EN 13205-2:2014

(Main)Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency

Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency

This European Standard specifies a laboratory performance test for samplers for the inhalable, thoracic and respirable aerosol fractions, based on determining the sampling efficiency curve of a candidate sampler at a minimum of nine particle sizes. It specifies methods for testing aerosol samplers under prescribed laboratory conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1:2014.

This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air.

Exposition am Arbeitsplatz - Beurteilung der Leistungsfähigkeit von Sammlern für die Messung der Konzentration luftgetragener Partikel - Teil 2: Laborprüfung der Leistungsfähigkeit basierend auf der Bestimmung des Probenahmewirkungsgrads

Diese Europäische Norm legt eine Laborprüfung der Leistungsfähigkeit von Sammlern für die einatembare, thorakale und alveolengängige Fraktion von Aerosolen auf der Grundlage der Bestimmung der Kurve des Probenahmewirkungsgrads eines zu prüfenden Sammlers bei mindestens neun Partikelgrößen fest. Es werden Verfahren zur Prüfung von Aerosolsammlern unter vorgeschriebenen Laborbedingungen festgelegt, um zu prüfen, ob die Leistungsfähigkeit eines zu prüfenden Sammlers die Anforderungen nach EN 13205-1:2014 erfüllt.

Dieser Teil von EN 13205 gilt für alle Sammler, die für die gesundheitsbezogene Probenahme von Partikeln aus der Luft am Arbeitsplatz eingesetzt werden.

Exposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations de particules en suspension dans l'air - Partie 2: Essai de performances en laboratoire par détermination de l'efficacité de prélèvement

La présente Norme européenne spécifie un essai de performance en laboratoire pour des dispositifs de prélèvement de fractions d'aérosol inhalable, thoracique et alvéolaire, fondé sur la détermination de la courbe d'efficacité de prélèvement d'un dispositif de prélèvement à évaluer pour neuf tailles de particules au minimum. Elle spécifie des méthodes pour soumettre à essai des dispositifs de prélèvement d'aérosol dans des conditions de laboratoire prescrites, afin de vérifier si la performance d'un dispositif de prélèvement à évaluer satisfait aux exigences de l’EN 13205-1:2014.

La présente partie de l'EN 13205 s'applique à tous les dispositifs de prélèvement utilisés pour le prélèvement, à des fins sanitaires, des particules présentes sur les lieux de travail.

Izpostavljenost na delovnem mestu - Ocenjevanje lastnosti merilnikov za merjenje koncentracij lebdečih delcev - 2. del: Preskušanje usposobljenosti laboratorija na osnovi učinkovitosti vzorčenja

Standard EN 13205-2 določa preskušanje usposobljenosti laboratorija za merilnike inhalabilnih, torakalnih in respirabilnih delcev aerosolov na osnovi krivulje učinkovitosti vzorčenja merilnika kandidata pri najmanj devetih velikostih delcev. Določa metode za preskušanje merilnikov aerosolov pod določenimi laboratorijskimi pogoji, da se preskusi, ali delovanje merilnika kandidata izpolnjuje zahteve iz standarda EN 13205-1:2014. Ta del standarda EN 13205 velja za vse merilnike, ki se uporabljajo za vzorčenje delcev v zraku, ki vplivajo na zdravje na delovnem mestu.

General Information

- Status

- Published

- Publication Date

- 17-Jun-2014

- Technical Committee

- CEN/TC 137 - Assessment of workplace exposure

- Drafting Committee

- CEN/TC 137/WG 3 - Particulate matter

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 01-Aug-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 07-Mar-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13205-2:2014 is a CEN European Standard that defines a laboratory performance test for aerosol samplers used in workplace exposure assessment. The test is based on determining the sampling efficiency curve of a candidate sampler for the inhalable, thoracic and respirable particle fractions. EN 13205-2 specifies the test conditions, variables and calculation methods required to decide whether a sampler’s performance meets the general requirements of EN 13205-1:2014.

Key topics and technical requirements

- Sampling efficiency curve: Determination of sampling efficiency at a minimum of nine particle sizes to characterise sampler performance across the size range.

- Fraction coverage: Applicable to the inhalable, thoracic and respirable conventions used for health-related workplace sampling.

- Test variables and conditions: Prescribed laboratory conditions include control of particle size, wind speed and direction, aerosol composition and charge, sampler flow-rate and specimen variability. The inhalable convention is undefined for particles >100 µm or wind speeds >4 m/s, so tests are limited accordingly.

- Size distribution limits: The standard restricts lower-size content-particles <0.5 µm are generally not sampled aerodynamically; at least **84% of aerosol mass** used for evaluation should consist of particles >0.5 µm.

- Uncertainty and bias: Defines methods to calculate sampler bias and expanded uncertainty (replacing the older “accuracy” concept), incorporating major uncertainty sources such as calibration of the test system, estimation of sampled concentration, bias relative to the sampling convention, individual sampler variability and flow-rate excursions.

- Experimental and reporting requirements: Specifies experimental design, data analysis, and mandatory elements of the test report (laboratory and sponsor details, sampler description, methods, results, data analysis and summary guidance for users).

Practical applications and users

- Manufacturers: Validate and document sampler performance under defined laboratory conditions before market release.

- Accredited testing laboratories: Perform laboratory validation tests and provide performance reports used for certification and compliance.

- Occupational hygienists and employers: Select samplers with documented performance for workplace monitoring that align with EN 481/EN 482 sampling conventions.

- Regulators and certification bodies: Use standardized test results to assess sampler suitability for regulatory monitoring and inter-laboratory comparisons.

Related standards

- EN 13205-1:2014 - General requirements for sampler performance assessment

- CEN/TR 13205-3:2014 - Analysis of sampling efficiency data (technical report)

- EN 13205-5:2014 - Workplace sampler performance and comparison at workplaces

- EN 1540 - Workplace exposure terminology

- EN ISO 13137 - Pumps for personal sampling (requirements and test methods)

Keywords: EN 13205-2:2014, sampler performance, sampling efficiency, airborne particle concentrations, workplace exposure, inhalable thoracic respirable, laboratory performance test, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 13205-2:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency". This standard covers: This European Standard specifies a laboratory performance test for samplers for the inhalable, thoracic and respirable aerosol fractions, based on determining the sampling efficiency curve of a candidate sampler at a minimum of nine particle sizes. It specifies methods for testing aerosol samplers under prescribed laboratory conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1:2014. This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air.

This European Standard specifies a laboratory performance test for samplers for the inhalable, thoracic and respirable aerosol fractions, based on determining the sampling efficiency curve of a candidate sampler at a minimum of nine particle sizes. It specifies methods for testing aerosol samplers under prescribed laboratory conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1:2014. This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air.

EN 13205-2:2014 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13205-2:2014 has the following relationships with other standards: It is inter standard links to EN 13205:2001, prEN 13205, CEN/TR 13205-3:2014, EN 1540:2021, EN 13205-5:2014, EN ISO 13137:2022, EN ISO 13138:2012, EN 13890:2009, EN 17199-5:2019, EN 482:2012, EN 15051:2006, EN 17199-5:2025, EN ISO 10882-1:2011, EN 482:2021, EN 17199-4:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13205-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Exposition am Arbeitsplatz - Bewertung der Leistungsfähigkeit von Sammlern für die Messsung der Konzentration luftgetragener Partikel - Teil 2: Laborprüfung der Leistungsfähigkeit basierend auf der Bestimmung des ProbenahmewirkungsgradesExposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations d'aérosols - Partie 2 : Essai de performances en laboratoire par détermination de l'efficacité de prélèvementWorkplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency13.040.30Kakovost zraka na delovnem mestuWorkplace atmospheresICS:Ta slovenski standard je istoveten z:EN 13205-2:2014SIST EN 13205-2:2014en,fr,de01-september-2014SIST EN 13205-2:2014SLOVENSKI

STANDARDSIST EN 13205:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13205-2

June 2014 ICS 13.040.30 Supersedes EN 13205:2001English Version

Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency

Exposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations de particules en suspension dans l'air - Partie 2: Essai de performances en laboratoire par détermination de l'efficacité de prélèvement

Exposition am Arbeitsplatz - Beurteilung der Leistungsfähigkeit von Sammlern für die Messung der Konzentration luftgetragener Partikel - Teil 2: Laborprüfung der Leistungsfähigkeit basierend auf der Bestimmung des Probenahmewirkungsgrads This European Standard was approved by CEN on 7 May 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13205-2:2014 ESIST EN 13205-2:2014

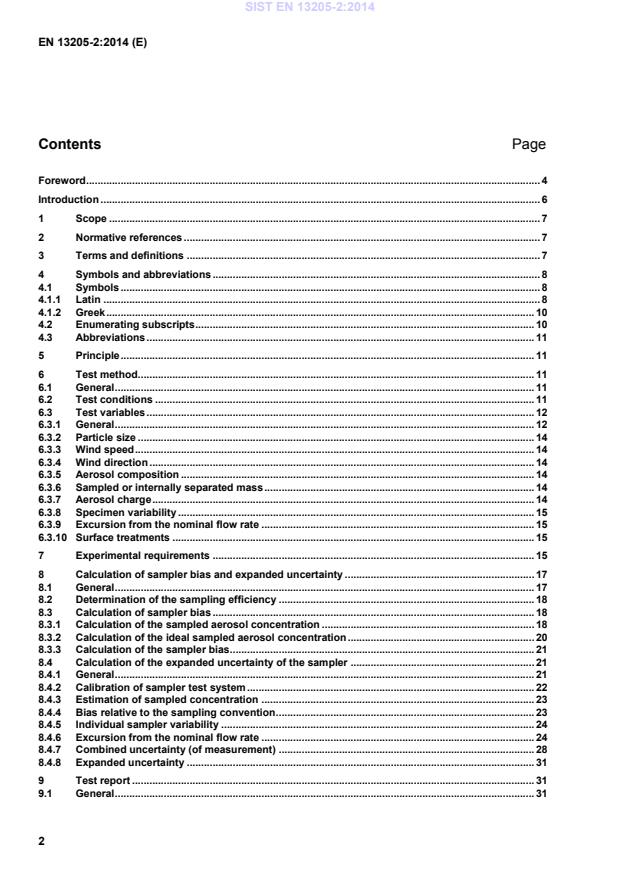

Foreword . 4

Introduction . 6 1 Scope . 7 2 Normative references . 7 3 Terms and definitions . 7 4 Symbols and abbreviations . 8 4.1 Symbols . 8 4.1.1 Latin . 8 4.1.2 Greek . 10 4.2 Enumerating subscripts . 10 4.3 Abbreviations . 11 5 Principle . 11 6 Test method . 11 6.1 General . 11 6.2 Test conditions . 11 6.3 Test variables . 12 6.3.1 General . 12 6.3.2 Particle size . 14 6.3.3 Wind speed . 14 6.3.4 Wind direction . 14 6.3.5 Aerosol composition . 14 6.3.6 Sampled or internally separated mass . 14 6.3.7 Aerosol charge . 14 6.3.8 Specimen variability . 15 6.3.9 Excursion from the nominal flow rate . 15 6.3.10 Surface treatments . 15 7 Experimental requirements . 15 8 Calculation of sampler bias and expanded uncertainty . 17 8.1 General . 17 8.2 Determination of the sampling efficiency . 18 8.3 Calculation of sampler bias . 18 8.3.1 Calculation of the sampled aerosol concentration . 18 8.3.2 Calculation of the ideal sampled aerosol concentration . 20 8.3.3 Calculation of the sampler bias . 21 8.4 Calculation of the expanded uncertainty of the sampler . 21 8.4.1 General . 21 8.4.2 Calibration of sampler test system . 22 8.4.3 Estimation of sampled concentration . 23 8.4.4 Bias relative to the sampling convention . 23 8.4.5 Individual sampler variability . 24 8.4.6 Excursion from the nominal flow rate . 24 8.4.7 Combined uncertainty (of measurement) . 28 8.4.8 Expanded uncertainty . 31 9 Test report . 31 9.1 General . 31 SIST EN 13205-2:2014

— The method of calculating the uncertainty of a sampler or a measuring procedure has been revised in order to comply with ENV 13005. The concept of “accuracy” is no longer used, instead the concept of “expanded uncertainty” is used. — The five major sources of uncertainty due to aspects of the sampling performance of an aerosol sampler (calibration of sampler test system, estimation of sampled concentration, bias relative to the sampling convention, individual sampler variability and excursion from nominal flow rate) are described with equations on how to incorporate these uncertainties into the expanded uncertainty of a sampler. CEN/TR 13205-3 gives recommendations how these entities may be calculated from measured sampling efficiency data. — The list of the particle size distributions (per sampling convention) to be used for the evaluation of sampler performance has been restricted at the lower end to reflect that particles with an aerodynamic SIST EN 13205-2:2014

1) The inhalable convention is undefined for particle sizes in excess of 100 µm or for wind speeds greater than 4 m/s. The tests required to assess performance are therefore limited to these conditions. If such large particle sizes or wind speeds actually existed at the time of sampling, it is possible that different samplers meeting this document give different results. SIST EN 13205-2:2014

ADA,σA,D() relative lognormal aerosol size distribution, with mass median aerodynamic diameter DA and geometric standard deviation 1A, [1/µm] NOTE The word “relative” means that the total amount of particles is unity [-], i.e. ADA,σA,D()dD0∞∫=1.

Cstd target sampled relative aerosol concentration, expressed as a fraction of the total airborne aerosol concentration, that would have been sampled using an ideal sampler with a sampling efficiency identical to the sampling convention, FD(), for aerosol size distribution A, [-] Ci mean sampled relative aerosol concentration, expressed as a fraction of the total airborne aerosol concentration, calculated to be obtained when using the candidate sampler, for aerosol size distribution A at influence variable valueςi, [-] c candidate sampler correction factor for bias correction, either prescribed by sampler manufacturer or measuring procedure, or assigned the value c = 1.00, [-] D aerodynamic diameter, [µm]

DA mass median aerodynamic diameter of a lognormal aerosol size distribution A, [µm]

DAa mass median aerodynamic diameter a of a lognormal aerosol size distribution A, [µm]

Dmax diameter of the end of the integration range of the sampled aerosol, [µm]

Dmin diameter of the beginning of the integration range of the sampled aerosol, [µm] Dp aerodynamic diameter of test particle p (p = 1 toNP), [µm] EiDp() mean sampling efficiency of the candidate sampler for test particle size p at influence variable valueςi, [-] – (polygonal approximation method) EiQ,Dp() mean sampling efficiency curve of the candidate sampler at flow rate Q for test particle size p at influence variable valueςi, [-] – (polygonal approximation method)

estEisD() fitted sampling efficiency curve of the candidate sampler individual s at influence variable valueςi, [-] – (curve-fitting method)

estEisQ,D() fitted sampling efficiency curve of the candidate sampler individual s at flow rate Q for influence variable valueςi, [-] – (curve-fitting method) eipr[s]andeips[r] experimentally determined efficiency value, with notation for polygonal approximation and curve-fitting methods, respectively. The subscripts are for influence variable valueςi, particle size F (p = 1 toNP), sampler individual s (s = 1 toNS) and repeat r (r = 1 toNR), [-] – (notation for polygonal approximation and curve-fitting methods, respectively) FD() target sampling convention, [-] SIST EN 13205-2:2014

miDA,σA,Q() mean sampled aerosol mass, expressed as a fraction of the total airborne aerosol mass, calculated to be obtained when using the candidate sampler with flow rateQ, to sample aerosol size distribution A at influence variable valueςi, [-]

NIV number of values for the other influence variables at which tests were performed,

NP number of test particle sizes

NRep number of repeats at particle size p for candidate sampler individual s at influence variable value ςi – (in the polygonal approximation method

NRep equals the number of repeats, whereas in the curve-fitting method it equals the number of repeats per candidate sampler individual)

NS number of candidate sampler individuals – (In the polygonal approximation method

NS equals the number of sampler individuals tested per repeat, whereas in the curve-fitting method it equals the total number of sampler individuals tested.) Q actual flow rate of candidate sampler, [l/min]

Q0 nominal flow rate of sampler, [l/min]

q0 parameter expressing whether the nominal or actual flow rate is used for the calculation of sampled respirable and thoracic aerosol fractions, [-]

qiDA,σA() flow rate dependence of sampled mass for aerosol size distribution A at influence variable valueςi, [-]

sCandSampl-Flowia non-random uncertainty (of measurement) of the calculated sampled concentration, due to excursion from nominal flow and/or deviation from initial flow, for the ath aerosol size distribution A at influence variable valueςi, [-]

sδFlowSet+δPump() random uncertainty for combined rectangular distribution based on allowed initial flow deviation from nominal flow rate and pump flow deviation, [-]

UCandSampl expanded uncertainty (of measurement) of the calculated sampled concentration due to the candidate sampler, [-]

uCandSampl combined uncertainty (of measurement) of the calculated sampled concentration due to the candidate sampler, [-]

uCandSampli combined uncertainty (of measurement) of the candidate sampler, at influence variable valueςi, [-]

uCandSampl-Biasi standard uncertainty (of measurement) due to bias (non-random errors) in relation to the sampling convention of the candidate sampler at influence variable valueςi, [-]

uCandSampl-Calibri standard uncertainty (of measurement) (non-random and random errors) of the SIST EN 13205-2:2014

NSD aerosol size distributions A at influence variable valueςi, [-]

uCandSampl-Flowi standard uncertainty (of measurement) of the calculated sampled concentration, due to flow rate deviation at influence variable valueςi, [-]

uCandSampl-ModelCalci standard uncertainty (of measurement) of the calculated sampled concentration (random errors), due to the uncertainty of the fitted model, calculated as the RMS of the corresponding relative uncertainties over all

NSD aerosol size distributions A at influence variable valueςi, [-]

uCandSampl-nR combined uncertainty (of measurement) of the sampled concentration (non-random errors) due to the candidate sampler, [-]

uCandSampl-nRi combined uncertainty (of measurement) of the sampled concentration (non-random errors) due to the candidate sampler, at influence variable valueςi, [-]

uCandSampl-R combined uncertainty (of measurement) of the sampled concentration (random errors) due to the candidate sampler, [-]

uCandSampl-Ri combined uncertainty (of measurement) of the sampled concentration (random errors) due to the candidate sampler, at influence variable valueςi, [-]

uCandSampl-Variabilityi standard uncertainty (of measurement) of the sampled concentration (random errors) due to differences among candidate sampler individuals at influence variable valueςi, [-] Wp weighted average of integration of aerosol size distribution A between two particle sizes, [-] – (polygonal approximation) 4.1.2 Greek ∆i bias or relative error in the aerosol concentration measured using the candidate sampler, for aerosol size distribution A, at influence variable valueςi, [-]

δFlowSet maximum relative error allowed in setting the flow rate, [-]

δPump maximum relative change in flow rate allowed by pump flow rate stability, [-] []iprsεand[]ipsrε Random experimental error at particle size p, repeat r and candidate sampler s at influence variable valueςi, [-] – (notations for polygonal approximation and curve-fitting methods, respectively) ς value of other influence variable values, as for example wind speed and mass loading of sampler, with values for i = 1 to NIV, [various dimensions] ςi ith value of any other influence variable NOTE The dimension of each ςi depends on the influence variable. The dimension selected, however, is not critical, as the values are never part in any calculation.

σA geometric standard deviation of a lognormal aerosol size distribution A from Table A.2 [-]

σAa geometric standard deviation a of a lognormal aerosol size distribution A, [µm] – 4.2 Enumerating subscripts a for test aerosols SIST EN 13205-2:2014

for selected value of distinguishable values of an influence variable i for influence variable values, ς i0

for selected value of non-distinguishable values of an influence variable which causes the largest combined standard uncertainty for the candidate sampler p for test particle size r for repeats s for candidate sampler individual 4.3 Abbreviations RMS Root Mean Square 5 Principle The test method described in this part of EN 13205 is based on the measurement of the candidate sampler’s sampling efficiency as a function of particle aerodynamic diameter, whether all aspirated particles are part of the sample (as for most inhalable samplers) or if a particle size-dependent penetration occurs between the inlet and the collection substrate (as for thoracic and respirable samplers). The bias versus the sampling convention is calculated based on the measured sampling efficiencies. Other sampling errors due to non-random and random sources of error are also determined, e.g. individual sampler variability, excursion from nominal flow rate, estimation of sampled concentration and experimental errors. The purpose of the laboratory experiments is to determine the sampling efficiency as a function of particle aerodynamic diameter over the relevant size range, and also as a function of any other relevant variables (as determined in the critical review, see EN 13205-1:2014, 6.2). Mathematical modelling is used to estimate the concentrations that would be sampled from a range of ideal log-normally distributed aerosols, using both the measured sampler efficiency and the target sampling convention. From these data, the sampler performance is estimated. 6 Test method 6.1 General The sampling efficiency values are calculated from dividing the aerosol concentrations measured using the candidate sampler, by measured values of the total airborne particle concentration. An experimental design shall be devised that gives due attention to randomization and to estimation of the main effects. The design, and its associated statistical model, shall be explained in the test report. An example of a suitable design is given in CEN/TR 13205-3:2014. 6.2 Test conditions Experiments to test samplers for the inhalable fraction shall be carried out in a wind tunnel or in an aerosol chamber. Personal inhalable samplers for the inhalable particle fraction, intended for use outdoors or in environments with strong forced ventilation (i.e. wind speeds in excess of 0,5 m/s), shall be tested while mounted on a life-size mannequin, or on a simulated torso. The mannequin or simulated torso set-up shall reproduce the aerodynamic effects of the presence of a life-size, human-shaped head and torso2). In a wind-tunnel of size (1,2 × 1,8) m it has been shown that a simulated torso with the width, height and depth equal to 33 cm, 21 cm and 21 cm, respectively, with samplers mounted on all four vertical planes give similar results as a life-size mannequin3). The size and nature of the mannequin/ simulated torso used shall be described in

2) For examples of performance evaluations of personal inhalable samplers, see Bibliography, references [2] to [5]. 3) See for example Bibliography, references [6] and [7], for reported experiments. SIST EN 13205-2:2014

0 m/s to 4,0 m/s: 2: ≤ 0,1 m/s and 1 m/s Wind Direction C Omnidirectional average Continuous revolution or ≥ 4 values stepwise 6.3.4 Aerosol composition O Phase: solid and/or liquid; Particles of known shape Choose suitable materials 6.3.5 Aerosol agglomeration O Unagglomerated dust; Highly agglomerated dust Choose and document 6.3.5 Collected mass and/or internally separated mass O Collected mass corresponding to: up to maximum concentration x nominal flow rate x sampling time Internally separated mass corresponding to: maximum uncollected concentration x nominal flow rate x sampling time ≥ 3 6.3.6 Aerosol charge O Charged or neutralised aerosol; Conducting or insulating sampler Choose and document 6.3.7 Sampler specimen variability C* Test group to be as large as possible ≥ 6 6.3.8 Excursion from the nominal flow rate C* Nominal flow rate plus lower and higher flow rates at one wind speed ≥ 6 specimen tested at 3 flow rates 6.3.9 Particle collection substrates O Choice of materials (e. g. filters, foams) and details of any surface treatments to be stated

6.3.10 C compulsory C* compulsory for some samplers for the respirable and thoracic aerosol fractions only O optional

Table 1 also summarises the ranges of values for which the selected variables shall be tested, and the number of values within these ranges. In general, the values chosen need not include the extremes of the range, although specific requirements are stated in some cases. Where the experimental design requires a choice to be made, for example the composition of the aerosol used for the tests, or the type of collection substrate used, the effect of the choices made on the applicability of the test results to routine sampling shall be considered in the critical review and the noted in the test report. This part of EN 13205 only gives specific information on how to calculate the uncertainty components, and how to add them into the expanded uncertainty, for uncertainty components pertaining to compulsory test influence variables. For optional test influence variables, the user will need to specify the tests, how they are evaluated and how the corresponding uncertainty components are added into the expanded uncertainty. SIST EN 13205-2:2014

4) See Bibliography, reference [8], for the data presented by BALDWIN and MAYNARD. 5) See, for example, Bibliography, reference [9] on a study regarding the electrical charge on dry airborne particles produced by mechanical aerosol generators and Bibliography, reference [10] on a study regarding the effect of electrical particle charge on cyclone penetration. SIST EN 13205-2:2014

6) For examples of published performance evaluations using polydisperse aerosols (generally for respirable or thoracic samplers) see Bibliography, references [11] to [18]. 7) See, for example, Bibliography, references [19] to [21]. SIST EN 13205-2:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...