EN 17199-4:2019

(Main)Workplace exposure - Measurement of dustiness of bulk materials that contain or release respirable NOAA or other respirable particles - Part 4: Small rotating drum method

Workplace exposure - Measurement of dustiness of bulk materials that contain or release respirable NOAA or other respirable particles - Part 4: Small rotating drum method

This document describes the methodology for measuring and characterizing the dustiness of bulk materials that contain or release respirable NOAA or other respirable particles, under standard and reproducible conditions and specifies for that purpose the small rotating drum method.

This document specifies the selection of instruments and devices and the procedures for calculating and presenting the results. It also gives guidelines on the evaluation and reporting of the data.

The methodology described in this document enables

a) the measurement of the respirable dustiness mass fraction,

b) the measurement of the number-based dustiness index of respirable particles in the particle size range from about 10 nm to about 1 µm,

c) the measurement of the initial number-based emission rate and the time to reach 50 % of the total particle number released during testing,

d) the measurement of the number-based particle size distribution of the released aerosol in the particle size range from about 10 nm to about 10 µm,

e) the collection of released airborne particles in the respirable dustiness mass fraction for subsequent observations and analysis by analytical electron microscopy.

NOTE 1 The particle size range described above is based on the equipment used during the pre-normative research [8].

This document is applicable to the testing of a wide range of bulk materials including powders, granules or pellets containing or releasing respirable NOAA or other respirable particles in either unbound, bound uncoated and coated forms.

NOTE 2 Currently no number-based classification scheme in terms of particle number and emission rate has been established for powder dustiness. Eventually, when a large number of measurement data has been obtained, the intention is to revise the document and to introduce such a classification scheme, if applicable.

NOTE 3 The small rotating drum method has been applied to test the dustiness of a range of materials including nanoparticle oxides, nanoflakes, organoclays, clays, carbon black, graphite, carbon nanotubes, organic pigments, and pharmaceutical active ingredients. The method has thereby been proven to enable testing of a many different materials that can contain nanomaterials as the main component.

Exposition am Arbeitsplatz - Messung des Staubungsverhaltens von Schüttgütern, die alveolengängige NOAA oder andere alveolengängige Partikel enthalten oder freisetzen - Teil 4: Verfahren mit kleiner rotierender Trommel

Diese Europäische Norm enthält die Methodik für die Messung und Charakterisierung des Staubungsverhaltens von Schüttgütern, die Nanoobjekte oder Partikel im Submikrometerbereich enthalten oder unter wiederholbaren und Standardbedingungen freisetzen, und legt zu diesem Zweck das Verfahren mit kleiner rotierender Trommel fest.

Darüber hinaus legt diese Europäische Norm die Auswahl der Instrumente und Vorrichtungen sowie die Verfahren für die Berechnung und Präsentation der Ergebnisse fest. Des Weiteren enthält die Norm eine Anleitung für die Auswertung und Angabe der Daten.

Die in dieser Europäischen Norm festgelegte Methodik ermöglicht

a) die Berechnung des Massenanteils an alveolengängigem Staub,

b) die Messung des zahlenbasierten Staubindex alveolengängiger Partikel im Größenbereich zwischen ungefähr 10 nm und 1 000 nm,

c) die Messung der zahlenbasierten Größenverteilung des freigesetzten Aerosols im Größenbereich zwischen ungefähr 10 nm und 10 µm,

d) die Quantifizierung der ersten Staubemissionsrate und der Dauer bis zur Erreichung von 50 % der während der Prüfung freigesetzten Gesamtpartikelzahl und

e) die Charakterisierung des Aerosols auf der Grundlage seiner Partikelgrößenverteilung und der Morphologie und chemischen Zusammensetzung seiner Partikel.

Diese Europäische Norm gilt für die Prüfung einer Vielzahl unterschiedlicher Schüttgüter einschließlich Pulver, Granulate oder Pellets, die Nanoobjekte oder Partikel im Submikrometerbereich in ungebundener, gebundener und unbeschichteter und beschichteter Form enthalten oder freisetzen.

ANMERKUNG 1 Bisher wurde noch kein zahlenbasiertes Klassifizierungsschema für das Staubungsverhalten von Pulver im Hinblick auf die Partikelzahl und das Emissionsverhalten entwickelt. Schließlich, wenn eine große Anzahl an Messdaten vorliegt, ist beabsichtigt, diese Europäische Norm zu revidieren und ein solches Klassifizierungsschema einzuführen.

ANMERKUNG 2 Das Verfahren mit kleiner rotierender Trommel wurde angewendet, um das Staubungsverhalten verschiedener Materialien, einschließlich Nanopartikeloxide, Nanoplättchen, Organokaolin, Ton, Kohlenschwarz, Graphit, Carbon-Nanoröhrchen, organischer Pigmente und pharmazeutischer aktiver Inhaltsstoffe zu prüfen. Das Verfahren ermöglicht daher nachweislich die Prüfung vieler verschiedener Materialien, die Nanomaterialien als Hauptkomponente enthalten können.

Exposition sur les lieux de travail - Mesurage du pouvoir de resuspension des matériaux en vrac contenant ou émettant des nano-objets et leurs agrégats et agglomérats (NOAA) ou autres particules en fraction alvéolaire - Partie 4: Méthode impliquant l'utilisation d'un petit tambour rotatif

Le présent document décrit la méthodologie permettant de mesurer et de caractériser le pouvoir de resuspension de matériaux en vrac contenant ou émettant des NOAA ou autres particules en fraction alvéolaire dans des conditions normalisées et reproductibles et spécifie, à cette fin, le but de la méthode du petit tambour rotatif.

Le présent document spécifie le choix des instruments et dispositifs ainsi que les procédures de calcul et d’expression des résultats. Il fournit également des lignes directrices concernant l’évaluation et la consignation des données.

La méthodologie décrite dans le présent document permet :

a) le mesurage de la fraction massique des poussières alvéolaires ;

b) le mesurage de l’indice du pouvoir de resuspension en nombre de particules alvéolaires dans la plage granulométrique comprise entre environ 10 nm et 1 µm ;

c) le mesurage du taux initial d’émission en nombre et du temps nécessaire pour atteindre 50 % du nombre total de particules libérées au cours des essais ;

d) le mesurage de la distribution granulométrique en nombre des particules d’aérosol libérées dans la plage granulométrique comprise entre environ 10 nm 10 µm ;

e) la collecte des particules en suspension dans l’air libérées dans la fraction massique des poussières alvéolaires pour des observations et une analyse supplémentaires par microscopie électronique.

NOTE 1 La plage granulométrique décrite ci-dessus a été établie sur la base de l’équipement utilisé au cours des recherches préalables à la normalisation [8].

Le présent document est applicable aux essais relatifs à une gamme étendue de matériaux en vrac, y compris des matériaux granulaires, en poudre ou sous forme de pastilles contenant ou émettant des NOAA ou autres particules en fraction alvéolaire sous formes revêtues, non revêtues, liées et non liées.

NOTE 2 Jusqu’à présent, aucun système de classification basé sur le nombre en termes de nombre de particules et de taux d’émission n’a été établi concernant l’aptitude à l’empoussièrement des poudres. Dès lors que des données de mesure seront disponibles en grand nombre, il est prévu de réviser le présent document et d’introduire un tel système de classification, le cas échéant.

NOTE 3 La méthode du petit tambour rotatif a été employée pour déterminer le pouvoir de resuspension d’une gamme de matériaux parmi lesquels des nanoparticules d’oxydes, des nanoflocons, des argiles organiques, des argiles, du noir de carbone, du graphite, des nanotubes de carbone, des pigments organiques et des ingrédients pharmaceutiques actifs. Ainsi, il s’est avéré que la méthode était appropriée pour les essais relatifs à un grand nombre de matériaux différents pouvant contenir des nanomatériaux en tant que composant principal.

Izpostavljenost na delovnem mestu - Meritve prašnosti razsutih materialov, ki vsebujejo ali sproščajo respirabilne nanopredmete ter njihove agregate in aglomerate (NOAA) in druge respirabilne delce - 4. del: Metoda z majhnim vrtečim bobnom

Ta evropski standard določa metodologijo za merjenje in opredelitev prašnosti razsutih materialov, ki vsebujejo ali sproščajo nanopredmete ali submikrometrske delce v standardnih in ponovljivih pogojih, ter za ta namen določa metodo z majhnim vrtečim bobnom.

Poleg tega navaja ta evropski standard tudi izbiro instrumentov in naprav ter postopke za izračun in predstavitev rezultatov. Podaja tudi smernice za vrednotenje in poročanje podatkov.

Metodologija, ki je opisana v tem evropskem standardu, omogoča:

a) merjenje masnega deleža pri respirabilni prašnosti,

b) merjenje indeksa prašnosti respirabilnih delcev na podlagi števila v razponu velikosti od približno 10 nm to 1000 nm,

c) merjenje porazdelitve velikosti sproščenega aerosola na podlagi števila v razponu velikosti od približno 10 nm to 10 µm,

d) kvantifikacija začetne stopnje prašnih emisij in časa, dokler ni doseženih 50 % skupnega števila delcev, sproščenih med preskušanjem, in

e) karakterizacijo aerosola na podlagi porazdelitve velikosti delcev ter morfologije in kemijske sestave njegovih delcev.

Ta evropski standard se uporablja za preskušanje širokega nabora razsutih materialov, vključno s praški, granulami in peleti, ki vsebujejo ali sproščajo nanopredmete ali submikrometrske delce v nevezani, vezani, prevlečeni ali neprevlečeni obliki.

OPOMBA 1: Za prašnost praška v smislu števila delcev in stopnje emisij trenutno še ni vzpostavljena nobena klasifikacijska shema na podlagi števil. ko bo sčasoma pridobljenih veliko merilnih podatkov, je predvidena revizija evropskega standarda in uvedba take klasifikacijske sheme, če bo to ustrezno.

OPOMBA 2: Metoda z majhnim vrtečim bobnom je bila uporabljena za preskušanje prašnosti več različnih materialov, vključno z oksidi nanodelcev, nanoluskami, organskimi glinami, glinami, oglenimi sajami, grafitom, ogljikovimi nanocevkami, organskimi pigmenti in aktivnimi farmacevtskimi sestavinami. S tem metoda dokazano omogoča preskušanje veliko različnih materialov, v katerih so lahko nanodelci glavna sestavina.

General Information

- Status

- Published

- Publication Date

- 26-Mar-2019

- Withdrawal Date

- 29-Sep-2019

- Technical Committee

- CEN/TC 137 - Assessment of workplace exposure

- Drafting Committee

- CEN/TC 137/WG 3 - Particulate matter

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 01-Nov-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 80004-1:2023 - Nanotechnologies - Vocabulary - Part 1: Core vocabulary (ISO 80004-1:2023) - Effective Date

- 28-Jan-2026

Overview

EN 17199-4:2019 (CEN) specifies a standardized method - the small rotating drum method - for measuring and characterizing the dustiness of bulk materials that contain or release respirable NOAA (nano‑objects, their aggregates/agglomerates) or other respirable particles. The document defines instrument selection, test procedures, data evaluation and reporting to deliver reproducible dustiness measurements under controlled conditions. Key outputs include mass‑based and number‑based dustiness metrics and particle size distributions of released aerosols.

Key topics and requirements

- Test principle: agitation in a small rotating drum to simulate handling (tipping, pouring, scooping) and generate airborne dust for sampling.

- Measured parameters:

- Respirable dustiness mass fraction (mass-based respirable fraction).

- Number-based dustiness index for respirable particles (~10 nm to ~1 µm).

- Initial number-based emission rate and the time to reach 50% of total particle number released.

- Number-based particle size distribution of released aerosol (~10 nm to ~10 µm).

- Collection of respirable fraction for off-line analysis (e.g., analytical electron microscopy).

- Equipment and sampling: specifies selection of aerosol instruments (e.g., CPCs, ELPI-like instrumentation), cyclones for respirable fraction, and sampling layout to ensure dust transmission and representative collection.

- Procedures: conditioning of materials and equipment, sample mass selection, run sequences, cleaning, and calculation methods for emission rates, dustiness indices and kinetics.

- Reporting and evaluation: guidelines for presenting results, including time‑resolved emission data, size distributions, morphology and chemistry observations.

- Scope limits: applicable to powders, granules and pellets in unbound, bound, coated or uncoated forms. Note that no formal number‑based dustiness classification scheme is yet established.

Applications

- Product development and formulation optimization to reduce dustiness of powders and nanomaterial-containing products.

- Occupational risk assessment and workplace exposure evaluation for industries handling powders, pigments, pharmaceuticals, carbon materials and engineered nanomaterials.

- Selection of control measures (engineering controls, handling procedures) and safer material choices.

- Research and regulatory studies requiring reproducible dust emission and particle size data, and morphological/chemical characterization via off‑line microscopy.

Who uses this standard

- Manufacturers and material producers, occupational hygienists, testing laboratories, regulators, and researchers involved in aerosol exposure assessment, nanomaterial safety and industrial hygiene.

Related standards

- EN 17199 series (Parts 1–5), EN 15051-1/2, EN 16897 and CEN/ISO technical reports referenced for aerosol terminology and sampler performance.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 17199-4:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Workplace exposure - Measurement of dustiness of bulk materials that contain or release respirable NOAA or other respirable particles - Part 4: Small rotating drum method". This standard covers: This document describes the methodology for measuring and characterizing the dustiness of bulk materials that contain or release respirable NOAA or other respirable particles, under standard and reproducible conditions and specifies for that purpose the small rotating drum method. This document specifies the selection of instruments and devices and the procedures for calculating and presenting the results. It also gives guidelines on the evaluation and reporting of the data. The methodology described in this document enables a) the measurement of the respirable dustiness mass fraction, b) the measurement of the number-based dustiness index of respirable particles in the particle size range from about 10 nm to about 1 µm, c) the measurement of the initial number-based emission rate and the time to reach 50 % of the total particle number released during testing, d) the measurement of the number-based particle size distribution of the released aerosol in the particle size range from about 10 nm to about 10 µm, e) the collection of released airborne particles in the respirable dustiness mass fraction for subsequent observations and analysis by analytical electron microscopy. NOTE 1 The particle size range described above is based on the equipment used during the pre-normative research [8]. This document is applicable to the testing of a wide range of bulk materials including powders, granules or pellets containing or releasing respirable NOAA or other respirable particles in either unbound, bound uncoated and coated forms. NOTE 2 Currently no number-based classification scheme in terms of particle number and emission rate has been established for powder dustiness. Eventually, when a large number of measurement data has been obtained, the intention is to revise the document and to introduce such a classification scheme, if applicable. NOTE 3 The small rotating drum method has been applied to test the dustiness of a range of materials including nanoparticle oxides, nanoflakes, organoclays, clays, carbon black, graphite, carbon nanotubes, organic pigments, and pharmaceutical active ingredients. The method has thereby been proven to enable testing of a many different materials that can contain nanomaterials as the main component.

This document describes the methodology for measuring and characterizing the dustiness of bulk materials that contain or release respirable NOAA or other respirable particles, under standard and reproducible conditions and specifies for that purpose the small rotating drum method. This document specifies the selection of instruments and devices and the procedures for calculating and presenting the results. It also gives guidelines on the evaluation and reporting of the data. The methodology described in this document enables a) the measurement of the respirable dustiness mass fraction, b) the measurement of the number-based dustiness index of respirable particles in the particle size range from about 10 nm to about 1 µm, c) the measurement of the initial number-based emission rate and the time to reach 50 % of the total particle number released during testing, d) the measurement of the number-based particle size distribution of the released aerosol in the particle size range from about 10 nm to about 10 µm, e) the collection of released airborne particles in the respirable dustiness mass fraction for subsequent observations and analysis by analytical electron microscopy. NOTE 1 The particle size range described above is based on the equipment used during the pre-normative research [8]. This document is applicable to the testing of a wide range of bulk materials including powders, granules or pellets containing or releasing respirable NOAA or other respirable particles in either unbound, bound uncoated and coated forms. NOTE 2 Currently no number-based classification scheme in terms of particle number and emission rate has been established for powder dustiness. Eventually, when a large number of measurement data has been obtained, the intention is to revise the document and to introduce such a classification scheme, if applicable. NOTE 3 The small rotating drum method has been applied to test the dustiness of a range of materials including nanoparticle oxides, nanoflakes, organoclays, clays, carbon black, graphite, carbon nanotubes, organic pigments, and pharmaceutical active ingredients. The method has thereby been proven to enable testing of a many different materials that can contain nanomaterials as the main component.

EN 17199-4:2019 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17199-4:2019 has the following relationships with other standards: It is inter standard links to ISO 27891:2015, ISO 15767:2009, EN 15051-1:2025, EN 1540:2021, EN 13205-2:2014, EN 17199-1:2019, EN 16897:2017, EN 481:1993, EN ISO 80004-1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17199-4:2019 is associated with the following European legislation: Standardization Mandates: M/461. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17199-4:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2019

Izpostavljenost na delovnem mestu - Meritve prašnosti razsutih materialov, ki

vsebujejo ali sproščajo respirabilne nanopredmete ter njihove agregate in

aglomerate (NOAA) in druge respirabilne delce - 4. del: Metoda z majhnim vrtečim

bobnom

Workplace exposure - Measurement of dustiness of bulk materials that contain or

release respirable NOAA or other respirable particles - Part 4: Small rotating drum

method

Exposition am Arbeitsplatz - Messung des Staubungsverhaltens von Schüttgütern, die

Nanoobjekte oder Submikrometerpartikel enthalten oder freisetzen - Teil 4: Verfahren mit

kleiner rotierender Trommel

Exposition sur les lieux de travail - Mesurage du pouvoir de resuspension des matériaux

en vrac contenant ou émettant des nano-objets et leurs agrégats et agglomérats (NOAA)

ou autres particules en fraction alvéolaire - Partie 4: Méthode impliquant l'utilisation d'un

petit tambour rotatif

Ta slovenski standard je istoveten z: EN 17199-4:2019

ICS:

13.040.30 Kakovost zraka na delovnem Workplace atmospheres

mestu

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17199-4

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2019

EUROPÄISCHE NORM

ICS 13.040.30

English Version

Workplace exposure - Measurement of dustiness of bulk

materials that contain or release respirable NOAA or other

respirable particles - Part 4: Small rotating drum method

Exposition sur les lieux de travail - Mesurage du Exposition am Arbeitsplatz - Messung des

pouvoir de resuspension des matériaux en vrac Staubungsverhaltens von Schüttgütern, die

contenant ou émettant des nano-objets et leurs Nanoobjekte oder Submikrometerpartikel enthalten

agrégats et agglomérats (NOAA) ou autres particules oder freisetzen - Teil 4: Verfahren mit kleiner

en fraction alvéolaire - Partie 4: Méthode impliquant rotierender Trommel

l'utilisation d'un petit tambour rotatif

This European Standard was approved by CEN on 8 February 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17199-4:2019 E

worldwide for CEN national Members.

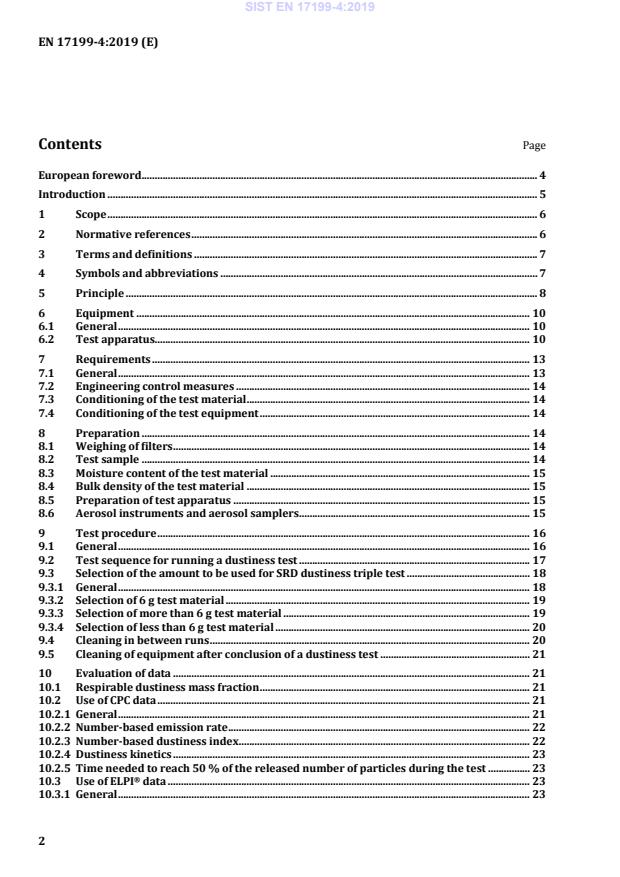

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 7

5 Principle . 8

6 Equipment . 10

6.1 General . 10

6.2 Test apparatus. 10

7 Requirements . 13

7.1 General . 13

7.2 Engineering control measures . 14

7.3 Conditioning of the test material . 14

7.4 Conditioning of the test equipment . 14

8 Preparation . 14

8.1 Weighing of filters . 14

8.2 Test sample . 14

8.3 Moisture content of the test material . 15

8.4 Bulk density of the test material . 15

8.5 Preparation of test apparatus . 15

8.6 Aerosol instruments and aerosol samplers. 15

9 Test procedure . 16

9.1 General . 16

9.2 Test sequence for running a dustiness test . 17

9.3 Selection of the amount to be used for SRD dustiness triple test . 18

9.3.1 General . 18

9.3.2 Selection of 6 g test material . 19

9.3.3 Selection of more than 6 g test material . 19

9.3.4 Selection of less than 6 g test material . 20

9.4 Cleaning in between runs . 20

9.5 Cleaning of equipment after conclusion of a dustiness test . 21

10 Evaluation of data . 21

10.1 Respirable dustiness mass fraction . 21

10.2 Use of CPC data . 21

10.2.1 General . 21

10.2.2 Number-based emission rate . 22

10.2.3 Number-based dustiness index . 22

10.2.4 Dustiness kinetics . 23

10.2.5 Time needed to reach 50 % of the released number of particles during the test . 23 ®

10.3 Use of ELPI data . 23

10.3.1 General . 23 ®

10.3.2 Modal aerodynamic equivalent diameters obtained by ELPI (aerodynamic D , µm) . 23

p

10.4 Morphology and chemical characterization of the particles . 24

11 Test report . 24

Annex A (informative) Example of a small rotating drum set-up . 26

Bibliography . 27

European foreword

This document (EN 17199-4:2019) has been prepared by Technical Committee CEN/TC 137 “Assessment

of workplace exposure to chemical and biological agents”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2019 and conflicting national standards shall

be withdrawn at the latest by September 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands,

Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

the United Kingdom.

Introduction

Dustiness measurement and characterization provide users (e.g. manufacturers, producers, occupational

hygienists and workers) with information on the potential for dust emissions when the bulk material is

handled or processed in workplaces. They provide the manufacturers of bulk materials containing NOAA

with information that can help to improve their products and reduce their dustiness. It allows the users

of the bulk materials containing NOAA to assess the controls and precautions required for handling and

working with the material and the effects of pre-treatment (e.g. modify surface properties or chemistry).

It also allows the users to select less dusty products, if available. The particle size distribution of the

aerosol and the morphology and chemical composition of its particles can be used by occupational

hygienists, scientists and regulators to further characterize the aerosol in terms of particle size

distribution and chemical composition and to thus aid users to evaluate and control the health risk of

airborne dust.

This document gives details on the design and operation of the small rotating drum method that can be

used to measure the dustiness of bulk materials that contain or release respirable NOAA or other

respirable particles in terms of dustiness indices or emission rates. Dustiness indices as well as particle

emission rates can be mass-based of the health-related respirable dustiness mass fraction using a cyclone

for the respirable dust fraction and by number using real-time sampling of particle number

concentrations. The particle size distribution of the released aerosol is measured using direct-reading

aerosol instruments. The released dust particles can be further sampled and characterized for, e.g.

physical size distribution, morphology and chemical composition by off-line analysis (as required).This

test uses the same dust generation principle as EN 15051-2 and EN 17199-2 [1], but the rotating drum

volume and diameter is smaller and the sampling design different, which allows testing of small sample

volumes and simultaneous sampling of all realtime data and dust for off-line analysis.

The small rotating drum method has been designed to simulate workplace scenarios and to represent

general bulk material handling processes, including processes where bulk material is tipped, poured,

mixed, scooped, dropped or similar, either mechanically or by hand.

The small rotating drum method presented here differs from the rotating drum, continuous drop and the

vortex shaker methods presented in EN 17199-2 [1], EN 17199-3 [2] and EN 17199-5 [3] respectively.

The rotating drum and small rotating drum methods perform, both, repeated pouring or agitation of a

bulk material. The continuous drop method simulates continuous feed of a bulk material while the vortex

shaker method simulates vigorous agitation of a bulk material.

This document was developed based on results in scientific literature [4,5,6,7] and pre-normative

research [8]. The pre-normative research project investigated the dustiness of ten bulk materials

(including nine bulk nanomaterials) with the intention to test as wide a range of bulk materials as

possible in terms of magnitude of dustiness, chemical composition and primary particle size distribution

as indicated by a large range in specific surface area.

Subsequently, the sampling line was optimized to improve dust transmission in the system and make the

sampling closer to the efficiency in the prototype by [4] and EN 15051-2 [9].

1 Scope

This document describes the methodology for measuring and characterizing the dustiness of bulk

materials that contain or release respirable NOAA or other respirable particles, under standard and

reproducible conditions and specifies for that purpose the small rotating drum method.

This document specifies the selection of instruments and devices and the procedures for calculating and

presenting the results. It also gives guidelines on the evaluation and reporting of the data.

The methodology described in this document enables

a) the measurement of the respirable dustiness mass fraction,

b) the measurement of the number-based dustiness index of respirable particles in the particle size

range from about 10 nm to about 1 µm,

c) the measurement of the initial number-based emission rate and the time to reach 50 % of the total

particle number released during testing,

d) the measurement of the number-based particle size distribution of the released aerosol in the

particle size range from about 10 nm to about 10 µm,

e) the collection of released airborne particles in the respirable dustiness mass fraction for subsequent

observations and analysis by analytical electron microscopy.

NOTE 1 The particle size range described above is based on the equipment used during the pre-normative

research [8].

This document is applicable to the testing of a wide range of bulk materials including powders, granules

or pellets containing or releasing respirable NOAA or other respirable particles in either unbound, bound

uncoated and coated forms.

NOTE 2 Currently no number-based classification scheme in terms of particle number and emission rate has

been established for powder dustiness. Eventually, when a large number of measurement data has been obtained,

the intention is to revise the document and to introduce such a classification scheme, if applicable.

NOTE 3 The small rotating drum method has been applied to test the dustiness of a range of materials including

nanoparticle oxides, nanoflakes, organoclays, clays, carbon black, graphite, carbon nanotubes, organic pigments,

and pharmaceutical active ingredients. The method has thereby been proven to enable testing of a many different

materials that can contain nanomaterials as the main component.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CEN ISO/TS 80004-2, Nanotechnologies - Vocabulary - Part 2: Nano-objects (ISO/TS 80004-2)

EN 481, Workplace atmospheres - Size fraction definitions for measurement of airborne particles

EN 1540, Workplace exposure - Terminology

EN 13205-2, Workplace exposure - Assessment of sampler performance for measurement of airborne

particle concentrations - Part 2: Laboratory performance test based on determination of sampling efficiency

EN 15051-1, Workplace exposure - Measurement of the dustiness of bulk materials - Part 1: Requirements

and choice of test methods

EN 16897, Workplace exposure - Characterization of ultrafine aerosols/nanoaerosols - Determination of

number concentration using condensation particle counters

EN 17199-1, Workplace exposure - Measurement of dustiness of bulk materials that contain or release

respirable NOAA or other respirable particles - Part 1: Requirements and choice of test methods

ISO 15767, Workplace atmospheres - Controlling and characterizing uncertainty in weighing collected

aerosols

ISO 27891, Aerosol particle number concentration - Calibration of condensation particle counters

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1540, EN 15051-1,

CEN ISO/TS 80004-2 and EN 17199-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Symbols and abbreviations

CPC Condensation Particle Counter

d A lower particle size at which the counting or sampling efficiency is 50 %

)

®1

Electrical Low Pressure Impactor

ELPI

EM Electron Microscopy

FTIR Fourier Transform Infra-Red Spectroscopy

GC Gas Chromatography

HEPA High Efficiency Particulate Arrestance

HPLC High Performance Liquid Chromatography

ICP Inductive Coupled Plasma

ID Inner Diameter

LOQ Limit Of Quantification

MS Mass Spectrometry

NOAA Nano-objects, and their aggregates and agglomerates > 100 nm

®

1) ELPI is the trade name or trademark of a product supplied by Dekati. This information is given for the

convenience of users of this European Standard and does not constitute an endorsement by CEN of the product

named. Equivalent products may be used if they can be shown to lead to the same results.

Raman Raman Spectroscopy

RH Relative Humidity

SEM Scanning Electron Microscopy

SRD Small Rotating Drum

TEM Transmission Electron Microscopy

XRF X-ray Fluorescence

5 Principle

The small rotating drum (SRD) method described in this document measures the dustiness of bulk

materials in terms of

— the respirable dustiness mass fraction,

— the number-based dustiness index,

— the number-based emission rates, and

— the time period to generate 50 % of the emitted particle numbers.

In addition, this document describes the procedures by which the aerosols can be further characterized

in terms of their particle size distributions and the morphology and chemical composition of their

airborne particles.

The sampling for the purpose of and the execution of qualitative or quantitative analysis of the

morphology and chemical composition of the collected airborne particles are described. Performing these

analyses is optional but can provide confirmation of the sizes of the particles generated and

complementary information to the real-time instruments.

Table 1 provides

— an overview of the different measurands,

— information on whether determining these measurands is mandatory or not, and

— the aerosol instruments and sampling devices needed to determine a measurand.

Table 1 — Measurands, aerosol instruments/sampling devices and associated recommendations

for the small rotating drum method

Method/Device specific to

Measurand Mandatory/optional

measurand

25 mm- or 37 mm- air

sampling cassette mounted

Respirable dustiness mass fraction Mandatory

on a cyclone for the

(mg/kg)

respirable dust fraction

Number-based dustiness index of

respirable particles in the particle size Condensation Particle

Mandatory

range from about 10 nm to about 1 µm Counter (CPC)

(1/mg)

Number-based average emission rate

of respirable particles in the particle Condensation Particle

Mandatory

size range from about 10 nm to about Counter (CPC)

1 µm (1/mg·s)

Number-based initial dustiness

kinetics considering the number of

Condensation Particle

particles released in the particle size Mandatory

Counter (CPC)

range from about 10 nm to about 1 µm

(1/mg·s )

Time-based dustiness kinetics

assessed as the time required to

generate 50 % of the total number of Condensation Particle

Mandatory

particles released in the particle size Counter (CPC)

range from about 10 nm to about 1 µm

(s)

Number of modes of the time-averaged

Mandatory

number-based particle size

Time- and size-resolving

distributionas dN/dlogD (-)

i

instrument covering the

Modal aerodynamic equivalent

particle size range from

diameters corresponding to the

about 10 nm up to about 10

highest mode (M1 ) and to the second

N

µm

Mandatory

highest mode (M2 ) of the time-

N

averaged number-based particle size

distribution as dN/dlogD (µm)

i

Number of modes of the time-averaged

mass-based particle size distribution Optional

as dM/dlogD (-)

i

Cascade impactor covering

Modal aerodynamic equivalent

the particle size range from

diameters corresponding to the

about 10 nm up to about 10

highest mode (M1 ) and to the second

M

µm

Optional

highest mode (M2 ) of the time-

M

averaged mass-based particle size

distribution as dM/dlogD (µm)

i

Method/Device specific to

Measurand Mandatory/optional

measurand

Optional

E.g. a TEM-grid holder

Particles on TEM-grids may be

Morphological characterization of the

equipped with porous carbon

analysed by transmission (TEM)

particles including NOAA

film TEM-grid

or scanning (SEM) electron

microscopy

25 mm- or 37 mm- air Optional

sampling cassette mounted

Filters may be analysed

on a cyclone for the

chemically after weighing using

respirable dust fraction

Chemical characterization of the

e.g. XRF, ICP-MS, GC-MS, HPLC-

particles including NOAA

MS, FTIR, and Raman

spectrometry depending on

needs and suitability of the

sample.

NOTE The particle size range described above is based on the equipment used during the pre-normative research.

6 Equipment

6.1 General

Figure 1 gives a schematic example for a small rotating drum set-up, which is configured with a bypass

tube to bypass the test atmosphere while preparing and cleaning the small rotating drum.

6.2 Test apparatus

The usual laboratory apparatus and, in particular, the following:

6.2.1 Small rotating drum

The small rotating drum consists of the components described in detail in 6.2.2 to 6.2.12. The small drum

consists of a cylindrical part with a radius of 8,15 cm and a length of 23 cm and two 45° truncated conical

ends with a centre depth of 6,3 cm (see Figure 1 and Figure A.1). These dimensions give a total volume of

about 5,675 l. The cylindrical part of the drum contains three powder lifter vanes (2 cm × 22,5 cm) placed

120° apart. The inner surfaces shall be polished to reach an arithmetical mean roughness profile of 0,19

µm, which can be obtained by vibratory finishing. The drum is rotated driven by a cogwheel belt

connected to a programmable electrical engine.

The volume-flow-balance shall be as follows: ®

— Q is 10 l/min to the ELPI ;

E

— Q = Q + Q +Q ;

A B1 B2 C

— Q + Q = Q = 10 l/min.

C D E

If measurement systems and sampling systems with different volume flows are applied, the entire

sampling line shall be redesigned to allow isokinetic (or at least near-isokinetic) sampling. See also 6.2.4.

Mass flow controllers should be used to ensure a stable volume flow of humidified air to deliver Q and

A

Q .

D

Key

1 temperature and RH-controlled test atmosphere directed into the test system at Q = 11 l/min

A

2 valves to direct air flow through or bypass the small rotating drum

3 small rotating drum (inlet and outlet tube inner diameters of 20,25 mm)

4 tight-fitting stainless steel tube connector (with inner diameter of 20,25 mm)

5 three-way aerosol flow splitter (connection to dust transfer line with an inner diameter of 20,25 mm)

6 sampling tube for the CPC and the electron microscopy sampler (optional) allowing isokinetic sampling from

the flow-splitter at 1 l/min (QB2)

7 Y-split connector

8 0,3 l/min (Q ) flow directed to the electron microscopy sampler and bypass filter.

B2a

9 0,7 l/min (QB2b) flow directed to the CPC

10 valve to direct the flow towards the electron microscopy sampler or the bypass filter

11 electron microscopy sampler

12 particle filter to protect the pump

13 pump enabling sampling at QB2a = 0,3 l/min

14 CPC sampling at Q = 0,7 l/min

B2b

15 sampling tube for the cyclone for the respirable dust fraction allowing (near-)isokinetic sampling from three-

way flow-splitter at QB1 = 4,2 l/min.

16 cyclone for the respirable dust fraction with pump sampling at QB1 = 4,2 l/min ®

17 sampling tube for the ELPI allowing (near-)isokinetic sampling of Q = 5,8 l/min

C ®

18 4,2 l/min (QD) temperature- and RH-controlled make-up air to balance the ELPI volume flow

19 T-split connector ®

20 10 l/min (Q ) volume flow to the ELPI

E

21 ELPI® sampling at Q = 10 l/min.

E

Figure 1 — Small Rotating Drum with sampling line in a configuration where sampling is made

using a CPC, a cyclone for the respirable dust fraction, an electron microscopy sampler and an ®

ELPI

6.2.2 System for minimizing the risk of human inhalation exposure

Examples of such a system are a safety cabinet, a fume-hood or an enclosure.

6.2.3 System for humidifying experimental air

The system for humidifying experimental air shall be capable of delivering 11 l/min through the drum

and 7,4 l/min dilution air or a total of 18,4 l/min air with highly controlled temperature at (21 ± 3) °C and

(50 ± 5) % RH (see Figure 1).

Humidifiers for this method should be designed to not transmit particles into the test atmosphere.

Testing should be possible under variable relative humidity conditions (20 % RH to 80 % RH).

6.2.4 Sampling line with isokinetic sampling outlets

The drum is connected to the aerosol samplers and the aerosol instruments by using a three-way aerosol

flow splitter. This allows particle sampling of respirable dust, electron microscopy samples, and real-time ®

measurement using the CPC and ELPI aerosol monitoring devices (see Figure 1).

It is important that the sampling line is configured in a manner that prevents particle losses in the

respirable particle size range to ensure interlaboratory comparability.

6.2.5 Electrically conductive tubing

To minimize losses in sampling lines during the measurement of airborne particle size distributions and

number concentrations, electrically conductive tubing should be used.

Transition tube lengths and bent in tubing should be kept to a minimum to minimize particle losses.

If diffusion chargers are connected to the sampling line, these should be connected using the types of

tubes distributed with the instruments or similar.

6.2.6 Cyclone for the respirable dust fraction

Cyclone with a flow rate of 4,2 l/min and mounted with filters with 25 mm- or 37 mm- cassettes, enabling

sampling of the respirable dust, according to EN 481 and validated according to EN 13205-2.

NOTE Sampling is performed using an individual pump.

6.2.7 Collection filter, 25 mm or 37 mm, preferably made of polytetrafluorethylene (PTFE)

The user may select a filter type of another material with a lower limit of quantification.

6.2.8 Direct-reading size-resolved aerosol instrument for time-averaged number-based particle

size distribution

Number-based particle size distribution shall be measured using a direct reading number-based low

pressure cascade impactor and the number of modes and the modal aerodynamic

equivalentdiameter(s)of the time-averaged particle number shall be derived from the data. The device

shall be able to count and classify particles in the particle size range from at least 10 nm to 10 µm.

The measurement of the number-based particle size distribution in aerodynamic equivalent diameter

shall be preferred and shall be performed with a time step of 1 s.

) ®

An Electrical Low Pressure Impactor (ELPI ) has been selected as the benchmark equipment for this

measurement. ®

NOTE 1 In the ELPI , the number concentration in each channel is calculated from the measured current by

applying the charger efficiency curve which is dependent on mobility-equivalent diameter, itself related to the

aerodynamic diameter. Therefore, it is necessary that the density which relates these two equivalent diameters is

known to calculate the number concentration in each channel. The density mentioned here corresponds to the

effective density of airborne particles, which is theoretically dependent on particle diameter (the larger the

agglomerates and aggregates, the smaller their effective density; the closer to the primary particle diameter, the ®

closer to the material density of the compound), see [5] and [6]. Concerning the ELPI , the value considered for the ®

density can have a strong impact on the number concentration. Over the particle size range covered by the ELPI

3 3

and a range of density from 0,1 g/cm to 10 g/cm , the under estimation or overestimation can reach up to a factor

of 25. Despite this, the effect on relative particle size distributions is limited and the modal aerodynamic equivalent

diameters are therefore less affected.

6.2.9 Direct-reading aerosol instrument for particle number concentration, with a detectable

particle size range from 10 nm to 1 µm

Particle number concentration shall be measured at 1 s resolution using a condensation particle counter

(CPC). The CPC shall be able to count particles in the particle size range from at least 10 nm to 1 µm and

3 3

to 100 000 particles/cm in single particle counts. The

at concentrations ranging from 0 particles/cm

working fluid of the instrument shall be alcohol.

The CPC shall be calibrated in accordance with ISO 27891 and its response checked following EN 16897.

6.2.10 Sampler for analytical electron microscopy (optional), where sampling air is drawn by an

individual pump

NOTE It is advised to mount a valve to enable bypassing air through a millipore filter cassette during the time

when electron microscopy sampling is not performed. Thereby the volume flow is balanced throughout the test.

6.2.11 Flow meters, capable of measuring and monitoring volume flows ranging from 0,3 l/min to

11 l/min with a measurement uncertainty of 5 % or less.

6.2.12 Equipment for gravimetric analysis, capable of weighing at 0,1 µg resolution or lower and with

a limit of quantification (LOQ) of filter weight less than 1 µg, under temperature- and % RH-controlled

conditions, if temperature is (22 ± 1) °C and relative humidity (50 ± 3) %.

Using the balance in the weighing atmosphere with the selected filter material and particle size shall have

an LOQ less than 15 μg according to ISO 15767.

NOTE Using a dedicated temperature- and % RH-controlled weighing room ensures accuracy in weighing.

7 Requirements

7.1 General

The general procedures outlined in EN 17199-1 shall be applied.

Fundamental requirement for standard testing is a stable rotation speed of the SRD at eleven revolutions

per minute, a stable flow of controlled relative humidity (50 % RH) high efficiency particulate arrestance

2) See Footnote 1.

(HEPA) filtered air through the drum at 11 l/min and an isokinetic to near-isokinetic sampling line with

no or minimal and well-characterized particle loss for sampling and quantification of the end points a) to

e) mentioned in the Scope. To test powders under general use conditions testing of dustiness should be

enabled in the range from 20 % RH to 80 % RH.

The volume flow through the sampling line shall not exceed 11 l/min, which is sufficient to the indicated

samplers and real-time monitors for air sampling. For instruments, which require higher volume-flows

than those provided from the 11 l/min flow through the dustiness system itself, make-up air needs to be

supplied between the monitor and the sampling line (see Figure 1).

7.2 Engineering control measures

Appropriate engineering control measures (e.g. enclosure, use of local exhaust ventilation) shall be

implemented to prevent exposure of the operator during the tests, but also during disassembly and

cleaning sequences between individual test runs.

Occupational risks should be assessed according to national regulations.

7.3 Conditioning of the test material

Because powders and the number-based dustiness index can be sensitive to the relative humidity during

storage, the test powder samples shall be conditioned at least 12 h (overnight) before testing. In standard

test conditions, the samples shall be stored at room temperature with air conditioned at (50 ± 5) % RH.

NOTE The storage at controlled % RH test conditions can be done in different ways. One possibility is to use

the same humidifier, which is used to condition the air for dustiness testing, and connect this to a chamber suitable

in size. Alternatively, a humidity-controlled laboratory room or a separate humidity-controlled chamber can be

used.

7.4 Conditioning of the test equipment

For testing under standard conditions, the average conditions for temperature and relative humidity

inside the drum shall be (21 ± 3) °C and (50 ± 5 % RH), respectively, and shall be stable throughout the

entire test period. These conditions are provided by the air from the humidifier feeding the test

atmosphere into the drum (see Figure 1).

The test apparatus shall be electrically grounded to prevent charge accumulation.

8 Preparation

8.1 Weighing of filters

At least four filters (depending on which filter type has lowest limit of quantification in the specific

laboratory) shall be prepared for each powder sample for collection of respirable dust with the cyclone

for the respirable dust fraction. The four filters include one backup, if a fourth sample will be needed to

reduce uncertainty or errors. For each weighing round (e.g., one-week-sets of tests) three blank filters

shall be included to take into account filter variations and handling.

Before weighing (before and after use in test), the filters shall be conditioned, at least overnight, in a

climate-controlled weighing room and weighed.

8.2 Test sample

One 2 g sample for “conditioning testing” and four at least 6 g samples for quantitative dustiness testing

are incubated for 24 h at the intended test conditions (i.e. (21 ± 5) °C; (50 ± 5) % RH).

For the determination of moisture content and bulk density (see 8.3 and 8.4) sufficient sample amounts

are incubated at the desired test conditions.

8.3 Moisture content of the test material

The moisture content of the test material shall be determined and documented according to the

procedure given in EN 17199-1.

8.4 Bulk density of the test material

The bulk density of the test material shall be determined and documented according to the procedure

given in EN 17199-1.

8.5 Preparation of test apparatus

Prior to the tests being carried out, the rotating drum is cleaned thoroughly using a suitable vacuum

cleaner, wiped with a damp cloth (e.g. alcohol-wetted cloths) and allowed to dry. For test materials that

stick to the internal surfaces, it can also be necessary to wash the surfaces with a solution of a detergent

in water followed by thorough washing with water, or to clean with a suitable solvent (e.g. propanol).

The tube connecting the drum (item number 1 in Figure 1) and the sampling line (item number 4 in Figure

1) is attached to the outlet stage of the drum using a rotating coupling device. The dust transmission line

is connected to the sampling line using a tight fitting stainless connecter (item number 3 in Figure 1).

The volume flow rates of air provided by the humidifiers and all the pumps, devices and real-time

instruments are checked using air volume flow meters and adjusted, if necessary, to balance the total

collection air volume flow to the total volume flow of 11 l/min into the drum as depicted in Figure 1.

The instruments are connected to the sampling line using stainless metal or alloy tubes or conductive

tubing as shown in Figure 1. Bends in tubing shall be avoided to the extent possible.

8.6 Aerosol instruments and aerosol samplers

Instruments shall be switched on in due time to allow equilibration of the real-time monitors. For ®

is used, it shall be switched on several hours before any measurements take place,

example, if the ELPI

preferably the day before. This allows the electrometers to fully stabilize. ®

Sintered collection plates shall be prepared as recommended by the manufacturer of the ELPI . In case

Al-plates are used, greasing shall be done using one to two drops of vacuum pump oil per plate. When a

new powder sample is being tested, the plates and insulators need to be cleaned in an ultrasonic bath

with alcohol. ®

The ELPI leak test and zeroing procedure shall take place prior to any measurements. The “zeroing”

procedure shall be performed with the drum empty, the instrument connected to the drum and the other

instruments and devices operating. The external HEPA-filter to the air inlet may be used and the charger

shall be on during the “zeroing” procedure.

At the start of a test day, a zero check of the CPC shall be carried out by applying HEPA-filters to the

sampling line.

All devices and instruments flow rates shall be checked using in-line air flowmeters before and after the

test, and the values shall be recorded. ®

Sintered ELPI plates shall be checked between testing powder replicates and only cleaned or wiped if

necessary between replicates.

9 Test procedure

9.1 General

The test procedure starts with a conditioning run to coat the drum and sampling tube surfaces with dust

(see 9.1). The real-time monitoring data from the pre-conditioning test is also used to assess whether the

standard 6 g powder used for the test is suitable to generate quantitative respirable mass and real-time

monitoring data (see 9.2). The conditioning run is followed by a minimum of three tests to establish the

quantitative dustiness data (see 9.3). The SRD is cleaned by gentle vacuum cleaning in between runs (see

9.4) and thoroughly cleaned after completion of the dustiness test for one material and before starting

testing the dustiness testing on the next material (see 9.5).

The test procedure consists of the following steps:

1) Set the direction of the test atmosphere to by-pass the drum.

2) Start the humidified air-flow for the test-line and lead it through the bypass tubing. Follow the

instructions for directing the air-flow carefully.

3) Start all real-time monitoring instruments to be used in the test as well as humidifiers ensuring the ®

test atmosphere and the make-up air to the ELPI . ®

4) Start the ELPI in due time as explained in 8.6.

5) Ensure that the test atmosphere and make-up air is at the correct conditions (standard conditions:

(21 ± 3) °C and (50 ± 5) % RH) and recorded.

6) Ensure all instruments are time synchronized to the extent possible and set to log data

simultaneously.

7) Start the controller and program it to rotate the drum at eleven revolutions per min for 60 s, if not

already pre-programmed. Follow the instructions given for programming the controller.

8) Mount the filter cassette in the cyclone for the respirable dust fraction; connect all instruments,

samplers and make-up air pump to the sampling line as shown in Figure 1.

9) Use a clean filter cassette mounted with an unexposed filter in the cyclone for the respirable dust

fraction for each run.

10) Zero the mounted drum to position a lifter vane in bottom position.

11) Start all pumps and ensure that all monitoring devices are attached to the sampling line and running;

12) Set the valves of the system to direct the test atmosphere through the drum. ®

13) Perform the “zeroing” procedure of the ELPI as described in 8.6. Perform a “blank” measurement

with the drum empty and rotating on to check the level of “background” particles within the drum. A

background of less than 20 particles/cm measured using the CPC shall be achieved inside the drum.

14) Set the direction of the test atmosphere back to by-pass the drum. ®

15) Disconnect the ELPI and switch off the pumps to the respirable dust sampler and EM samplers.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...