EN 1492-2:2000+A1:2008

(Main)Textile slings - Safety - Part 2: Roundslings made of man-made fibres for general purpose use

Textile slings - Safety - Part 2: Roundslings made of man-made fibres for general purpose use

This European Standard specifies the requirements related to safety, including methods of rating and testing roundslings up to 40 tonnes working load limit (in straight lift) and two-, three-, and four-leg roundsling assemblies, with or without fittings, made of polyamide, polyester and polypropylene.

The roundslings covered by this Part of EN 1492 are intended for general purpose lifting operations, i.e. when used for lifting objects, materials or goods which require no deviations from the requirements, safety factors or WLL’s specified. Lifting operations not covered by this standard include the lifting of persons, potentially dangerous materials such as molten metal and acids, glass sheets, fissile materials, nuclear reactors and where special conditions apply.

Roundslings conforming to this European Standard are suitable for use and storage in the following temperature ranges:

a) polyester and polyamide: -40 °C to 100 °C,

b) polypropylene: -40 °C to 80 °C

This European Standard does not apply to the types of roundsling indicated below:

a) roundslings designed for securing or lashing of cargoes to each other on pallets and platforms or in vehicles;

b) slings of tubular webbing without filling.

This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the use of roundslings when carried out in accordance with the instructions and specifications given by the manufacturer or authorized representative.

Textile Anschlagmittel - Sicherheit - Teil 2: Rundschlingen aus Chemiefasern für allgemeine Verwendungszwecke

Diese Europäische Norm legt Anforderungen an die Sicherheit sowie Verfahren zur Bewertung und Prüfung von Rundschlingen mit einer Tragfähigkeit bis 40 t (in der Anschlagart direkt) sowie von ein-, zwei-, drei- und viersträngigen Rundschling-Einheiten, mit oder ohne Beschlagteilen, aus Polyamid, Polyester und Polypropylen fest.

Die in diesem Teil von EN 1492 erfassten Rundschlingen sind für allgemeine Hebevorgänge vorgesehen, d. h. für Anwendungen zum Anheben von Gegenständen, Materialien oder Lasten, die keine Abweichungen von den festgelegten Anforderungen, Sicherheitsfaktoren oder Tragfähigkeiten erfordern. In dieser Norm nicht festgelegt werden das Anheben von Personen, von möglicherweise gefährlichen Materialien, z. B. geschmolzenem Metall und Säuren, Glasplatten, spaltbaren Materialien, Teilen von Kernreaktoren und alle Hebevorgänge, für die Sonderbedingun¬gen gelten.

Rundschlingen, die dieser Europäischen Norm entsprechen, sind für eine Benutzung und Lagerung bei Temperaturen in folgenden Bereichen geeignet:

a) Polyester und Polyamid: -40 °C bis 100 °C;

b) Polypropylen: -40 °C bis 80 °C.

Diese Europäische Norm gilt nicht für die nachfolgend angegebenen Typen von Rundschlingen:

a) Rundschlingen, die zum Sichern oder Verzurren von Lasten miteinander auf Paletten und Ladeflächen oder in Fahrzeugen vorgesehen sind;

b) Rundschlingen aus schlauchförmigem Gurtbandgewebe ohne Füllfasern.

Diese Europäische Norm legt die zu beachtenden technischen Anforderungen zur Verringerung der im Abschnitt 4 aufgeführten Gefahren fest, die bei Anwendung von Rundschlingen auftreten können, wenn sie nach den vom Hersteller oder seinem bevollmächtigten Vertreter erteilten Anweisungen und Anforderungen entsprechend angewendet werden.

Elingues textiles - Sécurité - Partie 2: Elingues rondes en textiles chimiques d'usage courant

La présente norme spécifie les exigences relatives à la sécurité, y compris les méthodes de classification et d’essais

des élingues rondes de charge maximale d’utilisation jusqu’à 40 tonnes (en levage direct) et les assemblages

d’élingues rondes à deux, trois et quatre brins, avec ou sans accessoires, en polyamide, polyester et polypropylène.

Les élingues rondes couvertes par la présente partie de l’EN 1492 sont prévues pour des applications de levage

générales, c’est-à-dire le levage d’objet, de matériels ou de marchandises qui ne nécessitent aucun écart par rapport

aux exigences, coefficients de sécurité ou charge maximale d’utilisation spécifiés. Les opérations de levage non

couvertes par la présente norme sont le levage de personnes, de matériaux potentiellement dangereux tels que le

métal fondu, les acides, les vitres, les matériaux fissiles, les réacteurs nucléaires ou lorsque des conditions spéciales

s’appliquent.

Les élingues rondes conformes à la présente norme européenne sont adaptées pour l’utilisation et le stockage dans

les plages de températures suivantes :

a) polyester et polyamide – 40 °C à 100 °C ;

b) polypropylène – 40°C à 80 °C.

La présente norme européenne ne s’applique pas aux types d’élingues rondes suivantes :

a) élingues rondes conçues pour la fixation ou l’arrimage des charges entre elles sur des palettes et plateaux ou dans

des véhicules ;

b) élingues constituées de sangles tubulaires sans liage.

La présente norme européenne traite des exigences techniques pour minimiser les phénomènes dangereux listés

dans l’article 4 qui peuvent survenir lorsque les élingues rondes sont utilisées conformément aux instructions et aux

spécifications données par le fabricant ou son représentant autorisé.

Tekstilne obese - Varnost - 2. del: Obese z okroglim presekom iz umetnih vlaken za splošno uporabo

General Information

- Status

- Published

- Publication Date

- 11-Nov-2008

- Withdrawal Date

- 27-Dec-2009

- Technical Committee

- CEN/TC 168 - Chains, ropes, webbing, slings and accessories - safaty

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 13-Apr-2023

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 22-Dec-2008

- Refers

EN 1677-3:2001 - Components for slings - Safety - Part 3: Forged steel self-locking hooks - Grade 8 - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1492-2:2000+A1:2008 is the CEN European standard for textile slings - Part 2: Roundslings made of man‑made fibres for general purpose use. It specifies safety, rating and testing requirements for endless roundslings and multi‑leg roundsling assemblies (two-, three- and four‑leg), made from polyamide (PA), polyester (PES) or polypropylene (PP). The standard covers roundsling Working Load Limits (WLL) up to 40 tonnes (straight lift) and sets rules for manufacture, verification, marking, documentation and user information.

Key topics and technical requirements

- Scope & exclusions: Intended for general lifting operations; explicitly excludes lifting of persons, molten metal, acids, glass sheets, fissile materials, nuclear reactors, and special‑condition lifts. Not applicable to cargo lashing slings or tubular webbing without filling.

- Materials: Core, cover and sewing threads must be from certified high‑tenacity multifilament yarns (PA, PES or PP) with specified tenacity and appropriate stabilization.

- Core & cover construction: Core formed from an endless hank (minimum winding turns) and enclosed in a woven tubular cover with a closed surface treatment to resist abrasion and contamination.

- Sewing & fittings: Seams use locking stitch machines and matching material threads; fittings and master links for multi‑leg assemblies are covered.

- Performance limits: WLL values, mode factors for different hitching methods, and multi‑leg assembly rules (master link attachments).

- Testing & verification: Mandatory type and routine tests, representative sling testing, and specified testing intervals to verify safety requirements (see Annex A for methods).

- Marking & documentation: Labels, colour codes, manufacturer’s certificate and detailed instructions for use, inspection and maintenance are required.

- Temperature suitability: Polyester and polyamide: -40 °C to 100 °C; polypropylene: -40 °C to 80 °C.

- Hazard minimization: Addresses mechanical strength, fitting errors, falling/ejected objects, and selection/use guidance; annexes provide test methods and user information.

Applications and who uses this standard

EN 1492-2 is used by:

- Manufacturers of roundsling lifting accessories to design and certify products to European safety requirements.

- Quality / conformity assessors and testing laboratories performing type and routine tests.

- Safety engineers, riggers and lifting supervisors specifying slings and creating risk assessments for general lifting operations.

- Procurement and maintenance teams selecting and inspecting slings for workshops, construction, transport, ports and industrial plants.

- Training providers and competent persons who perform in‑service inspections and periodic testing.

Practical applications include general material handling, lifting of goods, assembly components and multi‑leg lifts where the specified WLLs and conditions are met.

Related standards

- EN 1492‑1: Specification for flat woven webbing slings (man‑made fibres)

- EN 1492‑4: Lifting slings from natural and man‑made fibre rope

- EN 292 / EN 1050 and related CEN documents cited for safety principles, testing and conformity

Keywords: EN 1492-2, roundsling, textile slings, working load limit, WLL, polyamide roundsling, polyester roundsling, polypropylene roundsling, lifting safety, roundsling testing, CEN standard.

Frequently Asked Questions

EN 1492-2:2000+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Textile slings - Safety - Part 2: Roundslings made of man-made fibres for general purpose use". This standard covers: This European Standard specifies the requirements related to safety, including methods of rating and testing roundslings up to 40 tonnes working load limit (in straight lift) and two-, three-, and four-leg roundsling assemblies, with or without fittings, made of polyamide, polyester and polypropylene. The roundslings covered by this Part of EN 1492 are intended for general purpose lifting operations, i.e. when used for lifting objects, materials or goods which require no deviations from the requirements, safety factors or WLL’s specified. Lifting operations not covered by this standard include the lifting of persons, potentially dangerous materials such as molten metal and acids, glass sheets, fissile materials, nuclear reactors and where special conditions apply. Roundslings conforming to this European Standard are suitable for use and storage in the following temperature ranges: a) polyester and polyamide: -40 °C to 100 °C, b) polypropylene: -40 °C to 80 °C This European Standard does not apply to the types of roundsling indicated below: a) roundslings designed for securing or lashing of cargoes to each other on pallets and platforms or in vehicles; b) slings of tubular webbing without filling. This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the use of roundslings when carried out in accordance with the instructions and specifications given by the manufacturer or authorized representative.

This European Standard specifies the requirements related to safety, including methods of rating and testing roundslings up to 40 tonnes working load limit (in straight lift) and two-, three-, and four-leg roundsling assemblies, with or without fittings, made of polyamide, polyester and polypropylene. The roundslings covered by this Part of EN 1492 are intended for general purpose lifting operations, i.e. when used for lifting objects, materials or goods which require no deviations from the requirements, safety factors or WLL’s specified. Lifting operations not covered by this standard include the lifting of persons, potentially dangerous materials such as molten metal and acids, glass sheets, fissile materials, nuclear reactors and where special conditions apply. Roundslings conforming to this European Standard are suitable for use and storage in the following temperature ranges: a) polyester and polyamide: -40 °C to 100 °C, b) polypropylene: -40 °C to 80 °C This European Standard does not apply to the types of roundsling indicated below: a) roundslings designed for securing or lashing of cargoes to each other on pallets and platforms or in vehicles; b) slings of tubular webbing without filling. This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the use of roundslings when carried out in accordance with the instructions and specifications given by the manufacturer or authorized representative.

EN 1492-2:2000+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 53.020.30 - Accessories for lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1492-2:2000+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1492-2:2000/AC:2006, EN 1492-2:2000, EN 1677-3:2001, EN 292-2:1991/A1:1995, EN 1677-4:2000, EN 10002-2:1991, EN 1677-1:2000, EN ISO 9001:2015, EN 1050:1996, EN 1677-6:2001, EN 1677-5:2001, EN 1677-2:2000, EN 13155:2020, EN 1677-3:2001+A1:2008, EN 1677-5:2001+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1492-2:2000+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1492-2:2000+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tekstilne obese - Varnost - 2. del: Obese z okroglim presekom iz umetnih vlaken za splošno uporaboTextile Anschlagmittel - Sicherheit - Teil 2: Rundschlingen aus Chemiefasern für allgemeine VerwendungszweckeElingues textiles - Sécurité - Partie 2: Elingues rondes en textiles chimiques d'usage courantTextile slings - Safety - Part 2: Roundslings made of man-made fibres for general purpose use53.020.30Pribor za dvigalno opremoAccessories for lifting equipmentICS:Ta slovenski standard je istoveten z:EN 1492-2:2000+A1:2008SIST EN 1492-2:2001+A1:2009en,fr01-januar-2009SIST EN 1492-2:2001+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1492-2:2000+A1

November 2008 ICS 53.020.30 Supersedes EN 1492-2:2000 English Version

Textile slings - Safety - Part 2: Roundslings made of man-made fibres for general purpose use

Elingues textiles - Sécurité - Partie 2: Elingues rondes en textiles chimiques d'usage courant

Textile Anschlagmittel - Sicherheit - Teil 2: Rundschlingen aus Chemiefasern für allgemeine Verwendungszwecke This European Standard was approved by CEN on 30 June 2000 and includes Corrigendum 1 issued by CEN on 7 June 2006 and Amendment 1 approved by CEN on 11 September 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1492-2:2000+A1:2008: ESIST EN 1492-2:2001+A1:2009

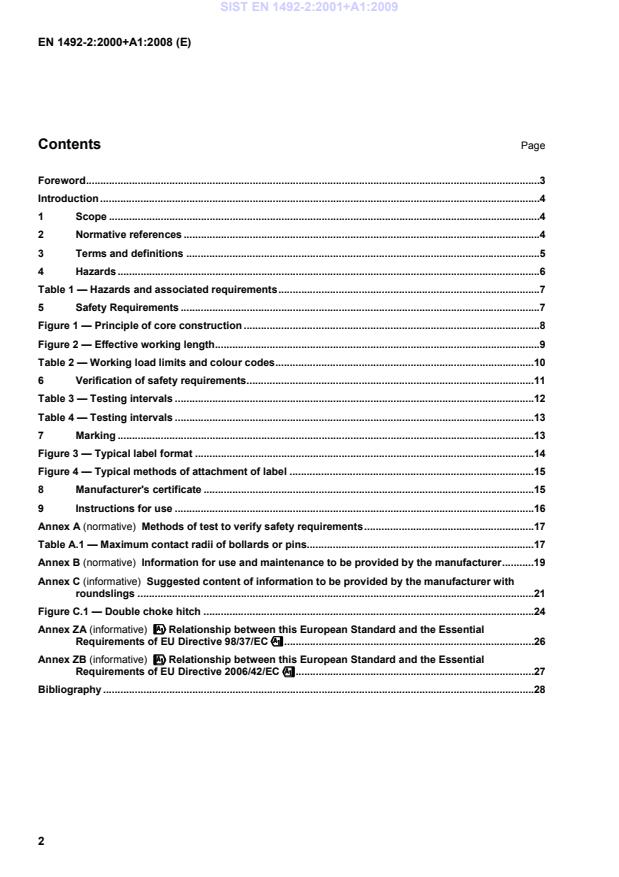

Methods of test to verify safety requirements.17 Table A.1 — Maximum contact radii of bollards or pins.17 Annex B (normative)

Information for use and maintenance to be provided by the manufacturer.19 Annex C (informative)

Suggested content of information to be provided by the manufacturer with roundslings.21 Figure C.1 — Double choke hitch.24 Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""".26 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""".27 Bibliography.28

prEN 1677-4:1998, Components for slings – Safety - Part 4: Links, Grade 8 prEN 1677-5:1998, Components for slings – Safety - Part 5: Forged steel lifting hooks with latch, Grade 4 prEN 1677-6:1998, Components for slings – Safety - Part 6: Links, Grade 4 EN 10002-2:1991, Metallic materials - Tensile testing - Part 2: Verification of the force measuring system of the tensile testing machines EN 45012, General requirements for bodies operating assessment and certification/registration of quality systems (ISO/IEC Guide 62:1996) EN ISO 9002:1994, Quality systems - Model for quality assurance in production, installation and servicing (ISO 9002:1994) 3 Terms and definitions For the purposes of this standard, the following terms and definitions, symbols and abbreviations apply. 3.1 roundsling endless flexible sling consisting of a loadbearing core of yarn, completely enclosed in a woven cover, with or without fittings.

3.2 multi-leg sling assembly roundsling assembly, consisting of two, three or four identical roundslings attached to a master link (See

table 2)

3.3 representative sling roundsling representative of roundslings of the same type, which is used for verification purposes (See 6.2 and 6.3) NOTE This may differ from the production roundsling in length only

3.4 core hank of yarn which comprises the loadbearing part of a roundsling.

3.5 cover woven tubular webbing, or tube made from woven fabric and joined along its length, and which encloses the core.

3.6 closed surface webbing surface (of cover) which, when visually and manually examined, appears closed, as is the case following thermofixing or colouring with additional substances, and where the single fibres support each other.

3.8 master link link, or link assembly, forming the upper terminal fitting of a multi-leg sling assembly by means of which the sling assembly is attached to the hook of a crane, other lifting machine or lifting accessory.

3.9 nominal length specified length of the roundsling, inclusive of fittings, from bearing point to bearing point (See 5.5)

3.10 effective working length (EWL) actual finished length of the roundsling, inclusive of fittings, from bearing point to bearing point (See 5.5)

3.11 working load limit (WLL) maximum mass which a roundsling is designed to sustain in straight lift and which a sling or sling assembly is authorized to sustain in general lifting service (See table 2)

3.12 mode factor (M) factor applied to the WLL of a roundsling in order to arrive at the WLL of the roundsling or sling assembly for a given mode of assembly or use.

3.13 competent person designated person, suitably trained and qualified by knowledge and practical experience, and with the necessary instructions to enable the required tests and examination to be carried out. NOTE 4.18 of EN ISO 9002:1994 gives guidance on training. 4 Hazards The accidental release of a load, or release of a load due to failure of a component puts at risk, either directly or indirectly, the safety or health of those persons within the danger zone. In order to provide the necessary strength and durability of lifting accessories this Part of EN 1492 specifies requirements for the design, manufacture and testing to ensure the specified levels of performance are met. Endurance has not been identified as a hazard when roundslings having the specified levels of performance given in this Part of EN 1492 are used in general lifting service. Since failure can be caused by the incorrect choice of WLL and specification of lifting accessory this Part of EN 1492 also gives the requirements for marking and the manufacturer’s certificate. Aspects of safe use associated with good practice are given in annex B (normative) and annex C (informative). Table 1 lists those hazards in as far as they are dealt with in this standard that require action to reduce those risks identified by risk assessment as being specific and significant for roundslings made of polyamide, polyester and polypropylene. SIST EN 1492-2:2001+A1:2009

Table 1 — Hazards and associated requirements

Hazards identified in annex A of EN 1050:1996 Relevant clause of annex A of EN 292-2: 1991/A1: 1995 Relevant clause/sub-clause of this Part of EN 1492 1.e) Mechanical hazard due to inadequacy of strength 1.3.2 4.1.2.3 4.1.2.5 4.2.4 1.7.3 4.3.2 4.2.4 5 5 5 6 7 7 8 15 Errors of fitting hazard 1.5.4 5 17 Falling or ejected objects hazard 1.3.3 Annex B 26 Insufficient instructions for the driver/operator 1.7.4 4.4.1 9, annex B 9, annex B 27.1.5 Inadequate holding devices/accessories hazard 4.4.1 5.9 27.6 Inadequate selection of lifting accessories hazard 4.1.2.5 4.3.2 5.9 7

5 Safety Requirements 5.1 Materials The roundsling shall be produced wholly from industrial yarns certified by the manufacturer as being fast to light and heat-stabilized with a tenacity of not less than 60 cN/tex, from one of the following materials: polyamide (PA), high tenacity multifilament; polyester (PES), high tenacity multifilament; polypropylene (PP), high tenacity multifilament. NOTE The definitions for these are given in ISO 2076. The content of the constituent materials may be determined in accordance with ISO 1833. NOTE Attention is drawn to the different resistance of man-made fibres to chemicals, which are summarized in annex C. SIST EN 1492-2:2001+A1:2009

1) Roundsling 2) Cover 3) Core yarns 4) Additional join 5) Minimum of four turns of yarn 6) Join forming endless hank Figure 1 — Principle of core construction

5.3 Cover The cover shall be of webbing woven from identical parent material (see 5.1) as the core, and made with the ends overlapped and sewn. The edges of the woven cover material shall be finished in such a way that they cannot unravel. If the cover is welded, care shall be taken to ensure that the welding does not affect the core. The woven material of the cover shall be treated to produce a closed surface. NOTE These treatments inhibit abrasion and the ingress of abrasive materials and may be applied to the woven material and/or the yarn. 5.4 Sewing The thread of all seams shall be made of identical parent material (see 5.1) as the cover and core, and the seam shall be made with a locking stitch machine. SIST EN 1492-2:2001+A1:2009

1) Effective working length (l1) 2) Roundsling 3) Integral fitting Figure 2 — Effective working length

5.6 Colour coding The colour of the cover shall be as given in table 2 to indicate the WLL of the roundsling in straight lift. Roundslings of any other nominal WLL’s, not indicated in table 2, shall not be denoted with the colours indicated therein. 5.7 Working load limits The WLL of a roundsling, or sling assembly, for a given mode of assembly or use shall be derived from the WLL of the roundsling in straight lift multiplied by the appropriate mode factor, M, in accordance with table 2.

Parallel ß =

0 to 45° ß = 45° to 60° ß = 0 to 45° ß = 45° to 60° ß = 0 to 45° ß = 45° to 60°

M = 1 M = 0,8 M = 2 M = 1,4 M = 1 M = 1,4 M = 1 M = 2,1 M = 1,5 1,0 2,0 3,0 4,0 5,0 6,0 8,0 10,0 Over 10,0 Violet Green Yellow Grey Red Brown Blue Orange Orange 1,0 2,0 3,0 4,0 5,0 6,0 8,0 10,0 0,8 1,6 2,4 3,2 4,0 4,8 6,4 8,0 2,0 4,0 6,0 8,0 10,0 12,0 16,0 20,0 1,4 2,8 4,2 5,6 7,0 8,4 11,2 14,0 1,0 2,0 3,0 4,0 5,0 6,0 8,0 10,0 1,4 2,8 4,2 5,6 7,0 8,4 11,2 14,0 1,0 2,0 3,0 4,0 5,0 6,0 8,0 10,0 2,1 4,2 6,3 8,4 10,5 12,6 16,8 21 1,5 3,0 4,5 6,0 7,5 9,0 12,0 15,0

M = Mode factor for symmetrical loading. Handling tolerance for slings or parts of slings indicated as vertical = 6° SIST EN 1492-2:2001+A1:2009

If, during testing, the roundsling does not sustain a force equivalent to seven times the WLL, but sustains a load of not less than 90 % of this force, three further samples shal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...