ASTM D5185-09

(Test Method)Standard Test Method for Determination of Additive Elements, Wear Metals, and Contaminants in Used Lubricating Oils and Determination of Selected Elements in Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

Standard Test Method for Determination of Additive Elements, Wear Metals, and Contaminants in Used Lubricating Oils and Determination of Selected Elements in Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

SIGNIFICANCE AND USE

This test method covers the rapid determination of 22 elements in used lubricating oils and in base oils, and it provides rapid screening of used oils for indications of wear. Test times approximate a few minutes per test specimen, and detectability for most elements is in the low mg/kg range. In addition, this test method covers a wide variety of metals in virgin and re-refined base oils. Twenty-two elements can be determined rapidly, with test times approximating several minutes per test specimen.

When the predominant source of additive elements in used lubricating oils is the additive package, significant differences between the concentrations of the additive elements and their respective specifications can indicate that the incorrect oil is being used. The concentrations of wear metals can be indicative of abnormal wear if there are baseline concentration data for comparison. A marked increase in boron, sodium, or potassium levels can be indicative of contamination as a result of coolant leakage in the equipment. This test method can be used to monitor equipment condition and define when corrective actions are needed.

The concentrations of metals in re-refined base oils can be indicative of the efficiency of the re-refining process. This test method can be used to determine if the base oil meets specifications with respect to metal content.

SCOPE

1.1 This test method covers the determination of additive elements, wear metals, and contaminants in used lubricating oils by inductively coupled plasma atomic emission spectrometry (ICP-AES). The specific elements are listed in Table 1.

1.2 This test method covers the determination of selected elements, listed in Table 1, in re-refined and virgin base oils.

1.3 For analysis of any element using wavelengths below 190 nm, a vacuum or inert-gas optical path is required. The determination of sodium and potassium is not possible on some instruments having a limited spectral range.

1.4 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble particulates. Analytical results are particle size dependent, and low results are obtained for particles larger than a few micrometers.

1.5 Elements present at concentrations above the upper limit of the calibration curves can be determined with additional, appropriate dilutions and with no degradation of precision.

1.6 For elements other than calcium, sulfur, and zinc, the low limits listed in Table 2 and Table 3 were estimated to be ten times the repeatability standard deviation. For calcium, sulfur, and zinc, the low limits represent the lowest concentrations tested in the interlaboratory study.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 6.1, 8.2, and 8.4.

TABLE 1 Elements Determined and Suggested WavelengthsA ElementWavelength, nm Aluminum308.22, 396.15, 309.27 Barium233.53, 455.40, 493.41 Boron249.77 Calcium315.89, 317.93, 364.44, 422.67 Chromium205.55, 267.72 Copper324.75 Iron259.94, 238.20 Lead220.35 Magnesium279.08, 279.55, 285.21 Manganese257.61, 293.31, 293.93 Molybdenum202.03, 281.62 Nickel231.60, 227.02, 221.65 Phosphorus177.51, 178.29, 213.62, 214.91, 253.40 Potassium766.49 Sodium589.59 Silicon288.16, 251.61 Silver328.07 Sulfur180.73, 182.04, 182.62 Tin189.99, 242.95 Titanium337.28, 350.50, 334.94 Vanadium292.40, 309.31, 310.23, 311.07 Zinc202.55, 206.20, 213.86, 334.58, 481.05

A These wavelengths are only suggested and do not represent all possible choices.

TABLE 2 Repeatability ElementRange, mg/kgRepeatability,...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5185 − 09 AnAmerican National Standard

Standard Test Method for

Determination of Additive Elements, Wear Metals, and

Contaminants in Used Lubricating Oils and Determination of

Selected Elements in Base Oils by Inductively Coupled

1

Plasma Atomic Emission Spectrometry (ICP-AES)

This standard is issued under the fixed designation D5185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

Costs associated with maintenance due to engine and machine wear can be significant. Therefore,

diagnostic methods for determining the condition of engines and other machinery can be important.

This test method is intended to quantify, for the purpose of equipment monitoring, the concentration

of metals in used lubricating oils. Although the precision statement was determined by analyzing a

varietyofusedoilsthistestmethodcan,inprinciple,beusedfortheanalysisofunusedoilstoprovide

more complete elemental composition data than Test Methods D4628, D4927,or D4951.

1. Scope* 1.6 For elements other than calcium, sulfur, and zinc, the

lowlimitslistedinTable2andTable3wereestimatedtobeten

1.1 This test method covers the determination of additive

times the repeatability standard deviation. For calcium, sulfur,

elements, wear metals, and contaminants in used lubricating

and zinc, the low limits represent the lowest concentrations

oils by inductively coupled plasma atomic emission spectrom-

tested in the interlaboratory study.

etry (ICP-AES). The specific elements are listed in Table 1.

1.7 The values stated in SI units are to be regarded as

1.2 This test method covers the determination of selected

standard. No other units of measurement are included in this

elements, listed in Table 1, in re-refined and virgin base oils.

standard.

1.3 For analysis of any element using wavelengths below

1.8 This standard does not purport to address all of the

190 nm, a vacuum or inert-gas optical path is required. The

safety concerns, if any, associated with its use. It is the

determinationofsodiumandpotassiumisnotpossibleonsome

responsibility of the user of this standard to establish appro-

instruments having a limited spectral range.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific warning

1.4 This test method uses oil-soluble metals for calibration

statements are given in 6.1, 8.2, and 8.4.

and does not purport to quantitatively determine insoluble

particulates.Analytical results are particle size dependent, and

2. Referenced Documents

low results are obtained for particles larger than a few

2

3

micrometers.

2.1 ASTM Standards:

C1109 Practice for Analysis of Aqueous Leachates from

1.5 Elementspresentatconcentrationsabovetheupperlimit

Nuclear Waste Materials Using Inductively Coupled

of the calibration curves can be determined with additional,

Plasma-Atomic Emission Spectroscopy

appropriate dilutions and with no degradation of precision.

D1552 Test Method for Sulfur in Petroleum Products (High-

Temperature Method)

D4057 Practice for Manual Sampling of Petroleum and

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved April 15, 2009. Published May 2009. Originally

3

approved in 1991. Last previous edition approved in 2005 as D5185–05. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D5185-09. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Eisentraut, K. J., Newman, R. W., Saba, C. S., Kauffman, R. E., and Rhine, W. Standards volume information, refer to the standard’s Document Summary page on

E., Analytical Chemistry, Vol 56, 1984. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5185 − 09

A

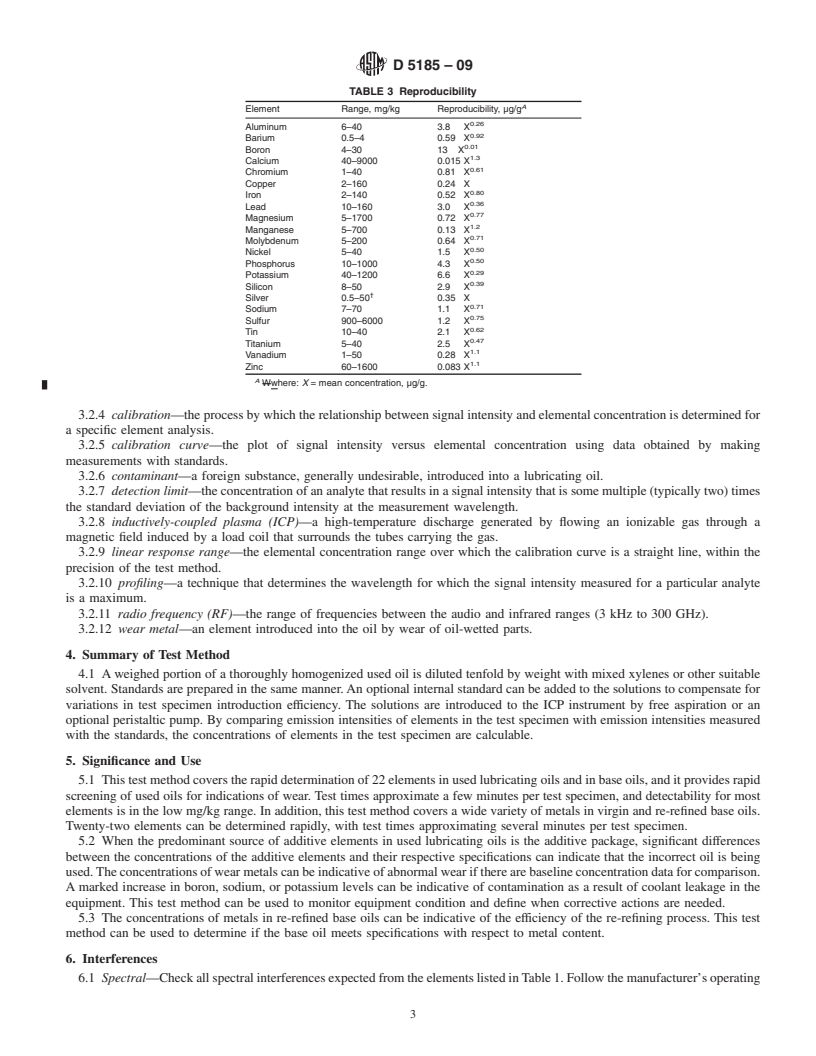

TABLE 1 Elements Determined and Suggested Wavelengths TABLE 3 Reproducibility

A

Element Wavelength, nm

Element Range, mg/kg Reproducibility, µg/g

0.26

Aluminum 308.22, 396.15, 309.27

Aluminum 6–40 3.8 X

0.92

Barium 233.53, 455.40, 493.41

Barium 0.5–4 0.59 X

0.01

Boron 249.77

Boron 4–30 13 X

1.3

Calcium 315.89, 317.93, 364.44, 422.67

Calcium 40–9000 0.015 X

0.61

Chromium 205.55, 267.72

Chromium 1–40 0.81 X

Copper 324.75

Copper 2–160 0.24 X

0.80

Iron

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D5185–05 Designation: D 5185 – 09

Standard Test Method for

Determination of Additive Elements, Wear Metals, and

Contaminants in Used Lubricating Oils and Determination of

Selected Elements in Base Oils by Inductively Coupled

1

Plasma Atomic Emission Spectrometry (ICP-AES)

This standard is issued under the fixed designation D 5185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

Costs associated with maintenance due to engine and machine wear can be significant. Therefore,

diagnostic methods for determining the condition of engines and other machinery can be important.

This test method is intended to quantify, for the purpose of equipment monitoring, the concentration

of metals in used lubricating oils. Although the precision statement was determined by analyzing a

varietyofusedoilsthistestmethodcan,inprinciple,beusedfortheanalysisofunusedoilstoprovide

more complete elemental composition data than Test Methods D 4628, D 4927, or D 4951.

1. Scope*

1.1 This test method covers the determination of additive elements, wear metals, and contaminants in used lubricating oils by

inductively coupled plasma atomic emission spectrometry (ICP-AES). The specific elements are listed in Table 1.

1.2 This test method covers the determination of selected elements, listed in Table 1, in re-refined and virgin base oils.

1.3 For analysis of any element using wavelengths below 190 nm, a vacuum or inert-gas optical path is required. The

determination of sodium and potassium is not possible on some instruments having a limited spectral range.

1.4 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble

2

particulates.Analyticalresultsareparticlesizedependent,andlowresultsareobtainedforparticleslargerthanafewmicrometers.

1.5 Elements present at concentrations above the upper limit of the calibration curves can be determined with additional,

appropriate dilutions and with no degradation of precision.

1.6 For elements other than calcium, sulfur, and zinc, the low limits listed inTable 2 andTable 3 were estimated to be ten times

the repeatability standard deviation. For calcium, sulfur, and zinc, the low limits represent the lowest concentrations tested in the

interlaboratory study.

1.7

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements are given in 6.1, 8.2, and 8.4.

2. Referenced Documents

3

2.1 ASTM Standards:

C 1109 Test Method Practice for Analysis of Aqueous Leachates from Nuclear Waste Materials Using Inductively Coupled

Plasma-Atomic Emission SpectrometrySpectroscopy

D 1552 Test Method for Sulfur in Petroleum Products (High-Temperature Method)

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

´2

Current edition approved Nov. 1, 2005. Published November 2005. Originally approved in 1991. Last previous edition approved in 2002 as D5185–02 .

Current edition approved April 15, 2009. Published May 2009. Originally approved in 1991. Last previous edition approved in 2005 as D 5185–05.

2

Eisentraut, K. J., Newman, R. W., Saba, C. S., Kauffman, R. E., and Rhine, W. E., Analytical Chemistry, Vol 56, 1984.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.