EN 1127-1:2019

(Main)Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology

Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology

This document specifies methods for the identification and assessment of hazardous situations leading to explosion and the design and construction measures appropriate for the required safety. This is achieved by:

- risk assessment;

- risk reduction.

The safety of equipment, protective systems and components can be achieved by eliminating hazards and/or limiting the risk, i.e. by:

a) appropriate design (without using safeguarding);

b) safeguarding;

c) information for use;

d) any other preventive measures.

Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in Clause 6, measures according to c) against explosions are dealt with in Clause 7. Measures in accordance with d) are not specified in this document. They are dealt with in EN ISO 12100:2010, Clause 6.

The preventive and protective measures described in this document will not provide the required level of safety unless the equipment, protective systems and components are operated within their intended use and are installed and maintained according to the relevant codes of practice or requirements.

This document specifies general design and construction methods to help designers and manufacturers in achieving explosion safety in the design of equipment, protective systems and components.

This document is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres, under atmospheric conditions. These atmospheres can arise from flammable/combustible substances processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components.

This document is applicable to equipment, protective systems and components at all stages of its use.

This document is only applicable to equipment group II which is intended for use in other places than underground parts of mines and those parts of surface installations of such mines endangered by firedamp and/or combustible dust.

This document is not applicable to:

1) medical devices intended for use in a medical environment;

2) equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosive substances or unstable chemical substances;

3) equipment, protective systems and components where the explosion can occur by reaction of substances with other oxidizers than atmospheric oxygen or by other hazardous reactions or by other than atmospheric conditions;

4) equipment intended for use in domestic and non-commercial environments where potentially explosive atmospheres may only rarely be created, solely as a result of the accidental leakage of fuel gas;

5) personal protective equipment covered by Regulation (EU) 2016/425;

6) seagoing vessels and mobile offshore units together with equipment on board such vessels or units;

7) means of transport, i.e. vehicles and their trailers intended solely for transporting passengers by air or by road, rail or water networks, as well as means of transport insofar as such means are designed for transporting goods by air, by public road or rail networks or by water; vehicles intended for use in a potentially explosive atmosphere shall not be excluded;

8) the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres.

Explosionsfähige Atmosphären - Explosionsschutz - Teil 1: Grundlagen und Methodik

Dieses Dokument legt Verfahrensweisen zum Erkennen und Bewerten von gefährlichen Situationen fest, die zu Explosionen führen können, und beschreibt geeignete Planungs- und Fertigungsmaßnahmen, um die erforderliche Sicherheit zu erreichen. Das wird erreicht durch:

- Risikobewertung;

- Risikoverringerung.

Die Sicherheit von Geräten, Schutzsystemen und Komponenten lässt sich durch das Beseitigen von Gefährdungen und/oder eine Begrenzung des Risikos erreichen, d. h. durch:

a) geeignete konstruktive Auslegung (ohne Anwendung von technischen Schutzmaßnahmen);

b) technische Schutzmaßnahmen;

c) Benutzerinformation;

d) sonstige Vorsichts- und Sicherheitsmaßnahmen.

Maßnahmen nach a) (Vorbeugung) und b) (Schutz) werden in Abschnitt 6 behandelt, Maßnahmen nach c) gegen Explosionen werden in Abschnitt 7 behandelt. Maßnahmen nach d) sind in diesem Dokument nicht festgelegt. Sie werden in EN ISO 12100:2010, Abschnitt 6, behandelt.

Die in diesem Dokument beschriebenen Schutzmaßnahmen führen nur dann zu der erforderlichen Sicher-heit, wenn die Geräte, Schutzsysteme und Komponenten bestimmungsgemäß betrieben und entsprechend den für sie geltenden Anwendungsregeln oder Anforderungen installiert und gewartet werden.

Dieses Dokument legt allgemeine Verfahrensweisen für Entwurf und Ausführung fest, um Konstrukteure und Hersteller bei Entwurf und Ausführung von Geräten, Schutzsystemen und Komponenten in Bezug auf den Explosionsschutz zu unterstützen.

Dieses Dokument gilt für alle Geräte, Schutzsysteme und Komponenten, die bestimmungsgemäß in explo-sionsgefährdeten Bereichen unter atmosphärischen Bedingungen eingesetzt werden. Solche Bereiche können vorliegen, wenn entzündbare/brennbare Stoffe verarbeitet, verwendet oder von den Geräten, Schutz¬systemen und Komponenten oder von Stoffen in der Umgebung von Geräten, Schutzsystemen und Komponenten und/oder aus den Konstruktionswerkstoffen der Geräte, Schutzsysteme und Komponenten freigesetzt werden.

Dieses Dokument gilt für Geräte, Schutzsysteme und Komponenten in allen Anwendungsphasen.

Dieses Dokument ist nur anwendbar auf die Gerätegruppe II für den bestimmungsgemäßen Gebrauch an anderen Orten als in Untertagebereichen von Bergwerken und außerhalb derartiger Einrichtungen von Bergwerken über Tage, die durch Schlagwetter und/oder brennbaren Staub gefährdet sind.

Dieses Dokument ist nicht anwendbar auf:

1) medizinische Geräte zur bestimmungsgemäßen Verwendung in medizinischen Bereichen;

2) Geräte, Schutzsysteme und Komponenten, bei denen die Explosionsgefahr ausschließlich durch die Anwesenheit von Sprengstoffen oder chemisch instabilen Stoffen hervorgerufen wird;

3) Geräte, Schutzsysteme und Komponenten, bei denen die Explosion durch Reaktion von Stoffen mit anderen Oxidationsmitteln als Luftsauerstoff oder durch andere gefährliche Reaktionen oder andere als atmosphärische Bedingungen erfolgen können;

4) Geräte, die zur Verwendung in häuslicher und nichtkommerzieller Umgebung vorgesehen sind, in der eine explosionsfähige Atmosphäre nur selten und lediglich infolge eines unbeabsichtigten Brenn¬stoffaustritts gebildet werden kann;

5) persönliche Schutzausrüstungen im Sinne der Verordnung (EU) 2016/425;

6) Seeschiffe und bewegliche Offshore-Anlagen sowie die Ausrüstungen an Bord dieser Schiffe oder Anlagen;

7) Beförderungsmittel, d. h. Fahrzeuge und dazugehörige Anhänger, die ausschließlich für die Beförderung von Personen in der Luft, auf Straßen- und Schienennetzen oder auf dem Wasserweg bestimmt sind, und Beförderungsmittel, soweit sie für den Transport von Gütern in der Luft, auf öffentlichen Straßen- und Schienennetzen oder auf dem Wasserweg konzipiert sind; nicht aus-genommen sind Fahrzeuge, die in explosionsgefährdeten Bereichen eingesetzt werden sollen;

(...)

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 1 : Notions fondamentales et méthodologie

La présente Norme européenne spécifie des méthodes pour identifier et évaluer les situations dangereuses conduisant à l'explosion, ainsi que les mesures de conception et de construction appropriées pour la sécurité requise. Cette sécurité est obtenue :

- en appréciant les risques ;

- en réduisant les risques.

La sécurité des appareils, systèmes de protection et composants peut être obtenue par l'élimination des phénomènes dangereux et/ou la limitation des risques, c’est-à-dire par :

a) une conception appropriée (ne nécessitant pas de dispositif de protection) ;

b) des dispositifs de protection ;

c) des informations d'utilisation ;

d) toute autre mesure de prévention.

Les mesures contre les explosions correspondant à a) (prévention) et b) (protection) sont traitées dans l'Article 6, les mesures contre les explosions correspondant à c) sont traitées dans l'Article 7. Les mesures correspondant à d) ne sont pas spécifiées dans la présente Norme européenne. Elles sont traitées dans l'EN ISO 12100:2010, Article 6.

Les mesures de prévention et de protection décrites dans la présente Norme européenne procureront le niveau de sécurité requis à condition que les appareils, systèmes de protection et composants soient utilisés conformément à leur destination et soient installés et entretenus conformément aux codes de bonnes pratiques ou aux exigences appropriés.

La présente norme spécifie des méthodes générales de conception et de construction pour aider les concepteurs et les fabricants à parvenir à une conception sécurisée contre les explosions des appareils, systèmes de protection et composants.

La présente Norme européenne est applicable à tout appareil, système de protection et composant destiné à être utilisé en atmosphères explosibles, dans les conditions atmosphériques. Ces atmosphères peuvent provenir de substances inflammables fabriquées et manipulées dans les appareils, systèmes de protection et composants ou dégagées par ceux-ci, ou de substances présentes au voisinage des appareils, systèmes de protection et composants et/ou des matériaux constitutifs des appareils, systèmes de protection et composants.

La présente Norme européenne est applicable aux appareils, aux systèmes de protection et aux composants à tous les stades de leur utilisation.

La présente Norme européenne ne s'applique qu'aux appareils du groupe II qui sont destinés à être utilisés dans des emplacements autres que les parties souterraines des mines et les parties des installations de surface de ces mines exposées aux risques de grisou et/ou de poussières inflammables.

La présente Norme européenne n'est pas applicable aux :

1) dispositifs médicaux destinés à être utilisés dans un environnement médical ;

2) appareils, systèmes de protection et composants lorsque le phénomène dangereux d'explosion est exclusivement dû à la présence de matières explosives ou de matières chimiques instables ;

3) appareils, systèmes de protection et composants lorsque l'explosion peut se produire en raison de la réaction de substances avec d'autres comburants que l'oxygène de l’atmosphère ou en raison d'autres réactions dangereuses ou encore dans des conditions autres qu'atmosphériques ;

4) équipements destinés à être utilisés dans des environnements domestiques et non commerciaux dans lesquels les atmosphères explosibles ne peuvent être produites que rarement, uniquement à la suite d'une fuite accidentelle de gaz combustible ;

5) équipements de protection individuelle couverts par la Directive 89/686/CEE ;

6) navires de mer et unités mobiles offshore ainsi qu'aux équipements à bord de ces navires ou unités ;

(...)

Eksplozivne atmosfere - Protieksplozijska zaščita - 1. del: Osnovni pojmi in metodologija

Ta dokument določa metode za ugotavljanje in ocenjevanje nevarnih okoliščin, ki lahko povzročijo eksplozije, ter strukturne in konstrukcijske ukrepe, primerne za potrebno varnost. To se doseže z: – oceno tveganja; – zmanjšanjem tveganja. Varnost opreme, zaščitnih sistemov in komponent je mogoče doseči z odpravo nevarnosti in/ali omejevanjem tveganja, tj. a) z ustreznim načrtovanjem (brez uporabe zaščite); b) z zaščito; c) z informacijami za uporabo; d) s kakršnimi koli drugimi preventivnimi ukrepi. Ukrepi v skladu z a) (preprečevanje) in b) (zaščita) proti eksploziji so obravnavani v točki 6; ukrepi v skladu s c) proti eksploziji so obravnavani v točki 7. Ukrepi v skladu z d) niso določeni v tem dokumentu. Obravnavani so v točki 6 standarda EN ISO 12100:2010. Preventivni in zaščitni ukrepi, opisani v tem dokumentu, ne zagotavljajo zahtevane ravni varnosti, razen če se oprema, zaščitni sistemi in komponente uporabljajo v skladu z njihovim namenom uporabe ter so nameščeni in vzdrževani v skladu z ustreznimi kodeksi ravnanja ali zahtevami. Ta dokument določa splošne metode za načrtovanje in konstruiranje, ki bodo projektantom in proizvajalcem v pomoč pri doseganju protieksplozivne zaščite pri načrtovanju opreme, zaščitnih sistemov in komponent. Ta dokument se uporablja za vso opremo, zaščitne sisteme in komponente, ki so namenjeni za uporabo v potencialno eksplozivnih atmosferah v atmosferskih pogojih. Te atmosfere lahko nastanejo iz vnetljivih/gorljivih snovi, ki jih obdelujejo, uporabljajo ali sproščajo oprema, zaščitni sistemi in komponente, iz materialov v bližini opreme, zaščitnih sistemov in komponent, in/ali iz konstrukcijskih materialov opreme, zaščitnih sistemov in komponent. Ta dokument se uporablja za opremo, zaščitne sisteme in komponente na vseh stopnjah uporabe. Ta dokument se uporablja samo za opremo skupine II, ki je namenjena uporabi na mestih, ki niso podzemni deli rudnikov in deli površinskih instalacij takih rudnikov, ki jih ogroža jamski eksplozivni plin in/ali vnetljiv prah. Ta dokument se ne uporablja za: 1) medicinske pripomočke, namenjene uporabi v medicinskem okolju; 2) opremo, zaščitne sisteme in komponente, pri katerih je nevarnost eksplozije izključno posledica navzočnosti eksplozivnih snovi ali nestabilnih kemikalij; 3) opremo, zaščitne sisteme in komponente, pri katerih je eksplozija lahko posledica reakcije snovi z oksidantom, razen atmosferskega kisika, ali drugih nevarnih reakcij ali pogojev, razen atmosferskih pogojev; 4) oprema, namenjena za uporabo v domačem in nekomercialnem okolju, pri kateri eksplozivna atmosfera nastane zelo redko, in sicer izključno zaradi naključnega uhajanja kurilnega plina; 5) osebno zaščitno opremo, zajeto z Direktivo(EU) 2016/425; 6) pomorska plovila in premične enote na morju skupaj z opremo na krovu takšnih plovil ali enot; 7) prevozna sredstva, tj. vozila in njihove prikolice, ki so namenjeni izključno prevozu potnikov po zraku ali cesti, po železniških ali vodnih omrežjih, ter prevozna sredstva, v kolikor so ta zasnovana za prevoz blaga po zraku, javnih cestnih ali železniških omrežjih ali po vodi; vozila, ki so namenjena za uporabo v potencialno eksplozivnih atmosferah, ne smejo biti izključena; 8) projektiranje in gradnjo sistemov, ki vsebujejo želene, nadzorovane procese zgorevanja, razen če lahko delujejo kot viri vžiga v potencialno eksplozivnih atmosferah.

General Information

- Status

- Published

- Publication Date

- 13-Aug-2019

- Withdrawal Date

- 27-Feb-2022

- Technical Committee

- CEN/TC 305 - Potentially explosive atmospheres - Explosion prevention and protection

- Drafting Committee

- CEN/TC 305/WG 4 - Terminology and Methodology

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 14-Aug-2019

- Due Date

- 24-Dec-2019

- Completion Date

- 14-Aug-2019

Relations

- Effective Date

- 21-Aug-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 1012-2:1996+A1:2009 - Compressors and vacuum pumps - Safety requirements - Part 2: Vacuum pumps - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1127-1:2019 - Explosive atmospheres: Explosion prevention and protection - Part 1: Basic concepts and methodology is a European standard published by CEN that defines methods for identifying and assessing hazardous situations leading to explosions and for selecting appropriate design and construction measures to achieve the required safety. The standard emphasizes risk assessment and risk reduction for equipment, protective systems and components intended for use in potentially explosive atmospheres under atmospheric conditions. It applies to equipment group II (non‑mining environments) and supports conformity with relevant EU directives.

Key topics and requirements

- Risk assessment methodology: systematic identification of explosion and ignition hazards, estimation of likelihood and consequence, and assessment of hazardous explosive atmospheres (see Clause 4).

- Ignition source identification: detailed consideration of possible ignition sources (hot surfaces, flames, electrical equipment, static electricity, RF/EM fields, ultrasonic, shock waves, self‑heating dusts, etc.) (Clause 5).

- Risk reduction principles: hierarchy of measures including prevention by design, safeguarding, information for use, and other preventive measures (Clause 6). Prevention (design) and protection (safeguarding) measures are covered in Clause 6; information for safe use, commissioning and maintenance is covered in Clause 7.

- Design and construction guidance: general methods to help designers and manufacturers achieve explosion safety; requirements to avoid effective ignition sources and to limit explosion effects (Clauses 6.4–6.5).

- Operational limits and maintenance: stresses that preventive/protective measures are effective only when equipment is used, installed and maintained according to intended use and codes of practice.

- Supporting annexes: informative and normative annexes (tools in explosive atmospheres, equipment tightness, verification procedures, and changes from the previous edition), plus Annexes ZA/ZB linking the standard to EU directives.

Practical applications

- Use EN 1127-1:2019 to perform explosion risk assessments, identify hazardous areas, and define design requirements for plant equipment and protective systems.

- Apply the standard when designing or selecting motors, enclosures, process vessels, dust‑handling equipment, control systems and other components to be used where flammable gases, vapours or combustible dusts may be present.

- Integrate the standard into safety documentation for procurement, CE/ATEX conformity, commissioning, maintenance planning and operator training.

Who should use this standard

- Designers and manufacturers of equipment for potentially explosive atmospheres

- Safety engineers, process engineers and facility managers in chemical, petrochemical, pharmaceutical, food/grain handling, paint/coatings and related industries

- Compliance officers preparing technical documentation for EU Directive conformity

Related standards

- EN ISO 12100:2010 - General principles for risk assessment and risk reduction (referenced for additional preventive measures)

- Annexes ZA/ZB in EN 1127-1:2019 describe relationships to EU Directive 2014/34/EU (ATEX) and Directive 2006/42/EC (Machinery)

Using EN 1127-1:2019 helps organizations systematically reduce explosion risk and demonstrate compliance when operating in potentially explosive atmospheres.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1127-1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology". This standard covers: This document specifies methods for the identification and assessment of hazardous situations leading to explosion and the design and construction measures appropriate for the required safety. This is achieved by: - risk assessment; - risk reduction. The safety of equipment, protective systems and components can be achieved by eliminating hazards and/or limiting the risk, i.e. by: a) appropriate design (without using safeguarding); b) safeguarding; c) information for use; d) any other preventive measures. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in Clause 6, measures according to c) against explosions are dealt with in Clause 7. Measures in accordance with d) are not specified in this document. They are dealt with in EN ISO 12100:2010, Clause 6. The preventive and protective measures described in this document will not provide the required level of safety unless the equipment, protective systems and components are operated within their intended use and are installed and maintained according to the relevant codes of practice or requirements. This document specifies general design and construction methods to help designers and manufacturers in achieving explosion safety in the design of equipment, protective systems and components. This document is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres, under atmospheric conditions. These atmospheres can arise from flammable/combustible substances processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. This document is applicable to equipment, protective systems and components at all stages of its use. This document is only applicable to equipment group II which is intended for use in other places than underground parts of mines and those parts of surface installations of such mines endangered by firedamp and/or combustible dust. This document is not applicable to: 1) medical devices intended for use in a medical environment; 2) equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosive substances or unstable chemical substances; 3) equipment, protective systems and components where the explosion can occur by reaction of substances with other oxidizers than atmospheric oxygen or by other hazardous reactions or by other than atmospheric conditions; 4) equipment intended for use in domestic and non-commercial environments where potentially explosive atmospheres may only rarely be created, solely as a result of the accidental leakage of fuel gas; 5) personal protective equipment covered by Regulation (EU) 2016/425; 6) seagoing vessels and mobile offshore units together with equipment on board such vessels or units; 7) means of transport, i.e. vehicles and their trailers intended solely for transporting passengers by air or by road, rail or water networks, as well as means of transport insofar as such means are designed for transporting goods by air, by public road or rail networks or by water; vehicles intended for use in a potentially explosive atmosphere shall not be excluded; 8) the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres.

This document specifies methods for the identification and assessment of hazardous situations leading to explosion and the design and construction measures appropriate for the required safety. This is achieved by: - risk assessment; - risk reduction. The safety of equipment, protective systems and components can be achieved by eliminating hazards and/or limiting the risk, i.e. by: a) appropriate design (without using safeguarding); b) safeguarding; c) information for use; d) any other preventive measures. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in Clause 6, measures according to c) against explosions are dealt with in Clause 7. Measures in accordance with d) are not specified in this document. They are dealt with in EN ISO 12100:2010, Clause 6. The preventive and protective measures described in this document will not provide the required level of safety unless the equipment, protective systems and components are operated within their intended use and are installed and maintained according to the relevant codes of practice or requirements. This document specifies general design and construction methods to help designers and manufacturers in achieving explosion safety in the design of equipment, protective systems and components. This document is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres, under atmospheric conditions. These atmospheres can arise from flammable/combustible substances processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. This document is applicable to equipment, protective systems and components at all stages of its use. This document is only applicable to equipment group II which is intended for use in other places than underground parts of mines and those parts of surface installations of such mines endangered by firedamp and/or combustible dust. This document is not applicable to: 1) medical devices intended for use in a medical environment; 2) equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosive substances or unstable chemical substances; 3) equipment, protective systems and components where the explosion can occur by reaction of substances with other oxidizers than atmospheric oxygen or by other hazardous reactions or by other than atmospheric conditions; 4) equipment intended for use in domestic and non-commercial environments where potentially explosive atmospheres may only rarely be created, solely as a result of the accidental leakage of fuel gas; 5) personal protective equipment covered by Regulation (EU) 2016/425; 6) seagoing vessels and mobile offshore units together with equipment on board such vessels or units; 7) means of transport, i.e. vehicles and their trailers intended solely for transporting passengers by air or by road, rail or water networks, as well as means of transport insofar as such means are designed for transporting goods by air, by public road or rail networks or by water; vehicles intended for use in a potentially explosive atmosphere shall not be excluded; 8) the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres.

EN 1127-1:2019 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1127-1:2019 has the following relationships with other standards: It is inter standard links to EN 1127-1:2011, EN 13237:2012, EN ISO 80079-36:2016, EN 15198:2007, EN ISO 12100:2010, EN 17348:2022, EN 14677:2008, EN 13617-3:2021, EN 12952-9:2022, EN 1012-2:1996+A1:2009, EN 13617-4:2021, EN 13852-1:2025, EN ISO 11111-1:2016, EN 617:2001+A1:2010, EN ISO 20257-1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1127-1:2019 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC; Standardization Mandates: M/396, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1127-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2019

Nadomešča:

SIST EN 1127-1:2011

Eksplozivne atmosfere - Protieksplozijska zaščita - 1. del: Osnovni pojmi in

metodologija

Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts

and methodology

Explosionsfähige Atmosphären - Explosionsschutz - Teil 1: Grundlagen und Methodik

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion -

Partie 1 : Notions fondamentales et méthodologie

Ta slovenski standard je istoveten z: EN 1127-1:2019

ICS:

13.230 Varstvo pred eksplozijo Explosion protection

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1127-1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 13.230 Supersedes EN 1127-1:2011

English Version

Explosive atmospheres - Explosion prevention and

protection - Part 1: Basic concepts and methodology

Atmosphères explosives - Prévention de l'explosion et Explosionsfähige Atmosphären - Explosionsschutz -

protection contre l'explosion - Partie 1 : Notions Teil 1: Grundlagen und Methodik

fondamentales et méthodologie

This European Standard was approved by CEN on 3 June 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1127-1:2019 E

worldwide for CEN national Members.

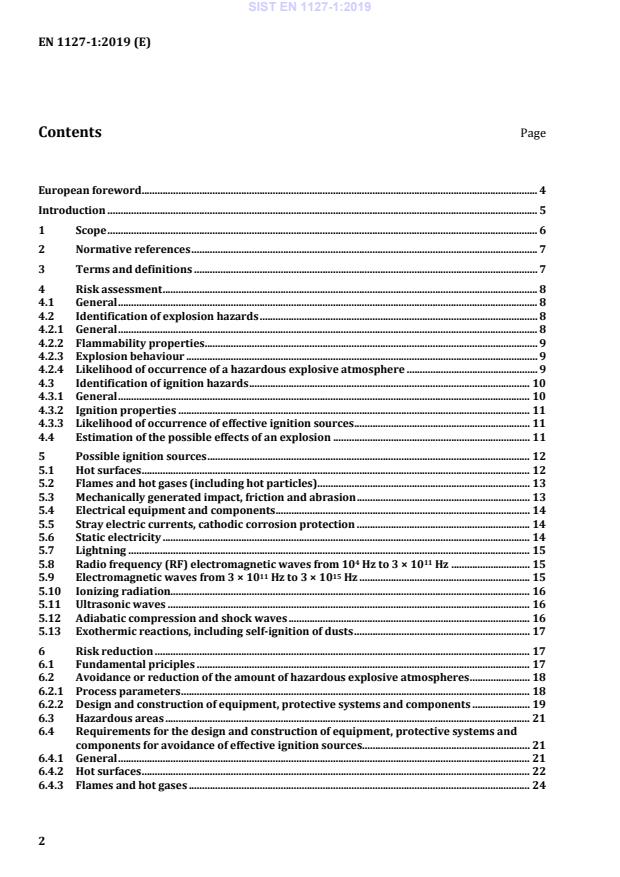

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 7

4 Risk assessment . 8

4.1 General . 8

4.2 Identification of explosion hazards . 8

4.2.1 General . 8

4.2.2 Flammability properties . 9

4.2.3 Explosion behaviour . 9

4.2.4 Likelihood of occurrence of a hazardous explosive atmosphere . 9

4.3 Identification of ignition hazards . 10

4.3.1 General . 10

4.3.2 Ignition properties . 11

4.3.3 Likelihood of occurrence of effective ignition sources . 11

4.4 Estimation of the possible effects of an explosion . 11

5 Possible ignition sources . 12

5.1 Hot surfaces . 12

5.2 Flames and hot gases (including hot particles) . 13

5.3 Mechanically generated impact, friction and abrasion . 13

5.4 Electrical equipment and components . 14

5.5 Stray electric currents, cathodic corrosion protection . 14

5.6 Static electricity . 14

5.7 Lightning . 15

4 11

5.8 Radio frequency (RF) electromagnetic waves from 10 Hz to 3 × 10 Hz . 15

11 15

5.9 Electromagnetic waves from 3 × 10 Hz to 3 × 10 Hz . 15

5.10 Ionizing radiation. 16

5.11 Ultrasonic waves . 16

5.12 Adiabatic compression and shock waves . 16

5.13 Exothermic reactions, including self-ignition of dusts . 17

6 Risk reduction . 17

6.1 Fundamental priciples . 17

6.2 Avoidance or reduction of the amount of hazardous explosive atmospheres . 18

6.2.1 Process parameters . 18

6.2.2 Design and construction of equipment, protective systems and components . 19

6.3 Hazardous areas . 21

6.4 Requirements for the design and construction of equipment, protective systems and

components for avoidance of effective ignition sources. 21

6.4.1 General . 21

6.4.2 Hot surfaces . 22

6.4.3 Flames and hot gases . 24

6.4.4 Mechanically generated impact, friction and grinding . 24

6.4.5 Electrical equipment and components . 25

6.4.6 Stray electric currents and cathodic corrosion protection . 25

6.4.7 Static electricity . 26

6.4.8 Lightning . 26

4 11

6.4.9 Radio frequency (RF) electromagnetic waves from 10 Hz to 3 × 10 Hz . 27

11 15

6.4.10 Electromagnetic waves from 3 × 10 Hz to 3 × 10 Hz . 28

6.4.11 Ionizing radiation . 28

6.4.12 Ultrasonic waves . 29

6.4.13 Adiabatic compression and shock waves . 30

6.4.14 Exothermic reactions, including self-ignition of dusts . 31

6.5 Requirements for the design and construction of equipment, protective systems and

components to reduce the explosion effects . 31

6.6 Provisions for emergency measures . 32

6.7 Principles of measuring and control systems for explosion prevention and

protection . 32

7 Information for use . 33

7.1 General . 33

7.2 Information for commissioning, maintenance and repair to prevent explosion . 34

7.3 Qualifications and training . 34

Annex A (informative) Information for the use of tools in potentially explosive

atmospheres . 35

Annex B (informative) Tightness of equipment . 36

B.1 General . 36

B.2 Normal tightness . 36

B.3 Enhanced tightness . 37

Annex C (normative) Verification procedure for the threshold limit of ultrasound in liquids . 38

Annex D (informative) Significant technical changes between this document and the

previous edition of this document. 40

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2014/34/EU aimed to be covered . 42

Annex ZB (informative) Relationship between This document and the essential

requirements of Directive 2006/42/EC aimed to be covered . 43

Bibliography . 44

European foreword

This document (EN 1127-1:2019) has been prepared by Technical Committee CEN/TC 305 “Potentially

explosive atmospheres - Explosion prevention and protection”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards

shall be withdrawn at the latest by February 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1127-1:2011.

Annex D provides details of significant technical changes between this document and the previous

edition EN 1127-1:2011.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directives.

For relationship with EU Directives, see informative Annex ZA and ZB, which are integral parts of this

document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

CEN and CENELEC are producing a set of standards to assist designers, manufacturers and other

interested bodies to interpret the essential safety requirements in order to achieve conformity with

European Legislation. Within this series of standards CEN has undertaken to draw up a standard to give

guidance in the field of explosion prevention and protection, as hazards from explosions are intended to

be considered in accordance with EN ISO 12100:2010.

In accordance with EN ISO 12100:2010, it is a type B standard.

This standard describes the basic concepts and methodology of explosion prevention and protection.

CEN/TC 305 has a mandate in this area to produce B-type, and C-type standards, which will allow

verification of conformity with the essential safety requirements.

Explosions can occur from:

a) materials processed or used by the equipment, protective systems and components;

b) materials released by the equipment, protective systems and components;

c) materials in the vicinity of the equipment, protective systems and components;

d) materials of construction of the equipment, protective systems and components.

Since safety depends not only on equipment, protective systems and components but also on the

material being handled and its use, this standard includes aspects related to the intended use and

foreseeable misuse, i.e. the manufacturer should consider in which way and for which purpose the

equipment, protective systems and components will be used and take this into account during its design

and construction. This is the only way hazards inherent in equipment, protective systems and

components can be reduced.

NOTE This standard can also serve as a guide for users of equipment, protective systems and components

when assessing the risk of explosion in the workplace and selecting the appropriate equipment, protective

systems and components.

1 Scope

This document specifies methods for the identification and assessment of hazardous situations leading

to explosion and the design and construction measures appropriate for the required safety. This is

achieved by:

— risk assessment;

— risk reduction.

The safety of equipment, protective systems and components can be achieved by eliminating hazards

and/or limiting the risk, i.e. by:

a) appropriate design (without using safeguarding);

b) safeguarding;

c) information for use;

d) any other preventive measures.

Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in

Clause 6, measures according to c) against explosions are dealt with in Clause 7. Measures in

accordance with d) are not specified in this document. They are dealt with in

EN ISO 12100:2010, Clause 6.

The preventive and protective measures described in this document will not provide the required level

of safety unless the equipment, protective systems and components are operated within their intended

use and are installed and maintained according to the relevant codes of practice or requirements.

This document specifies general design and construction methods to help designers and manufacturers

in achieving explosion safety in the design of equipment, protective systems and components.

This document is applicable to any equipment, protective systems and components intended to be used

in potentially explosive atmospheres, under atmospheric conditions. These atmospheres can arise from

flammable/combustible substances processed, used or released by the equipment, protective systems

and components or from materials in the vicinity of the equipment, protective systems and components

and/or from the materials of construction of the equipment, protective systems and components.

This document is applicable to equipment, protective systems and components at all stages of its use.

This document is only applicable to equipment group II which is intended for use in other places than

underground parts of mines and those parts of surface installations of such mines endangered by

firedamp and/or combustible dust.

This document is not applicable to:

1) medical devices intended for use in a medical environment;

2) equipment, protective systems and components where the explosion hazard results exclusively

from the presence of explosive substances or unstable chemical substances;

3) equipment, protective systems and components where the explosion can occur by reaction of

substances with other oxidizers than atmospheric oxygen or by other hazardous reactions or by

other than atmospheric conditions;

4) equipment intended for use in domestic and non-commercial environments where potentially

explosive atmospheres may only rarely be created, solely as a result of the accidental leakage of fuel

gas;

5) personal protective equipment covered by Regulation (EU) 2016/425;

6) seagoing vessels and mobile offshore units together with equipment on board such vessels or units;

7) means of transport, i.e. vehicles and their trailers intended solely for transporting passengers by air

or by road, rail or water networks, as well as means of transport insofar as such means are

designed for transporting goods by air, by public road or rail networks or by water; vehicles

intended for use in a potentially explosive atmosphere shall not be excluded;

8) the design and construction of systems containing desired, controlled combustion processes, unless

they can act as ignition sources in potentially explosive atmospheres.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13237:2012, Potentially explosive atmospheres — Terms and definitions for equipment and protective

systems intended for use in potentially explosive atmospheres

EN 15198:2007, Methodology for the risk assessment of non-electrical equipment and components for

intended use in potentially explosive atmospheres

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction

EN ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13237:2012 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

normal tightness

absence of leakage when any of the tightness tests or tightness monitorings appropriate for the

application does not reveal any hazardous leaks during normal operation

3.2

enhanced tightness

absence of leakage when due to the design and measures of maintenance any of the tightness tests or

tightness monitorings appropriate for the application does not reveal any hazardous leaks during

normal operations and expected malfunctions

4 Risk assessment

4.1 General

For non-electrical equipment, components, protective systems, devices and assemblies of these non-

electrical products, which have their own potential ignition sources and are intended for use in

explosive atmospheres, risk assessment shall be carried out according to EN ISO 80079-36:2016. For

other situations, risk assessment shall be carried out in accordance with EN ISO 12100:2010 and/or

EN 15198:2007 unless other standards can be identified as being more appropriate, considering the

following:

a) identification of explosion hazards and determination of the likelihood of occurrence of a

hazardous explosive atmosphere (see 4.2);

b) identification of ignition hazards and determination of the likelihood of occurrence of potential

ignition sources (see 4.3);

c) estimation of the possible effects of an explosion in case of ignition (see 4.4);

d) evaluation of the risk and whether the intended level of protection has been achieved;

NOTE The intended level of protection is defined by at least legal requirements and, if necessary, additional

requirements specified by the user.

e) consideration of measures to reduce of the risks (see Clause 6).

A comprehensive approach shall be taken, especially for complex equipment, protective systems and

components, plants comprising individual units and, above all, for extended plants. This risk assessment

shall take into account the ignition and explosion hazard from:

1) the equipment, protective systems and components themselves;

2) the interaction between the equipment, protective systems and components and the substances

being handled;

3) the particular process performed in the equipment, protective systems and components;

4) the surroundings of the equipment, protective systems and components and possible interaction

with neighbouring processes.

4.2 Identification of explosion hazards

4.2.1 General

The explosion hazard is generally related to the materials and substances processed, used or released

by equipment, protective systems and components and materials used to construct equipment,

protective systems and components. Some of these released substances can undergo combustion

processes in air. These processes are often accompanied by the release of considerable amounts of heat

and can be associated with a pressure build-up and the release of hazardous materials. In contrast to

burning in a fire, an explosion is essentially a self-sustained propagation of the reaction zone (flame)

through the hazardous explosive atmosphere. This potential hazard associated with the hazardous

explosive atmosphere is released when ignited by an effective ignition source.

The safety characteristics listed in 4.2.2 and 4.2.3 describe safety relevant properties of

flammable/combustible substances. The material properties and the safety characteristics are used for

the identification of the explosion hazard.

It is necessary to bear in mind that such safety characteristics are not constants but depend for instance

on the techniques used for their measurement. Also, for dusts, tabulated safety data are for guidance

only because the values depend on particle size and shape, moisture content and the presence of

additives even in trace concentrations. For a specific application, samples of the dust present in the

equipment should be tested and the data obtained used in the hazard identification.

4.2.2 Flammability properties

Since in this context it is not the material itself that represents the potential hazard but its contact or

mixing with air, the properties of the mixture of the flammable/combustible substance with air shall be

determined. These properties give information about a substance's burning behaviour and whether it

could give rise to fire or explosions. Relevant data are e.g.:

a) lower explosion point (see EN 15794), that can be substituted by flash point (with a safety factor), if

lower explosion point is not available;

b) explosion limits (LEL, UEL) (see EN 14034-3 and EN 1839);

NOTE Lower explosion limit (LEL) and upper explosion limit (UEL) are named lower flammability limit (LFL)

and upper flammability limit (UFL) in EN ISO/IEC 80079-20-1.

c) limiting oxygen concentration (LOC) (see EN 14034-4 and EN 1839).

4.2.3 Explosion behaviour

The behaviour of the explosive atmosphere after ignition shall be characterized by data such as:

a) maximum explosion pressure (p ) (see EN 14034-1, EN 14034-4 and EN 15967);

max

b) maximum rate of explosion pressure rise ((d /d ) ) (see EN 14034-2, EN 14491 and EN 15967);

p t max

c) maximum experimental safe gap (MESG) (see EN 60079-20-1).

4.2.4 Likelihood of occurrence of a hazardous explosive atmosphere

The likelihood of occurrence of a hazardous explosive atmosphere depends on the following:

— presence of a flammable/combustible substance;

— degree of dispersion of the flammable/combustible substance (e.g. gases, vapours, mists, dusts);

— concentration of the flammable/combustible substance in air within the explosion range;

— amount of explosive atmosphere sufficient to cause injury or damage in case of ignition.

In assessment of the likelihood of occurrence of a hazardous explosive atmosphere, possible formation

of the hazardous explosive atmosphere through chemical reactions, pyrolysis and biological processes

from the materials present shall be taken into account.

If it is impossible to estimate the likelihood of occurrence of a hazardous explosive atmosphere, the

assumption shall be made that such an atmosphere is always present.

a) Presence of a flammable/combustible substance

Flammable/combustible substances shall be considered as materials which can form a hazardous

explosive atmosphere unless an investigation of their properties has shown that in mixtures with air

they are incapable of self-sustained propagation of an explosion. In assessment of the likelihood of

occurrence of a hazardous explosive atmosphere, possible formation of the hazardous explosive

atmosphere through chemical reactions, pyrolysis and biological processes from the materials present

shall be taken into account.

b) Degree of dispersion of flammable/combustible substances

By their very nature, gases, vapours and mists have a degree of dispersion high enough to produce a

hazardous explosive atmosphere. For dusts the occurrence of a hazardous explosive atmosphere can be

assumed if the particle size fractions are equal or less than 0,5 mm.

NOTE 1 Numerous mists, aerosols and types of dusts that occur in actual practice have particle sizes between

0,001 mm and 0,1 mm.

NOTE 2 Combustible flyings are a type of dust (group III A, see EN IEC 60079-0), including fibres (e.g.

cotton/carbon/jute fibres), where one dimension is greater than 0,5 mm and which may form with air a

hazardous explosive atmosphere.

Attention shall be paid to the fact that explosions can occur in hybrid mixtures though none of the

flammable/combustible substances of the mixture is individually within the explosion range.

c) Concentration of flammable/combustible substances

An explosion is possible when the concentration of the dispersed flammable/combustible substance in

air achieves a minimum value (lower explosion limit). An explosion will not occur when the

concentration exceeds a maximum value (upper explosion limit).

NOTE 3 Some chemically unstable substances, e.g. acetylene and ethylene oxide, can undergo exothermic

reactions even in the absence of oxygen and have an upper explosion limit of 100 %.

The explosion limits vary with pressure and temperature. As a rule, the concentration range between

the explosion limits increases with increasing pressure and temperature. In the case of mixtures with

oxygen, the upper explosion limits are far higher than for mixtures with air.

If the surface temperature of a combustible liquid exceeds the lower explosion point, a hazardous

explosive atmosphere can be formed (see 6.2.1.2).

NOTE 4 Hybrid mixtures, e.g. aerosols and mists, can become an explosive mixture at temperatures that are far

below the lower explosion point (LEP).

The explosion limits for dusts do not have the same significance as those for gases and vapours. Dust

clouds are usually inhomogeneous. The dust concentration can fluctuate greatly due to dust depositing

and dispersion into the atmosphere. Consideration shall always be given to the possible formation of

hazardous explosive atmospheres when deposits of combustible dust are present.

d) Amount of hazardous explosive atmosphere

The assessment whether an explosive atmosphere is present in a hazardous amount depends on the

possible effects of the explosion (see 4.4).

4.3 Identification of ignition hazards

4.3.1 General

At first it shall be determined which types of ignition sources are possible and which are related to the

equipment (or components or protective systems). The different ignition sources are considered in

Clause 5. The significance of all ignition sources that could come into contact with the hazardous

explosive atmosphere shall be assessed.

The ignition capability of all equipment related ignition sources shall then be compared with the

ignition properties of the flammable/combustible substance (see 4.3.2).

This step shall result in a complete list of all potential ignition sources of the equipment, component or

protective system. Afterwards the likelihood of occurrence of the potential ignition sources to become

effective shall be assessed, taking also into account those that can be introduced e.g. by maintenance

and cleaning activities.

4.3.2 Ignition properties

The ignition properties of the hazardous explosive atmosphere shall be determined. Relevant data are,

e.g.:

a) minimum ignition energy (see EN ISO/IEC 80079-20-2);

b) minimum ignition temperature of an explosive dust atmosphere (see EN ISO/IEC 80079-20-2);

c) auto-ignition temperature of an explosive gas atmosphere (see EN ISO/IEC 80079-20-1).

4.3.3 Likelihood of occurrence of effective ignition sources

The potential ignition sources shall be classified according to the likelihood to become effective in the

following manner:

a) ignition sources which can occur continuously or frequently;

b) ignition sources which can occur in rare situations;

c) ignition sources which can occur in very rare situations;

In terms of the equipment, protective systems and components used this classification shall be

considered equivalent to:

d) ignition sources which can occur during normal operation;

e) ignition sources which can occur solely as a result of malfunctions;

f) ignition sources which can occur solely as a result of rare malfunctions.

NOTE Protective measures can be used to make the ignition source non-effective (see 6.4).

If the likelihood of occurrence of an effective ignition source cannot be estimated, the assumption shall

be made that the ignition source is present at all times.

4.4 Estimation of the possible effects of an explosion

To estimate the possible effects of an explosion the following shall be considered, e.g.:

— pressure waves;

— flames and hot gases;

— thermal radiation;

— flying debris;

— hazardous releases of materials.

The consequences of the above are related to the:

— chemical and physical properties of the flammable/combustible substances;

— quantity and confinement of the hazardous explosive atmosphere;

— geometry of the surroundings taking into account obstacles;

— strength of enclosure and supporting structures;

— protective equipment worn by the endangered personnel;

— physical properties of the endangered objects.

Information on the consequences of an explosion is required for the estimation of the expected injury to

persons, domestic animals or properties and the size of the endangered place by the user. Appropriate

information shall be part of the user instructions.

NOTE This procedure can also serve as a guide for users of equipment, protective systems and components

when assessing the risk of explosion in the workplace and selecting the appropriate equipment, protective

systems and components.

5 Possible ignition sources

5.1 Hot surfaces

If an explosive atmosphere comes into contact with a heated surface ignition can occur. Not only a hot

surface itself can act as an ignition source, but a dust layer or a combustible solid in contact with a hot

surface and ignited by the hot surface can also act as an ignition source for an explosive atmosphere

(see 5.2).

The capability of a heated surface to cause ignition depends on the type and concentration of the

particular substance in the mixture with air. This capability becomes greater with increasing

temperature and increasing surface area. Moreover, the temperature that triggers ignition depends on

the size and shape of the heated body, on the concentration gradient in the vicinity of the surface, the

flow velocity of the explosive atmosphere around the hot surface and, to a certain extent, also on the

surface material. Thus, for example, an explosive gas or vapour atmosphere inside fairly large heated

spaces (approximately 1 l or more) can be ignited by surface temperatures lower than those measured

in accordance with EN ISO/IEC 80079-20-1 or by other equivalent methods. On the other hand, in the

case of heated bodies with convex rather than concave surfaces, a higher surface temperature is

necessary for ignition; the minimum ignition temperature increases, for example, with spheres or pipes

as the diameter decreases. When an explosive atmosphere flows past heated surfaces, a higher surface

temperature could be necessary for ignition owing to the brief contact time.

If the explosive atmosphere remains in contact with the hot surface for a relatively long time,

preliminary reactions can occur, e.g. cool flames, so that more easily ignitable decomposition products

are formed, which promote the ignition of the original atmospheres.

In addition to easily recognizable hot surfaces such as radiators, drying cabinets, heating coils and

others, mechanical and machining processes can also lead to hazardous temperatures. These processes

also include equipment, protective systems and components which convert mechanical energy into

heat, i.e. all kinds of friction clutches and mechanically operating brakes (e.g. on vehicles and

centrifuges). Furthermore, all moving parts in bearings, shaft passages, glands, etc. can become ignition

sources if they are not sufficiently lubricated. In tight housings of moving parts, the ingress of foreign

bodies or shifting of the axis can also lead to friction which, in turn, can lead to high surface

temperatures, in some cases quite rapidly.

Hot surfaces can also occur by heating absorbers created by other ignition sources, e.g. electromagnetic

waves (see 5.8 and 5.9) and ultrasonic waves (see 5.11).

Consideration shall also be given to temperature increases due to chemical reactions (e.g. with

lubricants and cleaning solvents).

For ignition hazards in welding and cutting work, see 5.2.

For protective measures against ignition hazards from hot surfaces, see 6.4.2. Where hot surfaces are

wholly or partly covered more specifically by other clauses these clauses shall apply, see 6.4.4, 6.4.9,

6.4.10, 6.4.12.

5.2 Flames and hot gases (including hot particles)

Flames are associated with combustion reactions at temperatures of typically more than 1 000 °C. Hot

gases are produced as reaction products and, in the case of dusty and/or sooty flames, glowing solid

particles are also produced. Flames, their hot reaction products or otherwise (without combustion)

highly heated gases can ignite an explosive atmosphere. Flames, even very small ones, are among the

most effective ignition sources.

If an explosive atmosphere is present inside as well as outside an equipment, protective system or

component or in adjacent parts of the installation and if ignition occurs in one of these places, the flame

can spread to the other places through openings such as ventilation ducts. The prevention of flame

propagation calls for specially designed protective measures (see 6.5).

Welding beads that occur when welding or cutting is carried out are sparks with a very large surface

and therefore they are among the most effective ignition sources.

For protective measures against ignition hazards due to flames and hot gases, see 6.4.3.

5.3 Mechanically generated impact, friction and abrasion

As a result of friction, impact or abrasion processes such as grinding, particles can become separated

from solid materials and become hot owing to the energy used in the separation process. If these

particles consist of oxidizable substances, for example iron or steel, they can undergo an oxidation

process, thus reaching even higher temperatures. These particles (sparks) can ignite flammable gases

and certain dust/air-mixtures (especially metal dust/air mixtures). In deposited dust, smouldering can

be caused by the sparks and this can be an ignition source for an explosive atmosphere.

The ingress of foreign materials to equipment, protective systems and components, e.g. stones or tramp

metals, as a cause of sparking shall be considered.

Rubbing friction, even between similar ferrous metals and between certain ceramics, can generate hot

spots and sparks similar to grinding sparks. These can cause ignition of explosive atmospheres.

When stainless steel is involved in impact, friction or grinding it will easily produce hot surfaces which

may become an effective ignition source. Applying high contact pressure in case of friction or grinding a

burst of sparks will be created additionally.

Impacts involving rust and light metals (e.g. aluminium and magnesium) and their alloys can initiate a

thermite reaction which can cause ignition of explosive atmospheres.

The light metals titanium and zirconium can also form incendive sparks under impact or friction against

any sufficiently hard material, even in the absence of rust.

For ignition hazards in welding and cutting work, see 5.2.

For protective measures against ignition hazards due to mechanically generated sparks, see 6.4.4.

5.4 Electrical equipment and components

In the case of electrical equipment and components, electric sparks and hot surfaces (see 5.1) can occur

as ignition sources. Electric sparks and hot surfaces can be generated, e.g.:

— when electric circuits are opened and closed;

— by loose connections;

— by stray currents (see 5.5);

— by overload or insufficient cooling;

— by short circuits.

It is pointed out explicitly that an extra low voltage (ELV, e.g. less than 50 V) is designed for personal

protection against electric shock and is not a measure aimed at explosion protection. However, voltages

lower than this can still produce sufficient energy to ignite an explosive atmosphere.

For protective measures against ignition hazards due to electrical equipment and components,

see 6.4.5.

5.5 Stray electric currents, cathodic corrosion protection

Stray currents can flow in electrically conductive systems or parts of systems as:

— return currents in power generating systems — especially in the vicinity of electric railways and

large welding systems — when, for example, conductive electrical system components such as rails

and cable sheathing laid underground lower the resistance of this return current path;

— a result of a short-circuit or of an earth fault owing to faults in the electrical installations;

— a result of magnetic induction (e.g. near electrical installations with high currents or radio

frequencies, see also 5.8); and

— a result of lightning (see 5.7).

If parts of a system able to carry stray currents are disconnected, connected or bridged — even in the

case of slight potential differences — an explosive atmosphere can be ignited as a result of electric

sparks and/or arcs. Moreover, ignition can also occur due to the heating up of these current paths.

When impressed current cathodic corrosion protection is used, the above-mentioned ignition risks are

also possible. However, if sacrificial anodes are used, ignition risks due to electric sparks are unlikely,

unless the anodes are aluminium or magnesium.

For protective measures against ignition hazards due to stray electric currents and cathodic corrosion

protection, see 6.4.6.

5.6 Static electricity

Incendive discharges of static electricity can occur under certain conditions (see CLC/TR 60079-32-1).

The discharge of charged, insulated conductive parts can easily lead to incendive sparks. With charged

parts made of non-conductive materials, and these include most plastics as well as some other

materials, brush discharges and, in special cases, during fast separation processes (e.g. films moving

over rollers, drive belts, or by combination of conductive and non-conduc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...