EN 10305-6:2016

(Main)Steel tubes for precision applications - Technical delivery conditions - Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems

Steel tubes for precision applications - Technical delivery conditions - Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems

This European Standard specifies the technical delivery conditions for welded cold drawn tubes of circular cross section for use in hydraulic and pneumatic power systems.

Tubes according to this part of EN 10305 are characterized by having precisely defined tolerances on dimensions and a specified surface roughness.

The allowed pressure rates and upper temperatures are the responsibility of the customer in accordance with the state of the art and in application of the safety coefficients specified in the applicable regulations, codes or standards. Concerning the lower temperature range applicability the impact energy requirements are given at 0 °C.

NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESRs) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done.

Präzisionsstahlrohre - Technische Lieferbedingungen - Teil 6: Geschweißte kaltgezogene Rohre für Hydraulik- und Pneumatik-Druckleitungen

Dieser Teil der EN 10305 enthält die technischen Lieferbedingungen für geschweißte kaltgezogene Präzisionsrohre mit kreisförmigem Querschnitt für die Anwendung in hydraulischen und pneumatischen Druckleitungssystemen.

Rohre nach diesem Teil der EN 10305 sind durch genau definierte Grenzabmaße und eine fest¬gelegte Oberflächenrauheit charakterisiert.

Die Beachtung der zulässigen Druckbeaufschlagung und Höchsttemperaturen nach dem Stand der Technik und unter Anwendung der in den entsprechenden Vorschriften, Regelwerken oder Normen festgelegten Sicherheitskoeffizienten liegt in der Verantwortung des Anwenders. Für die Anwendungen im unteren Temperaturbereich wurden Anforderungen an die Kerbschlagarbeit bei 0 °C festgelegt.

ANMERKUNG Nach Veröffentlichung dieser Norm im EU Amtsblatt (OJEU) unter der Richtlinie 97/23/EG ist die Annahme ihrer Konformität mit den grundlegenden Anforderungen (ESR) der Richtlinie 97/23/EG auf die technischen Daten von Werkstoffen in dieser Europäischen Norm beschränkt, und es darf nicht angenommen werden, dass damit die Eignung des Werkstoffs für ein bestimmtes Ausrüstungsteil festgestellt ist. Folglich müssen die in dieser Werkstoffnorm angegebenen technischen Parameter im Hinblick auf die konstruktiven Anforderungen dieses bestimmten Ausrüstungs¬teils ermittelt werden, um damit zu verifizieren, dass den ESR der Richtlinie 97/23/EG entsprochen wird.

Tubes de précision en acier - Conditions techniques de livraison - Partie 6 : Tubes soudés étirés à froid pour circuits hydrauliques et pneumatiques

La présente norme européenne spécifie les conditions techniques de livraison pour les tubes soudés en acier, étirés à froid, de section circulaire, utilisés dans les circuits hydrauliques et pneumatiques.

Les tubes conformes à la présente partie de l'EN 10305 se caractérisent par des tolérances dimensionnelles définies précisément et par une rugosité spécifiée.

Les taux de pression et les températures autorisés relèvent de la responsabilité du client conformément aux règles de l'art et en application des coefficients de sécurité spécifiés dans les réglementations, codes ou normes applicables. Pour la plage de basse température applicable les exigences concernant l’énergie de choc sont données à une température de 0°C.

NOTE Lorsque cette norme sera publiée dans le Journal Officiel de l’Union Européenne (JOUE) sous la Directive 2014/68/EU la présomption de conformité aux exigences essentielles de sécurité (EES) est limitée aux données techniques concernant les matériaux, et ne présume pas de l’adéquation du matériau avec un composant particulier de l’équipement. En conséquence, la vérification des données techniques figurant dans la norme au regard des exigences de conception applicables à ce composant particulier de l’équipement, pour vérifier que les EES de la Directive Equipements sous Pression, doit être faite.

Jeklene cevi za precizno uporabo - Tehnični dobavni pogoji - 6. del: Hladno vlečene varjene cevi za hidravlične in pnevmatične tlačne vode

Ta del standarda EN 10305 določa tehnične dobavne pogoje za hladno vlečene varjene cevi s krožnim prečnim prerezom za uporabo v hidravličnih in pnevmatičnih tlačnih vodih.

Cevi v skladu s tem delom standarda EN 10305 imajo natančno opredeljene tolerance za mere in določeno največjo površinsko hrapavost.

Za dovoljene ravni tlaka in najvišje temperature je odgovorna stranka v skladu s stanjem tehnike in ob uporabi varnostnih koeficientov, določenih v veljavnih predpisih, kodeksih ali standardih. Kar zadeva ustreznost razpona nižjih temperatur, so zahteve glede udarne moči podane pri 0 °C.

OPOMBA: Ko bo ta standard objavljen v Uradnem listu Evropske unije (OJEU) v okviru Direktive 97/23/ES, bodo zagotovila o skladnosti z osnovnimi varnostnimi zahtevami (ESR) Direktive 97/23/ES omejena na tehnične podatke o materialih, navedene v tem evropskem standardu, standard pa ne bo zagotavljal ustreznosti materiala za določen element opreme. Zato bo potrebno oceniti tehnične podatke, podane v tem standardu za materiale, glede na zahteve zasnove določenega elementa opreme, da se zagotovi, da so izpolnjene osnovne varnostne zahteve Direktive o tlačni opremi.

General Information

- Status

- Published

- Publication Date

- 29-Mar-2016

- Withdrawal Date

- 29-Sep-2016

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Sep-2021

- Completion Date

- 02-Sep-2021

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 06-Apr-2016

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10305-6:2016 - Steel tubes for precision applications - Part 6 defines the technical delivery conditions for welded cold drawn tubes of circular cross section intended for hydraulic and pneumatic power systems. The standard focuses on precision steel tubes with strict dimensional tolerances and specified surface roughness, and it sets requirements for manufacture, inspection and documentation. Customers remain responsible for selecting allowable pressure ratings and maximum operating temperatures in line with applicable safety coefficients and regulations.

Key topics and technical requirements

- Scope and purpose: Applies to welded cold drawn precision tubes for hydraulic and pneumatic circuits; impact energy requirements for low temperatures are given at 0 °C.

- Dimensional control: Tubes are characterized by precisely defined tolerances (outer diameter and wall thickness preferred) and geometric requirements.

- Surface quality: Specified surface roughness and options for reduced internal roughness and surface roughness measurement.

- Mechanical verification: Mechanical properties verified by tensile testing and the drift-expanding test (now accepted alongside tensile tests).

- Non-destructive testing (NDT): Options include automated electromagnetic, eddy-current, flux-leakage and ultrasonic methods (EN ISO 10893 series) for detection of imperfections.

- Manufacturing and materials: Steelmaking processes are at manufacturers’ discretion (fully killed steels required); designation follows EN 10027.

- Ordering and documentation: Mandatory purchaser information (quantity, tube dimensions D x T, steel grade, length, inspection certificate type). Example order format provided (e.g., D 20 x T 2,5 - EN 10305-6 - E235 - standard length - inspection certificate 3.1).

- Packaging, marking and protection: Options for end protection, phosphatization, electrolytic zinc coating, and alternative marking or packaging methods.

- Regulatory note: When referenced under the Pressure Equipment Directive (Directive 2014/68/EU), conformity is presumed only for material technical data; suitability for a specific pressure equipment design must be assessed separately.

Applications and users

- Applications: Hydraulic cylinders, pneumatic actuators, high-precision fluid lines, control systems and other power transmission components requiring tight tolerances and smooth internal surfaces.

- Who uses it: Tube manufacturers, component and system designers, hydraulic/pneumatic equipment manufacturers, procurement/specification engineers, and QA/NDT professionals.

Related standards

- EN 10305 series (Parts 1–5), EN 10020, EN 10204, EN ISO 6892-1 (tensile test), EN ISO 8493 (drift-expanding), EN ISO 10893 (NDT methods).

EN 10305-6:2016 is essential when specifying precision welded cold drawn tubes for reliable hydraulic and pneumatic system performance, ensuring consistent quality, traceability and compliance with delivery conditions.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10305-6:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steel tubes for precision applications - Technical delivery conditions - Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems". This standard covers: This European Standard specifies the technical delivery conditions for welded cold drawn tubes of circular cross section for use in hydraulic and pneumatic power systems. Tubes according to this part of EN 10305 are characterized by having precisely defined tolerances on dimensions and a specified surface roughness. The allowed pressure rates and upper temperatures are the responsibility of the customer in accordance with the state of the art and in application of the safety coefficients specified in the applicable regulations, codes or standards. Concerning the lower temperature range applicability the impact energy requirements are given at 0 °C. NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESRs) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done.

This European Standard specifies the technical delivery conditions for welded cold drawn tubes of circular cross section for use in hydraulic and pneumatic power systems. Tubes according to this part of EN 10305 are characterized by having precisely defined tolerances on dimensions and a specified surface roughness. The allowed pressure rates and upper temperatures are the responsibility of the customer in accordance with the state of the art and in application of the safety coefficients specified in the applicable regulations, codes or standards. Concerning the lower temperature range applicability the impact energy requirements are given at 0 °C. NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESRs) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done.

EN 10305-6:2016 is classified under the following ICS (International Classification for Standards) categories: 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10305-6:2016 has the following relationships with other standards: It is inter standard links to EN 10305-6:2005, ISO 11484:2009, EN 10027-2:2015, EN ISO 10893-2:2011, EN ISO 21920-2:2022, EN ISO 10893-1:2011, EN ISO 8493:2004, EN 10020:2000, EN ISO 10893-3:2011, EN 10168:2004, EN ISO 10893-10:2011, EN 10021:2006, EN 10052:1993, EN ISO 6892-1:2019, EN 10204:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10305-6:2016 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10305-6:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Präzisionsstahlrohre - Technische Lieferbedingungen - Teil 6: Geschweißte kaltgezogene Rohre für Hydraulik- und Pneumatik-DruckleitungenTubes de précision en acier - Conditions techniques de livraison - Partie 6 : Tubes soudés étirés à froid pour circuits hydrauliques et pneumatiquesSteel tubes for precision applications - Technical delivery conditions - Part 6: Welded cold drawn tubes for hydraulic and pneumatic power systems77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific useICS:Ta slovenski standard je istoveten z:EN 10305-6:2016SIST EN 10305-6:2016en,fr,de01-oktober-2016SIST EN 10305-6:2016SLOVENSKI

STANDARDSIST EN 10305-6:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 10305-6

March

t r s x ICS

y yä s v rä y w Supersedes EN

s r u r wæ xã t r r wEnglish Version

Steel tubes for precision applications æ Technical delivery conditions æ Part

xã Welded cold drawn tubes for hydraulic and pneumatic power systems Tubes de prßcision en acier æ Conditions techniques de livraison æ Partie

x ã Tubes soudßs ßtirßs à froid pour circuits hydrauliques et pneumatiques

Präzisionsstahlrohre æ Technische Lieferbedingungen æTeil

xã Geschweißte kaltgezogene Rohre für Hydraulikæund PneumatikæDruckleitungen This European Standard was approved by CEN on

s z January

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s r u r wæ xã t r s x ESIST EN 10305-6:2016

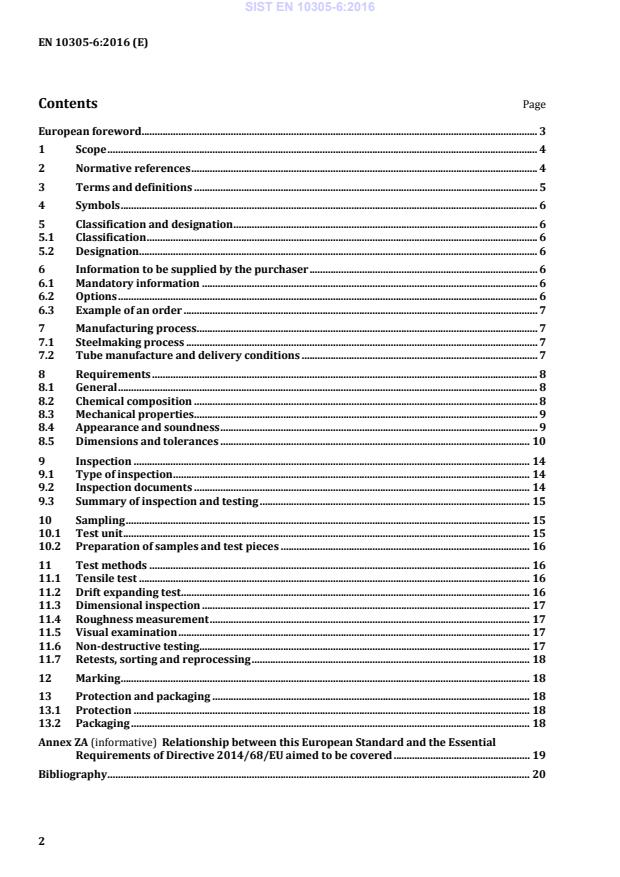

Relationship between this European Standard and the Essential Requirements of Directive 2014/68/EU aimed to be covered . 19 Bibliography . 20

Option 7: Reduced internal roughness of

¶ 2 8.4.3);

Option 8: Measurement of surface roughness (see 8.4.4);

Option 12: Non-destructive testing for the detection of longitudinal imperfections (see 8.4.7);

Option 21: another specified length and/or tolerance (see 8.5.2);

Option 22: Reduced maximum deviation from straightness (see 8.5.3); SIST EN 10305-6:2016

Option 24: higher test pressure for hydrostatic test (see 11.6.2);

Option 28: alternative marking (see Clause 12);

Option 31: protection by phosphatization (see 13.1);

Option 32: protection by electrolytical zinc coating (see 13.1);

Option 37: protection of tube ends (see 13.1);

Option 38: unbundled tubes or specific method of packaging (see 13.2). 6.3 Example of an order 1 000 tubes with an outside diameter of D = 20 mm and a specified wall thickness of T = 2,5 mm in accordance with this document, made of steel grade E235, delivered in standard lengths with an inspection certificate 3.1 in accordance with EN 10204:2004: 1 000 tubes – D 20 x T 2,5 – EN 10305-6 – E235 – standard length – inspection certificate 3.1 7 Manufacturing process 7.1 Steelmaking process The steel making process is at the discretion of the manufacturer with the exception that the open hearth (Siemens-Martin) process shall not be employed unless in combination with a secondary steelmaking or ladle refining process. Steels shall be fully killed. NOTE This excludes the use of rimming, balanced or semi-killed steel. 7.2 Tube manufacture and delivery conditions 7.2.1 The tubes shall be manufactured from electric welded tubes by cold drawing. Other suitable methods of cold working are permitted. The tubes shall be delivered in the delivery condition +N, which means that after final cold drawing (or other processing) the tubes are normalized in a controlled atmosphere. 7.2.2 Welding shall be carried out by suitably qualified personnel according to suitable operating procedures. For tube to be used for pressure equipment in categories II, III, and IV (of Directive 2014/68/EU), the operating procedures and the personnel shall be approved by a competent third-party. Tubes not processed according to this requirement shall be marked “C 1”. 7.2.3 All non-destructive testing (NDT) activities shall be carried out by qualified and competent level 1, 2 and/or 3 personnel authorized to operate by the employer. The qualification shall be in accordance with ISO 11484:2009 or, at least, an equivalent to it. It is recommended that the level 3 personnel be certified in accordance with EN ISO 9712 or, at least, an equivalent to it. The operating authorization issued by the employer shall be in accordance with a written procedure. NDT operations shall be authorized by a level 3 NDT individual approved by the employer. SIST EN 10305-6:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...