EN 12203:2003+A1:2009

(Main)Footwear, leather and imitation leather goods manufacturing machines - Shoe and leather presses - Safety requirements

Footwear, leather and imitation leather goods manufacturing machines - Shoe and leather presses - Safety requirements

This European Standard is applicable to shoe and leather presses (see 3.1) used in the manufacture of footwear, leather and imitation leather goods and other related components. These machines are:

- Sole attaching presses (open and closed types);

- Sole and insole moulding machines;

- Back part moulding machines;

- Backer, lining and toe puff attaching presses;

- Ironing presses;

- Marking, stamping, labelling and embossing machines;

- Stitch marking machines;

- Upper preforming machines;

- Automatic shoe and leather presses;

a) Premoulding machines for thermoplastic counters and counter forming machines;

b) Integrated manufacturing systems;

c) Presses with mobile stations and rotary configuration;

- Folding presses;

- Activating presses;

- Relasting and last slipping machines;

- Top piece attaching presses;

- Leather button covering machines.

1.2 This European Standard is not applicable to:

- Cutting and punching machines;

NOTE !See EN 12044."

- Eyelet, hook and decorative nail attaching machines;

"deleted text"

- Presses used for shoe repair and orthopaedic works

NOTE "See EN 12387."

1.3 This European Standard specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1.

It takes account of intended use, foreseeable misuse, component and system failure.

1.4 This European Standard covers significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (List of hazards see 4.)

This European Standard does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health.

The use of machines within the scope of this European Standard in industries other than those specified in 1.1 can give rise to hazard not considered during its preparation.

Maschinen zur Herstellung von Schuhen, Leder- und Kunstlederwaren - Schuh- und Lederpressen - Sicherheitsanforderungen

Machines pour la fabrication des chaussures et articles chaussants en cuir et matériaux similaires - Presses pour la fabrication de chaussures et articles en cuir - Exigences de sécurité

1.1 La présente Norme européenne s'applique aux presses pour la fabrication de chaussures et d'articles en cuir (voir 3.1) utilisées pour la fabrication d'articles chaussants et autres articles en cuir ou matériaux en imitation cuir, ou autres accessoires de même type. La liste de ces machines est la suivante :

- machines à souder les semelles ;

- machines à galber les semelles et/ou les premières ;

- machines à galber l'emboîtage ;

- machines à gutter les renforts, la doublure et les bouts durs ;

- machines à déplisser ;

- machines à griffer, marquer, étiqueter et gaufrer ;

- machines à imprimer les piqûres ;

- machines à prégalber la tige ;

- presses automatiques pour la fabrication de chaussures et articles en cuirs :

- machines à prégalber les contreforts thermoplastiques et machines à galber des contreforts ;

- systèmes intégrés de fabrication ;

- presses à postes mobiles et configuration rotative ;

- presses à remplier ;

- presses à activer ;

- machines à monter sur forme et à déformer ;

- presses à bonbouter ;

- machines à recouvrir les boutons de cuir.

1.2 La présente Norme européenne ne s'applique pas dans les cas suivants :

- machines à découper et à poinçonner ;

NOTE !Voir EN 12044."

- machines à poser les œillets, crochets et clous décoratifs ;

!texte supprimé"

- machines pour réparation de chaussures ou pour applications orthopédiques.

NOTE !Voir EN 12387."

1.3 La présente Norme européenne spécifie les exigences de sécurité pour la construction, le transport, l'installation, la mise au point, le réglage, l’apprentissage et le changement de processus de fabrication, le fonctionnement, le nettoyage, la maintenance, la mise hors service, le démontage et, dans la mesure où la sécurité est concernée, la mise au rebut des machines mentionnées en 1.1.

Elle prend en compte l'utilisation normale, le mauvais usage prévisible ainsi que les défaillances des composants et du système.

(...)

Stroji za izdelavo obutve, izdelkov iz usnja in njegovih imitacij - Stiskalnice za čevlje in usnje - Varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 11-Aug-2009

- Technical Committee

- CEN/TC 201 - Leather and imitation leather goods and footwear manufacturing machinery - Safety

- Drafting Committee

- CEN/TC 201/WG 7 - Shoe and leather presses

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 22-Jun-2022

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 20-Jun-2009

- Effective Date

- 20-Jun-2009

- Effective Date

- 20-Jun-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12203:2003+A1:2009 is a European Standard (CEN) that specifies safety requirements for shoe and leather presses used in the manufacture of footwear, leather and imitation‑leather goods. It covers a wide family of machines - from sole‑attaching and moulding presses to ironing, stamping, preforming and fully automatic presses - and addresses safety across the machine lifecycle: construction, transport, installation, adjustment, operation, cleaning, maintenance, decommissioning and disposal (see scope/Clause 1.3). The standard is a type C machine‑specific standard (EN ISO 12100 framework) and supports EU Machinery Directive requirements (see informative Annexes ZA/ZB).

Key Topics

EN 12203 focuses on practical machine safety areas relevant to footwear machinery, including:

- Hazard identification and risk assessment (significant hazards listed in Clause 4)

- Mechanical safety and guards (fixed and movable guards, interlocking, Annex A–B)

- Control systems and electrical safety (control strategies, two‑fault safety, Annex J)

- Protective devices - trip devices, two‑hand controls, hold‑to‑run, pressure mats (Annex C–F)

- Thermal protection and burn thresholds (Annex M)

- Noise control and measurement (design stage noise control and noise test code, Annex O)

- Ergonomics, tool setting and feeding systems (operator interaction and safe tooling, Annex G)

- Pressurized fluid systems and safety strokes

- Verification, documentation and information for use (testing, manuals, marking, declared noise values)

- Special requirements for specific machine types (sole attaching, folding, activating, relasting, button covering, automatic systems - Clause 5 and Annex N for automatic systems planning)

Note: the standard does not provide precise technical measures for control of fumes and dusts detrimental to health.

Applications / Who Uses It

EN 12203 is essential for:

- Machine manufacturers and designers building shoe and leather presses to meet European safety requirements

- Safety engineers and OEM compliance teams performing risk assessments and selecting guards, interlocks and control systems

- Plant managers and maintenance staff implementing safe operation, adjustment and maintenance procedures

- Notified bodies, test laboratories and certification authorities verifying conformity with the Machinery Directive

- System integrators designing automated footwear production lines (see Annex N)

Practical uses include preparing operating manuals, specifying safety devices (ESPDs, interlocks, two‑hand controls), setting up verification tests (noise, guards), and ensuring safe machine installation and decommissioning.

Related Standards

- EN 12044 - cutting and punching machines (see note in EN 12203)

- EN 12387 - machines for shoe repair and orthopaedic work (excluded from scope)

- EN ISO 12100 - general principles for machine safety (type A/B/C standard structure)

Keywords: EN 12203, footwear machinery safety, shoe presses, leather presses, machine guarding, noise test code, CEN standard, Machinery Directive, risk assessment.

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Bureau Veritas Bangladesh

Bureau Veritas certification services in Bangladesh.

ECOCERT France

Leader in organic and sustainability certification worldwide.

Sponsored listings

Frequently Asked Questions

EN 12203:2003+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Footwear, leather and imitation leather goods manufacturing machines - Shoe and leather presses - Safety requirements". This standard covers: This European Standard is applicable to shoe and leather presses (see 3.1) used in the manufacture of footwear, leather and imitation leather goods and other related components. These machines are: - Sole attaching presses (open and closed types); - Sole and insole moulding machines; - Back part moulding machines; - Backer, lining and toe puff attaching presses; - Ironing presses; - Marking, stamping, labelling and embossing machines; - Stitch marking machines; - Upper preforming machines; - Automatic shoe and leather presses; a) Premoulding machines for thermoplastic counters and counter forming machines; b) Integrated manufacturing systems; c) Presses with mobile stations and rotary configuration; - Folding presses; - Activating presses; - Relasting and last slipping machines; - Top piece attaching presses; - Leather button covering machines. 1.2 This European Standard is not applicable to: - Cutting and punching machines; NOTE !See EN 12044." - Eyelet, hook and decorative nail attaching machines; "deleted text" - Presses used for shoe repair and orthopaedic works NOTE "See EN 12387." 1.3 This European Standard specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1. It takes account of intended use, foreseeable misuse, component and system failure. 1.4 This European Standard covers significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (List of hazards see 4.) This European Standard does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health. The use of machines within the scope of this European Standard in industries other than those specified in 1.1 can give rise to hazard not considered during its preparation.

This European Standard is applicable to shoe and leather presses (see 3.1) used in the manufacture of footwear, leather and imitation leather goods and other related components. These machines are: - Sole attaching presses (open and closed types); - Sole and insole moulding machines; - Back part moulding machines; - Backer, lining and toe puff attaching presses; - Ironing presses; - Marking, stamping, labelling and embossing machines; - Stitch marking machines; - Upper preforming machines; - Automatic shoe and leather presses; a) Premoulding machines for thermoplastic counters and counter forming machines; b) Integrated manufacturing systems; c) Presses with mobile stations and rotary configuration; - Folding presses; - Activating presses; - Relasting and last slipping machines; - Top piece attaching presses; - Leather button covering machines. 1.2 This European Standard is not applicable to: - Cutting and punching machines; NOTE !See EN 12044." - Eyelet, hook and decorative nail attaching machines; "deleted text" - Presses used for shoe repair and orthopaedic works NOTE "See EN 12387." 1.3 This European Standard specifies safety requirements for construction, transport, installation, adjustment, setting, teaching or process change-over, operation, cleaning, maintenance, decommissioning, dismantling and, as far as safety is concerned, disposal for machines mentioned in 1.1. It takes account of intended use, foreseeable misuse, component and system failure. 1.4 This European Standard covers significant hazards relevant to the footwear, leather and imitation leather goods manufacturing industries. (List of hazards see 4.) This European Standard does not deal with precise technical measures for reducing the risks of fumes and dusts detrimental to health. The use of machines within the scope of this European Standard in industries other than those specified in 1.1 can give rise to hazard not considered during its preparation.

EN 12203:2003+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 59.140.40 - Machines and equipment for leather and fur production; 61.060 - Footwear. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12203:2003+A1:2009 has the following relationships with other standards: It is inter standard links to EN 12203:2003/prA1, EN 12203:2003, EN 12203:2003/AC:2006, EN IEC 60947-5-1:2025, EN 61496-1:2004, CLC/TS 61496-2:2006, EN 2286:1989, EN 547-2:1996+A1:2008, EN 294:1992, EN 547-1:1996+A1:2008, EN 349:1993, EN 894-2:1997+A1:2008, EN ISO 4414:2010, EN 1760-1:1997, EN 574:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12203:2003+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12203:2003+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Maschinen zur Herstellung von Schuhen, Leder- und Kunstlederwaren - Schuh- und Lederpressen - SicherheitsanforderungenMachines pour la fabrication des chaussures et articles chaussants en cuir et matériaux similaires - Presses pour la fabrication de chaussures et articles en cuir - Exigences de sécuritéFootwear, leather and imitation leather goods manufacturing machines - Shoe and leather presses - Safety requirements61.060ObuvalaFootwear59.140.40Stroji in oprema za proizvodnjo usnja in krznaMachines and equipment for leather and fur productionICS:Ta slovenski standard je istoveten z:EN 12203:2003+A1:2009SIST EN 12203:2004+A1:2009en01-oktober-2009SIST EN 12203:2004+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12203:2003+A1

August 2009 ICS 59.140.40; 61.060 Supersedes EN 12203:2003English Version

Footwear, leather and imitation leather goods manufacturing machines - Shoe and leather presses - Safety requirements

Machines pour la fabrication des chaussures et articles chaussants en cuir et matériaux similaires - Presses pour la fabrication de chaussures et articles en cuir - Exigences de sécurité

Maschinen zur Herstellung von Schuhen, Leder- und Kunstlederwaren - Schuh- und Lederpressen - Sicherheitsanforderungen This European Standard was approved by CEN on 1 November 2002 and includes Corrigendum 1 issued by CEN on 5 July 2006 and Amendment 1 approved by CEN on 16 July 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12203:2003+A1:2009: ESIST EN 12203:2004+A1:2009

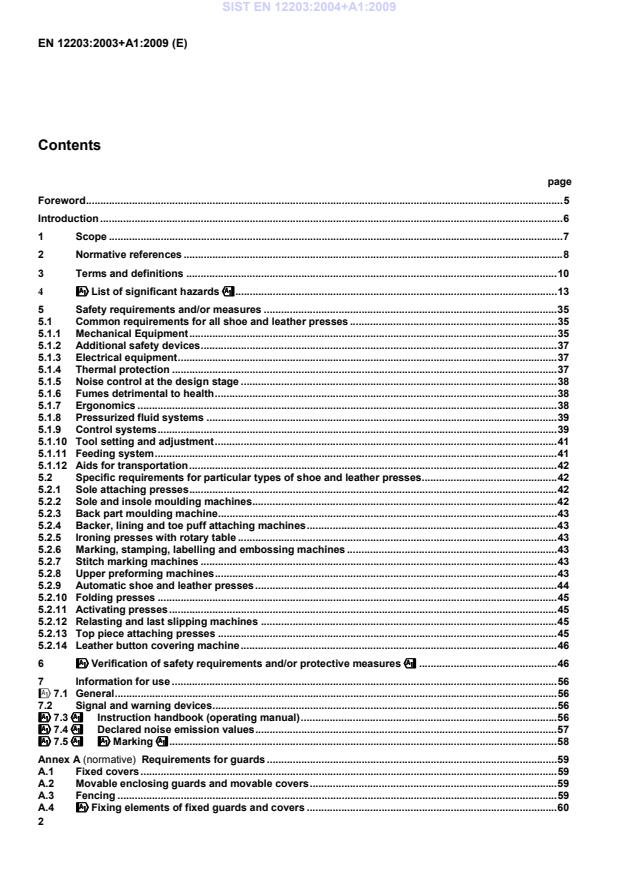

Requirements for guards . 59A.1Fixed covers . 59A.2Movable enclosing guards and movable covers . 59A.3Fencing . 59A.4!!!!Fixing elements of fixed guards and covers . 60SIST EN 12203:2004+A1:2009

Requirements for interlocking devices Interlocking guards with and without guard locking . 61B.1Interlocking guards without guard locking with one interlocking system and one position sensor . 61B.2!!!!Interlocking guards without guard locking, with one interlocking system and two position sensors"""" . 61B.3Interlocking guards with one interlocking system and one position sensor with guard locking . 61Annex C (normative)

Requirements for trip devices . 62C.1Mechanical trip device with one position sensor . 62C.2Electro-sensitive protective devices (ESPD) with normal level . 62C.3Electro-sensitive protective devices (ESPD) with high level . 63C.4Electro-sensitive protective devices (high level) with control function . 64Annex D (normative)

Requirements for two-hand control devices . 65D.1Two-hand control devices (normal level) . 65D.2Two-hand control devices (high level) . 65Annex E (normative)

Requirements for hold-to-run control devices . 68E.1Hold-to-run control devices (stop function) . 68E.2Hold-to-run control devices (reverse function) . 68Annex F (normative)

Requirements for pressure sensitive mats and floors . 70Annex G (normative)

Requirements for safe tools . 71Annex H (normative)

Requirements for stop and release control devices . 72Annex I (normative)

Requirements for safety stroke devices . 73Annex J (normative)

Two-fault safety of machine control system . 74Annex K (normative)

Control measures for the suspension of safeguards . 75Annex L (normative)

Requirements for control guards (interlocking guards with start function) . 77Annex M (normative)

Temperatures of burn threshold . 78Annex N (normative)

Important considerations and requirements for planning, design and construction of automatic manufacturing systems . 79N.1Project organisation . 79N.2Application of a safety strategy . 79N.3Risk assessment . 79N.4Requirements for documentation . 79N.5Starting . 79N.6Emergency stop . 80Annex O (normative)

!!!!Noise test code for shoe and leather presses . 82O.1Scope . 82O.2Definitions . 82O.2.1Material . 82O.2.2Processing temperature. 82O.2.3Test cycle . 82O.2.4Operator standing / sitting area (operating area) . 82O.3Description of machinery family . 82O.4Measurement of A-weighted sound power level . 82O.5Measurement of A-weighted emission sound pressure level . 83O.5.1 Position of microphone for determination of A-weighted emission sound pressure level at the workstation . 83O.6Operating conditions . 83O.7Measurement uncertainties . 83O.8Documentation . 83Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""" . 85SIST EN 12203:2004+A1:2009

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 86

1 Scope 1.1 This European Standard is applicable to shoe and leather presses (see 3.1) used in the manufacture of footwear, leather and imitation leather goods and other related components. These machines are: Sole attaching presses (open and closed types); Sole and insole moulding machines; Back part moulding machines; Backer, lining and toe puff attaching presses; Ironing presses; Marking, stamping, labelling and embossing machines; Stitch marking machines; Upper preforming machines; Automatic shoe and leather presses; a) Premoulding machines for thermoplastic counters and counter forming machines; b) Integrated manufacturing systems; c) Presses with mobile stations and rotary configuration; Folding presses; Activating presses; Relasting and last slipping machines; Top piece attaching presses; Leather button covering machines. 1.2 This European Standard is not applicable to: Cutting and punching machines; NOTE !!!!See EN 12044." Eyelet, hook and decorative nail attaching machines; !deleted text" Presses used for shoe repair and orthopaedic works NOTE !See EN 12387." SIST EN 12203:2004+A1:2009

3.1 shoe and leather press machine with closing movements for attaching, moulding, ironing, marking, stamping, labelling, embossing, preforming, folding, activating, relasting, last slipping and button covering 3.2 sole attaching press (see Figure 1) machine for attaching precemented soles to lasted uppers by pressure 3.3 sole and insole moulding machine (see Figure 2) machine used to preform soles and insoles to the shape of last bottom by means of moulds and pressure 3.4 back part moulding machine (see Figure 3) machine used for laminating upper counter and lining and preforming to the heel part shape of last by pressure and heat 3.5 backer, lining and toe puff attaching press (see e.g. Figure 4) machine used for laminating backer, lining and toe puffs to the upper by pressure and heat 3.6 ironing press (see e. g. Figure 5) machine used for attaching, smoothing, flattening and shaping the upper by pressure and heat 3.7 marking, stamping, labelling and embossing machine (see e.g. Figures 6 and 7) machine used for marking, designation and decoration of shoes, leather goods and related components by pressure and heat including sling-form presses 3.8 stitch marking machine (see Figure 8) machine used to mark the location of stitch seams and components on relevant workpieces by pressure and heat 3.9 upper preforming machine (see Figure 9) machine used to preshape uppers to style related requirements by pressure and heat 3.10 premoulding machine for thermoplastic counter (see Figure 10) machine used to shape thermo-plastic counter blanks to the last form by pressure and heat or by pressure heat and cooking SIST EN 12203:2004+A1:2009

4.3.1 Transmission machinery and drive mechanism entanglement, drawing-in and trapping, friction, crushing

4.3.2 Moving machinery parts of

- Electrical crushing, shearing, impact, drawing-in or trapping

- Hydraulic

- Pneumatic

- mechanical units and workpieces

4.3.3 Feeding area

- clamping device crushing 3

- tray feeder impact 4, 6, 12

- rotary feeding table drawing-in or trapping, friction or abrasion 5, 7

- handling devices crushing and shearing 10, 11

- conveyor shearing, drawing in or trapping, friction or abrasion

4.3.4 Processing area

Closing and opening movements of

- pressing pad crushing 1

- moulding tools 1, 2, 3

- top and bottom pressing plate 4, 5

- marking tools

- stamping tools

- labelling tools

- embossing tools 6, 7

- attaching tools 1

- forming tools 9

- ironing tools 4, 5

- activating tools 13, 14

- stitch marking tools

- upper preforming/counter premoulding and forming tools

- folding tools

- tool components

- pressing tools

- tool for relasting and last slipping

Table 1 — !!!!List of significant hazards"""" (continued) Danger zone or source of hazard Type of hazard Figure 4.3.5 Operator’s area

- uneven, sloping, slippery platforms slipping, tripping and falling

- steps

- protruding parts

- unintended start up by foot-actuated controls all possible hazards

4.3.6 Movement of machine due to gravity while being transported crushing, shearing

4.4 Electrical hazards

Electrical contact, direct or indirect, caused by electric shock, burns

- component failure

- insulation failure

- incorrect design, installation or component specifications of the electrical equipment

4.5 Thermal hazards

Accidental contact with hot surfaces risk of burns

4.6 Noise

- hydraulic unit (pump) damage to hearing or loss of hearing, interference with speech-communication and perception of acoustic signals

- extraction equipment

- pneumatic unit

- mechanical impact

4.7 Neglect of ergonomic principles risk of occupational disease

- inadequate local lighting accidents resulting from poor visibility

- poor operator posture fatigue

- excessive effort during loading and unloading physical and mental stress

- poor control layout and display identification psychological stress

- unsuitable height and size in relations to human body dimensions muscolo-skeletal injury/respectively strain injury

Table 1 — !!!!List of significant hazards"""" (continued) Danger zone or source of hazard Type of hazard Figure 4.8 Functional disorders:

4.8.1 Controls and energy supply

- failure of control system (malfunction of safety devices and machine control) all possible hazards generated by unexpected dangerous movements (e. g. unexpected start or closing movement)

- fault of energy supply (irregularity failure, unexpected reconnection)

4.9 High pressure fluid ejection or ejection of a part of a burst component by failure of hydraulic or pneumatic equipment (broken hoses, fittings and pipework) injury from hot oil or impact from flexible hoses

Key a) open type b) closed type Figure 1 — Sole attaching press SIST EN 12203:2004+A1:2009

Key 1 tool, in pairs 2 storage for finished insoles Figure 2 — Semi-Automatic Sole and insole Moulding Machine SIST EN 12203:2004+A1:2009

Key a) processing area (moulding) b) loading area (clamping) Figure 3 — Back Part Moulding Machine SIST EN 12203:2004+A1:2009

Key a) feeding and processing area b) processing area - front view c) feeding area

- top view 1 processing 2 feeding Figure 4 — One-Station Toe Puff Attaching Machine SIST EN 12203:2004+A1:2009

Key a) feeding and processing area

b) feeding area – top view c) processing area – side view Figure 5 — Ironing Press with Rotating Table SIST EN 12203:2004+A1:2009

Key a) side view b) side view 1 feeding area

2 processing area Figure 6 — Single Station Embossing Machine SIST EN 12203:2004+A1:2009

Key 1 processing area 2 feeding area

Figure 7 — Embossing Machine with rotary configuration SIST EN 12203:2004+A1:2009

Key a) side view

Figure 8 — Stitch Marking Machine SIST EN 12203:2004+A1:2009

Key a) processing area – tool open – front view b) processing area – tool closed – front view c) processing area – end of forming movement – front view 1 feeding 2 closing Figure 9 — Upper Preforming Machine

Key 1 feeding area

Figure 10 — Premoulding machine for thermoplastic counters

Key a) view from top b) processing area

1 feeding area Figure 11 — Automatic Counter Forming Machine SIST EN 12203:2004+A1:2009

Key a) side view 1 processing 2 feeding Figure 12 — Folding presses SIST EN 12203:2004+A1:2009

Figure 13 — Activating Press (upper) SIST EN 12203:2004+A1:2009

Figure 14 — Activating Press (counter)

™ Figure 15 — Last Slipping Machine SIST EN 12203:2004+A1:2009

Figure 16 — Last Slipping Machine

Figure 17 — Top Piece Attaching Machine SIST EN 12203:2004+A1:2009

Figure 18 — Button Covering Machine SIST EN 12203:2004+A1:2009

EN 60204-1,

etc., the manufacturer should carry out a risk assessment to establish the requirements of the type B-standard to be applied. This specific risk assessment should be part of the general risk assessment of the machine. 5.1 Common requirements for all shoe and leather presses 5.1.1 Mechanical Equipment 5.1.1.1 Transmission machinery and drive mechanisms All transmission machinery and drive mechanisms shall be safeguarded by fixed enclosing guards which meet the requirements of EN 953 !and A.4," unless otherwise stated in 5.2 for a particular machine. 5.1.1.2 Moving machinery parts, feeding systems, workpieces 5.1.1.2.1 Hazardous motions of moving machinery parts, feeding system and workpieces shall be safeguarded with preference in the order of the following listing !deleted text" by fixed enclosing guards which meet the requirements of !A.4 and" EN 953; or fixed covers which meet the requirements of A.1 !and A.4"; or fencing which meets the requirements of A.3 !and A.4"; or interlocking guards which meet the requirements of EN 953 and A.1, A2 of this standard; or inlet safety devices which meet the requirements of B.1. 5.1.1.2.2 Where protective measures as given in 5.1.1.2.1 cannot be provided, because this is not the state of the art, devices shall be provided which will effect a shutdown of the hazardous motion before the danger point is reached. Devices which will effect this are: Inlet safety devices in form of a trip device, such as electro-sensitive protective device, which meets the requirements of C.2; mechanical trip bars which meet the requirements of C.1; pressure sensitive mats and floors which meet the requirements of Annex F; two-hand control devices which meet the requirements of D.1. 5.1.1.3 Processing area 5.1.1.3.1 Unless required by 5.2 for hand protection from the operator’s side the shoe and leather presses shall be safeguarded with preference in the order of the following listing by: safe tools which meet the requirements of Annex G; or SIST EN 12203:2004+A1:2009

b) the hazardous motions can only be actuated by a hold-to-run control device which meets the requirements of E.2 of this standard. 5.1.1.4 5.1.1.3.1 and 5.1.1.2.1 do not apply, and safeguards are not required if the maximum force of moving parts is limited to 150 N and the contact pressure is limited to 50 N/m2 until such time as a B-standard for maximum forces and contact pressures is agreed;

feeding gaps between moving surfaces in the processing area do not exceed 8,0 mm and the distance from any gap to the nearest danger point is equal to more than 20 mm in accordance with EN 294:1992, table 4. 5.1.1.5 To prevent access from the rear and the sides, shoe and leather presses of frame-type construction and automatic presses shall be safeguarded with preference in the order of the following listing by fixed enclosing guards which meet the requirements of !A.4 and" EN 953; or fixed covers which meet the requirements of A.1 !and A.4" of this standard; or interlocking guards which meet the requirements of EN 1088. 5.1.1.6 Operator’s area 5.1.1.6.1 At the area, where the operator is standing for recurring manual intervention platforms shall be of good grip and steps and protruding parts shall be avoided to prevent slipping, tripping and falling. 5.1.1.6.2 Foot-actuated controls which actuate hazardous motion and which are not fixed to the machine, and foot-actuated controls at standing working positions, shall be safeguarded against accidental operation by provision of a cover around the foot-actuated control. SIST EN 12203:2004+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...