ASTM D8315-20

(Test Method)Standard Test Method for Determination of Wear Metals and Contamination Elements in Used Industrial Oils by Sweeping Flat Electrode Atomic Emission Spectrometry

Standard Test Method for Determination of Wear Metals and Contamination Elements in Used Industrial Oils by Sweeping Flat Electrode Atomic Emission Spectrometry

SIGNIFICANCE AND USE

5.1 Used Industrial Oil—The detection of large particles are important inputs for used industrial lubricant condition mornitoring. For wear metals, these particles, in size, are represented by those between 20 μm and 50 μm in engine oil, 80 μm or greater in gear-box oil. In desert or windy areas, large sand and dust particles can enter in-service lubricant. The concentrations contributed from large particles can be more sensitive to serious or catastrophic failure of industrial equipment than those from 10 μm or less. In spectroscopic analysis, excluding large particles significantly under-reports the concentrations of wear and contamination elements. The corresponding results may not represent the actual state of in-service lubricant. Because this test method posts less limitation on the size of wear metal particles while still reporting normal fine wear particles, it provides a means to assess wear and contamination elements in a comprehensive range of the size of particulates and raises the fidelity of spectroscopic analysis of in-service lubricant.

5.2 Non-suspendable Particles in Used Industrial Oil—The increase of non-suspendable particles suggests excessive wear or poor sealing of machinery, or both. Large amounts of such particulate in industrial oil bulk itself are harmful to moving parts of machinery. This test method provides another means to identify the presence or absence of the non-suspendable particles for machinery condition monitoring.

SCOPE

1.1 This test method covers the determination of wear metals and contaminants in used industrial oils by sweeping flat electrode atomic emission spectroscopy (SFE-AES).2

1.2 Industrial oil includes lubricant oil, gear box oil, hydraulic fluid, compressor oil, turbine oil, synthetic oils, and other petroleum oils.

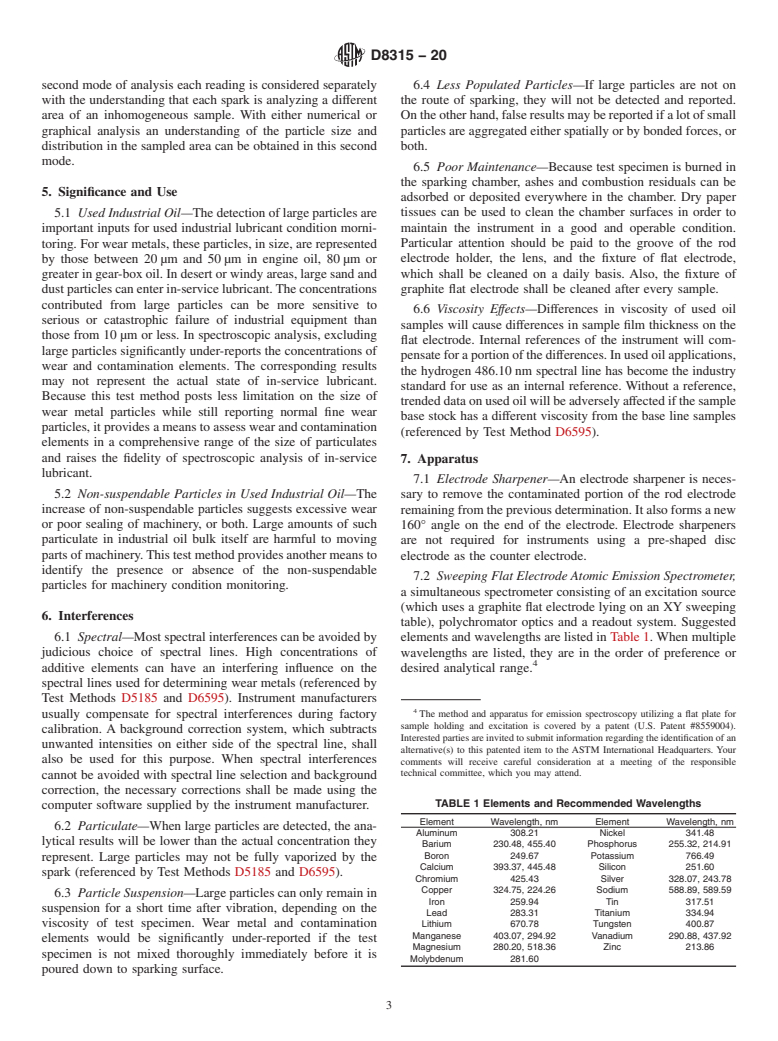

1.3 Method working range for every element is evaluated by equations in 15.2.1 and tabulated in Table 6.

1.4 Though this technique is designed to analyze non-suspended particles in lubricant samples, the precision statements published here were established solely from homogeneous oil samples per Practice D6300 requirements. Non-suspended particles, which are inhomogeneous by nature, were not sampled and evaluated for deriving precision statements for this test method (see Annex A1).

1.5 This test method provides a quick indication for abnormal wear and the presence of contamination in new or used industrial oils by immediately reporting:

1.5.1 Normal fine particles of specific wear metals;

1.5.2 Non-suspendable particles of specific wear metals and of contamination elements;

1.5.3 Less populated large particles (10 μm to 50 μm) of specific wear metals;

1.5.4 Contamination elements; and

1.5.5 Additive elements.

1.6 This test method uses oil-soluble elements for calibration and does not purport to relate quantitatively the values determined as insoluble particles to the dissolved metals. Analytical results are particle size dependent and low results may be obtained for those elements present in used oil samples as large particles (referenced by Test Methods D5185 and D6595).

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8315 − 20

Standard Test Method for

Determination of Wear Metals and Contamination Elements

in Used Industrial Oils by Sweeping Flat Electrode Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation D8315; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Analytical results are particle size dependent and low results

may be obtained for those elements present in used oil samples

1.1 This test method covers the determination of wear

as large particles (referenced by Test Methods D5185 and

metals and contaminants in used industrial oils by sweeping

2 D6595).

flat electrode atomic emission spectroscopy (SFE-AES).

1.7 The values stated in SI units are to be regarded as

1.2 Industrial oil includes lubricant oil, gear box oil, hy-

standard. No other units of measurement are included in this

draulic fluid, compressor oil, turbine oil, synthetic oils, and

standard.

other petroleum oils.

1.8 This standard does not purport to address all of the

1.3 Methodworkingrangeforeveryelementisevaluatedby

safety concerns, if any, associated with its use. It is the

equations in 15.2.1 and tabulated in Table 6.

responsibility of the user of this standard to establish appro-

1.4 Though this technique is designed to analyze non-

priate safety, health, and environmental practices and deter-

suspended particles in lubricant samples, the precision state-

mine the applicability of regulatory limitations prior to use.

ments published here were established solely from homoge-

1.9 This international standard was developed in accor-

neous oil samples per Practice D6300 requirements. Non-

dance with internationally recognized principles on standard-

suspended particles, which are inhomogeneous by nature, were

ization established in the Decision on Principles for the

notsampledandevaluatedforderivingprecisionstatementsfor

Development of International Standards, Guides and Recom-

this test method (see Annex A1).

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.5 This test method provides a quick indication for abnor-

mal wear and the presence of contamination in new or used

2. Referenced Documents

industrial oils by immediately reporting:

3

2.1 ASTM Standards:

1.5.1 Normal fine particles of specific wear metals;

1.5.2 Non-suspendable particles of specific wear metals and D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

of contamination elements;

1.5.3 Less populated large particles (10 µm to 50 µm) of D4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

specific wear metals;

1.5.4 Contamination elements; and D5185 Test Method for Multielement Determination of

Used and Unused Lubricating Oils and Base Oils by

1.5.5 Additive elements.

Inductively Coupled Plasma Atomic Emission Spectrom-

1.6 This test method uses oil-soluble elements for calibra-

etry (ICP-AES)

tion and does not purport to relate quantitatively the values

D6300 Practice for Determination of Precision and Bias

determined as insoluble particles to the dissolved metals.

Data for Use in Test Methods for Petroleum Products,

Liquid Fuels, and Lubricants

1

This test method is under the jurisdiction of ASTM Committee D02 on D6595 Test Method for Determination of Wear Metals and

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Contaminants in Used Lubricating Oils or Used Hydraulic

Subcommittee D02.03 on Elemental Analysis.

Fluids by Rotating Disc ElectrodeAtomic Emission Spec-

Current edition approved June 1, 2020. Published July 2020. DOI: 10.1520/

trometry

D8315-20.

2

The sole source of supply of the apparatus (COA Oil & Grease Analyzer and

accessories) known to the committee at this time is CYCP Oil Analyzers, LLC., 7

3

Beths Rd, Shrewsbury, MA01545, www.cycp-oilanalyzers.com. If you are aware of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

alternative suppliers, please provide this information to ASTM International contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Headquarters.Your comments will receive careful consideration at a meeting of the Standards volume information, refer to the standard’s Document Summary page on

1

responsible technical committee, which you may attend. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.