EN 14592:2022

(Main)Timber structures - Dowel-type fasteners - Requirements

Timber structures - Dowel-type fasteners - Requirements

This document specifies the characteristics of the following types of dowel-type fasteners:

- nails;

- staples;

- screws;

- dowels;

- bolts with nuts.

This document covers dowel-type fasteners for structural use in load bearing timber structures only. This document covers also the following additional intended uses of the screws:

- to fix roof or cladding elements to the timber structure, with or without insulation layers; and

- as reinforcement inserted in timber or in a glue laminated timber element to improve its resistance to compression perpendicular to the grain.

This document covers types of dowel-type fasteners, which are manufactured of either carbon steel or stainless steel and which may be coated for the following purposes:

- corrosion protection (as Type 1 coating);

- lubrication, to facilitate insertion (as Type 2 coating);

- withdrawal enhancement and/or collation for nails and staples (adhesive and/or resin coatings) (as Type 3 coating).

This document covers types of dowel-type fasteners, which are manufactured from materials and within the specifications for their geometry related properties, only as they are specified for:

- nails (see G.1);

- staples (see G.2);

- screws (see G.3);

- dowels (see G.4); and

- bolts with nuts (see G.5).

This document specifies also the assessment and verification of constancy of performance (AVCP) procedures of these characteristics and includes provisions for marking of dowel-type fasteners.

This document does not cover dowel-type fasteners treated with fire retardants to improve their fire performance, nor does it cover glued-in rods.

Holzbauwerke - Stiftförmige Verbindungsmittel - Anforderungen

Dieses Dokument legt die Merkmale von folgenden Arten von stiftförmigen Verbindungsmitteln fest:

— Nägel;

— Klammern;

— Schrauben;

— Stabdübel;

— Bolzen mit Muttern.

Dieses Dokument behandelt nur stiftförmige Verbindungsmittel für die Anwendung in tragenden Holzbaukonstruktionen. Dieses Dokument behandelt auch die folgenden zusätzlichen bestimmungsgemäßen Verwendungen von Schrauben:

— zur Befestigung von Dach oder Verkleidungselementen an der Holzbaukonstruktion, mit oder ohne Wärmedämmung und

— als Verstärkung, eingesetzt in Holz oder in ein Brettschichtholzelement zur Verbesserung des Widerstands gegenüber Druck, rechtwinklig zur Faser.

Dieses Dokument behandelt Arten von stiftförmigen Verbindungsmitteln, die entweder aus Kohlenstoffstahl oder nichtrostendem Stahl hergestellt werden und die für die folgenden Zwecke beschichtet werden dürfen:

— Korrosionsschutz (als Überzugsart 1);

— Gleitschicht, um das Eintreiben/Eindrehen zu erleichtern (als Überzugsart 2);

— Erhöhung der Ausziehfestigkeit und/oder der Magazinierung von Nägeln und Klammern (Klebe und/oder Harzüberzug) (als Überzugsart 3).

Dieses Dokument behandelt Arten von stiftförmigen Verbindungsmitteln, die aus Werkstoffen hergestellt sind und die innerhalb der Spezifikationen für die mit ihrer Geometrie verbundenen Eigenschaften hergestellt werden, wie sie nur spezifiziert sind für:

— Nägel (siehe G.1);

— Klammern (siehe G.2);

— Schrauben (siehe G.3);

— Stabdübel (siehe G.4) und

— Bolzen mit Muttern (siehe G.5).

Dieses Dokument legt außerdem die Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) dieser Merkmale fest und enthält Bestimmungen für die Kennzeichnung von stiftförmigen Verbin¬dungsmitteln.

Dieses Dokument gilt nicht für zur Verbesserung des Brandverhaltens mit Feuerschutzmitteln behandelte stiftförmige Verbindungsmittel und eingeklebte Gewindestangen.

Structures en bois - Éléments de fixation de type tige - Exigences

Le présent document spécifie les exigences pour les types suivants d’éléments de fixation de type tige :

- pointes ;

- agrafes ;

- vis ;

- broches ; et

- boulons et écrous.

Le présent document couvre uniquement les éléments de fixation de type tige fabriqués en acier et destinés à un usage structurel dans les structures porteuses en bois. En outre, le présent document couvre également l’utilisation de vis :

- pour la fixation à la structure en bois d’éléments de couverture ou de bardage de façade, avec ou sans couches isolantes ; et

- comme renfort inséré dans un élément en bois massif ou un élément en bois lamellé-collé, afin d’améliorer sa résistance à la compression perpendiculairement au fil.

Le présent document spécifie également les modes opératoires d’évaluation et de vérification de la constance des performances (EVCP) et intègre les exigences relatives au marquage de ces produits.

Le présent document couvre les éléments de fixation de type tige pouvant recevoir un revêtement à des fins :

- de protection contre la corrosion ;

- de lubrification (pour faciliter leur insertion) ;

- d’optimisation de la résistance à l’arrachement et/ou de solidarisation des agrafes (revêtements adhésifs et/ou en résine).

Le présent document ne couvre pas les éléments de fixation de type tige traités avec des produits ignifuges pour améliorer leurs performances au feu, ni les assemblages par goujons collés.

Lesene konstrukcije - Paličasta vezna sredstva - Zahteve

Ta osnutek evropskega standarda določa zahteve za naslednje vrste paličastih veznih sredstev: žeblji, sponke, vijaki, mozniki in sorniki z maticami.

Ta evropski standard obravnava samo za paličasta vezna sredstva, ki so proizvedena iz jekla in namenjena za konstrukcijsko uporabo pri nosilnih lesenih konstrukcijah. Ta osnutek evropskega standarda obravnava tudi uporabo vijakov:

– za pritrditev strešnih ali obložnih elementov na leseno konstrukcijo z izolacijskimi sloji ali brez;

in

– za ojačitev, ko so vstavljeni v leseni element ali element iz lepljenega laminiranega lesa z namenom izboljšanja tlačne trdnosti elementa pravokotno na lesna vlakna.

Ta osnutek evropskega standarda določa tudi postopke za ocenjevanje in preverjanje nespremenljivosti lastnosti (AVCP) ter vključuje zahteve za označevanje teh izdelkov.

Ta osnutek evropskega standarda obravnava paličasta vezna sredstva, ki so lahko prevlečena za naslednje namene:

– – zaščita proti koroziji;

– podmazovanje (lažje vstavljanje);

– izboljšanje odstranitve in/ali kolacije za sponke (lepilni in/ali smolni premazi).

Ta osnutek evropskega standarda ne obravnava veznih sredstev, obdelanih z zaščitnimi sredstvi proti ognju, ki izboljšujejo odpornost proti ognju, niti ne obravnava vlepljenih palic.

General Information

- Status

- Published

- Publication Date

- 26-Apr-2022

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 4 - Connectors

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 27-Apr-2022

- Due Date

- 16-Dec-2018

- Completion Date

- 27-Apr-2022

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 20-Jun-2012

- Effective Date

- 11-Feb-2026

- Effective Date

- 11-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14592:2022 - "Timber structures - Dowel-type fasteners - Requirements" defines the properties, testing and conformity procedures for dowel-type fasteners used in load‑bearing timber structures. The standard covers five fastener families: nails, staples, screws, dowels and bolts with nuts, manufactured from carbon or stainless steel and optionally coated for corrosion protection, lubrication or withdrawal enhancement.

Key topics and technical requirements

- Scope and intended use: Covers structural dowel‑type fasteners for timber structures and additional screw uses - fixing roof or cladding elements (with or without insulation) and reinforcement to improve compression perpendicular to the grain.

- Materials and coatings: Fasteners may be made of carbon steel or stainless steel and coated as:

- Type 1 - corrosion protection,

- Type 2 - lubrication for insertion,

- Type 3 - withdrawal enhancement/collation (nails and staples).

- Product geometry and material specs: Defines nominal diameter and other geometry‑related properties for each fastener family (see normative Annex G sections).

- Performance testing: Specifies test methods and sampling for general and product‑specific characteristics including corrosion resistance, withdrawal capacity, pull‑through resistance, torsional resistance and yield moment (referenced test standards: EN 1382, EN 1383, EN 409, EN 15737, etc.).

- Seismic performance: Introduces low cycle ductility classes and a test method for seismic (low cycle) ductility.

- Screw characteristics: Adds requirements for axial stiffness, static ductility and torsional ratio.

- Conformity & marking: Includes Assessment and Verification of Constancy of Performance (AVCP) procedures and marking requirements so manufacturers and specifiers can demonstrate compliance.

- Exclusions: Does not cover fire‑retardant treated fasteners for fire performance or glued‑in rods.

Practical applications and users

This standard is essential for:

- Structural engineers and designers specifying fasteners for load‑bearing timber structures (beams, trusses, connections).

- Manufacturers and quality managers of dowel‑type fasteners seeking CE/national compliance.

- Test laboratories performing performance and corrosion testing to verify product claims.

- Building inspectors and procurement teams verifying material, coating and marking requirements on site.

Practical uses include specifying appropriate nails, screws, dowels or bolts for timber connections, selecting coatings for durability in specific environments, and ensuring screws used for cladding and reinforcement meet structural requirements.

Related standards

EN 14592:2022 references several normative documents for test methods and material properties, for example:

- EN 1995‑1‑1 (Eurocode 5) - timber design rules

- EN 1382 / EN 1383 - withdrawal and pull‑through tests

- EN 409 - yield moment of dowel‑type fasteners

- EN ISO 3506‑1 / EN ISO 898‑1 - mechanical properties of fasteners

Keywords: EN 14592:2022, dowel-type fasteners, timber structures, nails, screws, staples, dowels, bolts, corrosion protection, AVCP, seismic performance, fastener testing.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 14592:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Timber structures - Dowel-type fasteners - Requirements". This standard covers: This document specifies the characteristics of the following types of dowel-type fasteners: - nails; - staples; - screws; - dowels; - bolts with nuts. This document covers dowel-type fasteners for structural use in load bearing timber structures only. This document covers also the following additional intended uses of the screws: - to fix roof or cladding elements to the timber structure, with or without insulation layers; and - as reinforcement inserted in timber or in a glue laminated timber element to improve its resistance to compression perpendicular to the grain. This document covers types of dowel-type fasteners, which are manufactured of either carbon steel or stainless steel and which may be coated for the following purposes: - corrosion protection (as Type 1 coating); - lubrication, to facilitate insertion (as Type 2 coating); - withdrawal enhancement and/or collation for nails and staples (adhesive and/or resin coatings) (as Type 3 coating). This document covers types of dowel-type fasteners, which are manufactured from materials and within the specifications for their geometry related properties, only as they are specified for: - nails (see G.1); - staples (see G.2); - screws (see G.3); - dowels (see G.4); and - bolts with nuts (see G.5). This document specifies also the assessment and verification of constancy of performance (AVCP) procedures of these characteristics and includes provisions for marking of dowel-type fasteners. This document does not cover dowel-type fasteners treated with fire retardants to improve their fire performance, nor does it cover glued-in rods.

This document specifies the characteristics of the following types of dowel-type fasteners: - nails; - staples; - screws; - dowels; - bolts with nuts. This document covers dowel-type fasteners for structural use in load bearing timber structures only. This document covers also the following additional intended uses of the screws: - to fix roof or cladding elements to the timber structure, with or without insulation layers; and - as reinforcement inserted in timber or in a glue laminated timber element to improve its resistance to compression perpendicular to the grain. This document covers types of dowel-type fasteners, which are manufactured of either carbon steel or stainless steel and which may be coated for the following purposes: - corrosion protection (as Type 1 coating); - lubrication, to facilitate insertion (as Type 2 coating); - withdrawal enhancement and/or collation for nails and staples (adhesive and/or resin coatings) (as Type 3 coating). This document covers types of dowel-type fasteners, which are manufactured from materials and within the specifications for their geometry related properties, only as they are specified for: - nails (see G.1); - staples (see G.2); - screws (see G.3); - dowels (see G.4); and - bolts with nuts (see G.5). This document specifies also the assessment and verification of constancy of performance (AVCP) procedures of these characteristics and includes provisions for marking of dowel-type fasteners. This document does not cover dowel-type fasteners treated with fire retardants to improve their fire performance, nor does it cover glued-in rods.

EN 14592:2022 is classified under the following ICS (International Classification for Standards) categories: 21.060.01 - Fasteners in general; 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14592:2022 has the following relationships with other standards: It is inter standard links to EN 14592:2008+A1:2012, ISO 965-1:2013, ISO 965-5:1998, EN ISO 10666:1999, EN ISO 16120-2:2017, EN ISO 21968:2019, EN ISO 8565:2011, EN 14081-1:2016+A1:2019, EN ISO 16120-3:2011, EN ISO 1460:1994, EN ISO 10684:2004, EN 1990:2002, EN 1993-1-4:2006/A1:2015, EN ISO 8407:2014, EN 10088-5:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14592:2022 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14592:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2022

Nadomešča:

SIST EN 14592:2009+A1:2012

Lesene konstrukcije - Paličasta vezna sredstva - Zahteve

Timber structures - Dowel-type fasteners - Requirements

Holzbauwerke - Stiftförmige Verbindungsmittel - Anforderungen

Structures en bois - Éléments de fixation de type tige - Exigences

Ta slovenski standard je istoveten z: EN 14592:2022

ICS:

21.060.01 Vezni elementi na splošno Fasteners in general

91.080.20 Lesene konstrukcije Timber structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14592

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2022

EUROPÄISCHE NORM

ICS 21.060.01; 91.080.20 Supersedes EN 14592:2008+A1:2012

English Version

Timber structures - Dowel-type fasteners - Requirements

Structures en bois - Éléments de fixation de type tige - Holzbauwerke - Stiftförmige Verbindungsmittel -

Exigences Anforderungen

This European Standard was approved by CEN on 13 February 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14592:2022 E

worldwide for CEN national Members.

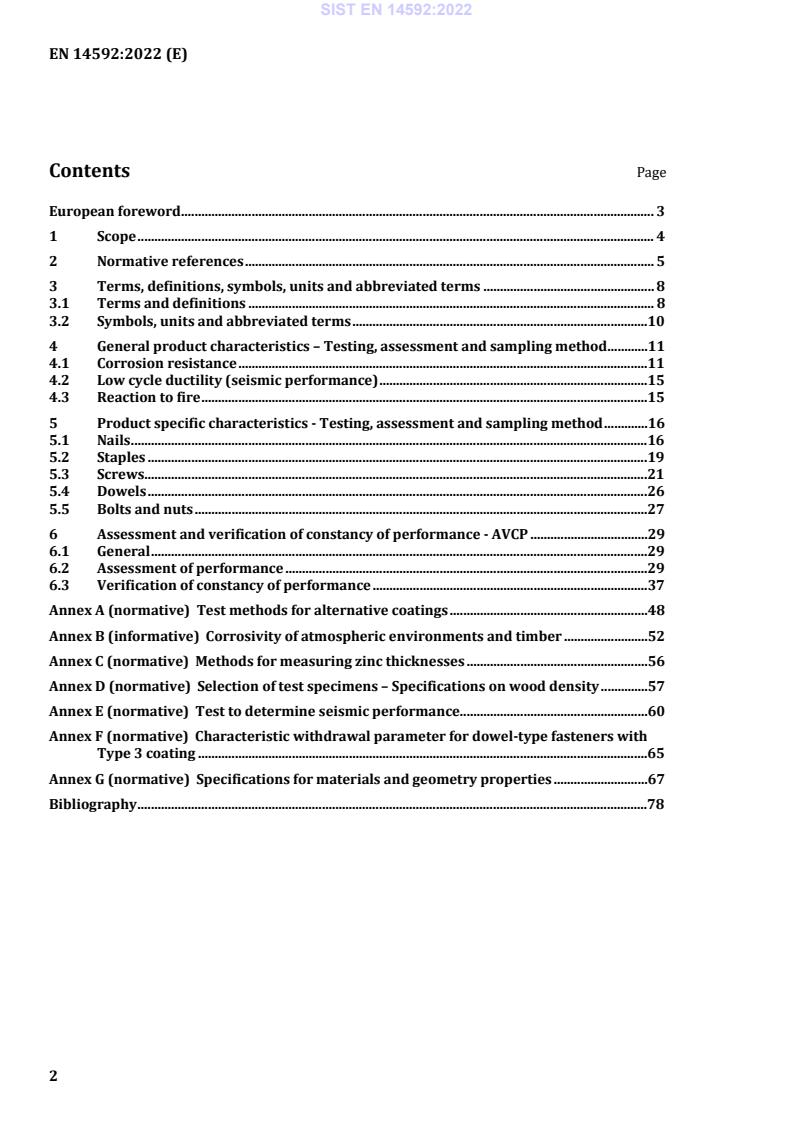

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 5

3 Terms, definitions, symbols, units and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Symbols, units and abbreviated terms .10

4 General product characteristics – Testing, assessment and sampling method .11

4.1 Corrosion resistance .11

4.2 Low cycle ductility (seismic performance) .15

4.3 Reaction to fire .15

5 Product specific characteristics - Testing, assessment and sampling method .16

5.1 Nails .16

5.2 Staples .19

5.3 Screws.21

5.4 Dowels .26

5.5 Bolts and nuts .27

6 Assessment and verification of constancy of performance - AVCP .29

6.1 General .29

6.2 Assessment of performance .29

6.3 Verification of constancy of performance .37

Annex A (normative) Test methods for alternative coatings .48

Annex B (informative) Corrosivity of atmospheric environments and timber .52

Annex C (normative) Methods for measuring zinc thicknesses .56

Annex D (normative) Selection of test specimens – Specifications on wood density .57

Annex E (normative) Test to determine seismic performance.60

Annex F (normative) Characteristic withdrawal parameter for dowel-type fasteners with

Type 3 coating .65

Annex G (normative) Specifications for materials and geometry properties .67

Bibliography .78

European foreword

This document (EN 14592:2022) has been prepared by Technical Committee CEN/TC 124 “Timber

structures”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2022 and conflicting national standards shall

be withdrawn at the latest by January 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14592:2008+A1:2012.

The main changes with respect to the previous edition are listed below:

— new concepts concerning dimensions and tolerances, e.g. target diameter;

— improved categories for corrosion protection;

— new specifications on wood density for testing of connections with dowel-type fasteners;

— low cycle ductility classes (seismic performance) and related test method;

— axial stiffness, static ductility and torsional ratio for screws.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies the characteristics of the following types of dowel-type fasteners:

— nails;

— staples;

— screws;

— dowels;

— bolts with nuts.

This document covers dowel-type fasteners for structural use in load bearing timber structures only. This

document covers also the following additional intended uses of the screws:

— to fix roof or cladding elements to the timber structure, with or without insulation layers; and

— as reinforcement inserted in timber or in a glue laminated timber element to improve its resistance

to compression perpendicular to the grain.

This document covers types of dowel-type fasteners, which are manufactured of either carbon steel or

stainless steel and which may be coated for the following purposes:

— corrosion protection (as Type 1 coating);

— lubrication, to facilitate insertion (as Type 2 coating);

— withdrawal enhancement and/or collation for nails and staples (adhesive and/or resin coatings) (as

Type 3 coating).

This document covers types of dowel-type fasteners, which are manufactured from materials and within

the specifications for their geometry related properties, only as they are specified for:

— nails (see G.1);

— staples (see G.2);

— screws (see G.3);

— dowels (see G.4); and

— bolts with nuts (see G.5).

This document specifies also the assessment and verification of constancy of performance (AVCP)

procedures of these characteristics and includes provisions for marking of dowel-type fasteners.

This document does not cover dowel-type fasteners treated with fire retardants to improve their fire

performance, nor does it cover glued-in rods.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 409:2009, Timber structures - Test methods - Determination of the yield moment of dowel type fasteners

EN 634-2:2007, Cement-bonded particleboards - Specifications - Part 2: Requirements for OPC bonded

particleboards for use in dry, humid and external conditions

EN 636:2012+A1:2015, Plywood - Specifications

EN 1382:2016, Timber Structures - Test methods - Withdrawal capacity of timber fasteners

EN 1383:2016, Timber structures - Test methods - Pull through resistance of timber fasteners

EN 1990:2002, Eurocode - Basis of structural design

EN 1993-1-4:2006/A1:2015, Eurocode 3 - Design of steel structures - Part 1-4: General rules -

Supplementary rules for stainless steels

EN 1995-1-1:2004 , Eurocode 5: Design of timber structures - Part 1-1: General - Common rules and rules

for buildings

EN 10025-2:2019, Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-

alloy structural steels

EN 10025-3:2019, Hot rolled products of structural steels - Part 3: Technical delivery conditions for

normalized/normalized rolled weldable fine grain structural steels

EN 10088-1:2014, Stainless steels - Part 1: List of stainless steels

EN 10088-2:2014, Stainless steels - Part 2: Technical delivery conditions for sheet/plate and strip of

corrosion resisting steels for general purposes

EN 10088-3:2014, Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars,

rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10088-4:2009, Stainless steels - Part 4: Technical delivery conditions for sheet/plate and strip of

corrosion resisting steels for construction purposes

EN 10088-5:2009, Stainless steels - Part 5: Technical delivery conditions for bars, rods, wire, sections and

bright products of corrosion resisting steels for construction purposes

EN 10149-1:2013, Hot rolled flat products made of high yield strength steels for cold forming - Part 1:

General technical delivery conditions

EN 10204:2004, Metallic products - Types of inspection documents

As impacted by EN 1995-1-1:2004/A1:2008 and EN 1995-1-1:2004/A2:2014.

EN 10218-1:2012, Steel wire and wire products - General - Part 1: Test methods

EN 10277:2018, Bright steel products - Technical delivery conditions

EN 13501-1:2018, Fire classification of construction products and building elements - Part 1: Classification

using data from reaction to fire tests

EN 13986:2004+A1:2015, Wood-based panels for use in construction - Characteristics, evaluation of

conformity and marking

EN 14081-1:2016+A1:2019, Timber structures - Strength graded structural timber with rectangular cross

section - Part 1: General requirements

EN 14358:2016, Timber structures - Calculation and verification of characteristic values

EN 15737:2009, Timber Structures - Test methods - Torsional resistance of driving in screws

EN ISO 898-1:2013 , Mechanical properties of fasteners made of carbon steel and alloy steel - Part 1: Bolts,

screws and studs with specified property classes - Coarse thread and fine pitch thread (ISO 898-1:2013)

EN ISO 898-2:2012, Mechanical properties of fasteners made of carbon steel and alloy steel - Part 2: Nuts

with specified property classes - Coarse thread and fine pitch thread (ISO 898-2:2012)

EN ISO 1460:1994, Metallic coatings - Hot dip galvanized coatings on ferrous materials - Gravimetric

determination of the mass per unit area (ISO 1460:1992)

EN ISO 1463:2004, Metallic and oxide coatings - Measurement of coating thickness - Microscopical method

(ISO 1463:2003)

EN ISO 2081:2018, Metallic and other inorganic coatings - Electroplated coatings of zinc with

supplementary treatments on iron or steel (ISO 2081:2018)

EN ISO 2178:2016, Non-magnetic coatings on magnetic substrates - Measurement of coating thickness -

Magnetic method (ISO 2178:2016)

EN ISO 3497:2000, Metallic coatings - Measurement of coating thickness - X-ray spectrometric methods

(ISO 3497:2000)

EN ISO 3506-1:2009, Mechanical properties of corrosion-resistant stainless steel fasteners - Part 1: Bolts,

screws and studs (ISO 3506-1:2009)

EN ISO 4042:2018, Fasteners - Electroplated coating systems (ISO 4042:2018)

EN ISO 6270-1:2018, Paints and varnishes - Determination of resistance to humidity - Part 1: Condensation

(single-sided exposure) (ISO 6270-1:2017)

EN ISO 6892-1:2019, Metallic materials - Tensile testing - Part 1: Method of test at room temperature (ISO

6892-1:2019)

As impacted by EN ISO 898-1:2013/AC:2013.

EN ISO 8407:2014, Corrosion of metals and alloys - Removal of corrosion products from corrosion test

specimens (ISO 8407:2009)

EN ISO 8565:2011, Metals and alloys - Atmospheric corrosion testing - General requirements (ISO

8565:2011)

EN ISO 9226:2012, Corrosion of metals and alloys - Corrosivity of atmospheres - Determination of corrosion

rate of standard specimens for the evaluation of corrosivity (ISO 9226:2012)

EN ISO 9227:2017, Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2017)

EN ISO 10289:2001, Methods for corrosion testing of metallic and other inorganic coatings on metallic

substrates - Rating of test specimens and manufactured articles subjected to corrosion tests (ISO

10289:1999)

EN ISO 10666:1999, Drilling screws with tapping screw thread - Mechanical and functional properties (ISO

10666:1999)

EN ISO 10684:2004, Fasteners - Hot dip galvanized coatings (ISO 10684:2004)

EN ISO 11997-1:2017, Paints and varnishes - Determination of resistance to cyclic corrosion conditions -

Part 1: Wet (salt fog)/dry/humid (ISO 11997-1:2017)

EN ISO 16120-1:2017, Non-alloy steel wire rod for conversion to wire - Part 1: General requirements (ISO

16120-1:2017)

EN ISO 16120-2:2017, Non-alloy steel wire rod for conversion to wire - Part 2: Specific requirements for

general purpose wire rod (ISO 16120-2:2017)

EN ISO 16120-3:2011, Non-alloy steel wire rod for conversion to wire - Part 3: Specific requirements for

rimmed and rimmed substitute, low-carbon steel wire rod (ISO 16120-3:2011)

EN ISO 16120-4:2017, Non-alloy steel wire rod for conversion to wire - Part 4: Specific requirements for

wire rod for special applications (ISO 16120-4:2017)

EN ISO 21968:2019, Non-magnetic metallic coatings on metallic and non-metallic basis materials -

Measurement of coating thickness - Phase-sensitive eddy-current method (ISO 21968:2019)

ISO 965-1:2013, ISO general purpose metric screw threads - Tolerances - Part 1: Principles and basic data

ISO 965-2:1998, ISO general purpose metric screw threads - Tolerances - Part 2: Limits of sizes for general

purpose external and internal screw threads - Medium quality

ISO 965-3:1998, ISO general purpose metric screw threads - Tolerances - Part 3: Deviations for

constructional screw threads

ISO 965-4:1998, ISO general purpose metric screw threads - Tolerances - Part 4: Limits of sizes for hot-dip

galvanized external screw threads to mate with internal screw threads tapped with tolerance position H or

G after galvanizing

As impacted by EN ISO 10684:2004/AC:2009.

ISO 965-5:1998, ISO general purpose metric screw threads - Tolerances - Part 5: Limits of sizes for internal

screw threads to mate with hot-dip galvanized external screw threads with maximum size of tolerance

position h before galvanizing

3 Terms, definitions, symbols, units and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1995-1-1:2004 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1.1

smooth shank nail

nail that has a constant cross-section along its entire length

EXAMPLE Round, square or grooved.

3.1.2

ring shank nail

nail that has a profiled shank along a part of its length

EXAMPLE Ringed or twisted.

Note 1 to entry: The profiled length l is defined in Figure G.1 b).

g

3.1.3

staple crown width

distance between the outer edges of the staple legs

3.1.4

dowel

cylindrical metal fastener that does not contain an integral head

3.1.5

bolt

cylindrical metal fastener consisting of a screw part and a nut part

3.1.6

nominal diameter

cross-sectional dimension of a dowel-type fastener for the determination of a load bearing capacity

Note 1 to entry: Nails: for smooth shank nails, spiral rolled nails or annular ring shank nails, d is the outer cross-

sectional diameter of the round nail wire, or the side length dimension of the cross-section for a square nail, for all

other profiled nails, d is the cross-sectional diameter of the original wire rod, from which the profiled nail has been

produced.

Note 2 to entry: Staples: d is the diameter of a round rod with the same area as that of the cross-sectional area of

one leg of the staple. See G.2 for exceptions.

Note 3 to entry: Screws: d is the outer thread diameter.

Note 4 to entry: Dowels: d is the diameter.

Note 5 to entry: Bolts: d is the nominal diameter of the threaded part of the screw.

3.1.7

target diameter

diameter used to declare the nominal diameter of screws intended for use in load bearing timber

structures as specified in G.3

Note 1 to entry: For the purpose of both production specifications and applicability, screws may only be

produced allowing some tolerances. Thus for production purposes these tolerances are measured on the target

diameter, d .

t

3.1.8

inner thread diameter

inner diameter of the thread of a screw

Note 1 to entry: The inner diameter is used in EN 1995-1-1:2004 to determine the effective diameter for laterally

loaded screws.

3.1.9

stiffness

force for a unit deformation

3.1.10

coating type

the purpose of a coating is defined as follows:

— Type 1 coating: corrosion protection, with either pure zinc coating or hot-dipped galvanized coating

or alternative coatings;

— Type 2 coating: lubrication, to facilitate insertion;

— Type 3 coating: withdrawal enhancement and/or collation for nails and staples (adhesive and/or

resin coatings)

Note 1 to entry: A coating can serve more than one purpose, i.e. for staples the coating is both adhesive and serves

collation purposes.

3.2 Symbols, units and abbreviated terms

For the purposes of this document, the symbols and abbreviations given in EN 1995-1-1:2004 and the

following apply:

A percentage elongation (%)

A nail head area (mm )

h

A staple leg cross-sectional area (mm )

s

b staple crown width (mm)

R

d nominal diameter (mm)

d head diameter (mm)

h

d diameter of the smooth shank of a screw (mm)

s

t

target diameter (mm)

d

d inner thread diameter; inner diameter of fluting (mm)

i

d secondary thread diameter (mm)

f characteristic withdrawal parameter (N/mm )

ax,k

f characteristic head pull-through parameter (N/mm )

head,k

F characteristic tensile capacity (N)

tens,k

f characteristic tensile yield stress (N/mm )

y,tens,k

f tensile strength of the wire (N/mm )

u

h nail head thickness (mm)

t

L nominal dowel-type fastener length (mm)

l length of profiling/threading (mm)

g

l length of the secondary profiling/threading (mm)

g,1

l length of the nail point (mm)

p

M characteristic yield moment (N.mm)

y,Rk

M characteristic torsional moment capacity (N.mm)

tor,Rk

o

α

bend angle ( )

o

α

bend angle under cyclic loading ( )

c

ρ characteristic timber density when conditioned to constant mass at 20 °C and 65 %

k

relative humidity (kg/m )

ω moisture content

As impacted by EN 1995-1-1:2004/A1:2008 and EN 1995-1-1:2004/A2:2014.

4 General product characteristics – Testing, assessment and sampling method

4.1 Corrosion resistance

4.1.1 General

Dowel-type fasteners shall withstand corrosion exposure of both the timber and the atmosphere for the

design service life. Pure zinc coated and hot-dipped galvanized coated dowel-type fasteners shall be

assigned to a T-category and C-category in accordance with Table 1 and Table 2. Stainless steel dowel-

type fasteners shall be assigned to a category for corrosion resistance in atmosphere expressed by a

Corrosion Resistance Class (CRC) and a T-category in accordance with Table 3 and Table 4. Alternative

coated dowel-type fasteners shall be assigned to a T-category and C-category in accordance with Table 5

and Table 6.

The T-category refers to the fastener resistance with respect corrosion caused by the timber. The

C-category and CRC refers to the fastener resistance with respect corrosion caused by the atmosphere.

The design service life is generally assumed to be 50 years for T-categories, C-categories and CRC. In

addition, for alternative coated dowel-type fasteners to be used in structures with shorter service life or

in replaceable structural parts, additional T-categories and C-categories with a design service life of

15 years are provided in Clause 4.1.4.

NOTE Advices on appropriate categories specification are given in Annex B.

4.1.2 Pure zinc coating and hot-dipped galvanized coating

4.1.2.1 Determination

The specifications to achieve a category of corrosion resistance with respect to timber and atmospheres

shall be determined in accordance with Table 1 and Table 2, respectively. The corrosion protection stated

in these tables is assumed to secure a design service life of 50 years.

4.1.2.2 Evaluation

The zinc thicknesses shall be measured in accordance with Annex C. The mean value of the coating

thickness, measured in accordance with Annex C, shall be greater than or equal to the thickness specified

by the manufacturer.

The zinc layer thickness of Table 1 and Table 2 may be reduced when a protective layer is applied. For

applications in C2 atmospheres, CrIII passivation may reduce the required coating thickness by 25 %, and

with CrVI passivation the required coating thickness may be reduced by 50 %.

4.1.2.3 Expression

The corrosion resistance of dowel-type fasteners made of pure zinc coated carbon steel or hot-dipped

galvanized coated carbon steel shall be expressed according to Table 1 and Table 2, giving the dowel-type

fastener a corrosion resistance category for both timber and atmosphere. The indication of the categories

implies fulfilment with the provisions for corrosion resistance.

EXAMPLE 1 T3/C3.

Table 1 — Categories for corrosion resistance of dowel-type fasteners in timber — Minimum

thicknesses for pure zinc coating and hot-dipped galvanized coating

Timber category T1 T2 T3 T4 T5

Zinc thickness on

– 10 μm 20 μm 55 μm n.a.

carbon steel

Table 2 — Categories for corrosion resistance of dowel-type fasteners in atmospheres —

Minimum thicknesses for pure zinc coating and hot-dipped galvanized coating

Atmosphere

C1 C2nw C2w C3 C4 C5

category

Zinc thickness on

– 10 μm 20 μm 55 μm 110 μm n.a.

carbon steel

NOTE The minimum zinc thicknesses are based on the upper limit of the average steady corrosion rate for zinc

in the first 20 years of EN ISO 9224:2012 and linearly extended to 50 years.

4.1.3 Stainless steel

4.1.3.1 Determination

The specifications to achieve a category of corrosion resistance with respect to atmospheres shall be

determined in accordance with Table 3. The specifications to achieve a category of corrosion resistance

with respect to timber shall be determined in accordance with Table 4. The corrosion protection stated

in these tables is assumed to secure a design service life of 50 years.

4.1.3.2 Evaluation

The assignment of stainless steel grades to CRC is given in Table 3.

4.1.3.3 Expression

The corrosion resistance of dowel-type fasteners made of stainless steel shall be expressed giving the

dowel-type fastener a corrosion resistance category for timber according to Table 4 and a CRC for

atmospheric corrosivity according to Table 3.

In addition, either the steel number according to EN 10088-1:2014 or steel grade according to

EN ISO 3506-1:2009, Table 1 may be added. The indication of the T-category and the CRC class implies

fulfilment with the provisions for corrosion resistance.

EXAMPLE 1 T3/CRC II.

EXAMPLE 2 T3/C3 (1.4567); T3/CII (A2).

Table 3 — Stainless steel grades assigned to Corrosion Resistance Classes

Corrosion Resistance Class Steel number according to

EN ISO 3506-1:2009, Table 1

(CRC) EN 10088-1:2014

1.4301 A2

1.4307 A2

1.4567 A2

1.4541 A3

CRC II

1.4318 -

1.4306 -

1.4311 -

1.4482 -

Corrosion Resistance Class Steel number according to

EN ISO 3506-1:2009, Table 1

(CRC) EN 10088-1:2014

1.4401 A4

1.4404 A4

1.4578 A4

1.4571 A5

1.4362 –

CRC III 1.4062 –

1.4162 –

1.4662 –

1.4429 -

1.4432 -

1.4435 -

1.4439 –

CRC IV 1.4462 –

1.4539 –

1.4565 –

1.4529 –

1.4547 –

CRC V

1.4410 -

1.4501 -

1.4507 -

NOTE Classes are in accordance with EN 1993-1-4:2006/A1:2015, Annex A.

Table 4 — Categories for corrosion resistance of dowel-type fasteners in timber — Minimum

specifications for stainless steel

Timber category T1 T2 T3 T4 T5

Corrosion

Resistance Class – – CRC II CRC III CRC III

for stainless steel

4.1.4 Alternative coatings

4.1.4.1 Determination

The specifications to achieve a category of corrosion resistance with respect to timber and atmospheres

shall be determined in accordance with Table 5 and Table 6, respectively. The corrosion protection stated

in these tables is assumed to secure a design service life of 50 years unless otherwise specified.

Alternative coated dowel-type fasteners satisfying test procedure according to A.2.1 shall be assigned to

classes T3 and C2w.

Alternative coated dowel-type fasteners satisfying test procedure according to A.3.1 shall be assigned to

classes T4 and C3.

Alternative coated dowel-type fasteners with coating made of inorganic materials with or without an

organic top coat satisfying test procedure according to A4.1.4 shall be assigned to classes T3(15) and

C4(15) or T2 and C2nw. Note that T3(15) and C4(15) assume to secure a design service life of 15 years.

Alternative coated dowel-type fasteners with coating made of organic materials with or without an

organic top coat satisfying test procedure according to A4.2.3 shall be assigned to classes T3(15) and

C4(15) or T2 and C2nw. Note that T3(15) and C4(15) assume to secure a design service life of 15 years.

4.1.4.2 Evaluation

For alternative coated dowel-type fasteners assigned to categories T3 and C2w the evaluation is defined

in A.2.2.

For alternative coated dowel-type fasteners assigned to categories T4 and C3 the evaluation is defined in

A.3.2.

For alternative coated dowel-type fasteners with coating made of inorganic materials with or without an

organic top coat assigned to classes T3(15) and C4(15) or T2 and C2nw the evaluation is defined in

A.4.1.5.

For alternative coated dowel-type fasteners with coating made of organic coatings with or without an

organic top coat assigned to classes T3(15) and C4(15) or T2 and C2nw the evaluation is defined in

A.4.2.3.

4.1.4.3 Expression

The corrosion resistance category of dowel-type fasteners made of alternative coated steel shall be

expressed according to Table 5 and Table 6, giving the dowel-type fastener a corrosion resistance

category for both timber and atmosphere. The indication of the categories implies fulfilment with the

provisions for corrosion resistance.

EXAMPLE 4 T3(15)/C4(15).

Table 5 — Categories for corrosion resistance of dowel-type fasteners in timber — Minimum

specifications for alternative coatings

Timber category T1 T2 T3(15) T3 T4 T5

Annex A Annex A Annex A Annex A

Alternative

– n.a.

coatings

A.4 A.4 A.2 A.3

Table 6 — Categories for corrosion resistance of dowel-type fasteners in atmospheres —

Minimum specifications for alternative coatings

Atmosphere

C1 C2nw C2w C3 C4(15) C4 C5

category

Annex A Annex A Annex A Annex A

Alternative

– n.a. n.a.

coatings

A.4 A.2 A.3 A.4

4.2 Low cycle ductility (seismic performance)

Dowel-type fasteners for use in seismic regions shall be assigned to one of the low cycle ductility classes

0,7

given in Table 7 where α is the minimum required bending angle under cyclic loading and α is 45/d

c

degrees (where d is in mm). Products shall be tested according to Annex E to ensure that the required

value of α is achieved.

c

NOTE The level of seismic performance increases from S1 to S3.

Table 7 — Minimum values of bending angle αc for the classification of dowel-type fasteners into

low cycle ductility classes

Low cycle ductility classes Minimum value of bending angle under cyclic

loading, α (°)

c

S1 1,0 α ≤ α < 1,5 α

c

S2 1,5 α ≤ α < 2,0 α

c

S3 α ≥ 2,0 α

c

4.3 Reaction to fire

4.3.1 General

The reaction to fire indicates the degree of contribution of the material to the behaviour of the

construction product in the event of fire. Reaction to fire performance of a dowel-type fastener shall be

based on the reaction to fire performance of its constituent materials and shall be expressed as one of the

following reaction to fire classes, according to EN 13501-1:2018:

a) class A1, without testing (WT), for inorganic materials, when meeting the criteria specified in 4.3.2 ;

or otherwise,

b) class, defined according to the result of testing of the organic material(s), for which the dowel-type

fastener is made of or its surface coated with, according to the standard(s) referred to in

EN 13501-1:2018, as specified in 4.3.3.

4.3.2 Classification without testing (WT)

The reaction to fire performance of a dowel-type fastener shall be expressed according to

EN 13501-1:2018 as Class A1 , without testing, provided that:

a) each of the constituent material(s) that the dowel-type fastener is made of, contains not more than

1 % of homogeneously distributed organic material, by mass or volume (whichever is the most

onerous) (e.g. for uncoated steel and stainless steel); and

b) any external coating, if applied over the surface area of the dowel-type fastener, is made on inorganic

material(s), which is/are also classified as Class A1 (e.g. for zinc coated steel, …).

5 See Decision of the Commission 96/603/EC of 1996-10-04 (see OJEU L 267 of 1996-10-19), as twice amended

by 2000/605/EC of 2000-09-26 (see OJEU L 258 of 2000-10-12) and by 2003/424/EC of 2003-06-06 (see OJEU

L 144 of 2003-06-12).

4.3.3 Classification according to the test results

For the reaction to fire performance of a dowel-type fastener each of its constituent organic material(s),

including those in surface coating of the fastener, if any, shall be assessed regarding its reaction to fire

classification according to EN 13501-1:2018 and only the lowest class of such materials shall be

expressed.

The reaction to fire class of an individual constituent organic material shall be obtained as the result of

the test method(s), relevant to the class claimed and as specified in the standards, referred to in

EN 13501-1:2018. Test specimens used for the test methods, applicable for this classification, shall be

prepared according to the relevant standards.

A constituent organic material of the dowel-type fastener, including those used in its surface coating, if

any, is considered as the “external non-substantial component” material.

5 Product specific characteristics - Testing, assessment and sampling method

5.1 Nails

5.1.1 Mechanical strength and stiffness

5.1.1.1 General

5.1.1.1.1 The following characteristics are applicable for assessing the mechanical strength and

stiffness of nails:

a) characteristic yield moment;

b) characteristic withdrawal parameter;

c) characteristic head pull-through parameter;

d) characteristic tensile capacity;

e) low cycle ductility (seismic performance).

5.1.1.1.2 For the purposes of strength, the characteristic values shall be determined either by:

i) testing in accordance with the standard or annex, identified in the subsequent subclauses, followed

by calculation in accordance with EN 1990:2002, Annex D for 5.1.1.1.1, a), d), e) or EN 14358:2016

for 5.1.1.1.1, b), c);

ii) by calculation using relevant formulae, given in EN 1995-1-1:2004 .

NOTE For the purposes of strength calculations for nailed joints, the nail diameter is taken as the nominal

diameter, d, measured in accordance with G.1.

6 See Item 2 in Annex to Commission Delegated Regulation (EU) 2016/364 of 2015-07-01 (see OJEU L 68 of

2016-03-15).

As impacted by EN 1995-1-1:2004/A1:2008 and EN 1995-1-1:2004/A2:2014.

5.1.1.1.3 For the purposes of stiffness (bending angle α) the characteristic yield moment M shall be

y,Rk

determined either by:

i) testing in accordance with the standard or annex, identified in the subsequent subclauses, followed

by calculation in accordance with EN 1990:2002, Annex D;

ii) by calculation using relevant formulae, given in EN 1995-1-1:2004 .

5.1.1.2 Characteristic yield moment

NOTE See 5.1.1.1.1, a).

5.1.1.2.1 For smooth shank nails, with round or square cross-section, uncoated or coated, the

characteristic yield moment M shall be determined either by:

y,Rk

a) 5.1.1.1.3, i) where test is based on EN 409:2009 (testing and calculation); or

b) 5.1.1.1.3, ii), (calculation).

5.1.1.2.2 For all other types of nail, including ring shank nails, coated or uncoated, the characteristic

yield moment M shall be determined in accordance with 5.1.1.1.3, i), where test is based on

y,Rk

EN 409:2009 (testing and calculation). For ring shank nails the characteristic yield moment M shall

y,Rk

be determined for the weakest part.

5.1.1.2.3 Performance of the characteristic yield moment M shall be expressed as value in Nmm.

y,Rk

The expression of the value of M implies compliance with the requirement M ≤ characteristic value

y,Rk y,Rk

from testing or calculated value.

5.1.1.3 Characteristic withdrawal parameter

NOTE See 5.1.1.1.1, b)

5.1.1.3.1 For smooth shank nails, uncoated or coated with Type 1 or Type 2 coatings, the characteristic

withdrawal parameter f shall be determined either by:

ax,k

a) 5.1.1.1.2, i), where test is based on EN 1382:2016, (testing and calculation); or

b) 5.1.1.1.2, ii) (calculation).

Test specimens shall be selected according to the provisions of Annex D, replacing those of EN 1382:2016.

If necessary, when testing according to EN 1382:2016 the measured value of the characteristic

withdrawal parameter shall be corrected for the wood densities in accordance with Annex D.

5.1.1.3.2 For all other types of nail, including ring shank nails, uncoated or coated with Type 1 or Type

shall be determined in accordance with 5.1.1.1.2,

2 coatings, the characteristic withdrawal parameter f

ax,k

i), where test is based on EN 1382:2016, (testing and calculation).

Test specimens shall be selected according to the provisions of Annex D, replacing those of EN 1382:2016.

If necessary, when testing according to EN 1382:2016 the measured value of the characteristic

withdrawal parameter shall be corrected for the wood densities in accordance with Annex D.

5.1.1.3.3 For nails with the Type 3 coating, the characteristic withdrawal parameter f shall be

ax,k

determined in accordance with Annex F, (testing and calculation).

5.1.1.3.4 Performance of the characteristic withdrawal parameter f shall be expressed as value in

ax,k

N/mm together with the value of the associated characteristic timber or wood-based product density ρ

k

in kg/m. The expression of the value of f implies compliance with the requirement

ax,k

f ≤ characteristic value from testing or calculated value.

ax,k

5.1.1.4 Characteristic head pull-through parameter

NOTE See 5.1.1.1.1, c).

5.1.1.4.1 For smooth shank nails, uncoated or coated, the characteristic head pull-through parameter

f shall be determined either by:

head,k

a) 5.1.1.1.2, i), where test is based on EN 1383:2016, (testing and calculation); or

b) 5.1.1.1.2, ii) (calculation).

Test specimens shall be selected according to the provisions of Annex D, replacing those of EN 1382:2016.

If necessary, when testing according to EN 1383:2016 the measured value of the characteristic head pull-

through parameter shall be corrected for the wood densities in accordance with Annex D.

5.1.1.4.2 For all other types of nail, including ring shank nails, uncoated or coated, the characteristic

head pull-through parameter f shall be determined in accordance with 5.1.1.1.2, i), where test is

head,k

based on EN 1383:2016, (testing and calculation).

Test specimens shall be selected according to the provisions of Annex D, replacing those of EN 1382:2016.

If necessary, when testing according to EN 1383:2016 the measured value of the characteristic head pull-

through parameter shall be corrected for the wood densities in accordance with Annex D.

5.1.1.4.3 Performance of the characteristic head pull-through parameter f shall be expressed as

head,k

value in N/mm together with the value of the associated characteristic timber or wood-based product

density ρ in kg/m . The expression of the value of f implies compliance with the requirement

k head,k

f ≤ characteristic value from testing or calculated value.

head,k

5.1.1.5 Characteristic tensile capacity

NOTE See 5.1.1.1.1, d).

5.1.1.5.1 For any types of nail, uncoated or coated, the characteristic tensile capacity F (head pull-

tens,k

off or shank tensile capacity) shall be determined in accordance with 5.1.1.1.2, i), where test is based on

EN 1383:2016, accounting for the following modifications (testing with calculation):

— use a steel plate to replace the head side timber member shown in Figure 4 of EN 1383:2016. The

steel plate shall be of sufficient thickness to induce either a pull-off failure of the head, or a tensile

failure of the shank and shall contain a pre-drilled hole for the nail which shall not exceed the

maximum outer diameter of the nail + 1 mm in diameter;

— for partially profiled nails, the area of transition from the profiled to the smooth part of the shank

shall be located within the free length of testing and shall have a clear distance from the jaws of the

testing equipment of at least 3 d;

— the rate of loading shall be chosen so that the failure load (ultimate load) is reached within 10 s ± 5 s.

Description of the mode and location of failure should be reported.

5.1.1.5.2 Performance of the characteristic tensile capacity F shall be expressed as value in N. The

tens,k

expression of the value of F implies compliance with the requirement F ≤ characteristic value

tens,k tens,k

from testing.

5.1.1.6 Low cycle ductility (seismic performance)

NOTE See 5.1.1.1.1, e).

5.1.1.6.1 For the purpose of assessing the seismic performance of any types of nail, uncoated or coated,

the following two moment capacities shall be determined in accordance with the method given in

Annex E, (testing with calculation)

a) reference mean yield moment capacity, determined on samples of the same batch by monotonic

tests;

b) residual moment capacity, determined after three fully reversed cycles carried out at the value of the

selected angle α considering that:

c

— for smooth shank nails, the cross section subjected to bending shall be in the middle part;

— for ring shank nails, the cross section subjected to bending shall be in the profiled part.

5.1.1.6.2 At the value of the selected α , the residual moment capacity of the nail shall be at least 80 %

c

of the mean yield moment capacity.

5.1.1.6.3 The seismic performance shall be expressed as one of the low cycle ductility classes (S1 to

S3), according to Table 8 in 4.2. Smooth shank non-hardened nails may be assumed to fulfil low cycle

ductility Class S1 without testing. The expression of the low cycle ductility class implies compliance with

the specifications for that class.

5.2 Staples

5.2.1 Mechanical strength and stiffness

5.2.1.1 General

5.2.1.1.1 The following characteristic are applicable for assessing the mechanical strength and stiffness

of staples:

a) characteristic yield moment;

b) characteristic withdrawal parameter;

c) characteristic head pull-through parameter;

d) low cycle ductility (seismic performance).

5.2.1.1.2 For the purposes of strength, the characteristic values shall be determined either by:

i) testing in accordance with the standard or annex, identified in the subsequent subclauses, followed

by calculation in accordance with EN 1990:2002, Annex D for 5.2.1.1.1, a), d), or EN 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...