EN 12697-11:2020

(Main)Bituminous mixtures - Test methods - Part 11: Determination of the affinity between aggregate and bitumen

Bituminous mixtures - Test methods - Part 11: Determination of the affinity between aggregate and bitumen

This document specifies procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. This property is intended to be of assistance to the designer for mixture design rather than as a type test. Susceptibility to stripping, as determined by these procedures, is an indirect measure of the power of a binder to adhere to various aggregates, or of various binders to adhere to a given aggregate. The procedures can also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without adhesion agents including liquids, such as amines, and fillers, such as hydrated lime or cement.

In the rolling bottle method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after influence of mechanical stirring action in the presence of water.

NOTE 1 The rolling bottle test is a simple but subjective test and suitable for routine testing. It is not appropriate for aggregates that are highly abrasive.

In the static test method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water.

NOTE 2 The static test is a simple, though subjective test that is generally less precise, but that can cope with high PSV-aggregates.

In the boiling water stripping test method, the affinity is expressed by determining the degree of bitumen-coverage on uncompacted bitumen-coated aggregate after immersion in boiling water under specified conditions.

NOTE 3 The boiling water stripping test is an objective test and has a high precision. However, it is a more specialist test because it requires greater skill of the operatives and uses chemicals as reagent. The latter point might also imply extra health and safety considerations.

NOTE 4 The boiling water stripping test procedure can be used for any binder-aggregate combinations in which the mineral aggregate is calcareous, silico-calcareous or siliceous by nature.

Asphalt - Prüfverfahren - Teil 11: Bestimmung der Affinität von Gesteinskörnungen und Bitumen

Dieses Dokument legt Verfahren zur Bestimmung der Affinität von Gesteinskörnungen und Bitumen und des Einflusses dieser Affinität auf die Anfälligkeit für das Ablösen des Bindemittels von der Gesteinskörnung fest. Diese Eigenschaft ist in erster Linie als Hilfestellung für Entwickler von Mischgutrezepturen und nicht als Eignungsprüfung gedacht. Die nach diesen Verfahren bestimmte Anfälligkeit für das Ablösen des Bindemittels von der Gesteinskörnung ist ein indirektes Maß für das Haftvermögen dieses Bindemittels an verschiedenen Gesteinskörnungen oder für das Haftvermögen verschiedener Bindemittel an einer bestimmten Gesteinskörnung. Diese Verfahren können auch zur Beurteilung der Auswirkung von Feuchte auf bestimmte Kombinationen aus Gesteinskörnung und Bindemittel mit oder ohne Haftvermittler einschließlich Flüssigkeiten, wie z. B. Aminen, und Zusätzen, wie z. B. hydratisierter Kalk oder Zement, herangezogen werden.

Bei Anwendung des Flaschen-Rollverfahrens wird die Affinität durch visuelle Beurteilung des Umhüllungs¬grades unverdichteter bitumenumhüllter Gesteinskörner nach Beanspruchung durch mechanisches Rühren in Anwesenheit von Wasser angegeben.

ANMERKUNG 1 Die Flaschen-Rollprüfung ist eine einfache, aber subjektive Prüfung, die für Routineüberprüfungen geeignet ist. Sie ist nicht auf stark abriebanfällige Gesteinskörnungen anwendbar.

Bei Anwendung des statischen Prüfverfahrens wird die Affinität durch visuelle Beurteilung des Umhüllungsgrades unverdichteter bitumenumhüllter Gesteinskörner nach Lagerung in Wasser angegeben.

ANMERKUNG 2 Die statische Prüfung ist eine einfache, aber subjektive Prüfung, die grundsätzlich weniger genau ist, aber auch auf Gesteinskörnungen mit hohem Polierwert angewendet werden kann.

Bei Anwendung des Prüfverfahrens des Ablösens in siedendem Wasser wird die Affinität durch Bestimmung des Umhüllungsgrades unverdichteter bitumenumhüllter Gesteinskörnungen nach erfolgtem Eintauchen in siedendem Wasser unter festgelegten Bedingungen angegeben.

ANMERKUNG 3 Die Prüfung des Ablösens in siedendem Wasser ist eine objektive Prüfung und von hoher Präzision. Es handelt sich dabei jedoch um eine recht spezielle Prüfung, die höhere Anforderungen an die Fähigkeiten der Prüfer stellt und die Verwendung von Chemikalien als Reagenzien erfordert. Letzteres könnte auch bedeuten, besondere Vorsichts¬maßnahmen im Hinblick auf die Einhaltung der Gesundheits und Sicherheitsvorschriften treffen zu müssen.

ANMERKUNG 4 Das Prüfverfahren des Ablösens in siedendem Wasser ist auf alle Kombinationen aus Bindemittel und Gesteinskörnung anwendbar, deren Gesteinskörnung im natürlichen Zustand kalkreich, silicium kalkreich oder siliciumreich ist.

Mélanges bitumineux - Méthodes d'essai - Partie 11 : Détermination de l'affinité granulat-bitume

Ce document spécifie des modes opératoires pour déterminer l’affinité entre granulat et bitume et son influence sur la susceptibilité de la combinaison au désenrobage. Cette propriété est plutôt destinée à aider le concepteur à formuler le mélange qu’à représenter un essai pour épreuve de formulation. La susceptibilité au désenrobage, telle que déterminée par ces modes opératoires, est une mesure indirecte de la capacité du liant à adhérer à différents granulats ou de différents liants à adhérer à un granulat donné. Les modes opératoires peuvent également être utilisés pour évaluer l’effet de l’eau sur une combinaison granulats-liant avec ou sans dope d’adhésivité que ce soit des liquides comme les amines, des fillers comme la chaux hydratée ou le ciment.

Dans la méthode « de la bouteille tournante », l’affinité est exprimée par le degré d’enrobage de bitume, déterminé visuellement, de granulats minéraux enrobés de bitume, non compactés, après une agitation mécanique en présence d’eau.

NOTE 1 L’essai « de la bouteille tournante » est simple mais subjectif et approprié pour des essais de routine. Il ne convient pas pour les granulats hautement abrasifs.

Dans la méthode de l’essai statique, l’affinité est exprimée par le degré d’enrobage de bitume, déterminé visuellement, de granulats minéraux enrobés de bitume, non compactés après stockage dans l’eau.

NOTE 2 L’essai statique est simple quoique subjectif ; il est généralement moins précis mais il est approprié aux granulats à haut coefficient de polissage accéléré.

Dans la méthode de l’essai de désenrobage à l’eau bouillante, l’affinité est exprimée par le degré d’enrobage de bitume de granulats minéraux enrobés de bitume, non compactés après immersion dans l’eau bouillante dans des conditions spécifiées.

NOTE 3 L’essai de désenrobage à l’eau bouillante est objectif et très précis. Toutefois, il s’agit d’un essai plus spécialisé car il exige un personnel plus qualifié et il utilise des réactifs chimiques. Ce dernier point peut aussi impliquer des considérations supplémentaires en matière d’hygiène et de sécurité.

NOTE 4 Le mode opératoire de l’essai de désenrobage à l’eau bouillante peut être utilisé pour toute combinaison granulats-liant dans laquelle les granulats minéraux sont de nature calcaire, silico-calcaire ou siliceuse.

Bitumenske zmesi - Preskusne metode - 11. del: Ugotavljanje sprijemljivosti med agregatom in bitumnom

General Information

- Status

- Published

- Publication Date

- 25-Feb-2020

- Withdrawal Date

- 30-Aug-2020

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Sep-2025

- Completion Date

- 02-Sep-2025

Relations

- Effective Date

- 04-Mar-2020

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13055:2016 - Lightweight aggregates - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12697-11:2020 - "Bituminous mixtures - Test methods - Part 11: Determination of the affinity between aggregate and bitumen" (CEN) specifies laboratory procedures to evaluate how well bitumen adheres to mineral aggregate and how susceptible that combination is to stripping by water. The standard is intended to support mixture design decisions rather than to act as a product type test. It defines three test approaches (rolling bottle, static and boiling water stripping) to express affinity between aggregate and bitumen as the degree of bitumen coverage on uncompacted, bitumen‑coated aggregate particles.

Key Topics and Requirements

- Purpose: Indirect measure of binder-to-aggregate adhesion and susceptibility to moisture‑induced stripping; also used to assess adhesion agents (liquid amines) and fillers (e.g., hydrated lime, cement).

- Test methods:

- Rolling bottle method - visual estimation of bitumen coverage after mechanical stirring in water; simple and suitable for routine testing but subjective and not recommended for highly abrasive aggregates.

- Static method - visual estimation after static storage in water (e.g., 48 h); simple but generally less precise; better suited to high PSV aggregates.

- Boiling water stripping method - objective, higher precision method using chemical reagents and calibration curves; more specialist, requires skilled operators and H&S controls.

- Terminology & metrics: Degree of bitumen coverage (percentage = 100 − percentage of stripping); definition of “completely coated”; molarity and acid/base equivalence factor used in chemical procedures.

- Sample preparation: Typical aggregate fractions specified (standard sizes such as 8–11.2 mm or 6.3–10 mm; not smaller than 2–4 mm) with washing, drying and uniform bitumen coating.

- Reporting & precision: Procedures include conditioning, repeated assessments (independent estimations), calculation methods, and precision statements. Safety considerations for chemical reagents are noted.

Applications and Users

Who uses EN 12697-11:2020:

- Pavement and mixture designers evaluating binder/aggregate compatibility

- Road materials laboratories performing QA and formulation trials

- Contractors and consultants assessing the effectiveness of adhesion agents or fillers

- Specification writers and authorities setting moisture‑susceptibility criteria

Typical applications:

- Screening aggregates and binders during mix design to reduce stripping risk

- Comparing performance of adhesion agents (liquid amines, hydrated lime, cement fillers)

- Routine lab checks for quality control and troubleshooting moisture damage

Related Standards

Relevant referenced standards include:

- EN 12697-2 - particle size distribution for bituminous mixtures

- EN 12697-35 - laboratory mixing procedures

- EN 58 - sampling bituminous binders

- EN 1426 - bitumen needle penetration

EN 12697-11:2020 should be used alongside these standards to ensure consistent sampling, mixing and interpretation when evaluating binder–aggregate affinity and moisture susceptibility.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12697-11:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods - Part 11: Determination of the affinity between aggregate and bitumen". This standard covers: This document specifies procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. This property is intended to be of assistance to the designer for mixture design rather than as a type test. Susceptibility to stripping, as determined by these procedures, is an indirect measure of the power of a binder to adhere to various aggregates, or of various binders to adhere to a given aggregate. The procedures can also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without adhesion agents including liquids, such as amines, and fillers, such as hydrated lime or cement. In the rolling bottle method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after influence of mechanical stirring action in the presence of water. NOTE 1 The rolling bottle test is a simple but subjective test and suitable for routine testing. It is not appropriate for aggregates that are highly abrasive. In the static test method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water. NOTE 2 The static test is a simple, though subjective test that is generally less precise, but that can cope with high PSV-aggregates. In the boiling water stripping test method, the affinity is expressed by determining the degree of bitumen-coverage on uncompacted bitumen-coated aggregate after immersion in boiling water under specified conditions. NOTE 3 The boiling water stripping test is an objective test and has a high precision. However, it is a more specialist test because it requires greater skill of the operatives and uses chemicals as reagent. The latter point might also imply extra health and safety considerations. NOTE 4 The boiling water stripping test procedure can be used for any binder-aggregate combinations in which the mineral aggregate is calcareous, silico-calcareous or siliceous by nature.

This document specifies procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. This property is intended to be of assistance to the designer for mixture design rather than as a type test. Susceptibility to stripping, as determined by these procedures, is an indirect measure of the power of a binder to adhere to various aggregates, or of various binders to adhere to a given aggregate. The procedures can also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without adhesion agents including liquids, such as amines, and fillers, such as hydrated lime or cement. In the rolling bottle method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after influence of mechanical stirring action in the presence of water. NOTE 1 The rolling bottle test is a simple but subjective test and suitable for routine testing. It is not appropriate for aggregates that are highly abrasive. In the static test method, the affinity is expressed by visual registration of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water. NOTE 2 The static test is a simple, though subjective test that is generally less precise, but that can cope with high PSV-aggregates. In the boiling water stripping test method, the affinity is expressed by determining the degree of bitumen-coverage on uncompacted bitumen-coated aggregate after immersion in boiling water under specified conditions. NOTE 3 The boiling water stripping test is an objective test and has a high precision. However, it is a more specialist test because it requires greater skill of the operatives and uses chemicals as reagent. The latter point might also imply extra health and safety considerations. NOTE 4 The boiling water stripping test procedure can be used for any binder-aggregate combinations in which the mineral aggregate is calcareous, silico-calcareous or siliceous by nature.

EN 12697-11:2020 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12697-11:2020 has the following relationships with other standards: It is inter standard links to EN 12697-11:2012, EN 1426:2024, EN 12697-2:2024, EN 12697-35:2025, EN 58:2012, EN 16236:2018, EN 13055-2:2004, EN 13108-7:2016, EN 13108-20:2016, EN 13043:2013, EN 13108-20:2006, EN 13055:2016, EN 13108-9:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12697-11:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Nadomešča:

SIST EN 12697-11:2012

Bitumenske zmesi - Preskusne metode - 11. del: Ugotavljanje sprijemljivosti med

agregatom in bitumnom

Bituminous mixtures - Test methods - Part 11: Determination of the affinity between

aggregate and bitumen

Asphalt - Prüfverfahren - Teil 11: Bestimmung der Affinität von Gesteinskörnungen und

Bitumen

Mélanges bitumineux - Essais pour - Partie 11 : Détermination de la affinité entre

granulation et bitume

Ta slovenski standard je istoveten z: EN 12697-11:2020

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12697-11

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2020

EUROPÄISCHE NORM

ICS 93.080.20 Supersedes EN 12697-11:2012

English Version

Bituminous mixtures - Test methods - Part 11:

Determination of the affinity between aggregate and

bitumen

Mélanges bitumineux - Méthodes d´essai - Partie 11 : Asphalt - Prüfverfahren - Teil 11: Bestimmung der

Détermination de l'affinité granulat-bitume Affinität von Gesteinskörnungen und Bitumen

This European Standard was approved by CEN on 18 November 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12697-11:2020 E

worldwide for CEN national Members.

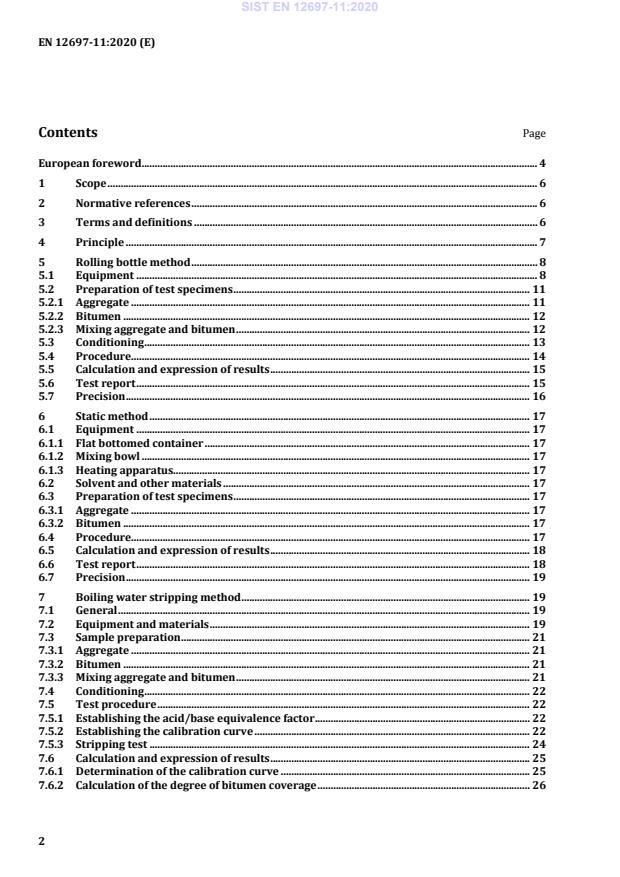

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Principle . 7

5 Rolling bottle method . 8

5.1 Equipment . 8

5.2 Preparation of test specimens . 11

5.2.1 Aggregate . 11

5.2.2 Bitumen . 12

5.2.3 Mixing aggregate and bitumen . 12

5.3 Conditioning . 13

5.4 Procedure. 14

5.5 Calculation and expression of results . 15

5.6 Test report . 15

5.7 Precision . 16

6 Static method . 17

6.1 Equipment . 17

6.1.1 Flat bottomed container . 17

6.1.2 Mixing bowl . 17

6.1.3 Heating apparatus. 17

6.2 Solvent and other materials . 17

6.3 Preparation of test specimens . 17

6.3.1 Aggregate . 17

6.3.2 Bitumen . 17

6.4 Procedure. 17

6.5 Calculation and expression of results . 18

6.6 Test report . 18

6.7 Precision . 19

7 Boiling water stripping method . 19

7.1 General . 19

7.2 Equipment and materials . 19

7.3 Sample preparation . 21

7.3.1 Aggregate . 21

7.3.2 Bitumen . 21

7.3.3 Mixing aggregate and bitumen . 21

7.4 Conditioning . 22

7.5 Test procedure . 22

7.5.1 Establishing the acid/base equivalence factor . 22

7.5.2 Establishing the calibration curve . 22

7.5.3 Stripping test . 24

7.6 Calculation and expression of results . 25

7.6.1 Determination of the calibration curve . 25

7.6.2 Calculation of the degree of bitumen coverage . 26

7.7 Test report . 26

7.8 Precision . 26

Annex A (informative) Guidance for estimation of the degree of bitumen coverage . 27

Bibliography . 28

European foreword

This document (EN 12697-11:2020) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2020, and conflicting national standards shall

be withdrawn at the latest by August 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12697-11:2012.

The following is a list of significant technical changes since the previous edition:

— the title no longer makes the method exclusively for hot mix asphalt;

— [ge] editorial update according to current standard template;

— [ge] NOTEs adjusted according to ISO/IEC Directives – Part 2:2016,24.5;

— [3.5] chemical expression for molar concentration updated. The definition “Normality, N” amended

to molarity. Amended description of the definition and change of unit to mol/l;

— [5.1.5] alternative procedure for addition of adhesion agent by using a syringe introduced. Change

of title for 5.1.5. The following clauses renumbered accordingly;

— [5.1.13] clarified that the speed requirements refer to bottle rather than machine rotation;

— [5.2.3.4] clarified procedure for the addition of liquid adhesion agents with time limits including

description for addition of small amounts (less than 0,4 g). Clarified that the weighed amount of

adhesive agent shall be reported in the test report. Description of the evaluation of heat stability of

adhesion agents introduced;

— [5.2.3.6] Formula (1) clarified. Keys added;

— [5.4.1] editorial: clarified and simplified description;

— [5.6] bullet e): completed with “amount”;

— [6.4.5] NOTE clarified that additional procedure has to be mentioned in the test report;

— [7.1 to 7.6.2.1] chemical expressions for concentration, “N”, amended to mol/l in relevant places in

line with changed definition in 3.5;

— [7.2.12] last paragraph clarified regarding concentration;

— [7.6.1.1] Formula (4) clarified. Keys added.

A list of all parts in the EN 12697 series can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies procedures for the determination of the affinity between aggregate and

bitumen and its influence on the susceptibility of the combination to stripping. This property is

intended to be of assistance to the designer for mixture design rather than as a type test. Susceptibility

to stripping, as determined by these procedures, is an indirect measure of the power of a binder to

adhere to various aggregates, or of various binders to adhere to a given aggregate. The procedures can

also be used to evaluate the effect of moisture on a given aggregate-binder combination with or without

adhesion agents including liquids, such as amines, and fillers, such as hydrated lime or cement.

In the rolling bottle method, the affinity is expressed by visual registration of the degree of bitumen

coverage on uncompacted bitumen-coated mineral aggregate particles after influence of mechanical

stirring action in the presence of water.

NOTE 1 The rolling bottle test is a simple but subjective test and suitable for routine testing. It is not

appropriate for aggregates that are highly abrasive.

In the static test method, the affinity is expressed by visual registration of the degree of bitumen

coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water.

NOTE 2 The static test is a simple, though subjective test that is generally less precise, but that can cope with

high PSV-aggregates.

In the boiling water stripping test method, the affinity is expressed by determining the degree of

bitumen-coverage on uncompacted bitumen-coated aggregate after immersion in boiling water under

specified conditions.

NOTE 3 The boiling water stripping test is an objective test and has a high precision. However, it is a more

specialist test because it requires greater skill of the operatives and uses chemicals as reagent. The latter point

might also imply extra health and safety considerations.

NOTE 4 The boiling water stripping test procedure can be used for any binder-aggregate combinations in

which the mineral aggregate is calcareous, silico-calcareous or siliceous by nature.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 58, Bitumen and bituminous binders — Sampling bituminous binders

EN 1426, Bitumen and bituminous binders — Determination of needle penetration

EN 12697-2, Bituminous mixtures — Test methods — Part 2: Determination of particle size distribution

EN 12697-35, Bituminous mixtures — Test methods — Part 35: Laboratory mixing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

acid/base equivalence factor

f

eq

ratio of the volume of base needed to neutralise 25 ml of acid

3.2

affinity between aggregate and bitumen

degree of bitumen coverage visually determined on uncompacted bitumen coated mineral aggregate

particles after influence of mechanical stirring action in the presence of water

3.3

completely coated

aggregate particle is completely coated by binder when there are no visible breaks, however small, in

the film of binder covering the particle

3.4

degree of bitumen coverage

average proportion of the surface area of the aggregate particles that are covered with bitumen,

expressed as a percentage (equal to 100 minus the percentage of stripping)

3.5

molarity

molar concentration expressed in mol/l

3.6

percentage of stripping

average proportion of the surface area of the aggregate particles from which the binder is soaked off

due to the action of water, expressed as a percentage

4 Principle

An aggregate is sieved in accordance with EN 12697-2. The standard size is 8 mm to 11,2 mm fraction

(Basic set plus set 1) or 6,3 mm to 10 mm fraction (Basic set plus set 2) which is washed, dried and

mixed with bitumen to obtain uniform, total coverage.

Other fractions may alternatively be used, but not smaller than the 2 mm to 4 mm fraction. However, to

avoid clusters, the above mentioned standard sizes should be used.

For the method described in Clause 5, the bitumen coated aggregate is placed loosely distributed on a

metal plate or silicone coated paper, stored at ambient temperature overnight, and then divided into

three part samples for analysis. Each part sample is transferred to a bottle filled with water. The bottle

is sealed and placed on a bottle-rolling device. The bottles are rolled at ambient temperature and at a

specified speed. At specified time intervals the degree of bitumen coverage on the aggregate particles is

visually estimated by two technicians independently (or alternatively by automated system).

For the method described in Clause 6, the bitumen coated aggregate is immersed in distilled water for

48 h and the number of particles that are no longer completely coated assessed.

For the method described in Clause 7, the bitumen coated aggregate is subjected to stripping in boiling

water under specified conditions, using a simple device in which no local overheating can occur. By

contact with a chemical reagent, the consumption of which is proportional to the uncoated surface of

the aggregate, the degree of bitumen coverage is determined with reference to a calibration curve

established by a well-defined procedure. The reagent used is hydrochloric acid for calcareous

aggregates and hydrofluoric acid for silico-calcareous or siliceous aggregates.

5 Rolling bottle method

5.1 Equipment

5.1.1 Test sieves.

Square openings conforming to EN 12697-2; 11,2 mm and 8 mm or 6,3 mm and 10 mm.

Alternatively, square opening test sieves of 5,6 mm, 6 mm and 8 mm may be used.

5.1.2 Ventilated oven, thermostatically controlled, adjustable from 100 °C to 180 °C, able to maintain

the sample at (110 ± 5) °C for drying procedure and at the specified mixing temperature ± 5 °C (refer to

5.2.3.1).

5.1.3 Temperature measuring device.

5.1.3.1 Temperature measuring device, capable of measuring the water temperature of 5 °C and

20 °C with an accuracy of ± 1 °C.

5.1.3.2 Temperature measuring device, capable of measuring the aggregate and bitumen

temperature at a range of 110 °C to 180 °C with an accuracy of ± 2 °C.

NOTE The temperature measuring device can be a thermometer or an electronical measuring device.

5.1.4 Balance.

Capacity not less than 600 g, capable of determining an aggregate portion of 510 g with an accuracy

of ± 2 g, and a balance capable of determining a binder test portion of 16 g to 18 g with an accuracy

of ± 0,2 g (see 5.2.1.3 and 5.2.3.6).

NOTE A 'dual range' type balance might allow to weigh the aggregate and bowl with an accuracy of ± 2 g and

after use of tare-function to determine the mass of binder added into the same mixing bowl with an accuracy

of ± 0,2 g.

Suitable equipment for measuring small portions of adhesion agent in the required precision. If a

balance is used, it shall allow for determining the adhesion agent portion with an accuracy of ± 0,001 g.

5.1.5 Syringe for measuring volume of adhesion agent

If a syringe is used for addition of adhesion agent, it shall allow for determining the volume of adhesion

agent with an accuracy of ± 1 µl.

5.1.6 Metal containers (tins)

Suitable size for bitumen heating and addition of adhesion agent.

5.1.7 Mixing bowl

Glazed porcelain bowl or other bowl with smooth non-absorbent surface, suitable for mixing the

specified test portion in accordance with 5.2.

NOTE A porcelain bowl with diameter of 200 mm and internal height 50 mm can be considered suitable.

5.1.8 Spatula, made of metal or other suitable, non-absorbent material for mixing of bitumen and

aggregate.

5.1.9 Silicone coated paper or a flat metal lid, for storage of coated aggregate particles as

individual, loose particles when cooling down after mixing.

NOTE A flat metal lid with a rim height of 10 mm and diameter 300 mm can be considered suitable.

5.1.10 Refrigerator, capable of maintaining a temperature of (5 ± 2) °C.

5.1.11 Test bottles, made of borosilicate glass for high wear resistance.

The volume capacity shall be approximately 500 ml. The bottles shall have a diameter of (80 ± 10) mm

and a height of (175 ± 10) mm. The bottle shall have a shoulder height of (110 ± 10) mm. The bottle

neck shall have an opening diameter of (30 ± 5) mm, equipped with a water-tight fitting screw cap.

5.1.12 Glass-rods, diameter of (6 ± 1) mm, equipped with (30 ± 10) mm long, fitting rubber tubes.

The rubber tube shall be positioned on one end of the glass-rod so that the length of the rod is extended

by approximately half of the tube length. The length of the glass-rod shall be proportioned, so that the

rod with rubber tube can be firmly fixed inside the test bottle between the bottom and the screw cap

(see Figure 3).

NOTE The glass rod ensures mechanical stirring and reduces risk of coated aggregate forming lumps.

5.1.13 Bottle rolling machine, capable of rolling not less than three test bottles at the same time.

−1 −1

The rotation speed shall be adjustable, so that a bottle rotation a speed of 40 min and 60 min can be

obtained with an accuracy of ± 10 %. The machine shall be positioned such that the bottles rotate

horizontally with a tolerance of ± 5°.

NOTE An example of bottle rolling machine is shown in Figure 2.

Figure 1 — Test bottle

Figure 2 — Bottle rolling machine

5.1.14 Glass beakers.

Volume not less than 200 ml.

5.1.15 Test bowls, suitable for visual determination of degree of binder coating on the aggregate.

The bowls shall be flat-bottomed and of sufficient diameter to allow for placing of a test portion of

(150 ± 2) g aggregate in a single layer, and of sufficient height to allow the test portion of aggregate to

be completely submerged in water.

NOTE Flat-bottomed 'Petri-dishes' made of glass with approximate diameter 120 mm and height 15 mm can

be considered suitable.

5.1.16 Lamp to provide a suitable light source to facilitate visual determination of binder coating on

aggregate.

5.1.17 Magnifying glass with low magnification, to facilitate determination of degree of binder coating

on aggregate (optional).

Dimensions in millimetres

Key

1 screw cap, bottle opening diameter (30 ± 5) mm

2 rubber tube

3 glass rod, diameter (6 ± 1) mm

4 glass test bottle

5 level A (shoulder)

Figure 3 — Test bottle with appropriate dimensions

5.2 Preparation of test specimens

5.2.1 Aggregate

5.2.1.1 Using test sieves from basic set plus set 1: Separate at least 600 g of aggregate passing the

11,2 mm test sieve and retained on the 8 mm sieve in accordance with EN 12697-2 to form a 8/11 mm

fraction of the aggregate to be tested. Wash the fraction on the 8 mm sieve.

Using test sieves from basic set plus set 2: Separate at least 600 g of aggregate passing the 10 mm test

sieve and retained on the 6,3 mm sieve in accordance with EN 12697-2 to form a 6/10 mm fraction of

the aggregate to be tested. Wash the fraction on the 6,3 mm sieve.

NOTE Alternatively, a smaller 5/8 mm fraction (passing the 8 mm sieve and retained on the 5,6 mm sieve,

basic set + set 1) can be used. However, bitumen coated particles of the smaller 5/8 mm aggregate fraction have

an increased risk of forming clusters during the rolling procedure, which can invalidate the test result. Also, use of

the smaller 5/8 mm fraction can complicate the visual determination of the degree of bitumen coverage on the

aggregate surfaces. Fractions smaller than 5/8 mm are not acceptable for the rolling bottle method. Therefore,

8/11 mm or 6/10 mm aggregates are preferred.

5.2.1.2 Place the aggregates in the ventilated oven set at (110 ± 5) °C and dry to a constant mass, i.e.

until three consecutive mass determinations with at least one minute intervals show a difference less

than 1 %.

NOTE It can be considered practical to let the aggregates dry overnight.

5.2.1.3 Place a portion of (510 ± 2) g aggregates in a mixing bowl.

5.2.2 Bitumen

5.2.2.1 Take a representative sample of the binder to be used in the plant mixtures in accordance

with EN 58. The sample shall include any modifiers and/or adhesion agents at the same proportion(s)

as they are to be used in the plant mixtures.

5.2.2.2 Pour the sampled bitumen into suitable metal containers that are covered. Ensure that the

containers are filled.

5.2.3 Mixing aggregate and bitumen

5.2.3.1 The mixing temperature shall be the reference temperature for mixtures as defined in

EN 12697-35.

5.2.3.2 Heat the aggregate in the mixing bowl to the mixing temperature by placing it in the

ventilated oven set at the mixing temperature ± 5 °C. Maintain the temperature for a duration of not less

than 3 h.

5.2.3.3 Heat the binder to the mixing temperature by placing a container with the binder in the

ventilated oven set at a temperature corresponding to the mixing temperature ± 5 °C when measured in

the vicinity of the binder for a duration of (3 ± 1) h. Before mixing, remove the coverage of the

container, check the binder temperature and stir the binder.

5.2.3.4 If a liquid adhesion agent is to be added to the bitumen, the adhesion agent shall be added to

a bitumen sample of not less than 100 g heated to the mixing temperature. The adhesion agent shall be

added to the bitumen (30 ± 10) min before mixing with the aggregate.

Mix the adhesion agent and the bitumen thoroughly by means of a spatula for 30 s and proceed

immediately to 5.2.3.6.

If the heat stability of the adhesion agent is to be evaluated, the time before mixing with aggregate may

be extended and noted in the test report, bullet j).

If small amounts are to be added (less than 0,4 g), the adhesion promoter shall first be weighed on a

spoon and then mixed with the binder.

The exact weighed amount of adhesive agent shall be noted in the test report.

5.2.3.5 If an adhesion improving filler is to be added to the mixture, the filler shall be added to the

aggregate test portion and carefully mixed with a spatula before addition of bitumen.

As the affinity is determined according to a procedure involving mechanical action, the test result may

be influenced by mechanical wear, which may be different if the aggregate coating does not consist of

pure binder. If the effect of an adhesion improving filler (e.g. cement or hydrated lime) is to be

evaluated, the reference sample should also contain a filler, as binder coating on aggregate without filler

is faster worn than binder coatings on aggregates mixed with filler (i.e. the coating is a stiffer

bitumen/filler mortar).

5.2.3.6 Using 8/11 mm aggregates, add a portion of (16,0 ± 0,2) g of bitumen into the mixing bowl

with aggregates. If 6/10 mm aggregates are used, add a portion of (17,0 ± 0,2) g bitumen into the

mixing bowl with aggregates.

NOTE The bitumen quantity specified corresponds to a bitumen content of 3,0 % (by weight of mix) for the

8/11 mm aggregate and is adjusted for 6/10 mm and 5/8 mm fractions to ensure that approximately the same

binder film thickness is obtained.

The amount of bitumen to be added shall be corrected to the actual aggregate density by multiplying by

the factor:

2, 650 Mg / m³

α = (1)

ρ

p

where

α is the correction factor;

ρ is the aggregate density (Mg/m ).

p

If 5/8 mm aggregates are used, add a portion of (18,0 ± 0,2) g bitumen into the mixing bowl with

aggregates.

5.2.3.7 Mix the aggregates and binder intensively by means of a spatula to obtain a uniform coating.

Ensure that the surfaces of the aggregates are completely covered by bitumen. Discard the mixed

material if total (100 %) bitumen coverage is not obtained. Any thin, brownish translucent areas at

edges of the aggregates shall be considered fully coated.

5.2.3.8 Spread the mixed material immediately onto the flat metal lid or silicone-coated paper.

Avoid any lumps in the bitumen coated aggregates. Ensure that the material is loosely spread as

individual particles.

5.2.3.9 Store the mixed material on the lid or silicone paper between 12 h and 64 h at ambient

temperature of (20 ± 5) °C. Avoid direct exposure to sunlight and contamination with dust.

5.3 Conditioning

5.3.1 Split the mixed material into three part samples each weighing (150 ± 2) g.

5.3.2 Mark the test bottles and fill them to approximately 50 % of the volume with distilled or de-

ionized water having a temperature of (5 ± 2) °C.

NOTE The low initial water temperature prevents the bitumen coated a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...