this European Standard. As well as familiar and traditional natural and manufactured aggregates Mandate M/125 "Aggregates" included recycled aggregates and some materials from new or unfamiliar sources. Recycled aggregates are included in the standards and new test methods for them are at an advanced stage of preparation. For unfamiliar materials from secondary sources, however, the work on standardization has only started recently and more time is needed to define clearly the origins and characteristics of these materials. In the meantime such unfamiliar materials when placed on the market as aggregates should comply fully with this standard and national regulations for dangerous substances (see annex ZA) depending upon their intended use. Additional characteristics and requirements can be specified on a case by case basis depending upon experience of use of the product, and defi

EN 13055-2:2004 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13055-2:2004 has the following relationships with other standards: It is inter standard links to EN 13055:2016, EN 932-1:1996, EN 1097-3:1998, EN 1097-5:2008, EN 1097-4:2008, EN 1097-10:2014, EN 933-5:2022, EN 933-2:2020, EN 1744-1:1998, EN 13055-1:2002, EN 1097-9:2014, EN 1744-3:2002, EN 12697-11:2020, EN 1367-5:2011, EN 12664:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13055-2:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13055-2:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lightweight aggregates - Part 2: Lightweight aggregates for bituminous mixtures and surface treatments and for unbound and bound applicationsLahki agregati – 2. del: Lahki agregati za bitumenske zmesi in površinske prevleke ter za uporabo v nevezanih in vezanih mešanicahGranulats légers - Partie 2 : Granulats légers pour mélanges hydrocarbonés, enduits superficiels et pour utilisation en couches traitées et non traitéesLeichte Gesteinskörnungen - Teil 2: Leichte Gesteinskörnungen für Asphalte und Oberflächenbehandlungen sowie für ungebundene und gebundene VerwendungTa slovenski standard je istoveten z:EN 13055-2:2004SIST EN 13055-2:2004en,fr,de91.100.15ICS:SLOVENSKI

STANDARDSIST EN 13055-2:200401-oktober-2004

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13055-2July 2004ICS 91.100.15English versionLightweight aggregates - Part 2: Lightweight aggregates forbituminous mixtures and surface treatments and for unboundand bound applicationsGranulats légers - Partie 2 : Granulats légers pourmélanges hydrocarbonés, enduits superficiels et pourutilisation en couches traitées et non traitéesLeichte Gesteinskörnungen - Teil 2: LeichteGesteinskörnungen für Asphalte undOberflächenbehandlungen sowie für ungebundene undgebundene VerwendungThis European Standard was approved by CEN on 23 April 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13055-2:2004: E

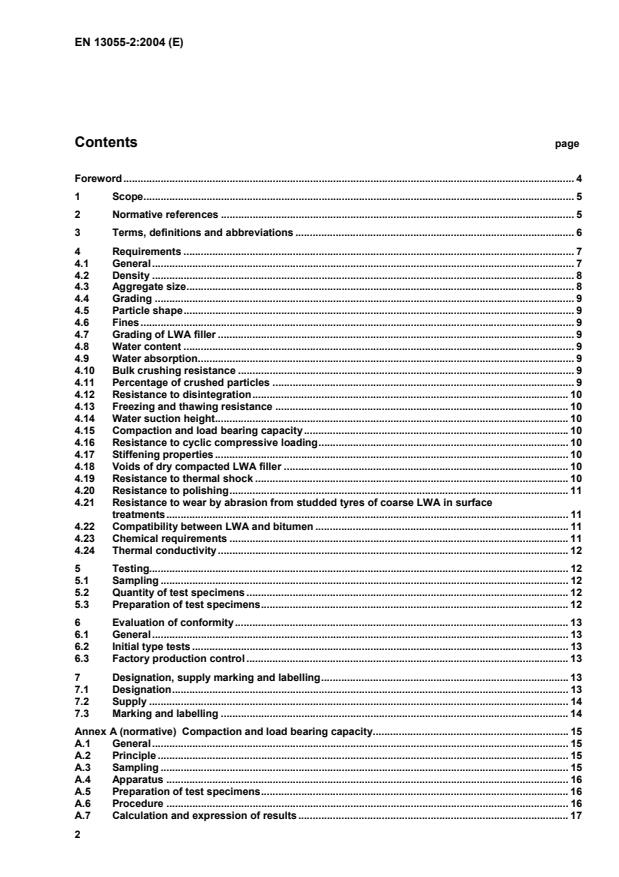

Compaction and load bearing capacity.15 A.1 General.15 A.2 Principle.15 A.3 Sampling.15 A.4 Apparatus.16 A.5 Preparation of test specimens.16 A.6 Procedure.16 A.7 Calculation and expression of results.17

Determination of resistance to freezing and thawing of lightweight aggregates.19 B.1 Introduction.19 B.2 Principle.19 B.3 Apparatus.19 B.4 Sampling.19 B.5 Test specimens.20 B.6 Procedure.20 B.7 Calculation and expression of results.21 B.8 Test report.21 Annex C (normative)

Factory production control.23 C.1 Introduction.23 C.2 Organization.23 C.3 Control procedures.23 C.4 Management of the production.24 C.5 Inspection and test.24 C.6 Records.27 C.7 Control of non-conforming product.27 C.8 Handling, storage and conditioning in production areas.28 C.9 Transport and packaging.28 C.10 Training of personnel.28 Annex D (informative)

Guidance on how to convert quantities by mass to quantities by volume.29 D.1 Background.29 D.2 Example calculation.29 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.30

EN 932-1, Tests for general properties of aggregates — Part 1: Methods for sampling. EN 932-2, Tests for general properties of aggregates — Part 2: Methods for reducing laboratory samples. EN 932-5, Tests for general properties of aggregates — Part 5: Common equipment and calibration. EN 933-1, Tests for geometrical properties of aggregates — Part 1: Determination of particle size distribution — Sieving method. EN 933-2, Tests for geometrical properties of aggregates — Part 2: Determination of particle size distribution — Test sieves, nominal size of apertures. EN 933-5, Tests for geometrical properties of aggregates — Part 5: Determination of percentage of crushed and broken surfaces in coarse aggregate particles.

4.2.1 Loose bulk density When required loose bulk density of LWA and LWA fillers shall be determined in accordance with EN 1097-3 and declared. It shall be in the range of ± 15 % with a maximum of ± 100 kg/m3 (0,10 Mg/m3) of the declared value. NOTE The container should be filled using a standard scoop held centrally over the container and without touching it. 4.2.2 Particle density When required the particle density of LWA shall be determined in accordance with EN 1097-6:2000, annex C and declared. It shall be in the range of ± 15 % with a maximum of ± 150 kg/m3 (0,15 Mg/m3) of the declared value. 4.3 Aggregate size 4.3.1 General Aggregate sizes shall be designated using a pair of sieve sizes selected from the basic set, or the basic set plus set 1, or the basic set plus set 2 specified in Table 1. NOTE This designation accepts the presence of some particles which will be retained on the upper sieve (oversize) and some which will pass the lower sieve (undersize). Table 1 — Sieve sizes for specifying aggregate product sizes Basic set Basic set plus set 1 Basic set plus set 2 (mm) (mm)(mm) 0 0 0 0,25 0,25 0,25 0,5 0,5 0,5 1 1 1 2 2 2 - 2,8 (3) 3,15 (3) 4 4 4 - 5,6 (5) - - - 6,3 (6) 8 8 8 - - 10 - 11,2 (11) - - - 12,5 (12) - - 14 16 16 16 - - 20 - 22,4 (22) - 31,5 (32) 31,5 (32) 31,5 (32) - - 40 - 45 - 63 63 63 NOTE

Figures in parenthesis can be used to provide simplified descriptions of aggregate product sizes.

When required the sieve through which 100 % of the aggregate passes shall be declared. 4.4 Grading The particle size distribution of LWA shall be determined in accordance with EN 933-1 without washing and declared. NOTE Care should be taken with friable aggregates to prevent degradation. 4.5 Particle shape When required particle shape of LWA shall be described and declared. NOTE Test methods for normal weight aggregates are not applicable. 4.6 Fines When required the content of fines in LWA shall be determined in accordance with EN 933-1 without washing and declared. NOTE Care should be taken with friable aggregates to prevent degradation. 4.7 Grading of LWA filler When required the particle size distribution of filler shall be determined in accordance with EN 933-10 and declared. 4.8 Water content When required the water content of the LWA shall be determined in accordance with EN 1097-5 and declared. 4.9 Water absorption When required the water absorption of LWA shall be determined in accordance with EN 1097-6:2000, annex C and declared. 4.10 Bulk crushing resistance When required the bulk crushing resistance of LWA shall be determined in accordance with EN 13055-1:2002, annex A and declared. NOTE There is no simple relationship between the bulk crushing resistance of LWA and the properties at its end use.

4.11 Percentage of crushed particles When required the percentage of crushed particles of LWA with a bulk density of not less than 150 kg/m3 (0,15 Mg/m3) shall be determined in accordance with EN 933-5 and declared.

4.17 Stiffening properties When required the stiffening properties of LWA filler in bituminous mixtures shall be determined in accordance with EN 13179-1 and declared. 4.18 Voids of dry compacted LWA filler

When required the voids of dry compacted LWA filler shall be determined in accordance with EN 1097-4 and declared. NOTE The test method developed primarily for normal weight aggregates has not been evaluated for its suitability for LWA to establish a pattern of use. 4.19 Resistance to thermal shock When required the resistance to thermal shock of LWA shall be determined in accordance with EN 1367-5 and declared.

is the comparison value; Vm

is the value measured in accordance with EN 1744-1; 1500 is the assumed nominal loose bulk density of normal weight aggregate. NOTE Further guidance is given in annex D. 4.23.2 Water solubility When required the water solubility of LWA filler used in bituminous mixtures shall be determined in accordance with EN 1744-1: 1998, clause 16, and declared. 4.23.3 Loss on ignition (for ashes only) The loss on ignition shall be determined in accordance with EN 1744-1 and declared.

4.23.4 Water-soluble constituents When a determination of water-soluble constituents is required the preparation of an eluate shall be made in accordance with EN 1744-3. 4.24 Thermal conductivity 4.24.1 General When required the thermal conductivity of LWA (including air voids) shall be determined in the air dry condition in accordance with EN 12664 or EN 12667 in the case of dry LWA with a thermal conductivity value less than 0,15 W/(mK). 4.24.2 Preparation of test specimens Care shall be taken to avoid excessive segregation and crushing when placing material in the apparatus. The density of the specimen shall be determined and declared, based on the mass of the specimen and the dimensions of the specimen enclosure. 4.24.3 Thickness of test specimens Test specimens shall be at least 10 times as thick as the mean aggregate size in the sample. NOTE Test specimen thickness of five times the mean aggregate size are permitted if it can be shown that the required accuracy of testing is obtained. 4.24.4 Correction for moisture Design values shall be obtained by correcting measured values in accordance with EN ISO 10456. 5 Testing 5.1 Sampling Sampling shall be carried out in accordance with EN 932-1. NOTE To ensure a representative sample care should be taken to avoid segregation.

5.2 Quantity of test specimens The test specimen quantity specified in any test method shall, if not taken into account for LWA, be corrected on the basis of loose bulk density (see 4.23). 5.3 Preparation of test specimens 5.3.1 Drying Test specimens shall be dried in accordance with EN 1097-5.

When required allow the test specimen to condition to moisture equilibrium at (23 ± 5) °C and (50 ± 10) % relative humidity. 6 Evaluation of conformity 6.1 General The producer shall undertake initial type tests (see 6.2) and Factory Production Control (see 6.3) to ensure that the product conforms to this European Standard and to declared values as appropriate. 6.2 Initial type tests Initial type tests relevant to the intended end use shall be carried out to check compliance with specified requirements in the following circumstances: a) A new source of aggregates is to be used. b) There is a major change in the nature of the raw materials or in the processing conditions which may affect the properties of the aggregates. The results of the initial tests shall be documented as the starting point of the factory production control for that material. This shall include the identification of any components likely to emit radiation above normal background levels, any components likely to release polyaromatic carbons or other dangerous substances if related regulations exist in the place of use of the aggregate. 6.3 Factory production control The producer shall have in place a system of factory production control that complies with the requirements of annex C. The records held by the producer shall indicate what control procedures are in operation during the production of the aggregate. NOTE The form of control applied to any aggregate depends upon its intended use and the regulations relating to that use. 7 Designation, supply marking and labelling 7.1 Designation LWA shall be identified in the following terms: a) the name of producer/supplier or trademark; b) aggregate size; c) the loose bulk density or particle density; d) reference to this standard; e) any additional information needed to identify the particular lightweight aggregate.

Compaction and load bearing capacity A.1 General This annex specifies a procedure for the determination of the compaction and load bearing capacity of LWA. The test is applicable to LWA and recycled aggregates up to a maximum size of 32 mm. A.2 Principle A specimen is placed in a steel container and then compacted by vibration. The test is performed as a compression test where the load is applied continuously (see Figure A.1).

Key 1

Load cell 4

Specimen 2

Spherical seating 5

Cylindrical test container 3

Load-distribution steel plate

Figure A.1 — Schematic test set-up A.3 Sampling Sampling and sample reduction shall be carried out in accordance with EN 932-1 and EN 932-2.

± 0,01 mm. A.4.5 Balance, of adequate capacity with an accuracy of

± 0,1 g. A.4.6 Load distribution steel plate, supplying 120 N, diameter (199 ± 0,5) mm and thickness (50 + 0,5) mm. A.4.7 Cylindrical test container, with a diameter and height of (200 ± 0,5) mm. A.5 Preparation of test specimens Prepare three test specimens of volume 8 l according to EN 932-2.

Then, dry the test specimens at (110 ± 5) °C to constant mass according to EN 1097-5 and condition the test specimens at (20 ± 5) °C for (24 ± 2) h. A.6 Procedure Place the test specimen in a plastic bag and then place the opening in the bottom of the test container.

Slowly lift the plastic bag and fill the container with the test specimen. Level the surface with a ruler.

Place the load distribution steel plate on the upper surface of the test specimen and measure the height of the test specimen (l0), see Figure A.2.

Vibrate the test specimen for 3 min and measure the height of the test specimen (l1) see Figure A.2. Place the test container in the test machine and zero the gauges. Apply the load (F) continuously at a rate of increase of (0,06 ± 0,002) kN/s. Increase the load until the deformation reaches 10% of the height after vibration. Record the load (F) and the deformation (δ) continuously as the mean value of the two gauges.

Key A, B: Dial gauge micrometers l0

Height before vibration l1

Height after vibration l2

Height under load F10

I0I1I2AB

Figure A.2 — Height measurements to be carried out before and after vibration

F = 10 %, in Newtons; A is the area of the load distribution steel plate, in square millimetres. The load bearing capacity shall be stated as the mean value of the three test specimens to one decimal place.

Calculate the density of the test specimen, ρ0 or ρ1, before and after vibration, in kilograms per cubic metre, in accordance with the following equations: Axlm00=ρ

or Axlm11=ρ where: m is the mass of the test specimen, in kilograms; A is the area of the load distributed steel plate, in square metres; l0 is the height of the test specimen, before vibration, in metres; l1 is the height of the test specimen, after vibration, in metres. The density before and after vibration shall be stated to the nearest whole number. A.8 Test report A.8.1 Required data a) reference to this European Standard; b) compaction (c) by vibration; c) deformation (DF) at load F; d) load bearing capacity (σF); e) density before and after vibration; f) identity of laboratory; g) identification of the specimen; h) date of receipt of specimen. A.8.2 Optional data a) name and location of the specimen source; b) date of test; c) any other information that could influence on the assessment of the test result.

Determination of resistance to freezing and thawing of lightweight aggregates B.1 Introduction The test method specified in this annex has been found to be suitable for lightweight aggregates with a particle size not less than 4 mm and a bulk density not less than 150 kg/m3 (0,15 Mg/m3). NOTE The principle of this test deviates from the test method specified in EN 1367-1. B.2 Principle A test portion of lightweight aggregates, having been soaked in water at atmospheric pressure, is subjected to 20 freeze-thaw cycles. This involves cooling down to below -15 °C in air and then thawing in a water bath at about 20 °C. After completion of the freeze-thaw cycles, the lightweight aggregates are examined for any changes such as crack formation and/or loss in mass. B.3 Apparatus B.3.1 All apparatus, unless otherwise stated, shall conform to the general requirements of

EN 932-5. B.3.2 Ventilated drying oven, with forced circulation of adequate capacity. The oven shall be capable of being maintained at (110 ± 5) °C. B.3.3 Balance, capable to weigh test specimens up to 400 g with an accuracy of ± 0,02 g and test specimens above 400 g with an accuracy of 0,05 g. B.3.4 Low temperature cabinet, (upright or chest) with air circulation. The cabinet shall be capable of being maintained at (-17,5 ± 2,5) °C. B.3.5 Containers, made from corrosion resistant material with a base area of approximate 0,02 m2 and a height of not less than 0,1 m. B.3.6 Grid, of a suitable size and aperture to prevent the lightweight aggregates floating in the container specified in B.3.5. B.3.7 Test sieves, conforming to EN 933-2 shall be used. B.3.8 Water, distilled or demineralised. B.4 Sampling Sampling shall be carried out in accordance with EN 932-1.

B.5.3 Preparation of test specimens Wash the test specimens and remove adhering particles. Dry the test specimens as specified in EN 1097-5, allow to cool to ambient temperature and weigh. NOTE For some lightweight aggregates it is recommended to allow the test specimens to condition to moisture equilibrium at (23 ± 5) °C and (50 ± 10) % relative humidity. Weighing shall be carried out to the following accuracies: Test specimens up to 400 g, to ± 0,04 g. Test specimens above 400 g, to ± 0,1 g. B.6 Procedure B.6.1 Soaking Store the test specimens at atmospheric pressure for (4 ± 0,2) h in the containers specified in B.3.5 at (20 ± 3) °C in distilled or demineralised water, ensuring that the water covers the test specimens by at least 10 mm for the full 4 h period of soaking.

In order to prevent the test specimens floating, the specimens are kept submerged by the grids specified in B.3.6. B.6.2 Exposure to freezing and thawing Remove the test specimens from the containers and allow them to drain on a sieve for about 1 min. Then place them back into the containers spreading them out evenly.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...