EN 16602-70-14:2018

(Main)Space product assurance - Corrosion

Space product assurance - Corrosion

The purpose of the proposed Standard is to summarise the (general) corrosion protection requirements applicable to the materials, surface treatments, finishing and manufacturing processes used for space flight hardware.

It contains the minimum requirements necessary to guarantee and verify the suitability of materials, coatings systems and processes for corrosion control of space rated products.

The Standard classifies the corrosion environments and requires the issuing of a Corrosion Prevention and Control Plan based on the identified environmental classes. Testing and acceptance criteria are specified for each environmental class.

The scope of the document would include all flight parts and components used for space missions including Ground Support Equipment (GSE), where the materials and processes used in interfacing ground support equipment, test equipment, hardware processing equipment, hardware packaging and hardware shipment are to be controlled in order to prevent damage to or contamination of flight hardware.

Raumfahrtproduktsicherung - Korrosion

Assurance produit des projets spatiaux - Corrosion

Le présent document spécifie les exigences minimales pour qualifier les matériaux et procédés sélectionnés afin d'obtenir une protection contre la corrosion. Des essais supplémentaires peuvent être réalisés pour satisfaire aux exigences relatives aux matériaux et procédés utilisés pour des applications de vol spécifiques.

La présente norme spécifie le comportement des métaux et alliages mais n'ôte pas la responsabilité concernant la dégradation des autres matériaux à considérer.

Le présent document ne couvre par les exigences relatives à la protection contre la fissuration par corrosion sous contrainte, traitées par une norme dédiée, l’ECSS-Q-ST-70-36.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d'un projet spatial, conformément à l'ECSS-S-ST-00.

Zagotavljanje varnih proizvodov v vesoljski tehniki - Korozija

Namen predlaganega standarda je povzeti (splošne) zahteve za zaščito pred korozijo, ki se uporabljajo za materiale, površinsko obdelavo, končno obdelavo in proizvodne procese, ki se uporabljajo za strojno opremo v vesoljskih poletih. Vsebuje minimalne zahteve, ki so potrebne za zagotovitev in preverjanje primernosti materialov, premaznih sistemov in procesov za nadzor korozije vesoljskih izdelkov. Standard razvršča korozijska okolja in zahteva izdajo načrta za preprečevanje in nadzor korozije, ki temelji na opredeljenih okoljskih razredih. Za vsak okoljski razred so določeni kriteriji preskušanja in sprejemljivosti. Področje uporabe dokumenta vključuje vse dele za letenje in komponente, ki se uporabljajo za vesoljske misije, vključno s podporno opremo na tleh (GSE), kjer se materiali in procesi, ki se uporabljajo pri povezovanju podporne opreme na tleh, preskusne opreme, opreme za obdelavo strojne opreme, embalaže strojne opreme in pošiljanja strojne opreme nadzorujejo, da se prepreči poškodovanje ali kontaminacija letalske strojne opreme.

General Information

- Status

- Published

- Publication Date

- 18-Dec-2018

- Withdrawal Date

- 29-Jun-2019

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5/WG 6 - Upstream standards

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Jun-2024

- Completion Date

- 03-Jun-2024

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16602-70-14:2018 - Space product assurance: Corrosion (CEN) defines the minimum requirements to control corrosion for space flight hardware. The standard summarizes corrosion protection needs for materials, surface treatments, finishing and manufacturing processes used on spacecraft and launchers, and it includes Ground Support Equipment (GSE) and handling/packaging processes that could damage or contaminate flight hardware. EN 16602-70-14:2018 classifies corrosive environments, requires a Corrosion Prevention and Control Plan, and prescribes test methods and acceptance criteria for each environmental class.

Key topics and requirements

- Environmental classification: Defines multiple corrosive environment classes (e.g., seawater immersion, seacoast/outdoor, indoor controlled/uncontrolled, chemical or microbial-induced) and links each class to required tests and acceptance criteria.

- Corrosion Prevention and Control Plan: Projects must issue a plan tailored to identified environmental classes and mission life (document covers ground exposure up to 10 years).

- Materials scope: Applies to metallic materials only; identifies corrosion‑resistant alloys (specific aluminium series and CRES) and non‑corrosion‑resistant metals.

- Testing and verification: Specifies test methods (e.g., salt spray, damp heat, alternate immersion) and references standards such as ISO 9227, ISO 11130, ASTM D5894 and MIL‑STD procedures. Annexes provide guidance (e.g., tape test, damp heat).

- Finishes and coatings: Verification and acceptance guidance for metallic finishes (nickel, chromium, zinc‑nickel, copper, silver, tin, gold), vapour‑deposited coatings (CVD/PVD), inorganic and organic finishes, and anodic oxidations.

- Design and process controls: Addresses cleaning, surface preparation, process verification, cut‑edge protection, drainage/airflow, galvanic compatibility and handling to reduce corrosion risk.

- Corrosion types: Describes eight forms of corrosion (general, galvanic, crevice, pitting, intergranular, dealloying, erosion, stress corrosion) and hydrogen damage considerations.

Applications and users

EN 16602-70-14:2018 is used by:

- Spacecraft and launcher materials & corrosion engineers

- Quality assurance, manufacturing and procurement teams

- GSE, test equipment and packaging suppliers interfacing with flight hardware

- Coatings and surface‑treatment vendors and test laboratories Practical uses include materials selection, coating/process qualification, development of corrosion control plans, procurement specifications, and acceptance testing to ensure long‑term flight hardware integrity.

Related standards

- ECSS-Q-ST-70-14 (origin) and ECSS-Q-ST-70-36 (stress corrosion cracking)

- ECSS-S-ST-00 (tailoring guidance)

- ISO 9227, ISO 11130, ASTM D5894, MIL‑STD‑1501F (referenced test/method standards)

Keywords: EN 16602-70-14:2018, space product assurance, corrosion prevention, corrosion control, corrosion testing, spacecraft coatings, ground support equipment.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16602-70-14:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space product assurance - Corrosion". This standard covers: The purpose of the proposed Standard is to summarise the (general) corrosion protection requirements applicable to the materials, surface treatments, finishing and manufacturing processes used for space flight hardware. It contains the minimum requirements necessary to guarantee and verify the suitability of materials, coatings systems and processes for corrosion control of space rated products. The Standard classifies the corrosion environments and requires the issuing of a Corrosion Prevention and Control Plan based on the identified environmental classes. Testing and acceptance criteria are specified for each environmental class. The scope of the document would include all flight parts and components used for space missions including Ground Support Equipment (GSE), where the materials and processes used in interfacing ground support equipment, test equipment, hardware processing equipment, hardware packaging and hardware shipment are to be controlled in order to prevent damage to or contamination of flight hardware.

The purpose of the proposed Standard is to summarise the (general) corrosion protection requirements applicable to the materials, surface treatments, finishing and manufacturing processes used for space flight hardware. It contains the minimum requirements necessary to guarantee and verify the suitability of materials, coatings systems and processes for corrosion control of space rated products. The Standard classifies the corrosion environments and requires the issuing of a Corrosion Prevention and Control Plan based on the identified environmental classes. Testing and acceptance criteria are specified for each environmental class. The scope of the document would include all flight parts and components used for space missions including Ground Support Equipment (GSE), where the materials and processes used in interfacing ground support equipment, test equipment, hardware processing equipment, hardware packaging and hardware shipment are to be controlled in order to prevent damage to or contamination of flight hardware.

EN 16602-70-14:2018 is classified under the following ICS (International Classification for Standards) categories: 49.040 - Coatings and related processes used in aerospace industry; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16602-70-14:2018 has the following relationships with other standards: It is inter standard links to ISO 9588:2007, ISO 11130:2010, EN 3475-603:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16602-70-14:2018 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16602-70-14:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zagotavljanje varnih proizvodov v vesoljski tehniki - KorozijaRaumfahrtproduktsicherung - KorrosionAssurance produit des projets spatiaux - CorrosionSpace product assurance - Corrosion49.140Vesoljski sistemi in operacijeSpace systems and operations49.040Prevleke in z njimi povezani postopki, ki se uporabljajo v letalski in vesoljski industrijiCoatings and related processes used in aerospace industryICS:Ta slovenski standard je istoveten z:EN 16602-70-14:2018SIST EN 16602-70-14:2019en,fr,de01-marec-2019SIST EN 16602-70-14:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-70-14

December

t r s z ICS

v {ä r v râ

v {ä s v r

English version

Space product assurance æ Corrosion

Assurance produit des projets spatiaux æ Corrosion

Raumfahrtproduktsicherung æ Korrosion This European Standard was approved by CEN on

s t October

t r s zä

C Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN and CENELEC memberä

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels y any means reserved worldwide for CEN national Members and for CENELEC Membersä Refä Noä EN

s x x r tæ y ræ s vã t r s z ESIST EN 16602-70-14:2019

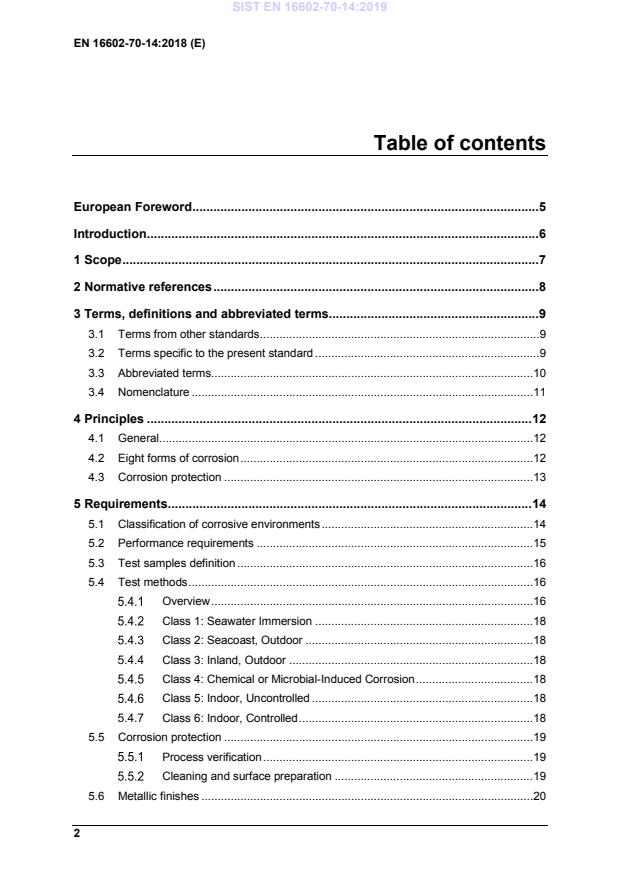

Overview . 16

Class 1: Seawater Immersion . 18

Class 2: Seacoast, Outdoor . 18

Class 3: Inland, Outdoor . 18

Class 4: Chemical or Microbial-Induced Corrosion . 18

Class 5: Indoor, Uncontrolled . 18

Class 6: Indoor, Controlled . 18 5.5 Corrosion protection . 19

Process verification . 19

Cleaning and surface preparation . 19 5.6 Metallic finishes . 20 SIST EN 16602-70-14:2019

Verification of metallic finishes . 20

Nickel plating . 20

Chromium plating . 21

Zinc-Nickel plating . 21

Copper plating . 22

Silver plating . 22

Tin plating . 22

Gold plating . 22

Vapour deposited coatings (CVD and PVD) . 22 5.7 Inorganic finishes . 23

Verification of inorganic finishes . 23

Anodic oxidations on aluminium and its alloys and titanium and its alloys. 23 5.8 Organic finishes . 23 5.9 Design considerations for corrosion control . 24

Surface treatments processes . 24

Cut edges . 24

Drainage and airflow . 24

Galvanic compatibility . 24 Annex A (informative) Corrosion . 25 A.1 Overview . 25 A.2 The eight forms of corrosion . 25 A.2.1 General corrosion . 25 A.2.2 Galvanic corrosion . 25 A.2.3 Crevice corrosion . 26 A.2.4 Pitting . 26 A.2.5 Intergranular corrosion . 27 A.2.6 Dealloying or Selective leaching . 27 A.2.7 Erosion corrosion . 27 A.2.8 Stress corrosion . 27 A.3 Hydrogen damage . 28 A.4 Corrosion in clean rooms . 28 Annex B (informative) Tape test method . 29 Annex C (informative) Damp heat test method . 30 C.1 Introduction . 30 C.2 Significance and use . 30 C.3 Apparatus and test specimens . 30 SIST EN 16602-70-14:2019

Figures

: Tape test method . 29

Tables Table 5-1: Definition of corrosive environment classes . 15 Table 5-2– Matrix of test methods versus environments . 17

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS System - Glossary of terms EN 16602-70 ECSS-Q-ST-70 Space product assurance - Materials, mechanical parts and processes

ASTM D 5894-10 (2010) Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures in a Fog/Dry Cabinet and a UV/Condensation Cabinet)

ISO 9227:2012 Corrosion tests in artificial atmospheres – Salt spray tests

ISO 9588:2007 Metallic and other inorganic coatings - Post-coating treatments of iron or steel to reduce the risk of hydrogen embrittlement

ISO 11130:2010 Corrosion of metals and alloys - Alternate immersion test in salt solution

MIL-STD-1501F (2011) Chromium Plating, Low Embrittlement, Electrodeposition SIST EN 16602-70-14:2019

The use of corrosion resistant alloys does not mean that corrosion cannot occur in all environments. 3.2.3 corrosion-resistant aluminium alloys 1000, 3000, 5000, and 6000 series alloys and all clad alloys 3.2.4 corrosion-Resistant Steel (CRES) steel having 12 % in weight or more chromium content 3.2.5 exterior surfaces surface in contact with or exposed to direct action of the environment NOTE

All other surfaces are considered interior surfaces. 3.2.6 non-corrosion-resistant aluminium alloys all other aluminium alloys not considered to be corrosion-resistant alloys SIST EN 16602-70-14:2019

Abbreviation Meaning AD applicable document AMS aerospace material specification ASTM American Society for Testing and Materials CRES corrosion-resistant steel CVD chemical vapour deposition °C degree Celsius DML declared materials list DMPL declared mechanical parts list DPL declared process list DRD document requirements definition EN

European Norm H/W hardware ISO

International Standardisation Organisation MIL-STD military standard MPa Megapascal NSST Neutral Salt Spray Test PVD

physical vapour deposition RD reference document RH relative humidity SAE Society of Automotive Engineers SCC stress-corrosion cracking SST salt spray test UTS ultimate tensile strength UV ultraviolet

Clause 5.1.9 of ECSS-Q-ST-70 states that: a. “For all materials that come into contact with atmospheric gases, cleaning fluids or other chemicals, it shall be demonstrated that the degradation of properties during their anticipated service life does not prevent to meet the performance and integrity requirements”. b. “All mechanical parts, assemblies and equipment including spares, shall be finished to provide protection from corrosion. NOTE

This applies equally to fasteners and other fixing devices, such as insert systems.” 4.2 Eight forms of corrosion Corrosion is classified according to eight forms: 1) general, 2) galvanic, 3) pitting, 4) crevice, 5) erosion corrosion, 6) intergranular, 7) stress corrosion cracking, 8) dealloying or selective leaching.

A full explanation of eight forms of corrosion is given in Annex A. Although some corrosion processes can be considered benign or even advantageous, the by-products of such reactions should also be considered. For example, hydrogen is generated as a by-product of many corrosion reactions. SIST EN 16602-70-14:2019

Selection of a corrosion protection system needs to ensure it complies with local environmental regulations. SIST EN 16602-70-14:2019

The supplier shall identify, the applicable classes of environments from the list specified in the Table 5-1 to which space flight hardware materials are exposed during hardware life cycle on ground or during mission. NOTE

A non-exhaustive list of standards that can be agreed between customer and supplier is given in the bibliography of this standard.

The supplier shall select corrosion protection systems for each space flight hardware material.

The selection of the relevant class of corrosive environment shall be based on the worst-case hardware exposure. 1 The exterior surfaces are typically the worst-case exposure. However it is necessary to evaluate each hardware individually. 2 The manufacturer can decide to put (or not) surface protection on materials or parts inside a hermetically sealed enclosure, containing a non-corrosive atmosphere.

Degree of severity increases from Class 6 to Class 1, except for Class 4 that shall be considered apart from other classes. SIST EN 16602-70-14:2019

1 Exposure to seawater (immersion) 2 Exposure to marine (atmospheric) environments 3 Exposure to inland outdoor environments. (See note 1). 4 Exposure to potentially corrosive chemical systems or microbial induced corrosion.

5 Exposure to indoor and uncontrolled humidity environments. 6 Continuous and exclusive exposure to temperature and humidity controlled (non-condensing) environment, dry air, and nitrogen- purged environments (maximum 65 % RH). (See note 2). Note 1: The weather conditions and prevailing winds mean that most of Europe is considered a marine environment. Use of this class in Europe need dedicated justification showing a chloride deposition rate of less than 5 mg.m2/day (mean annual value). Note 2: Examples of temperature and humidity controlled environments are clean room, flight hardware controlled storage areas

5.2 Performance requirements

It shall be shown that all environmentally exposed surfaces are protected from corrosion or resistant to corrosion in accordance with the test methods specified in the Table 5-2.

All corrosion tests shall be conducted using alloys with the heat treatment specified in the design documentation of the hardware.

For alloys in the same family, the most corrosion-susceptible alloy may be agreed between a customer and supplier and tested in lieu of the testing of all alloys in that family. NOTE

Sometimes it is not possible to select a single alloy to represent a family.

The supplier shall perform corrosion tests for the most severe environmental conditions anticipated.

In case the tests specified in Table 5-2 cannot be performed or are not representative, alternative justified corrosion test regimes for specific applications shall be submitted for customer approval.

Test acceptance criteria shall be specified by the supplier and agreed with the customer. 1 A typical acceptance criteria can be “no visible signs of corrosion at 5X magnification and no material removed when tape tested in accordance with ISO 2409 standard without cuts”. 2 See Tape Test method in Annex B.

At the conclusion of testing, the test samples shall be evaluated in accordance with acceptance criteria specified in the requirement 5.2f. SIST EN 16602-70-14:2019

Test samples shall be representative of the material listed in DML and DMPL specified in DRDs Annex A and Annex B from ECSS-Q-ST-70.

Test samples specified in the requirement 5.3a shall be manufactured with the same materials as the flight hardware and representative of the material form, finish, thermal treatment and size. 1 Examples of material form are cast, forged or extruded. 2 A typical sample has a minimum area of 1 dm2. In the case of small flight hardware, a smaller sample size can be acceptable.

A minimum number of test samples shall be subject to the customer approval. 5.4 Test methods

Overview The following clauses provide additional information on test methods versus environmental classes listed in Table 5-2.

1 2 3 4 5 6 Seawater Immersion Seacoast, Outdoor Inland, Outdoor Chemical or Microbial Indoor uncontrolled Indoor controlled Neutral Salt Spray Test (NSST) ISO 9227

500 h alternating with UV test

168 h

Chemical Resistance See Note 1

Specific test in accordance with corrosive agents

Damp Heat Test Damp Heat Test (see Annex C) (93 % RH 40 °C)

240 h UV ASTM D5894

7 days alternating with NSST

Alternate immersion ISO 11130 2x maximum allowed exposure 30 days

Note 1 Because for the environment class 4 there are no applicable test standards, the specific test in accordance with corrosive agents is performed.

Class 1: Seawater Immersion

In Class 1 environments, the protective finish shall withstand two times the maximum defined duration of immersion in seawater, when tested in accordance with ISO 11130.

Class 2: Seacoast, Outdoor

In Class 2 environments, the protective finish shall withstand 30 days when tested in accordance with ISO 11130.

Class 3: Inland, Outdoor

In Class 3 environments, the protective finish shall be tested by a combination of UV and NSST.

In Class 3 environments, the protective finish shall be tested alternating NSST and UV test, starting with UV testing.

In Class 3 environments, the total duration of test specified in the requirement 5.4.4b shall be seven days for UV and 500 h for NSST.

Class 4: Chemical or Microbial-Induced Corrosion

In Class 4 environments, specific tests shall be performed to confirm that the hardware is protected against corrosion during the anticipated chemical exposure or during exposure to microorganisms that induce corrosion.

Class 5: Indoor, Uncontrolled

In Class 5 environments, the hardware or representative samples shall be tested for 168 h in accordance with Neutral Salt Spray Test from ISO 9227.

Class 6: Indoor, Controlled

In Class 6 environments, all exposed surfaces shall be maintained in a continuous exposure to temperature- and humidity-controlled non-condensing enviro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...