EN 9138:2019

(Main)Aerospace Series - Quality Management Systems - Statistical Product - Acceptance Requirements

Aerospace Series - Quality Management Systems - Statistical Product - Acceptance Requirements

1.1 Purpose

This European standard establishes requirements when implementing statistical product acceptance methods to meet defined risk requirements. This standard also establishes the minimum content required to be covered in an organization’s documented procedures that govern their application of statistical product acceptance methods.

These general requirements and documented procedures apply the requirements of the EN 9100/EN 9110/EN 9120 quality management system standards, in addition to establishing requirements for retrievability, safety/critical characteristics, and quality parameters that protect the customer.

1.2 Application

This standard is applicable when invoked in a purchasing contract or specification, contractual document, customer agreement, or adopted by the organization. The purchase contract/agreement may or may not identify the appropriate EN 9138 clause(s) to be applied by the organization. All statistical methods of product acceptance require the use of Clause 4 and Clause 5.

To accept product produced:

- by individual lots, see Clause 6;

- under switching rules, see Clause 7;

- under process controls, see Clause 8; and

- by continuous sampling or special case methods, see Clause 9.

Luft- und Raumfahrt - Qualitätsmanagementsysteme - Statistische Anforderungen für die Produktannahme

1.1 Zweck

Diese Europäische Norm legt die Anforderungen für die Einführung statistischer Verfahren für die Pro-duktannahme zur Erfüllung festgelegter Risikoanforderungen fest. Diese Norm legt auch den erforderlichen Mindestinhalt fest, der in den dokumentierten Verfahren einer Organisation zu behandeln ist, die die Anwendung von statistischen Verfahren für die Produktannahme regeln.

Diese allgemeinen Anforderungen und dokumentierten Verfahren wenden die Anforderungen nach den Qualitätsmanagementsystemnormen EN 9100/EN 9110/EN 9120 an, zusätzlich zur Festlegung von Anfor-derungen an die Rückholbarkeit, Sicherheitsmerkmale/kritische Merkmale und Qualitätsparameter, die den Kunden schützen.

1.2 Anwendung

Diese Norm gilt, wenn sich ein Kaufvertrag oder eine Spezifikation, Vertragsdokument, Kundenvereinbarung darauf berufen oder sie von der Organisation übernommen wird. Der/Die Kaufvertrag/-vereinbarung darf den/die entsprechenden Abschnitt/Abschnitte nach EN 9138 benennen, der/die von der Organisation anzu¬wenden ist/sind oder dies unterlassen. Alle statistischen Verfahren für die Produktannahme erfordern die Anwendung von Abschnitt 4 und Abschnitt 5.

Um Produkte anzunehmen, die hergestellt wurden

- durch Einzellose, siehe Abschnitt 6,

- unter Variierung des Prüfumfangs, siehe Abschnitt 7,

- mit Prozessüberwachungen, siehe Abschnitt 8 und

- durch kontinuierliche Stichprobenahme oder Verfahren für Sonderfälle, siehe Abschnitt 9.

Série aérospatiale - Systèmes de management de la qualité - Exigences d'acceptation statistique des produits

La présente norme s’applique lorsqu’elle est invoquée dans un contrat d’achat ou une spécification, un document contractuel, un contrat client ou qu’elle est adoptée par l’organisme. L’accord/contrat d’achat peut identifier ou non le(s) article(s) approprié(s) de l’EN 9138 à appliquer par l’organisme. Toutes les méthodes statistiques d’acceptation des produits exigent d’utiliser les Articles 4 et 5.

Pour accepter le produit fabriqué :

- en lots individuels, voir l’Article 6 ;

- conformément aux règles de modification du contrôle, voir l’Article 7 ;

- conformément aux maîtrises du processus, voir l’Article 8 ; et

- par échantillonnage continu ou à l’aide de méthodes pour cas particuliers, voir l’Article 9.

Aeronavtika - Sistemi vodenja kakovosti - Statistični proizvod - Zahteve za sprejem

Ta dokument določa zahteve pri izvajanju metod sprejemanja statističnega proizvoda za izpolnjevanje določenih zahtev glede tveganja. Standard prav tako določa minimalno vsebino, ki mora biti zajeta v dokumentiranih postopkih organizacije, ki ureja uporabo metod sprejemanja statističnega proizvoda. Te splošne zahteve in dokumentirani postopki upoštevajo zahteve iz standardov za sisteme vodenja kakovosti EN 9100/EN 9110/EN 9120, poleg tega pa določajo zahteve za dostopnost, varnostne/kritične značilnosti in parametre za kakovost, ki varujejo potrošnika. Uporaba: Ta standard se uporablja ob sklicevanju nanj v prodajni pogodbi ali specifikaciji, pogodbenem dokumentu, pogodbi z uporabnikom, ali če ga sprejme organizacija. V prodajni pogodbi/dogovoru bodo morda upoštevane ustrezne točke standarda EN 9138, ki jih mora organizacija uveljaviti. Vse statistične metode za sprejem proizvoda zahtevajo uporabo točk 4 in 5. Za sprejem izdelanega proizvoda: – po posameznih serijah, glej točko 6; – pod pravili za zamenjavo, glej točko 7; – pod nadzori procesov, glej točko 8; in – z neprekinjenim vzorčenjem ali po metodah posebnih primerov, glej točko 9.

General Information

- Status

- Published

- Publication Date

- 05-Nov-2019

- Withdrawal Date

- 30-May-2020

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 6/S 1 - EAQG European Aerospace Quality Group

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 21-Jan-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 9110:2018 - Quality Management Systems - Requirements for Aviation Maintenance Organizations - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 9138:2019 - Aerospace Series - Quality Management Systems - Statistical Product - Acceptance Requirements (CEN) defines mandatory requirements and minimum documented-procedure content for using statistical product acceptance methods in the aerospace sector. The standard is intended to ensure that statistical acceptance techniques meet defined risk and customer-protection requirements (including retrievability, safety/critical characteristics and quality parameters) and to align with EN 9100 / EN 9110 / EN 9120 quality management systems.

EN 9138:2019 is applied when invoked in a purchasing contract, specification, customer agreement or when adopted by an organization. All statistical methods require compliance with Clause 4 (General requirements) and Clause 5 (Required documented information).

Key topics and requirements

- Scope & application: Applicable when specified contractually or by the organization; clauses for different acceptance methods must be applied as directed.

- Mandatory documented procedures: Minimum content requirements for procedures covering responsibilities, training, non‑conformance control, monitoring, data retention and customer approvals.

- General requirements (Clause 4): Trained personnel, identification of safety/critical characteristics, selection of samples, evaluation systems, and auditing of statistical techniques.

- Information to document (Clause 5): Initial reliability or quality-parameter values, assignment of responsibilities and where methods apply, training programs, and performance monitoring.

- Acceptance methods:

- Individual lot acceptance (Clause 6)

- Switching rules (Clause 7)

- Process-control based acceptance (Clause 8) - includes Statistical Process Control (SPC), measurement systems, control limits, stability and capability concepts, retrievability and periodic audits

- Continuous, skip‑lot, sequential and other special-case sampling (Clause 9)

- Data and records: Requirements for unbiased sampling, time/production sequence considerations, data retention, and retrievability for customer protection.

- Auditing and performance: Internal audits of statistical methods, evaluation of corrective actions and criteria for process re‑evaluation.

Practical applications and users

Who uses EN 9138:2019:

- Aerospace manufacturers, suppliers and subcontractors applying statistical acceptance to parts, assemblies or lots

- Quality managers implementing EN 9100/EN 9110/EN 9120 aligned QMS with statistical techniques

- Procurement professionals and contracting authorities who invoke statistical acceptance in purchasing contracts

- Engineers and process-control teams using SPC, switching rules or continuous/skip‑lot sampling to reduce inspection while protecting safety/critical characteristics

Practical uses:

- Defining sampling strategies for lot acceptance

- Establishing SPC-based acceptance plans and retrievability systems

- Documenting training, responsibilities and customer-approved procedures

- Demonstrating compliance in supplier agreements and audits

Related standards

- EN 9100, EN 9110, EN 9120 (aerospace QMS)

- ISO, ANSI, SAE and IAQG publications (normative references cited within EN 9138)

Keywords: EN 9138:2019, statistical product acceptance, aerospace, quality management systems, sampling plans, SPC, switching rules, continuous sampling, retrievability, safety critical characteristics.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 9138:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace Series - Quality Management Systems - Statistical Product - Acceptance Requirements". This standard covers: 1.1 Purpose This European standard establishes requirements when implementing statistical product acceptance methods to meet defined risk requirements. This standard also establishes the minimum content required to be covered in an organization’s documented procedures that govern their application of statistical product acceptance methods. These general requirements and documented procedures apply the requirements of the EN 9100/EN 9110/EN 9120 quality management system standards, in addition to establishing requirements for retrievability, safety/critical characteristics, and quality parameters that protect the customer. 1.2 Application This standard is applicable when invoked in a purchasing contract or specification, contractual document, customer agreement, or adopted by the organization. The purchase contract/agreement may or may not identify the appropriate EN 9138 clause(s) to be applied by the organization. All statistical methods of product acceptance require the use of Clause 4 and Clause 5. To accept product produced: - by individual lots, see Clause 6; - under switching rules, see Clause 7; - under process controls, see Clause 8; and - by continuous sampling or special case methods, see Clause 9.

1.1 Purpose This European standard establishes requirements when implementing statistical product acceptance methods to meet defined risk requirements. This standard also establishes the minimum content required to be covered in an organization’s documented procedures that govern their application of statistical product acceptance methods. These general requirements and documented procedures apply the requirements of the EN 9100/EN 9110/EN 9120 quality management system standards, in addition to establishing requirements for retrievability, safety/critical characteristics, and quality parameters that protect the customer. 1.2 Application This standard is applicable when invoked in a purchasing contract or specification, contractual document, customer agreement, or adopted by the organization. The purchase contract/agreement may or may not identify the appropriate EN 9138 clause(s) to be applied by the organization. All statistical methods of product acceptance require the use of Clause 4 and Clause 5. To accept product produced: - by individual lots, see Clause 6; - under switching rules, see Clause 7; - under process controls, see Clause 8; and - by continuous sampling or special case methods, see Clause 9.

EN 9138:2019 is classified under the following ICS (International Classification for Standards) categories: 03.120.10 - Quality management and quality assurance; 49.020 - Aircraft and space vehicles in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 9138:2019 has the following relationships with other standards: It is inter standard links to ISO/IEC Guide 98-4:2012, ISO 3951-1:2013, ISO 9000:2015, ISO/IEC Guide 98-1:2009, ISO 11462-2:2010, ISO/IEC Guide 98-3:2008, EN 9100:2018, EN 196-1:1994, EN 9120:2018, EN 9110:2018, EN 2943:2024, EN 9103:2023, EN 2943:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 9138:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2020

Aeronavtika - Sistemi vodenja kakovosti - Statistični proizvod - Zahteve za sprejem

Aerospace Series - Quality Management Systems - Statistical Product - Acceptance

Requirements

Luft- und Raumfahrt - Qualitätsmanagementsysteme - Statistische

Produktannahmeanforderungen

Série Aérospatiale - Système de management de la qualité - Exigences d'acceptation

statistique des produits

Ta slovenski standard je istoveten z: EN 9138:2019

ICS:

03.120.10 Vodenje in zagotavljanje Quality management and

kakovosti quality assurance

49.020 Letala in vesoljska vozila na Aircraft and space vehicles in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 9138

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2019

EUROPÄISCHE NORM

ICS 03.120.10; 49.020

English Version

Aerospace Series - Quality Management Systems -

Statistical Product - Acceptance Requirements

Série aérospatiale - Systèmes de management de la Luft- und Raumfahrt - Qualitätsmanagementsysteme -

qualité - Exigences d'acceptation statistique des Statistische Produktannahmeanforderungen

produits

This European Standard was approved by CEN on 10 December 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 9138:2019 E

worldwide for CEN national Members.

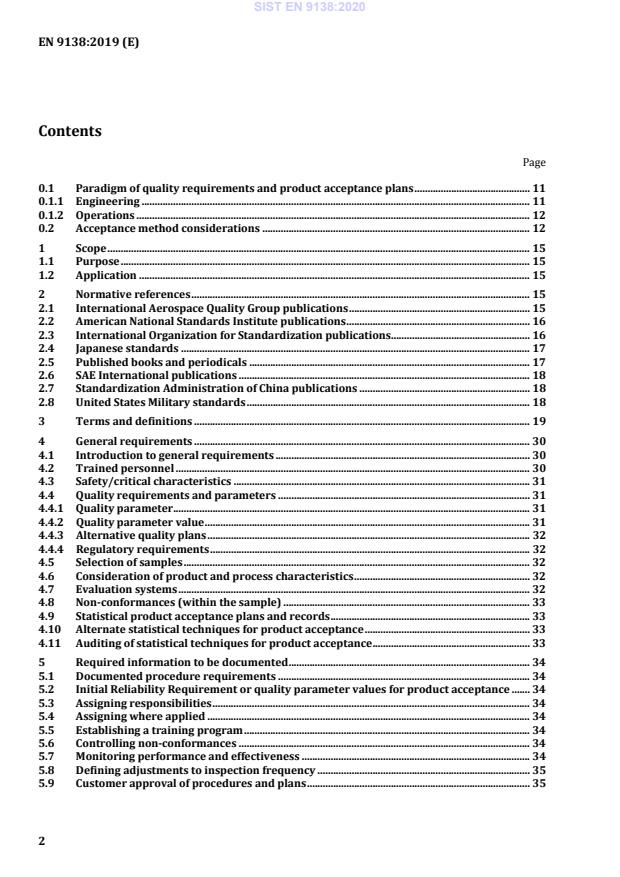

Contents

Page

0.1 Paradigm of quality requirements and product acceptance plans . 11

0.1.1 Engineering . 11

0.1.2 Operations . 12

0.2 Acceptance method considerations . 12

1 Scope . 15

1.1 Purpose . 15

1.2 Application . 15

2 Normative references . 15

2.1 International Aerospace Quality Group publications . 15

2.2 American National Standards Institute publications . 16

2.3 International Organization for Standardization publications . 16

2.4 Japanese standards . 17

2.5 Published books and periodicals . 17

2.6 SAE International publications . 18

2.7 Standardization Administration of China publications . 18

2.8 United States Military standards . 18

3 Terms and definitions . 19

4 General requirements . 30

4.1 Introduction to general requirements . 30

4.2 Trained personnel . 30

4.3 Safety/critical characteristics . 31

4.4 Quality requirements and parameters . 31

4.4.1 Quality parameter . 31

4.4.2 Quality parameter value . 31

4.4.3 Alternative quality plans . 32

4.4.4 Regulatory requirements . 32

4.5 Selection of samples . 32

4.6 Consideration of product and process characteristics . 32

4.7 Evaluation systems . 32

4.8 Non-conformances (within the sample) . 33

4.9 Statistical product acceptance plans and records . 33

4.10 Alternate statistical techniques for product acceptance . 33

4.11 Auditing of statistical techniques for product acceptance . 33

5 Required information to be documented . 34

5.1 Documented procedure requirements . 34

5.2 Initial Reliability Requirement or quality parameter values for product acceptance . 34

5.3 Assigning responsibilities . 34

5.4 Assigning where applied . 34

5.5 Establishing a training program . 34

5.6 Controlling non-conformances . 34

5.7 Monitoring performance and effectiveness . 34

5.8 Defining adjustments to inspection frequency . 35

5.9 Customer approval of procedures and plans . 35

6 Requirements for accepting product by individual lots . 35

6.1 General requirements for individual lot sampling . 35

6.2 Quality parameters for individual lot sampling . 35

6.2.1 Delivered product conformance probability parameters . 35

6.2.2 Probability of acceptance parameters . 35

6.3 Sample sizes for individual lots . 35

7 Requirements for accepting product under switching rules . 35

7.1 General requirements for switching rules . 35

7.2 Background information for switching rules . 36

7.3 Quality parameter with switching rules . 36

7.4 Requirements for accepting product with switching rules . 36

7.4.1 Sampling documentation . 36

7.4.2 General conditions . 36

7.4.3 Sampling plan criteria. 37

7.4.4 Qualification criteria for sampling . 37

7.5 Requirements for accepting product by variables sampling plans using switching

rules . 37

7.5.1 Variable sampling application limits . 37

7.5.2 Evaluating lot quality . 37

7.5.3 Related requirements . 37

8 Requirements for accepting product produced under process controls . 38

8.1 General process control requirements . 38

8.1.1 Data . 38

8.1.2 Reducing inspection with process controls . 38

8.1.3 Measurement systems . 38

8.1.4 Training program . 38

8.1.5 Process control points . 39

8.1.6 Process control acceptance plans and records . 39

8.1.7 Unbiased sampling . 39

8.1.8 Time or production order sequence . 39

8.1.9 Data retention plan . 39

8.1.10 Periodic internal audits . 39

8.1.11 Retrievability system . 39

8.1.12 Limiting errors in measurement and recording . 39

8.1.13 Evaluating effects of corrective actions . 39

8.2 Statistical Process Control . 39

8.2.1 Methods . 40

8.2.2 Location and dispersion . 40

8.2.3 Basis for control limits . 40

8.2.4 Basis for stability . 40

8.2.5 Investigation . 41

8.2.6 Violation of stability . 41

8.2.7 Re-evaluation of stability and capability . 41

8.2.8 Capability and process control . 41

8.2.9 Process monitoring frequency . 42

8.3 Variation restrictions . 42

8.4 Process parameter controls . 42

9 Additional requirements for accepting products based on continuous sampling,

skip-lot sampling, or methods for special cases . 43

9.1 Continuous sampling . 43

9.1.1 Quality parameters for continuous sampling . 43

9.1.2 Inspection sequence . 43

9.1.3 General conditions . 43

9.1.4 Supply Chain Management Handbook continuous sampling tables . 43

9.2 Skip-lot sampling. 44

9.2.1 General conditions for skip-lot sampling . 44

9.2.2 Quality protection equivalency . 44

9.2.3 Considerations for subsequent lots . 44

9.3 Sampling strategies for special cases . 44

9.3.1 Special sampling customer approvals . 44

9.3.2 Special case statistical validity . 44

9.3.3 Predicting quality from correlated variables . 45

9.3.4 Continuous manufacturing process – First and last unit for a lot produced . 45

9.3.5 Sequential sampling . 45

9.4 Other methods for special cases . 45

Annex A (informative) Guidelines for assigning Initial Reliability Requirement quality

levels . 46

A.1 Introduction . 46

A.2 Assigning quality levels . 46

A.3 Initial Reliability Requirements . 46

Annex B (informative) Acronym log . 49

Annex C (informative) Mathematics for accepting product under lot-by-lot inspection . 52

C.1 Yield estimation . 52

C.1.1 Yield estimates . 53

C.1.2 Confidence limits on yield estimates . 53

C.2 Probability of acceptance mathematics . 55

C.2.1 Hypergeometric probability of acceptance . 55

C.2.2 Legacy Pa lot acceptance mathematics . 56

C.2.3 Yield rates, discrete units, and conformance probabilities . 57

C.2.4 Impact lot sampling methods on delivered yield . 58

C.3 Controlling the probability of conformance for delivered product . 60

C.3.1 Average Outgoing Quality Limits . 60

C.3.2 Average Outgoing Quality Limit sample sizes . 61

C.3.3 Outgoing Quality Confidence Limit sample sizes . 62

C.3.4 Lot sampling with deliveries from the sample of failed lots . 63

C.3.5 Probability of acceptance sample sizes . 64

C.3.6 Lot sampling with destructive tests . 64

C.4 Mathematics to control clustering . 65

C.4.1 Formulation for cluster control . 65

C.4.2 Fixed number of maximum escapements . 66

C.4.3 Controlling clusters in increasing lot sizes . 66

Annex D (informative) Guidelines and recommendations for successful implementation of

statistical product acceptance methods . 67

D.1 Guidelines for 4.2 — Trained personnel. 67

D.1.1 General training . 67

D.1.2 Training for lot sampling . 67

D.1.3 Training for product acceptance based on process controls . 68

D.1.4 Training for continuous sampling, lot sampling with switching rules, skip-lot

sampling, or process control methods . 68

D.1.5 Non-published statistical methods . 68

D.2 Guidelines for 4.3 — Safety/critical characteristics . 68

D.3 Guidelines for 4.4 — Quality requirements and parameters . 69

D.3.1 Guidelines for Initial Reliability Requirement assignment . 69

D.3.2 Guidelines for quality parameter measures . 69

D.4 Guidelines for 4.5 — Selection of samples . 69

D.4.1 Sampling recommendations . 69

D.4.2 Simple random sampling . 70

D.4.3 Stratification sampling . 70

D.4.4 Systematic sampling . 70

D.4.5 Cluster sampling . 70

D.4.6 Representative sampling without randomization . 70

D.5 Guidelines for 4.6 — Identification of product characteristics . 71

D.6 Guidelines for 4.7 — Evaluation systems . 71

D.6.1 Measurement devices . 71

D.6.2 Non-Destructive Testing . 71

D.6.3 Destructive testing . 72

D.7 Guidelines for 4.8 — Non-conformances (within the sample) . 72

D.7.1 Non-conformance risks . 72

D.7.2 C = 0 sampling . 72

D.7.3 Retrievability in reduced, continuous, or skip-lot sampling . 73

D.8 Guidelines for 4.9 — Statistical product acceptance plans and records . 73

D.8.1 Statistical product acceptance plans . 73

D.8.2 Acceptance records . 73

D.8.3 Training records . 74

D.9 Guidelines for 4.10 — Alternate statistical techniques for product acceptance . 74

D.10 Guidelines for 4.11 — Auditing of statistical techniques for product acceptance . 74

D.11 Guidelines for 5.3 — Assigning responsibilities . 75

D.12 Guidelines for 5.4 — Assigning where applied . 75

D.13 Guidelines for 5.5 — Establishing a training program . 76

D.14 Guidelines for 5.6 — Controlling non-conformances . 76

D.15 Guidelines for 5.7 — Monitoring performance and effectiveness . 76

Annex E (informative) Discussion on the technical rationale and history of the relationship

of quality parameters to reliability . 77

E.1 Technical rationale for quality — Reliability relationship in quality parameters . 77

E.1.1 Minimum probability of conformance . 78

E.1.2 Probability of non-conformance . 78

E.1.3 Reliability . 78

E.2 History of quality — Reliability relationship in quality parameters . 78

E.2.1 Acceptable Quality Level . 79

E.2.2 Average Outgoing Quality Limit . 79

E.2.3 Short run sampling . 80

E.3 Recommended quality parameter choices . 80

E.4 Consideration of cluster effects . 81

Annex F (informative) Guidelines for choosing a statistical product acceptance technique

and quality parameter . 82

F.1 Guidance for choosing a method of statistical product acceptance . 82

F.1.1 General guidance . 82

F.1.2 Clause-specific guidance . 83

F.2 Directions to match a quality parameter to a statistical acceptance technique . 84

F.2.1 Guidelines for applying quality parameters . 84

F.2.2 Overview of quality parameter relationships to Initial Reliability Requirement . 84

F.2.3 Quality parameters for individual lot sampling . 84

F.2.4 Quality parameters for lot sampling with switching rules . 84

F.2.5 Quality parameters for product acceptance using process controls . 85

F.2.6 Quality parameters for continuous sampling and special methods . 85

F.3 Assigned by feature and tolerance. 85

Annex G (informative) Guidelines and recommendations for accepting product by

individual lots . 86

G.1 Introduction . 86

G.1.1 Process steps for evaluating individual or isolated lots . 86

G.1.2 Selecting an appropriate sampling model . 87

G.1.3 Screening lots . 88

G.2 Guidelines for 6.1.2 — Delivered product conformance probability parameters . 89

G.3 Guidelines for 6.2.2 — Probability of acceptance parameters . 89

G.4 Guidelines for relating AQL to a quality parameter . 90

G.5 Guidelines for 6.3 — Sample sizes for individual lots . 90

Annex H (informative) Guidelines for some special acceptance methods . 91

H.1 Continuous sampling extensions . 91

H.1.1 Guidelines for skip-lot sampling plans . 91

H.1.2 Guidelines for variables continuous sampling . 91

H.1.3 Poisson continuous sampling . 92

H.2 Process characterization . 93

H.2.1 Guidelines for 9.3.3 — Predicting quality from correlated variables . 93

H.2.2 Guidelines for 9.3.4 — Lot acceptance by first and last unit inspections . 94

H.2.3 Guidelines for Expected Outgoing Quality . 95

H.3 Probability Outgoing Quality Limit. 97

H.4 Validation of special acceptance methods — Simulation . 97

H.5 Guidance for small production volumes . 97

Annex I (informative) Guidelines and recommendations for accepting product produced

under switching rules . 98

I.1 Guidelines for Clause 7 — Requirements for accepting product produced under

switching rules . 98

I.2 Guidelines for 7.4 — Requirements for accepting product produced in repetitive lots

by attribute sampling plans . 98

I.3 Guidelines for 7.5 — Requirements for accepting product produced in repetitive lots

by variables sampling plans . 99

Annex J (informative) Guidelines and recommendations for accepting product produced

under process controls . 100

J.1 Guidelines for 8.1 — General process control requirements . 100

J.1.1 Guidelines for 8.1.12 — Limiting errors in measurement and recording . 100

J.2 Guidelines for 8.2 — Statistical Process Control. 100

J.2.1 Guidelines for 8.2.1 — Methods . 100

J.2.2 Guidelines for 8.2.3 — Basis for control limits . 101

J.2.3 Guidelines for 8.2.5 — Investigation . 101

J.2.4 Guidelines for 8.2.6 — Violation of stability . 102

J.3 Guidelines for 8.3 — Variation restrictions . 102

J.4 Guidelines for 8.4 — Process parameter controls . 102

J.5 Step-by-step summary . 103

Annex K (informative) Guidelines and recommendations for accepting product based on

continuous sampling . 104

K.1 Applicability of continuous sampling . 104

K.1.1 Conditions necessary for continuous sampling plans . 104

K.1.2 Conditions when continuous sampling inspection might be desirable . 105

K.1.3 Conditions when sampling plans require approval . 105

K.2 Types of continuous sampling plans . 105

K.3 Implementing continuous sampling . 106

K.3.1 Guidelines for 9.1.1 — Quality parameters . 106

K.3.2 Guidelines for 9.1.2 — Inspection sequence . 106

K.3.3 Submission of product . 106

K.3.4 Sample selection . 106

K.3.5 Corrective action indications . 106

K.3.6 Example continuous sampling plan . 106

Bibliography . 109

Figures

Figure 1 — Engineering and operations inputs into product acceptance plan . 11

Figure 2 — EN 9138 clause selection guide . 13

Figure 3 — Typical Statistical Process Control chart depicting control limits, warning limits, and

zones . 40

Figure C.1 — Average Outgoing Quality Operating Characteristic curve with Average Outgoing

Quality Limit and Initial Reliability Requirement limit . 62

Figure C.2 — Average Outgoing Quality Operating Characteristic curve where failed lots are

scrapped . 63

Figure C.3 — Points on Average Outgoing Quality Operating Characteristic curve for meeting

Initial Reliability Requirement when salvaging sample units from failed lots . 64

Figure G.1 — Flowchart for identifying lot sampling method . 88

Figure H.1 — Example graphic Confidence Level to match Initial Reliability Requirements . 94

Figure K.1 — Illustration of CSP-1 continuous sampling . 107

Tables

Table 1 — Acceptable Quality Level to Average Outgoing Quality Limit conversion . 32

Table 2 — True C requirements . 41

pk

Table A.1 — Minimum probability conformance values . 47

Table C.1 — Table of mathematical variables . 52

Table C.2 — Minimum sample sizes needed for a yield Confidence Level when no non-conformities

are detected . 55

Table C.3 — Expected escapements and delivered units . 59

Table C.4 — Average Outgoing Quality formulas for lot sampling categories. 60

Table C.5 — Average Outgoing Quality formulas for examining lot size limits . 61

Table C.6 — Expected escapements delivered units when tests are destructive . 64

Table E.1 — Formulas for converting quality parameter specifications into an Initial Reliability

Requirement . 80

Table E.2 — Conversion of Acceptable Quality Level specification to Average Outgoing Quality

Limit . 81

Table F.1 — Guidelines to determine inspection logistics . 82

Table F.2 — Quality parameter value to Initial Reliability Requirement value comparisons . 84

Table H.1 — Example computations for Expected Outgoing Quality . 96

Table I.1 — Example Acceptable Quality Level values to use to meet a required

3 % Average Outgoing Quality Limit . 99

Table K.1 — Values "i" for choice of "f" and Average Outgoing Quality Limit . 108

European foreword

This document (EN 9138:2019) has been prepared by the Aerospace and Defence Industries

Association of Europe - Standardization (ASD-STAN).

After enquiries and votes carried out in accordance with the rules of this Association, this Standard has

received the approval of the National Associations and the Official Services of the member countries of

ASD, prior to its presentation to CEN.

This European Standard shall be given the status of a national standard, either by pub

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...