EN 16602-70-38:2019

(Main)Space product assurance - High-reliability soldering for surface-mount and mixed technology

Space product assurance - High-reliability soldering for surface-mount and mixed technology

This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology.

The Standard defines acceptance and rejection criteria for high-reliability manufacture of surface-mount and mixed-technology circuit assemblies intended to withstand normal terrestrial conditions and the vibrational g loads and environment imposed by space flight.

The proper tools, correct materials, design and workmanship are covered by this document. Workmanship standards are included to permit discrimination between proper and improper work.

The assembly of leaded devices to through-hole terminations and general soldering principles are covered in ECSS-Q-ST-70-08.

Requirements related to printed circuit boards are contained in ECSS-Q-ST-70 10, ECSS-Q-ST-70-11 and ECSS-Q-ST-70-12 . The mounting and supporting of devices, terminals and conductors prescribed herein applies to assemblies at PCB level designed to continuously operate over the mission within the temperature limits of -55 C to +85 C.

For temperatures outside this normal range, special design, verification and qualification testing is performed to ensure the necessary environmental survival capability.

Special thermal heat sinks are applied to devices having high thermal dissipation (e.g. junction temperatures of 110 C, power transistors) in order to ensure that solder joints do not exceed 85 C.

Verification of SMD assembly processes is made on test vehicles (surface mount verification samples). Temperature cycling ensures the operational lifetime for spacecraft. However, mechanical testing only indicates SMD reliability as it is unlikely that the test vehicle represents every flight configuration.

This Standard does not cover the qualification and acceptance of the EQM and FM equipment with surface-mount and mixed-technology.

The qualification and acceptance tests of equipment manufactured in accordance with this Standard are covered by ECSS-E-ST-10-03.

This standard may be tailored for the specific characteristics and constraints of a space project, in accordance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Hochzuverlässiges Löten von Oberflächen-Befestigungen und gemischte Technologien

Assurance produit des projets spatiaux - Soudure haute fiabilité pour technologies à montage de surface et mixte

Zagotavljanje kakovosti proizvodov v vesoljski tehniki - Visoka zanesljivost spajkanja za površinsko montažo in mešano tehnologijo

Ta standard opredeljuje tehnične zahteve in določbe za zagotavljanje kakovosti za proizvodnjo in preverjanje visoko zanesljivih elektronskih vezij na podlagi površinsko montiranih elementov (SMD) in mešane tehnologije.

Standard določa merila za sprejem ali zavrnitev za visoko zanesljivo proizvodnjo površinsko montiranih sestavov vezij z mešano tehnologijo, ki naj bi prenesli običajne zemeljske pogoje in vibracijske obremenitve zaradi pospeška ter okolje, ki jih povzročijo vesoljski poleti.

Ta dokument obravnava ustrezna orodja, pravilne materiale, zasnovo in izvedbo. Izvedbeni standardi so vključeni, da se omogoči ločevanje med primernim in neprimernim delom.

Sestav osvinčenih elementov, terminali z luknjo in splošna načela spajkanja so zajeti v standardu ECSS-Q-ST-70-08.

Zahteve v zvezi s ploščami tiskanih vezij so podane v standardih ECSS-Q-ST-70 10, ECSS-Q-ST-70-11 in ECSS-Q-ST-70-12. Nameščanje in podpiranje komponent, terminalov in prevodnikov iz tega standarda se uporablja za sestave, namenjene delovanju v okviru temperaturnega razpona –55 C do +85 C.

Pri temperaturah zunaj tega običajnega razpona se izvede posebno preskušanje zasnove, preverjanja in kvalifikacij, da se zagotovi potrebna okoljska zmožnost preživetja.

Posebni toplotni ponori se uporabljajo za naprave z visokim toplotnim odvajanjem (npr. temperature stika 110 C, močnostni tranzistor), da se zagotovi, da spojeni spoji ne presežejo 85 C.

Preverjanje postopkov sestavov površinsko montiranih elementov se izvaja na testnih plovilih (vzorci preverjanja površinske montaže). Ciklične temperaturne spremembe zagotavljajo operativno življenjsko dobo vesoljskega plovila. Vendar pa mehansko preskušanje podaja samo zanesljivost površinsko montiranih elementov, saj je malo verjetno, da testno plovilo predstavlja konfiguracijo vsakega leta.

Ta standard ne zajema kvalifikacije in sprejemljivosti opreme EQM in FM s površinsko montažo in mešano tehnologijo.

Kvalifikacijski in sprejemljivostni preskusi opreme, izdelane v skladu s tem standardom, so obravnavani v standardu ECSS-E-ST-10-03.

Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Withdrawn

- Publication Date

- 16-Apr-2019

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5/WG 6 - Upstream standards

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Nov-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 17-Jun-2020

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Sponsored listings

Frequently Asked Questions

EN 16602-70-38:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space product assurance - High-reliability soldering for surface-mount and mixed technology". This standard covers: This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology. The Standard defines acceptance and rejection criteria for high-reliability manufacture of surface-mount and mixed-technology circuit assemblies intended to withstand normal terrestrial conditions and the vibrational g loads and environment imposed by space flight. The proper tools, correct materials, design and workmanship are covered by this document. Workmanship standards are included to permit discrimination between proper and improper work. The assembly of leaded devices to through-hole terminations and general soldering principles are covered in ECSS-Q-ST-70-08. Requirements related to printed circuit boards are contained in ECSS-Q-ST-70 10, ECSS-Q-ST-70-11 and ECSS-Q-ST-70-12 . The mounting and supporting of devices, terminals and conductors prescribed herein applies to assemblies at PCB level designed to continuously operate over the mission within the temperature limits of -55 C to +85 C. For temperatures outside this normal range, special design, verification and qualification testing is performed to ensure the necessary environmental survival capability. Special thermal heat sinks are applied to devices having high thermal dissipation (e.g. junction temperatures of 110 C, power transistors) in order to ensure that solder joints do not exceed 85 C. Verification of SMD assembly processes is made on test vehicles (surface mount verification samples). Temperature cycling ensures the operational lifetime for spacecraft. However, mechanical testing only indicates SMD reliability as it is unlikely that the test vehicle represents every flight configuration. This Standard does not cover the qualification and acceptance of the EQM and FM equipment with surface-mount and mixed-technology. The qualification and acceptance tests of equipment manufactured in accordance with this Standard are covered by ECSS-E-ST-10-03. This standard may be tailored for the specific characteristics and constraints of a space project, in accordance with ECSS-S-ST-00.

This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology. The Standard defines acceptance and rejection criteria for high-reliability manufacture of surface-mount and mixed-technology circuit assemblies intended to withstand normal terrestrial conditions and the vibrational g loads and environment imposed by space flight. The proper tools, correct materials, design and workmanship are covered by this document. Workmanship standards are included to permit discrimination between proper and improper work. The assembly of leaded devices to through-hole terminations and general soldering principles are covered in ECSS-Q-ST-70-08. Requirements related to printed circuit boards are contained in ECSS-Q-ST-70 10, ECSS-Q-ST-70-11 and ECSS-Q-ST-70-12 . The mounting and supporting of devices, terminals and conductors prescribed herein applies to assemblies at PCB level designed to continuously operate over the mission within the temperature limits of -55 C to +85 C. For temperatures outside this normal range, special design, verification and qualification testing is performed to ensure the necessary environmental survival capability. Special thermal heat sinks are applied to devices having high thermal dissipation (e.g. junction temperatures of 110 C, power transistors) in order to ensure that solder joints do not exceed 85 C. Verification of SMD assembly processes is made on test vehicles (surface mount verification samples). Temperature cycling ensures the operational lifetime for spacecraft. However, mechanical testing only indicates SMD reliability as it is unlikely that the test vehicle represents every flight configuration. This Standard does not cover the qualification and acceptance of the EQM and FM equipment with surface-mount and mixed-technology. The qualification and acceptance tests of equipment manufactured in accordance with this Standard are covered by ECSS-E-ST-10-03. This standard may be tailored for the specific characteristics and constraints of a space project, in accordance with ECSS-S-ST-00.

EN 16602-70-38:2019 is classified under the following ICS (International Classification for Standards) categories: 25.160.50 - Brazing and soldering; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16602-70-38:2019 has the following relationships with other standards: It is inter standard links to EN 16602-70-61:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16602-70-38:2019 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16602-70-38:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Zagotavljanje kakovosti proizvodov v vesoljski tehniki - Visoka zanesljivost

spajkanja za površinsko montažo in mešano tehnologijo

Space product assurance - High-reliability soldering for surface-mount and mixed

technology

Raumfahrtproduktsicherung - Hochzuverlässiges Löten von Oberflächen-Befestigungen

und gemischte Technologien

Assurance produit spatiale - Soudure haute fiabilité pour technologies à montage de

surface et mixte

Ta slovenski standard je istoveten z: EN 16602-70-38:2019

ICS:

25.160.50 Trdo in mehko lotanje Brazing and soldering

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 16602-70-38

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2019

ICS 25.160.50; 49.140

English version

Space product assurance - High-reliability soldering for

surface-mount and mixed technology

Assurance produit des projets spatiaux - Soudure Raumfahrtproduktsicherung - Hochzuverlässiges

haute fiabilité pour technologies à montage de surface Löten von Oberflächen-Befestigungen und gemischte

et mixte Technologien

This European Standard was approved by CEN on 5 October 2018.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany,

Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2019 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. EN 16602-70-38:2019 E

reserved worldwide for CEN national Members and for

CENELEC Members.

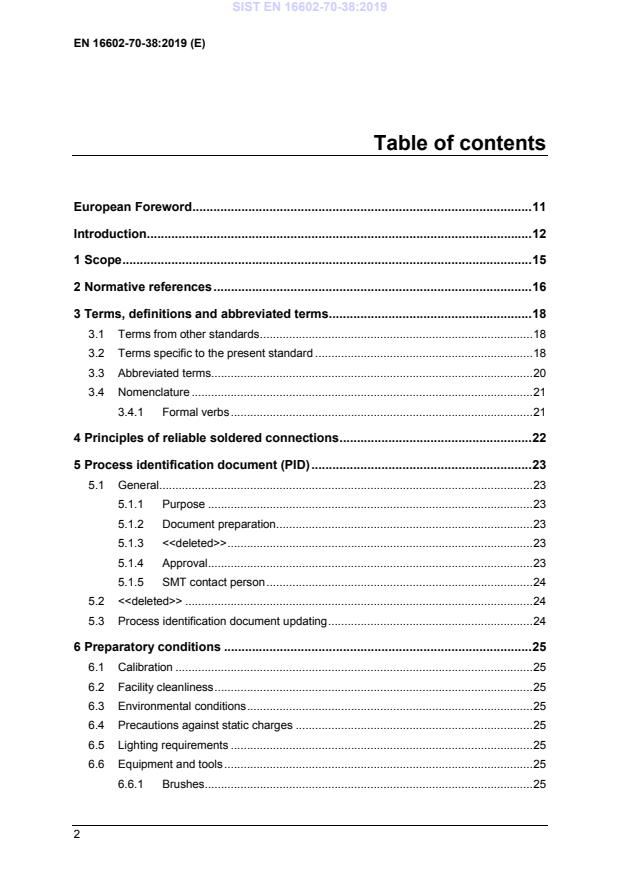

Table of contents

European Foreword . 11

Introduction . 12

1 Scope . 15

2 Normative references . 16

3 Terms, definitions and abbreviated terms . 18

3.1 Terms from other standards . 18

3.2 Terms specific to the present standard . 18

3.3 Abbreviated terms. 20

3.4 Nomenclature . 21

3.4.1 Formal verbs . 21

4 Principles of reliable soldered connections . 22

5 Process identification document (PID) . 23

5.1 General . 23

5.1.1 Purpose . 23

5.1.2 Document preparation . 23

5.1.3 <> . 23

5.1.4 Approval . 23

5.1.5 SMT contact person . 24

5.2 <> . 24

5.3 Process identification document updating . 24

6 Preparatory conditions . 25

6.1 Calibration . 25

6.2 Facility cleanliness . 25

6.3 Environmental conditions . 25

6.4 Precautions against static charges . 25

6.5 Lighting requirements . 25

6.6 Equipment and tools . 25

6.6.1 Brushes . 25

6.6.2 Cutters and Pliers . 26

6.6.3 Bending tools . 26

6.6.4 Clinching tools . 26

6.6.5 Insulation strippers . 26

6.6.6 Soldering tools . 26

6.6.7 Soldering irons and resistance soldering equipment . 26

6.6.8 <> . 26

6.6.9 Solder baths for degolding and pretinning . 26

6.7 Soldering machines and equipment . 27

6.7.1 General . 27

6.7.2 Dynamic wave-solder machines . 27

6.7.3 Condensation (vapour phase) reflow machines . 28

6.7.4 Hot gas reflow machines . 28

6.7.5 <> . 28

6.7.6 Convection and radiation reflow systems . 28

6.7.7 Other equipment for reflow soldering . 29

6.8 Ancillary equipment . 29

6.8.1 General . 29

6.8.2 Solder deposition equipment . 29

6.8.3 Automatic device placement equipment . 29

6.8.4 <> . 29

6.8.5 Cleanliness testing equipment . 30

6.8.6 Magnification aids . 30

6.8.7 X-ray inspection equipment . 30

6.8.8 Metallographic equipment . 30

7 Material selection . 31

7.1 General . 31

7.2 Solder . 31

7.2.1 Form . 31

7.2.2 Composition . 31

7.2.3 Solder paste . 31

7.2.4 Maintenance of paste purity . 33

7.3 Flux . 33

7.3.1 Rosin based flux . 33

7.3.2 Corrosive acid flux. 33

7.3.3 Flux controls for wave-soldering equipment . 33

7.4 Solvents . 33

7.5 Flexible insulation materials . 34

7.6 Terminals . 34

7.7 Wires . 34

7.8 Printed circuit substrates. 34

7.8.1 <> . 34

7.8.2 <> . 34

7.8.3 <> . 34

7.8.4 <> . 34

7.8.5 <> . 35

7.8.6 <> . 35

7.9 Devices . 35

7.9.1 General . 35

7.9.2 <> . 36

7.9.3 Moisture sensitive devices . 36

7.9.4 <> . 36

7.10 Adhesives, encapsulants and conformal coatings . 36

8 Preparation for soldering . 38

8.1 Preparation of devices and terminals . 38

8.1.1 Preparation of wires and terminals . 38

8.1.2 Preparation of surfaces to be soldered . 38

8.1.3 Degolding and pretinning of conductors . 38

8.1.4 Alloying of pure tin finish . 38

8.2 Preparation of solder bit . 39

8.3 Handling . 39

8.4 Storage . 39

8.5 Baking of PCBs and moisture sensitive devices . 39

9 Mounting of devices prior to soldering . 40

9.1 General requirements . 40

9.2 Lead bending and cutting requirements . 40

9.3 Mounting of terminals to PCBs. 40

9.4 Lead attachment to through holes . 40

9.5 Mounting of devices to terminals . 40

9.6 Mounting of through hole connectors to PCBs . 40

9.7 Surface mount requirements . 41

9.7.1 General . 41

9.7.2 Stress relief . 41

9.7.3 Registration of devices and footprints . 42

9.7.4 Lead forming . 42

9.7.5 Mounting devices in solder paste . 42

9.7.6 Leadless devices . 43

9.7.7 Leaded devices . 43

9.7.8 <> . 43

9.7.9 Stacking and bonding of heavy devices . 43

10 Attachment of conductors to terminals, solder cups and cables . 45

11 Soldering to printed circuit boards . 46

11.1 General . 46

11.2 <> . 46

11.3 Solder applications to PCBs . 46

11.4 Wicking . 46

11.5 Soldering of SMDs . 46

11.5.1 General requirements . 46

11.5.2 End-capped and end-metallized devices . 47

11.5.3 Bottom terminated chip devices . 49

11.5.4 Cylindrical and square end-capped devices . 50

11.5.5 Castellated chip carrier devices. 52

11.5.6 Flat pack and Gull-wing leaded devices with round, rectangular,

ribbon leads . 53

11.5.7 Devices with “J” leads . 54

11.5.8 Area array devices . 54

11.5.9 Devices with ribbon terminals without stress relief . 56

11.5.10 L-Shape inwards devices . 57

11.5.11 Stacked modules devices with leads protruding vertically from bottom. 58

11.5.12 Leaded device with plane termination . 59

11.5.13 Moulded magnetics . 59

11.6 <> . 60

11.7 <> . 60

11.8 <> . 60

12 Cleaning of PCB assemblies . 61

12.1 General . 61

12.2 Ultrasonic cleaning . 61

12.3 Monitoring for cleanliness . 61

13 Final inspection . 62

13.1 General . 62

13.2 Acceptance criteria . 62

13.3 Visual rejection criteria . 63

13.4 X-ray rejection criterion . 65

13.5 Warp and twist of populated boards . 65

13.6 Inspection records . 65

14 Verification procedure. 66

14.1 General . 66

14.2 Verification by similarity . 68

14.2.1 General . 68

14.2.2 Conditions for similarity . 69

14.3 Verification programme . 71

14.4 Electrical testing of devices . 75

14.4.1 General . 75

14.5 Vibration and shock . 78

14.6 Temperature cycling test. 78

14.7 Microsection . 79

14.7.1 Microsection facilities . 79

14.7.2 Microsectioning . 79

14.8 <> . 95

14.9 Special verification testing for hermetic ceramic area array packages . 95

14.9.1 <> . 95

14.9.2 <> . 95

14.9.3 General . 95

14.9.4 Evaluation of capability samples . 98

14.9.5 Verification . 98

14.10 Verification acceptance and rejection criteria . 99

14.11 Approval of verification . 108

14.12 Withdrawal of approval status . 108

14.13 Conditions for delta verification . 108

14.14 Verification of cleanliness . 111

14.15 Verification approval procedure . 111

14.15.1 Request for verification . 111

14.15.2 Technology sample . 111

14.15.3 Audit of assembly processing . 111

14.15.4 Verification programme . 112

14.15.5 Final verification review . 112

14.15.6 Certification approval of assembly line . 112

15 Quality assurance . 113

15.1 General . 113

15.2 Data . 113

15.3 Nonconformance . 113

15.4 Calibration . 113

15.5 Traceability . 113

15.6 Workmanship standards . 113

15.7 Inspection . 114

15.8 Operator and inspector training and certification . 114

15.9 Quality records . 114

16 <> . 115

Annex A (informative) <> . 116

Annex B (informative) <

Annex H>> . 117

Annex C (informative) <> . 118

Annex D (informative) Example of an SMT audit report . 119

Annex E (informative) Additional information . 128

E.1 <> . 128

E.2 Melting temperatures and choice . 128

Annex F (normative) Process Identification Document (PID) - DRD . 129

F.1 DRD identification . 129

F.1.1 Requirement identification and source document . 129

F.1.2 Purpose and objective . 129

F.2 Expected response . 129

F.2.1 Scope and content . 129

F.2.2 Special remarks . 131

Annex G (normative) Verification programme report - DRD . 132

G.1 DRD identification . 132

G.1.1 Requirement identification and source document . 132

G.1.2 Purpose and objective . 132

G.2 Expected response . 132

G.2.1 Scope and content . 132

G.2.2 Special remarks . 133

Annex H (normative) SMT summary table - DRD . 134

H.1 DRD identification . 134

H.1.1 Requirement identification and source document . 134

H.1.2 Purpose and objective . 134

H.2 Expected response . 134

H.2.1 Scope and content . 134

H.2.2 Special remarks . 134

Annex I (informative) Visual and X-ray workmanship standards . 136

I.1 Workmanship illustrations for standard SMDs . 136

I.1.1 Chip components . 136

I.1.2 MELF components . 139

I.1.3 Gull-wing leaded devices with round, rectangular, ribbon shape . 140

I.1.4 “J” leaded devices . 142

I.1.5 L-shape Inward leaded component . 144

I.1.6 LCC devices. 144

I.1.7 Miscellaneous soldering defects. 145

I.2 Workmanship illustrations for ball grid array devices . 146

I.3 Workmanship illustrations for column grid array devices . 148

Bibliography . 151

Figures

Figure 9-1: Exposed element. 43

Figure 11-1: Mounting of rectangular and square end-capped and end-metallized

devices . 48

Figure 11-2: Mounting of bottom terminated chip devices . 49

Figure 11-3: Mounting of cylindrical end-capped devices . 50

Figure 11-4: Mounting of square end-capped devices . 51

Figure 11-5: Mounting of castellated chip carrier devices . 52

Figure 11-6: Mounting of gull-wing leaded devices with round, rectangular, ribbon leads . 53

Figure 11-7: Mounting of devices with “J” leads . 54

Figure 11-8: <> . 55

Figure 11-9: Typical ceramic area array showing ball grid array configuration on left

and column grid array on right (CBGA & CCGA) . 55

Figure 11-10: Typical assembled CCGA device . 55

Figure 11-11: Mounting of devices without stress relief . 56

Figure 11-12: Mounting of devices with “L-shape inwards” leads (1 = Toe, 2 = Heel) . 57

Figure 11-13: Mounting of stacked modules devices with leads protruding vertically

from bottom . 58

Figure 11-14: Mounting of leaded devices with leads with plane termination . 59

Figure 11-15: <> . 60

Figure 14-1: Verification programme flow chart (standard flow) . 74

Figure 14-2: Verification programme flow chart (electrical testing) . 77

Figure 14-3: Verification programme flow chart (AAD) . 97

Figure 14-4: <> . 100

Figure I-1 : Preferred solder (see also Table 11-1) . 136

Figure I-2 : Acceptable, maximum solder (see also Table 11-1) . 136

Figure I-3 : Acceptable, minimum Solder (see also Table 11-1) . 137

Figure I-4 : Unacceptable, excessive solder (see also Table 11-1) . 137

Figure I-5 : Unacceptable, poor wetting (see also Table 11-1) . 137

Figure I-6 : Unacceptable, excessive tilt (see also Table 11-1) . 138

Figure I-7 : Unacceptable, tombstone effect . 138

Figure I-8 : Examples of Unacceptable solder joints - (see also Table 11-1) . 138

Figure I-9 : Acceptable, terminal wetted along end, face and sides (see also Table 11-1) . 139

Figure I-10 : Acceptable, maximum solder joint (see also Table 11-3) . 139

Figure I-11 : Not Acceptable, insufficient solder joint (see also Table 11-3) . 139

Figure I-12 : Unacceptable overhang . 139

Figure I-13 : Examples of Gullwing leads: Acceptable . 140

Figure I-14 : Examples of gull-wing device with rectangular lead: Acceptable . 140

Figure I-15 : Acceptable, minimum solder joint . 140

Figure I-16 : Unacceptable, insufficient heel fillet . 141

Figure I-17 : Unacceptable, excessive solder . 141

Figure I-18 : Unacceptable, excessive solder . 141

Figure I-19 : Preferred solder joint . 142

Figure I-20 : Acceptable solder joint . 142

Figure I-21 : Unacceptable, excessive solder joint . 143

Figure I-22 : Unacceptable, excessive degolding. 143

Figure I-23 : Acceptable, preferred solder joint . 144

Figure I-24 : LCC General view, acceptable solder joints . 144

Figure I-25 : Examples of unacceptable soldering . 145

Figure I-26 : Angled-transmission X-radiograph showing solder paste shadow due to

partial reflow: Reject . 146

Figure I-27 : Micrograph showing . 146

Figure I-28 : Perpendicular transmission X-radiograph showing unacceptable defects . 147

Figure I-29 : Perpendicular transmission X-radiograph showing non-wetted footprint . 147

Figure I-30 : Underside view showing missing column. 148

Figure I-31 : CGA mounted on PCB showing columns tilted < 10°: Accept . 148

Figure I-32 : X-radiograph of CGA mounted on PCB showing solder bridge: Reject . 149

Figure I-33 : X-radiograph of CGA showing solder fillets at base of columns: acceptable . 149

Figure I-34 : Micrograph of CGA mounted on PCB, bent column: reject . 150

Figure I-35 : Micrograph of CGA mounted on PCB . 150

Tables

Table 7-1: Chemical composition of spacecraft solders . 32

Table 7-2: <> . 34

Table 11-1: Dimensional and solder fillet for rectangular and square end capped

devices . 48

Table 11-2: Dimensional and solder fillet for bottom terminated chip devices . 49

Table 11-3: Dimensional and solder fillet for cylindrical end-capped devices . 50

Table 11-4: Dimensional and solder fillet for square end-capped devices . 51

Table 11-5: Dimensional and solder fillet for castellated chip carrier devices . 52

Table 11-6: Dimensional and solder fillet for gull-wing leaded devices with round,

rectangular, ribbon leads . 53

Table 11-7: Dimensional and solder fillet for devices with “J” leads . 54

Table 11-8: Dimensional and solder fillet for area array devices . 55

Table 11-9: Dimensional and solder fillet for devices without stress relief . 56

Table 11-10: Dimensional and solder fillet for “L-shape inwards” devices . 57

Table 11-11: Dimensional and solder fillet for stacked modules devices with leads

protruding vertically from bottom . 58

Table 11-12: Dimensional and solder fillet for leaded devices with plane termination . 59

Table 14-1: Device type classification . 68

Table 14-2: Device microsection location . 81

Table 14-3: Critical zone definition per device type and acceptance criteria . 101

Table 14-4: Conditions invoking verification . 110

Table E-1 : Guide for choice of solder type . 128

Table H-1 : Device type preparation and mounting configuration . 135

European Foreword

This document (EN 16602-70-38:2019) has been prepared by Technical

Committee CEN-CENELEC/TC 5 “Space”, the secretariat of which is held by

DIN.

This standard (EN 16602-70-38:2019) originates from ECSS-Q-ST-70-38C Rev.1.

This European Standard shall be given the status of a national standard, either

by publication of an identical text or by endorsement, at the latest by October

2019, and conflicting national standards shall be withdrawn at the latest by

October 2019.

Attention is drawn to the possibility that some of the elements of this document

may be the subject of patent rights. CEN [and/or CENELEC] shall not be held

responsible for identifying any or all such patent rights.

This document has been prepared under a standardization request given to

CEN by the European Commission and the European Free Trade Association.

This document has been developed to cover specifically space systems and has

therefore precedence over any EN covering the same scope but with a wider

domain of applicability (e.g. : aerospace).

According to the CEN-CENELEC Internal Regulations, the national standards

organizations of the following countries are bound to implement this European

Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This Standard prescribes requirements for electrical connections of leadless and

leaded surface mounted devices (SMD) on spacecraft and associated

equipment, utilising a range of substrate assemblies and employing solder as

the interconnection media. The principal types of SMDs can be gathered in the

following families:

Rectangular and square end-capped or end-metallized

device with rectangular body, leadless chip (see 11.5.2)

e.g. end capped chip resistors and end capped chip capacitors.

Cylindrical and square end-capped devices with

cylindrical body, leadless chip (see 11.5.4)

e.g. MELF for cylindrical end capped or

e.g. D-5A for square end capped

Bottom terminated chip device (see 11.5.3)

This type of device has metallised terminations on the bottom

side only.

e.g. inductors and SMD0.5, SMD1, SMD2, SMD0.2, SMD0.22

e.g. Quad Flat Pack No lead (QFN)

Castellated chip carrier device (see 11.5.5)

The main device of this type is leadless ceramic chip carrier

(LCCC).

e.g. LCC6

Flat pack and gull-wing leaded device with round,

rectangular , ribbon leads (see 11.5.6)

e.g. small-outline transistor (SOT), small—outline package (SO),

flat pack and quad flat pack (QFP) and SMD connectors with

stress-relief.

This family also comprises devices for through-hole mounting

that have been reconfigured to surface mounting.

Moulded magnetics (see 11.5.13)

e.g. 1553 interface transformers or specific transformers

“J” leaded device (see 11.5.7)

e.g. ceramic leaded chip carriers (CLCC) and plastic

leaded chip carriers (PLCC).

Area array devices (AAD) (see 11.5.8)

The interconnections between solder footprints on the devices

and solder footprints on the PCB consist entirely of solder.

The devices have either solder balls (Ball Grid Array - BGA) or

solder columns (Column Grid Array - CGA) applied to the

solder footprints on the devices prior to mounting on a PCB

(normally done by the device manufacturer). The solder balls on

the BGAs can consist of either eutectic solder or high

temperature solder (5 - 10 % Sn) whereas the solder columns on

the CGAs always consist of high temperature solder. Although

BGAs are usually presented as a device family, there exist a

large number of BGA devices with wide-ranging properties. The

vast majority of BGA devices are non hermetic.

Devices with ribbon terminals without stress relief (flat

lug leads) (see 11.5.9)

This package has flat leads extending from the sides

Device with Inward formed L-shaped leads (see 11.5.10)

e.g. moulded tantalum chip capacitors.

Stacked modules devices with leads protruding

vertically from bottom (see 11.5.11)

Leaded device with plane termination (see 11.5.12)

e.g. Diode PAcKage (DPAK or TO252)

Scope

This Standard defines the technical requirements and quality

assurance provisions for the manufacture and verification of high-reliability

electronic circuits based on surface mounted device (SMD) and mixed

technology.

The Standard defines acceptance and rejection criteria for high-reliability

manufacture of surface-mount and mixed-technology circuit assemblies

intended to withstand normal terrestrial conditions and the vibrational g-loads

and environment imposed by space flight.

The proper tools, correct materials, design and workmanship are covered by

this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...