EN 13616-1:2025

(Main)Overfill prevention devices for static tanks for liquid fuels - Part 1: Overfill prevention devices with closure device

Overfill prevention devices for static tanks for liquid fuels - Part 1: Overfill prevention devices with closure device

This document specifies requirements, test and assessment methods, marking, labelling and packaging applicable to overfill prevention devices with closure device. The devices are usually composed by:

- sensor;

- evaluation device;

- closure device.

Overfill prevention devices intended to be used in/with underground and/or above ground, non-pressurized, static tanks designed for liquid fuels.

NOTE Liquid fuel means liquids for internal combustion engines, heating/cooling boilers and generators.

Überfüllsicherungen für ortsfeste Tanks für flüssige Brenn- und Kraftstoffe - Teil 1: Überfüllsicherungen mit Schließeinrichtung

Dieses Dokument legt Anforderungen, Prüf- und Bewertungsverfahren, Kennzeichnung, Etikettierung und Verpackung fest, die für Überfüllsicherungen mit Schließeinrichtung gelten. Die Überfüllsicherungen bestehen gewöhnlich aus:

- Sensor;

- Bewertungseinrichtung;

- Schließeinrichtung.

Überfüllsicherungen sind für die Verwendung in/mit unter- und/oder oberirdischen, drucklosen, ortsfesten Tanks für flüssige Brenn- und Kraftstoffe vorgesehen.

ANMERKUNG Flüssige Brenn- und Kraftstoffe bedeutet Flüssigkeiten für Verbrennungsmotoren, Heiz-/Kühlkessel und Generatoren.

Dispositifs limiteurs de remplissage pour réservoirs statiques pour carburants liquides - Partie 1 : Dispositifs limiteurs de remplissage avec dispositif de fermeture

Le présent document spécifit les exigences, les méthodes d’essai et d’évaluation, le marquage, l’étiquetage et l’emballage applicables aux dispositifs limiteurs de remplissage avec dispositif de fermeture. Ces dispositifs sont généralement constitués :

- d’un capteur ;

- d’un dispositif d’évaluation ;

- d’un dispositif de fermeture.

Les dispositifs limiteurs de remplissage sont destinés à être utilisés dans/avec des réservoirs statiques enterrés et/ou aériens, hors pression, conçus pour les carburants liquides.

NOTE Le terme « carburants liquides » désigne les liquides utilisés pour les moteurs à combustion interne, les installations de chauffage/refroidissement et les générateurs.

Naprave za preprečitev prepolnitve za nepremične rezervoarje za tekoča goriva - 1. del: Naprave za preprečitev prepolnitve z zaporno napravo

General Information

- Status

- Published

- Publication Date

- 19-Aug-2025

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 20-Aug-2025

- Due Date

- 13-Aug-2025

- Completion Date

- 20-Aug-2025

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 13616-1:2025 (CEN)

EN 13616-1:2025 specifies requirements, test and assessment methods, marking, labelling and packaging for overfill prevention devices with closure device used with underground and/or above‑ground, non‑pressurized static tanks for liquid fuels. The standard covers device composition (sensor, evaluation device, closure device) and performance limits to reliably stop deliveries before a tank overfills. It was prepared by CEN/TC 393 and supersedes EN 13616-1:2016.

Key topics and technical requirements

- Device types and construction

- Devices are typically composed of a sensor, evaluation device, and closure device.

- Classified as vapour tight (no vapour leakage) or non‑vapour tight (limited vapour leak equivalent to a Ø3 ±0,05 mm hole at ~3,5 ±0,5 kPa).

- Performance and effectiveness

- Operational flow velocity range: 0.2–3 m/s (±5% tolerance).

- Closure behaviour: definitions for initial closure level (two‑stage devices) and final closure level (single or two‑stage devices).

- Pressure limits noted - e.g. device must not re‑open at static pressure > (15 ±5%) kPa after closure and withstand static pressure of at least (200 ±5%) kPa (for gravity filling).

- Operational leak rate limits after closure are defined.

- Testing and assessment

- Detailed test methods: chemical suitability, temperature range, component pressure tests, pressure surge, function tests, mechanical strength, vapour tight / non‑vapour tight procedures, and durability (closure cycling).

- Annexes provide test rig layouts, diameter/flow rate guidance and an environmental checklist.

- Marking, labelling and packaging

- Requirements for product identification, instruction plates and user instructions.

- Factory Production Control (FPC)

- Clause on FPC retained to ensure consistent manufacturing and quality.

Applications and users

- Practical for manufacturers and designers of overfill prevention devices, fuel handling equipment and tank components.

- Relevant to operators and safety managers at service stations, fleet depots, heating fuel storage sites, and facilities with static tanks for liquid fuels (vehicles, boilers, generators).

- Useful for test laboratories, conformity assessors and procurement/specification teams who need to ensure compliance with European safety and ATEX related requirements for equipment used in potentially explosive atmospheres.

Related standards and context

Standards and guidance referenced in EN 13616-1:2025 include: EN 228, EN 590, EN 14214, CEN/TR 15993, EN 1127-1, EN 60079-14, EN ISO 80079-36/37, and others addressing fuels, explosive atmospheres and non‑electrical equipment. Annex A addresses equipment use in hazardous areas and avoidance of ignition sources.

Keywords: EN 13616-1:2025, overfill prevention devices, static tanks, liquid fuels, closure device, vapour tight, operational leak rate, test methods, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 13616-1:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Overfill prevention devices for static tanks for liquid fuels - Part 1: Overfill prevention devices with closure device". This standard covers: This document specifies requirements, test and assessment methods, marking, labelling and packaging applicable to overfill prevention devices with closure device. The devices are usually composed by: - sensor; - evaluation device; - closure device. Overfill prevention devices intended to be used in/with underground and/or above ground, non-pressurized, static tanks designed for liquid fuels. NOTE Liquid fuel means liquids for internal combustion engines, heating/cooling boilers and generators.

This document specifies requirements, test and assessment methods, marking, labelling and packaging applicable to overfill prevention devices with closure device. The devices are usually composed by: - sensor; - evaluation device; - closure device. Overfill prevention devices intended to be used in/with underground and/or above ground, non-pressurized, static tanks designed for liquid fuels. NOTE Liquid fuel means liquids for internal combustion engines, heating/cooling boilers and generators.

EN 13616-1:2025 is classified under the following ICS (International Classification for Standards) categories: 23.020.10 - Stationary containers and tanks; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13616-1:2025 has the following relationships with other standards: It is inter standard links to EN 13616-1:2016, EN 60079-14:2014, EN 590:2022, EN 228:2012+A1:2017, EN 1127-1:2019, EN ISO 22854:2021, EN 14214:2012+A2:2019, CEN/TR 15993:2018, EN ISO 80079-37:2016, EN ISO 80079-36:2016, EN 12285-4:2025, EN 13341:2005+A1:2011, EN 15208:2014, EN 13575:2012, EN 15969-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13616-1:2025 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 305/2011; Standardization Mandates: M/131, M/596, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13616-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2025

Nadomešča:

SIST EN 13616-1:2016

Naprave za preprečitev prepolnitve za nepremične rezervoarje za tekoča goriva - 1.

del: Naprave za preprečitev prepolnitve z zaporno napravo

Overfill prevention devices for static tanks for liquid fuels - Part 1: Overfill prevention

devices with closure device

Überfüllsicherungen für ortsfeste Tanks für flüssige Brenn- und Kraftstoffe - Teil 1:

Überfüllsicherungen mit Schließeinrichtung

Dispositifs limiteurs de remplissage pour réservoirs statiques pour carburants liquides -

Partie 1 : Dispositifs limiteurs de remplissage avec dispositif de fermeture

Ta slovenski standard je istoveten z: EN 13616-1:2025

ICS:

23.020.10 Nepremične posode in Stationary containers and

rezervoarji tanks

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13616-1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2025

EUROPÄISCHE NORM

ICS 75.200 Supersedes EN 13616-1:2016

English Version

Overfill prevention devices for static tanks for liquid fuels -

Part 1: Overfill prevention devices with closure device

Dispositifs limiteurs de remplissage pour réservoirs Überfüllsicherungen für ortsfeste Tanks für flüssige

statiques pour carburants liquides - Partie 1 : Brenn- und Kraftstoffe - Teil 1: Überfüllsicherungen

Dispositifs limiteurs de remplissage avec dispositif de mit Schließeinrichtung

fermeture

This European Standard was approved by CEN on 13 July 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13616-1:2025 E

worldwide for CEN national Members.

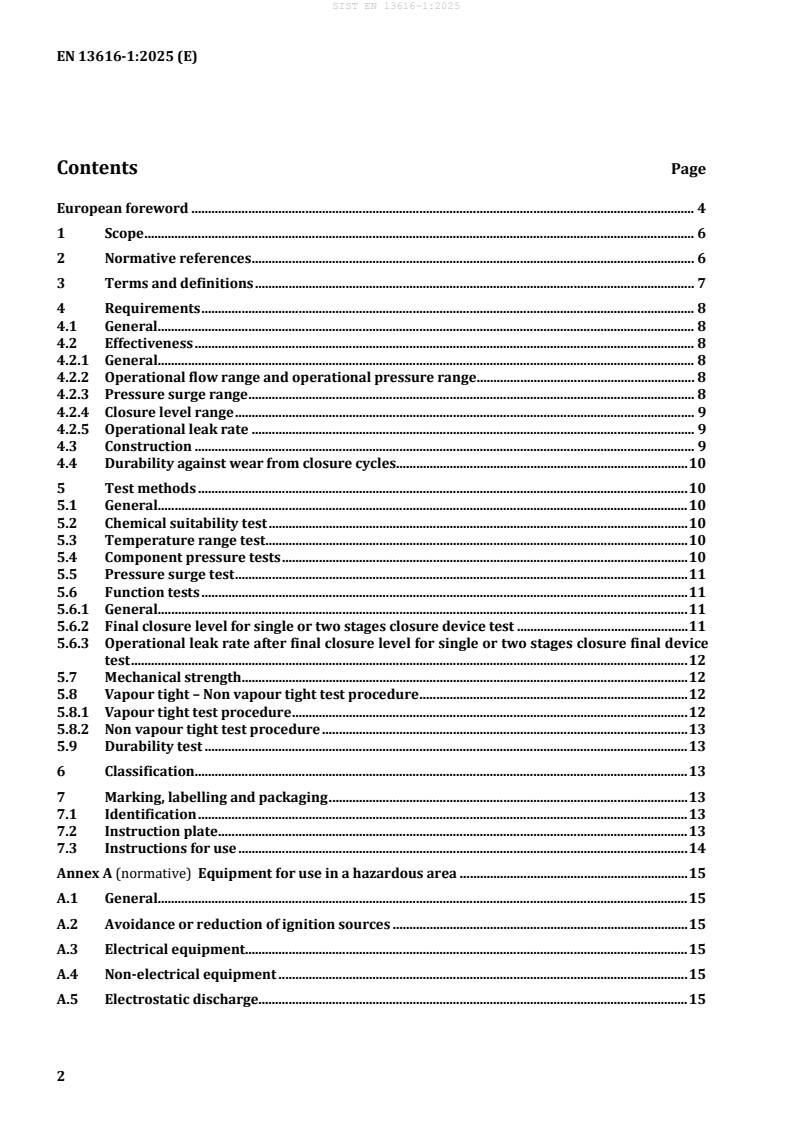

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Requirements . 8

4.1 General. 8

4.2 Effectiveness . 8

4.2.1 General. 8

4.2.2 Operational flow range and operational pressure range . 8

4.2.3 Pressure surge range . 8

4.2.4 Closure level range . 9

4.2.5 Operational leak rate . 9

4.3 Construction . 9

4.4 Durability against wear from closure cycles. 10

5 Test methods . 10

5.1 General. 10

5.2 Chemical suitability test . 10

5.3 Temperature range test. 10

5.4 Component pressure tests . 10

5.5 Pressure surge test . 11

5.6 Function tests . 11

5.6.1 General. 11

5.6.2 Final closure level for single or two stages closure device test . 11

5.6.3 Operational leak rate after final closure level for single or two stages closure final device

test . 12

5.7 Mechanical strength . 12

5.8 Vapour tight – Non vapour tight test procedure . 12

5.8.1 Vapour tight test procedure . 12

5.8.2 Non vapour tight test procedure . 13

5.9 Durability test . 13

6 Classification. 13

7 Marking, labelling and packaging . 13

7.1 Identification . 13

7.2 Instruction plate . 13

7.3 Instructions for use . 14

Annex A (normative) Equipment for use in a hazardous area . 15

A.1 General. 15

A.2 Avoidance or reduction of ignition sources . 15

A.3 Electrical equipment. 15

A.4 Non-electrical equipment . 15

A.5 Electrostatic discharge. 15

Annex B (normative) Test rig layouts . 16

Annex C (normative) Additional information on diameter and flow rate . 17

Annex D (informative) Environmental checklist . 18

Annex ZA (informative) Relationship between this European Standard and the essential health and

safety requirements of Directive 2014/34/EU aimed to be covered . 20

Bibliography . 23

European foreword

This document (EN 13616-1:2025) has been prepared by Technical Committee CEN/TC 393 “Equipment

for storage tanks and for service stations”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2026, and conflicting national standards shall

be withdrawn at the latest by February 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights other than those identified above. CEN shall not be held responsible for identifying any or

all such patent rights.

This document supersedes EN 13616-1:2016.

a) Clause 2: Normative references were updated;

b) 3.2: The term “initial closure level” was replaced by “initial closure level for two stages closure device

only”;

c) 3.3: The term “final closure level” was replaced by “final closure level for single or two stages closure

final device”;

d) 3.9: New definition was added;

e) 4.2.1 and 4.2.3: Tolerance of ±5 % was added;

f) 5.2: Chemical suitability test was updated;

g) 5.3: Temperature range for final closure simulation was deleted;

h) New subclause 5.5: Subclause relating to pressure surge test was removed from previous subclause

on function test (5.6);

i) New Clause 6: Only FPC (Factory Production Control) aspects were kept according to previous

Clause 6 “AVCP”;

j) Figure B.1: Key was updated;

k) Table C.1: Maximum flow rate values were updated;

l) Annex ZA “Construction products Regulation - CPR” was deleted due to the fact that revision is not

candidate to the harmonization to CPR (but only to ATEX Directive).

An environmental check-list is indicated in the informative Annex D.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies requirements, test and assessment methods, marking, labelling and packaging

applicable to overfill prevention devices with closure device. The devices are usually composed by:

— sensor;

— evaluation device;

— closure device.

Overfill prevention devices intended to be used in/with underground and/or above ground, non-

pressurized, static tanks designed for liquid fuels.

NOTE Liquid fuel means liquids for internal combustion engines, heating/cooling boilers and generators.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 228:2012+A1:2017, Automotive fuels — Unleaded petrol — Requirements and test methods

EN 590:2022, Automotive fuels — Diesel — Requirements and test methods

EN 1127-1:2019, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic concepts

and methodology

EN 14214:2012+A2:2019, Liquid petroleum products — Fatty acid methyl esters (FAME) for use in diesel

engines and heating applications — Requirements and test methods

CEN/TR 15993:2018, Automotive fuels — Ethanol (E85) automotive fuel — Background to the parameters

required and their respective limits and determination

EN ISO 22854:2021, Liquid petroleum products — Determination of hydrocarbon types and oxygenates in

automotive-motor gasoline and in ethanol (E85) automotive fuel — Multidimensional gas chromatography

method (ISO 22854:2021)

EN 60079-14:2014, Explosive atmospheres — Part 14: Electrical installations design, selection and

erection (IEC 60079-14:2013)

EN ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements (ISO 80079-36:2016)

EN ISO 80079-37:2016, Explosive atmospheres — Part 37: Non-electrical equipment for explosive

atmospheres — Non-electrical type of protection constructional safety ''c'', control of ignition sources ''b'',

liquid immersion ''k'' (ISO 80079-37:2016)

As impacted by EN 60079-14:2014/AC:2016.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

overfill prevention device

device installed in a supply system, which automatically stops the delivery, preventing the liquid level in

the tank exceeding a final closure level for single or two stages closure final device

3.2

initial closure level for two stages closure device only

lower level than final closure level at which the overfill prevention device stops the liquid flow and which

level it can be reopened

3.3

final closure level for single or two stages closure device

level at which the overfill prevention device prevents any further product, apart from a permissible leak

rate, entering the storage tank

3.4

supply system

connection hoses, fittings, devices, pumps and any fixed pipework through which the liquid is delivered

to the static tank from any tank vehicle

Note 1 to entry: The supply system includes both tank vehicle and stationary tank equipment.

Note 2 to entry: In case of gravity filling, the supply system will not include pumps.

3.5

tank vehicle

vehicle built to carry liquids in integral tanks comprising one or more compartments intended for

discharge to static tanks

Note 1 to entry: The tank vehicle can integrate a pump.

3.6

operational leak rate

permitted flow rate of liquid allowed to pass through the overfill prevention device after initial or final

closure

3.7

operational pressure

pressure in the filling pipe which can be reached during the filling of the tank, excluding the pressure

during the closure of the overfill prevention device

3.8

vapour tight overfill prevention device

device where no vapour can pass through from the ullage spaces in normal operation

3.9

non vapour tight overfill prevention device

device where vapour can pass through from the ullage spaces in normal operation

4 Requirements

4.1 General

The overfill prevention device shall be either vapour tight or non-vapour tight:

— Vapour tight: The overfill prevention device shall not leak vapour between the tank vapour space to

the filling pipe.

— Non vapour tight: The overfill prevention device shall not present an overall vapour leak greater than

the equivalent leak from a hole of Ø (3 ± 0,05) mm at a pressure (3,5 ± 0,5) kPa pressure.

NOTE An environmental check-list is provided in the informative Annex D.

4.2 Effectiveness

4.2.1 General

For pressure, flow velocity, flow rate and time the tolerances are ±5 %.

4.2.2 Operational flow range and operational pressure range

4.2.2.1 General

The diameter and flow rate for overfill prevention device with closure device are given in Annex C.

4.2.2.2 Overfill prevention device for gravity filling only

The device shall work at flow velocities between 0,2 m/s and 3 m/s ± 5 %.

The device shall not re-open at a static pressure > (15 ± 5 %) kPa after closure.

The device shall withstand static pressure of at least (200 ± 5 %) kPa after closure.

4.2.2.3 Overfill prevention device for gravity or pump filling

The device shall work at flow velocities between 0,2 m/s and 3 m/s ± 5 %.

The device shall not open at a static pressure > (15 ± 5 %) kPa after closure.

The device shall withstand a static pressure of at least (600 ± 5 %) kPa or (800 ± 5 %) kPa after closure

according to manufacturer’s declaration.

4.2.3 Pressure surge range

4.2.3.1 General

The operation of the overfill prevention device shall not generate pressure in excess of the design criteria

of the supply system.

4.2.3.2 Overfill prevention device for gravity filling only

Any pressure surge created by the overfill prevention device at closure, exceeding (300 ± 5 %) kPa, shall

not exceed a period of more than (10 ± 5 %) ms.

4.2.3.3 Overfill prevention device for gravity or pump filling

For pumps with a performance of (600 ± 5 %) kPa, any pressure surge created by the overfill prevention

device at closure exceeding (900 ± 5 %) kPa shall not exceed a period of more than (10 ± 5 %) ms.

For pumps with a performance of (800 ± 5 %) kPa any pressure surge created by the overfill prevention

device at closure exceeding (1 200 ± 5 %) kPa shall not exceed a period of more than (10 ± 5 %) ms.

4.2.4 Closure level range

4.2.4.1 General

For both, single and two stage closure devices once the final closure level for single or two stages closure

final device is reached, no further liquid other than the operational leak rate (see 4.2.5) shall enter the

tank.

The final closure level for single or two stages closure final device shall be set so that after final closure

of any device, the contents of the flexible delivery hose (and preferably the site delivery pipe) can be

emptied into the tank.

4.2.4.2 Single stage closure device

On filling the tank to the final closure level for single stage closure device, a complete and automatic

closure of the flow, other than the operational leak rate (see 4.2.5), shall be effected.

4.2.4.3 Two stages closure device

On filling the tank to the initial closure level and the final closure level for two stages closure device is

reached, a complete and automatic closure of the flow, other than the operational leak rate (see 4.2.5),

shall be effected.

4.2.5 Operational leak rate

The device shall not have a leak flow rate greater than (300 ± 20) l/h after initial or final closure level for

single or two stages closure final device at operational pressure.

4.3 Construction

4.3.1 Requirements for equipment for use in hazardous area according to Annex A.

4.3.2 All construction materials shall be compatible with and resist chemical attack by the liquid and

its vapours, within the temperature range of −20 °C to +40 °C. The manufacturer shall specify all materials

in contact with the liquid. Chemical suitability shall be tested in accordance with 5.2.

NOTE For equipment designed for operation in explosive atmospheres the normal ambient temperature range

is −20 °C to +40 °C, unless otherwise specified and marked.

See Annex A and relevant standards indicated for complete information.

4.3.3 The overfill prevention device shall be of a durable construction. Durability shall be tested in

accordance with 5.2, 5.6 and test rig according to Annex B.

4.3.4 All parts of the overfill prevention device situated either internally or externally on the tank shall

0 +10

withstand static negative pressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...