EN 1034-1:2000+A1:2010

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements

1.1 This standard applies to paper making and paper finishing machines. It contains definitions and requirements which apply to all paper making and paper finishing machines listed in annex A and shall be used in connection with the specific part applicable for the respective machine listed in annex A. Specific parts can contain additional requirements or deviations from EN 1034-1 in which case the specific stipulations take precedence over the specification made in EN 1034-1. The standard deals with the hazards listed in 4.

1.2 This standard does not apply to machines used in paper converting. See EN 1010-1 to EN 1010-5.

1.3 This standard applies to machines produced after............. (date of CEN approval).

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 1: Gemeinsame Anforderungen

Anforderungen, die für alle im Anhang A genannten Maschinen von Bedeutung sind, und ist in

Verbindung mit dem für die spezielle Maschine zutreffenden Teil dieser Norm zu verwenden. Die Spezialteile

können weitere oder von EN 1034-1 abweichende Spezifikationen enthalten. Die Spezifikationen der

Spezialteile haben Vorrang vor den Spezifikationen von EN 1034-1. Es werden die im Abschnitt 4 aufgelisteten

Gefährdungen behandelt.

1.2 Diese Norm gilt nicht für Papierverarbeitungsmaschinen. Siehe EN 1010-1 bis EN 1010-5.

1.3 Diese Norm gilt für Maschinen, die nach dem (Datum der CEN-Zustimmung) hergestellt werden.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 1: Prescriptions communes

1.1 La présente norme s'applique à toutes les machines de fabrication et de finition du papier. La présente norme

comprend les définitions et les prescriptions qui s'appliquent à toutes les machines de fabrication mentionnées

en annexe A.

Elle doit être utilisée conjointement avec la partie relative à la machine spécifique. Les autres parties spécifiques de

l’!EN 1034-1" peuvent contenir des prescriptions ou dérogations supplémentaires. Les prescriptions des autres

parties spécifiques de la norme ont la priorité sur celles de l’!EN 1034-1". Cette norme traite de tous les

phénomènes dangereux énumérés dans l'article 4.

1.2 La présente norme ne s'applique pas aux machines de transformation du papier. Voir EN 1010-1 à EN 1010-5.

1.3 La présente norme s'applique aux machines qui sont fabriquées après octobre 2000.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja - 1. del: Splošne zahteve

Ta standard se uporablja za stroje in opremo za izdelavo papirja. Vsebuje definicije in zahteve, ki veljajo za vse stroje in opremo za izdelavo papirja, naštete v Dodatku A, ter se uporabljajo v povezavi s posebnim delom, ki velja za ustrezen stroj, naštet v Dodatku A. Posebni deli lahko vsebujejo dodatne zahteve ali odstopanja od EN 1034-1; v takem primeru imajo posebne določbe prednost pred zahtevami, navedenimi v EN 1034-1. Standard obravnava nevarnosti, naštete v točki 4. Ta standard se ne uporablja za stroje, ki se uporabljajo za obdelavo papirja. Glej EN 1010-1 do EN 1010-5.

General Information

- Status

- Withdrawn

- Publication Date

- 02-Mar-2010

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 198 - Printing and paper machinery - Safety

- Drafting Committee

- CEN/TC 198/WG 2 - Paper Machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-May-2021

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 136, C 136, C 136, C 136, C 136, C 136, C 136, C OJ Date: 26-May-2010

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 19-May-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2014 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1034-1:2000+A1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements". This standard covers: 1.1 This standard applies to paper making and paper finishing machines. It contains definitions and requirements which apply to all paper making and paper finishing machines listed in annex A and shall be used in connection with the specific part applicable for the respective machine listed in annex A. Specific parts can contain additional requirements or deviations from EN 1034-1 in which case the specific stipulations take precedence over the specification made in EN 1034-1. The standard deals with the hazards listed in 4. 1.2 This standard does not apply to machines used in paper converting. See EN 1010-1 to EN 1010-5. 1.3 This standard applies to machines produced after............. (date of CEN approval).

1.1 This standard applies to paper making and paper finishing machines. It contains definitions and requirements which apply to all paper making and paper finishing machines listed in annex A and shall be used in connection with the specific part applicable for the respective machine listed in annex A. Specific parts can contain additional requirements or deviations from EN 1034-1 in which case the specific stipulations take precedence over the specification made in EN 1034-1. The standard deals with the hazards listed in 4. 1.2 This standard does not apply to machines used in paper converting. See EN 1010-1 to EN 1010-5. 1.3 This standard applies to machines produced after............. (date of CEN approval).

EN 1034-1:2000+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1034-1:2000+A1:2010 has the following relationships with other standards: It is inter standard links to EN 1034-1:2000, EN 1034-1:2000/FprA1, EN 1034-1:2021, EN 60529:1991, EN IEC 61496-2:2020, EN 60825-1:2014, EN IEC 61496-1:2020, EN 61511-1:2004, EN 60825-1:1994, EN 62061:2005, EN ISO 12643-1:2023, EN ISO 13856-2:2013, EN ISO 11688-1:1998, EN ISO 13854:2019, EN 894-2:1997+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1034-1:2000+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1034-1:2000+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitstechnische Anforderungen für Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 1: Gemeinsame AnforderungenSécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 1: Prescriptions communesSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-1:2000+A1:2010SIST EN 1034-1:2000+A1:2010en,fr01-maj-2010SIST EN 1034-1:2000+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1034-1:2000+A1

March 2010 ICS 85.100 Supersedes EN 1034-1:2000English Version

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 1: Prescriptions communes

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen für Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 1: Gemeinsame Anforderungen This European Standard was approved by CEN on 17 September 1999 and includes Amendment 1 approved by CEN on 17 January 2010. CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1034-1:2000+A1:2010: ESIST EN 1034-1:2000+A1:2010

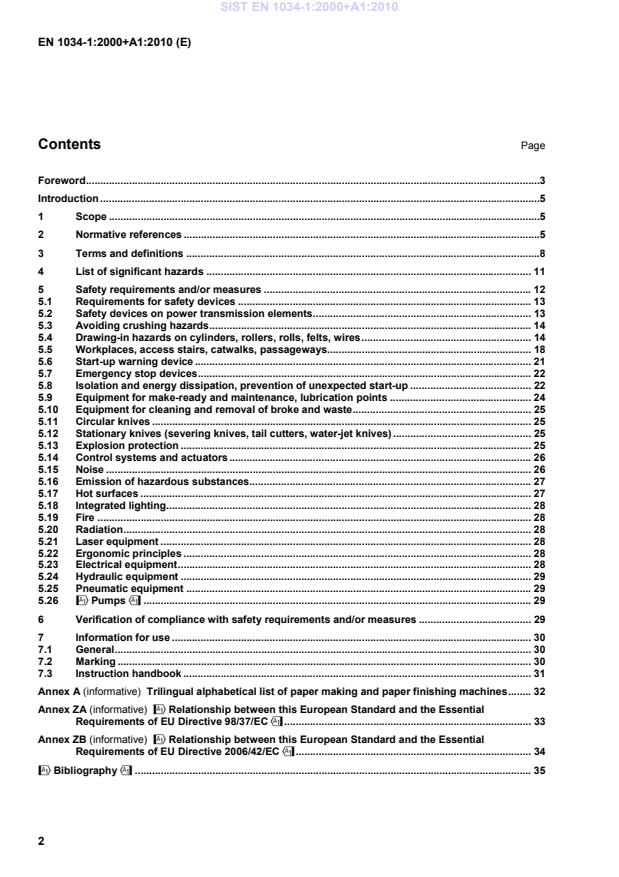

Trilingual alphabetical list of paper making and paper finishing machines . 32Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 33Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 34!Bibliography" . 35 SIST EN 1034-1:2000+A1:2010

annex A. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

(ISO 7731:1986 modified) EN 547-1, Safety of machinery — Human body measurements — Part 1: Principles for determining the dimensions required for openings for whole body access into machinery EN 547-2, Safety of machinery — Human body measurements — Part 2: Principles for determining the dimensions required for access openings EN 547-3, Safety of machinery — Human body measurements — Part 3: Anthropometric data !deleted text" EN 614-1, Safety of machinery — Ergonomics design principles — Part 1: Terminology and general principles EN 614-2, Safety of machinery — Ergonomics design principles — Part 2: Interaction between the design of machinery and tasks SIST EN 1034-1:2000+A1:2010

(ISO 13850:2006)" !EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)" !EN ISO 14121-1:2007, Safety of machinery — Risk assessment — Part 1: Principles

(ISO 14121-1:2007)" !EN ISO 14122-3, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001)" !EN ISO 14122-4, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed Ladders (ISO 14122-4:2004)" prEN 12198-1, Safety of machinery — Assessment and reduction of risks arising from radiation emitted by machinery — Part 1: General Principles !deleted text" !EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified)" EN 60529, Degrees of protection provided by enclosures (IP code) EN 60825-1, Safety of laser products — Part 1: Equipment classification, requirements and user’s guide SIST EN 1034-1:2000+A1:2010

v circumferential speed

NOTE Prevention of drawing-in hazard if d > 500 mm or d > 120 mm depending on the conditions defined in 5.4.1. Figure 1 — Examples of inrunning nips 3.7.2 Wrapping point danger point where moving materials, such as felts or screens and wires, aprons or ropes or strong board webs, are fed onto moving parts, such as rolls, cylinders or discs, which can draw in persons, parts of the body or clothing if adequate safety distances are not maintained. Examples of wrapping points are given in figure 2.

3.8 Paper generic term for paper and board, tissue.

3.9 Broke scraps of paper, paper breaks and paper with imperfections. SIST EN 1034-1:2000+A1:2010

3.10 Fence-type enclosure type of guard preventing access to a danger point with a minimum height of 1,4 m and a clearance between floor and lower edge of the fence of 0,4 m maximum. This definition does not relate to fall-off protections.

3.11 Nip bar type of guard arranged directly on the nip of a pair of rollers or some other nip. For examples of nip bars see figure 3.

A wrapping point 1 roller, cylinder E inrunning nip 2 rope 3 felt, screen Figure 2 — Examples of wrapping points SIST EN 1034-1:2000+A1:2010

14121-1" Mechanical hazards

1 Crushing hazard 5.1; 5.3 1.3.1 Shearing hazard 5.1 1.3.2 Cutting or severing hazard 5.1; 5.11; 5.12 1.3.3 Entanglement hazard 5.2 1.3.4 Drawing-in or trapping hazard 5.1; 5.4 1.3.5 Impact hazard 5.1 1.3.6 Stabbing or puncture hazard 5.1; 5.12 1.3.7 Friction or abrasion hazard 5.1 1.3.8 High-pressure fluid ejection hazard 5.24 1.3.9 Ejection of parts (parts of machines or processed material/workpieces) 5.2 1.1.4 Loss of stability (of machines or machine parts) 7 1.1.3 Slip, trip and fall hazards in relationship with machines (because of their mechanical nature) 5.5 19 Electrical hazards, for example

2 Electrical contact (direct or indirect) 5.23; 5.8 2.1 to 2 .3 Electrostatic phenomena 5.23 2.4 Thermal radiation or other phenomena such as ejection of molten particles, and chemical effects from short-circuits, overloads etc. 5.8; 5.23 2.5 External influences on electrical equipment 5.23 10.3 Thermal hazards resulting in:

3 Burns and scalds, by a possible contact of persons, by flames or explosions and also by the radiation of heat sources 5.13; 5.17 3.1 Health-damaging effects by hot or cold work environment 5.22 3.2 Hazards generated by noise, resulting in

4 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness) 5.15 4.1 Interferences with speech communication, acoustic signals 5.15 4.2 Hazards generated by radiation, especially:

6 Electric arcs 5.8; 5.23 2.3 Lasers 5.21 6.5 Ionizing radiation 5.20 6.4 Hazards generated by materials and substances processed, used or exhausted by machines, for example

7 Hazards resulting from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts 5.16 7.1

(continued) SIST EN 1034-1:2000+A1:2010

Table 1 (concluded)

Hazards !EN 1034-1" !EN ISO

14121-1" Fire or explosion hazards 5.13; 5.18;

5.19; 5.23 7.2 Hazards generated by neglecting ergonomic principles in machine caused for example by:

8 Unhealthy postures or excessive efforts 5.22 8.1 Inadequate consideration of human hand-arm or foot-leg anatomy 5.22 8.2 Neglected use of personal protection equipment 5.8; 5.9; 5.15; 7 8.3 Inadequate area lighting 5.18 8.4 Mental overload or underload, stress etc. 5.22 8.5 Human error 7 8.6 Hazard combinations 5. 6 9 Hazards caused by failure of energy supply, breaking down of machines parts and other functional disorders, for example

10 Failure of energy supply (of energy and/or control circuits) 5.8 10.2 Unexpected ejection of machine parts or fluids 5.24

Failure, malfunction of control system (unexpected start up, unexpected overrun) 5.14 10.1 Errors of fitting 7

Overturn, unexpected loss of machine stability 5.14 14 Hazards caused by missing and/or incorrectly positioned safety related measures/means, for example:

All kinds of guards 5.1; 5.2

All kinds of safety related (protection) devices 5.1; 5.14

Start-up and braking devices 5.14 8.7 Safety signs and signals 5.21 8.8 All kinds of information or warning devices 5.6 8.8 Energy supply disconnecting devices 5.8 13 Emergency devices 5.1.3; 5.7; 5.18; 5.19

Feeding/removal means of workpieces 5.10

Essential equipment and accessories for safe adjusting and/or maintaining 5.5; 5.9

Equipment evacuating gases etc. 5.13; 5.16 7.1

5 Safety requirements and/or measures Machinery shall comply with the safety requirements and/or measures of this clause. In addition, the machine shall be designed according to the principles of !EN ISO 12100-2:2003" for hazards relevant but not significant which are not dealt with by this standard. When required, further specification will be given in the machine-specific parts as listed in annex A of this standard. SIST EN 1034-1:2000+A1:2010

EN ISO 12100-2:2003". Guards shall be designed and selected in compliance with EN 953, interlocking guards with EN 1088, electro-sensitive protective devices with EN 61496-1 and pressure sensitive mats with EN 1760-1. !Guards and protective devices shall be securely held in place in accordance with 5.4.2 and 5.5 of

EN 953:1997. Fixed guards that have to removed periodically for maintenance (e.g. the guards on wrapping points of rolls for changing clothing) shall be constructed in such a way that their fixing systems remain attached to the guards or to the machinery when the guards are removed. An example is shown in Figure 11 of EN 953:1997. Where possible, guards shall be constructed in such a way that they also protect against ejected or falling materials and objects. Where possible, guards shall be constructed in such a way that they also protect against emissions generated by the machinery, for example against noise." 5.1.2 Movable guards for safeguarding danger points shall be designed as interlocking guards with guard locking or as interlocking guard without guard locking (see !3.6 or 3.5 of EN 953:1997"). 5.1.3 On fence-type enclosures equipped with interlocking doors, it shall be possible to open the doors from inside the enclosed area at any time so that persons locked in can escape from the danger zone. 5.1.4 Nip bars shall be so designed and mounted that they are able to maintain their safeguarding function even under mechanical stresses, vibration and heat. When forces of 1000 N are applied in the middle, the gap ‘a’ in figure 3 shall not be wider than 8 mm. 5.2 Safety devices on power transmission elements Danger points on power transmission elements shall be protected by fixed guards or interlocking guards with or without guard locking. Guards shall be arranged as close to the danger point as possible such as to prevent access from all sides. Where this is not possible, fence-type enclosures shall be arranged at a safety distance in accordance with !Table 2 and Table B.1 of EN ISO 13857:2008". Table 2 shall be taken into account when selecting the proper type of guarding for power transmission elements. SIST EN 1034-1:2000+A1:2010

Power transmission element Type of guarding Individual shafts, universal-joint shafts, belt drives fixed guard according to 3.2.1 of EN 953:1997

Line transmissions fixed distance guard according to 3.2.2 and 6.1.2 of EN 953:1997

Gear drives housing; fixed guard according to 3.2.1 of EN 953:1997 Spoke wheel drives fixed guard according to 3.2.1 of EN 953:1997, fencing

Chain drives fixed guard according to 3.2.1 of EN 953:1997 Clutches housing; fixed guard according to 3.2.1 of EN 953:1997; fixed distances guard according to 3.2.2 of EN 953:1997; interlocking guard with guard locking

5.3 Avoiding crushing hazards In order to avoid crushing hazards between fixed parts and machine parts that are moved in a lateral direction, the minimum distances specified in EN 349 shall be applied. Crushing hazards can also be avoided by limiting the forces applied at the crushing point to a non-hazardous level such that the movement can be stopped by reactive body force. NOTE As long as there is no relevant standard to refer to, it is taken that forces of less or equal 150 N generally do not present a risk of injury if it is a low-impulse movement and the contact surfaces are even or padded. 5.4 Drawing-in hazards on cylinders, rollers, rolls, felts, wires 5.4.1 Safety measures on inrunning nips The drawing-in hazards existing on inrunning nips of cylinders, rollers and rolls shall be avoided, wherever possible without restraining machine function, by providing adequate distance between rotating parts and fixed parts. The hazard of the whole body being drawn in is prevented if there is a safety distance of 500 mm between machine parts at the inrunning nip. See figure 1. The hazard of an arm being drawn in is prevented if there is a safe distance of at least 120 mm between machine parts at the inrunning nip. Applying the safety distance for the arm is only allowed if the inrunning nip cannot be reached by the body. Inrunning nips where drawing-in hazards cannot be avoided shall be protected by guards. NOTE This applies, for example, on the press section Suitable guards are: fixed or interlocking nip bars with guard locking according to EN 953 and EN 1088; fixed or interlocking distance guards with guard locking according to EN 953 and EN 1088; SIST EN 1034-1:2000+A1:2010

The gap between the guard and rotating machine parts should be as small as possible and shall not be more than 8 mm. The corner between the outer surface of the guard protecting the inrunning nip and the tangent line of the roller surface shall be obtuse or right angled. See figure 3. For guards that are not arranged directly on the inrunning nip, the distances listed in table 2 of

!EN ISO 13857:2008" shall apply. The following points shall be taken account of: The relevant distance „c“ between the guarding element and the danger area according to figure 2 of !EN ISO 13857:2008" is, when applied to inrunning nips, identical with the distance between guarding element and that plane in the inrunning nip where the distance „e“ is equal or more than 25 mm between the roller surfaces or between roller surface and fixed part. See figure 4.

Figure 3 — Examples of guards (nip bars) at inrunning nip (a ≤ 8mm)

Figure 4 — Example of distance guard protecting an inrunning nip. For values of a, b, c see figure 2 and table 2 of !EN ISO 13857:2008". e ≥ 25 mm 5.4.2 Safety measures on wrapping points

Wrapping points of felts, wires and tapes which are within the operator's reach shall be safeguarded by fixed guards. Preference shall be given to guards mounted directly on the wrapping point and thus preventing access. Where this is not possible or feasible, guards shall be mounted with safety distances according to

!EN ISO 13857:2008". Wrapping points which are accessible from passageways in the machine shall be protected by fixed guards machine-wide (see figure 5). 5.4.3 Instruction handbook The instruction handbook shall identify inrunning nips and wrapping points and describe their safeguarding. The instruction handbook shall also give instructions as to the proper fixing of guards after maintenance or felt changing.

a) front access b) side access

c) on felt guide roller d) on rope pulley f) fixed guard Figure 5 — Example of guard at wrapping point 5.5 Workplaces, access stairs, catwalks, passageways 5.5.1 For operating, make-ready, trouble-shooting as well as maintenance operations, work platforms including their access stairs and passageways shall be provided. Work platforms shall have adequate slip resistance and stability, protection against persons falling off as well as protection against mechanical and chemical effects including hazards from corrosion in the wet section. Platforms shall be designed both for a surface load of 5000 N/m² minimum and against vibration effects. 5.5.2 Access to stationary work platforms shall be selected and designed according to the specification given in table 3. The normal type of access to be provided is type 1. Type 1 access stairs have pitch angles of between 30° and 45°. SIST EN 1034-1:2000+A1:2010

Access

Type 1 (normal case) Type 2 (exception) Type 3 (exception) Designation stairs machine ladder stepladder Pitch angle 30° - 45° > 45°;

< 70° 70° - 90° Width1) > 0,60 m 0,50 - 0,80 m - 3) Height < 4,00 m < 4,00 m - 3) Height of railings2) 0,90 - 1,10 m 0,90 m - 3) Type of treads steps steps steps flat treads Further requirements !EN ISO 14122-3"!EN ISO 14122-3"!EN ISO 14122-4" 1) The width is measured between handrails 2) The height is measured on the front edge of the step 3) For requirements, see !EN ISO 14122-4".

Where type 1 access stairs cannot be used for productional reasons, type 2 access stairs shall be used or, where type 2 stairs are also not possible for technical reasons, type 3 stairs can be selected. Technical reasons can, for example, exist: a) where access stairs would unduly restrict the passage; b) where a connection is required between two adjacent workplaces of different height; c) where stairs would impede access to the machine for trouble shooting. For safe treading on any kind of access facility, steps are required to have a uniform height and depth, including the first and the last step. The maximum height of type 1 and type 2 access stairs shall be 4,00 m. Higher stairs shall be provided with an intermediate platform. 5.5.3 Type 2 access stairs described under 5.5.2 can have a pitch angle in the range of 45° to 70°. Pitch angles in excess of 60° should be avoided. Type 2 stairs with a height of more than 1,00 m shall be provided with two handrails for fall-off protection. The height of the handrail shall be 0,90 m above front edge of the tread. Intermediate rails are to be provided where the clearance below the handrail more than 0,50 m. See figure 6.

!

" Figure 6 — Access stairs type 2 5.5.4 Platform surfaces shall be slip resistant and avoid tripping hazards. 5.5.5 Covers on floor openings shall be capable of supporting possible traffic loads and shall be laid flush with the floor surface. It shall not be possible to unintentionally change the position of the cover nor shall projecting edges be caused by buckling or bending of the cover. SIST EN 1034-1:2000+A1:2010

In deviation, the height of safeguarding facilities against falling off can be less than 1,10 m where space available is restricted for operational reasons. In such cases, additional measures for fall-off protection shall be taken such as the provision of cranked rails. Railings shall be provided with a toe board designed in such a way as to prevent any person from slipping underneath the handrail. This can be achieved by fitting an intermediate rail with a maximum distance of 0,50 m between handrail and intermediate rail or between intermediate rail and toe board. The maximum distance between the outer railing elements and the adjacent fall-off protection elements such as individual railing elements, walls, frames, handrails on stairs shall not exceed 0,12 m. On working platforms with a falling height in the range of 0,60 m and 1,00 m, handrails shall be provided wherever possible without impeding productional or operational procedures. 5.5.8 Railings interrupted due to access to the work platform and catwalks having a falling height of more than 2,00 m shall be safeguarded against persons falling off. Danger of falling exists where access is via access stairs type 2 or type 3 according to 5.5.2. The risk of falling is considerably reduced where an intermediate platform is provided between access stairs and platform or catwalk or where access is from the narrow end of a catwalk. Safeguarding interrupted railings can be effected for example by automatically closing doors which open only in the direction of the work platforms or catwalk. Chains are no suitable means of safeguarding against persons falling off. 5.5.9 Stationary working platforms and their access stairs, catwalks and passageways shall have a clearance height of 2,00 m minimum. Where this height cannot be used for constructional reasons, the risk of injury shall be reduced by paddings and danger warning. 5.6 Start-up warning device 5.6.1 On machines where there is not a clear view of all work positions or where mutual communication is difficult, a start-up warning device shall be provided. Machinery that consists of several sections and where viewing and communication is difficult, a warning signal shall be issued prior to the start-up of each section. Start-up warning shall be made by an audible signal which can be supported by a visual signal. See EN 457. 5.6.2 The start-up warning device shall comply with !the Safety Integrity Level SIL 1 of EN 62061:2005 or the Performance Level PL c of EN ISO 13849-1:2008" unless otherwise required for the specific machines listed in annex A. The start-up warning device shall be coupled to the control element for starting the machine in such a way that between start of the warning signal and start-up of the machine there is sufficient time for persons to evacuate to a safe area.

Readiness of the machine to be started begins after elapse of the signal and the waiting time and ends after elapse of the release time. The waiting time is counted from the end of the signal. Start-up warnings are classified into categories A, B and C according to the table below. SIST EN 1034-1:2000+A1:2010

< 30 C 1 to 3 3

< 15

The machine-specific parts of this standard as listed in annex A of the present standard specify the category to be selected for the specific machine. Where no stipulations are made, category A shall be applied. 5.6.3 The function and handling of start-up warning devices shall be described in the instruction handbook. 5.7 Emergency stop devices Machines shall be equipped with an emergency stop device as defined in !5.5.2 of

EN ISO 12100-2:2003". The device shall satisfy the requirements of !EN ISO 13850" and EN 60204-1. It shall act on all hazardous movements of the machine. Emergency stop devices shall be sited within easy reach of the operator and shall be with a maximum distance of 15 m from any point on the machine. Emergency stop devices shall also be sited a) at every operator station; b) alongside the operating and drive sides; c) in machine pits; d) in all areas where access is required, for example for removing broke. Emergency stop devices shall be designed to take into account the fact that running with the rolls separated is likely to increase the dangers rather than to reduce them. For that reason, the opening of the roll nips in the course of an emergency function shall be possible only when the hazard of being drawn in has ceased to exist which in practical terms means the rotational movement has stopped. !The emergency stop function shall be available and operational at all times, regardless of the operating mode. Emergency stop devices shall be designed to back-up other safeguarding measures and not to substitute them." 5.8 Isolation and energy dissipation, prevention of unexpected start-up 5.8.1 For maintenance and inspection, adequate means shall be provided for isolation and dissipation of energy. They shall satisfy the requirements of EN 1037, 5.3 of !EN 60204-1:2006", EN 982, EN 983, and !5.5.4 of EN 12100-2:2003". Actuating devices for energy isolation shall be capable of being locked in the "isolated" position. Locking devices shall be designed such as to allow, where required, the provision of multiple padlock or key systems in accordance with 5.2 of EN 1037:1995. Means for energy isolation and dissipation are listed in table 5, classified according to type of energy: SIST EN 1034-1:2000+A1:2010

< 1 kV Supply disconnecting device according to 5.3 of !EN 60204-1:2006" Resistors for capacitators or other means according to !6.2.4 of EN 60204-1:2006" Electric current with voltage > 1kV Power supply switch disconnector with isolating properties, load disconnector, disconnector with interlocking to prevent switching in the current-carrying condition Means for earthing and short-circuiting Mechanical/kinetic energy from water steam or steam engine Disconnectable coupling Braking device Mechanical position energy (gravity) - Latch,

support, safety catch Hydraulics Supply disconnecting device according to 5.3 of !EN 60204-1:2006" for electrical supply; valve according to EN 982 Means according to EN 982 Pneumatics Shutoff valve according to 5.5.4.3 of EN 983:1996 Relief valve according to EN 983 Steam Valve and isolating device Drain pipe with valve

Supply disconnecting devices for electrical energy with voltages up to 1 kV are described in EN 60204-1. For voltages above 1 kV, isolating devices also need to provide an all-pole disconnection from the supply. Switching contact clearances shall be appropriate to ensure isolating for specific voltages. Switching/disconnecting devices shall be designed such that the risk of interference arcs is minimi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...