SIST EN 1365-2:2014

(Main)Fire resistance tests for loadbearing elements - Part 2: Floors and roofs

Fire resistance tests for loadbearing elements - Part 2: Floors and roofs

This European Standard specifies a method for determining the fire resistance of:

- floor constructions, without cavities or with unventilated cavities;

- roof constructions, with or without cavities (ventilated or unventilated);

- floor and roof constructions incorporating glazing;

with fire exposure from the underside.

This European Standard is used in conjunction with EN 1363-1.

Feuerwiderstandsprüfungen für tragende Bauteile - Teil 2: Decken und Dächer

Diese Europäische Norm legt ein Prüfverfahren zur Bestimmung der Feuerwiderstandsdauer von

- Deckenkonstruktionen ohne Hohlräume oder mit nicht belüfteten Hohlräumen;

- Dachkonstruktionen mit oder ohne Hohlräume(n) (belüftet oder unbelüftet);

- Decken- und Dachkonstruktionen unter Einbeziehung einer Verglasung;

fest, wobei die Beflammung von der Unterseite aus erfolgt.

Diese Europäische Norm gilt in Verbindung mit EN 1363 1.

Essais de résistance au feu des éléments porteurs - Partie 2: Planchers et toitures

La présente Norme européenne prescrit une méthode pour déterminer la résistance au feu :

- des planchers, sans plenum ou avec plenums non ventilés ;

- des toitures avec ou sans plenums (ventilés ou non) ;

- des planchers et des toitures comportant des vitrages ;

avec une exposition au feu par le dessous.

La présente Norme européenne est utilisée conjointement avec l’EN 1363-1.

Preskusi požarne odpornosti nosilnih elementov - 2. del: Stropi in strehe

Ta evropski standard določa metodo za ugotavljanje požarne odpornosti:

– stropnih konstrukcij, brez lukenj ali z luknjami brez prezračevanja;

– strešnih konstrukcij, z ali brez lukenj (z ali brez prezračevanja);

– stropnih in strešnih konstrukcij z zasteklitvijo;

za izpostavljenostjo požaru z zunanje strani.

Ta standard se uporablja v povezavi s standardom EN 1363-1.

General Information

- Status

- Published

- Public Enquiry End Date

- 27-Feb-2013

- Publication Date

- 25-Nov-2014

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Nov-2014

- Due Date

- 15-Jan-2015

- Completion Date

- 26-Nov-2014

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

SIST EN 1365-2:2001 - Fire resistance tests for loadbearing elements - Part 2: Floors and roofs - Effective Date

- 01-Dec-2014

Overview

EN 1365-2:2014 - “Fire resistance tests for loadbearing elements - Part 2: Floors and roofs” (CEN) defines a standardized method to determine the fire resistance of loadbearing floor and roof constructions with fire exposure from the underside. The standard covers:

- Floor constructions (without cavities or with unventilated cavities)

- Roof constructions (with or without cavities, ventilated or unventilated)

- Floors and roofs incorporating glazing (insulated or uninsulated)

EN 1365-2:2014 is a European test method used together with EN 1363-1 (General requirements) and references EN 1363‑2 and EN ISO 13943 for terminology.

Key topics and technical requirements

- Scope and specimen types: Definitions for floors, roofs, ceilings, cavities, glazed elements, panes, mullions and transoms - including sloped/pitched roof arrangements and configurations that include glazing.

- Test equipment & furnace conditions: Furnace heating, pressure and atmosphere requirements follow EN 1363‑1; for inclined specimens the furnace pressure reference is established 100 mm below the pressure reference line at the highest possible position.

- Loading conditions: Specimens are subjected to representative loads; loads should produce moments and shear forces equal to or greater than those in service. Uniform application via point-loading systems is specified; distribution plates must not exceed 0.09 m2 each or 16% of total surface area collectively.

- Specimen design & size: Requirements for specimen dimensions, support and restraint conditions, and construction details (including ceilings and pitched roofs).

- Instrumentation & measurements: Use of furnace thermocouples (plate thermometers), unexposed-surface thermocouples, pressure, deflection and radiation measurement. Annex A specifies additional instrumentation and criteria for constructions incorporating glazing, including average and maximum temperature rises, deflection limits and radiation checks.

- Performance criteria & reporting: Criteria for fire resistance (integrity, insulation where applicable, and radiation) and mandatory contents for the test report. Fields of direct application (limits on span, width, inclination and support types) are defined for transferability of test results.

Applications and who uses it

EN 1365-2:2014 is used by:

- Fire test laboratories conducting standardized fire-resistance tests

- Structural and fire safety engineers assessing loadbearing floor/roof performance under fire

- Manufacturers of floors, roofs, glazing systems and composite assemblies for product certification and CE marking

- Building designers and code officials for compliance demonstration and approval processes

Practical uses include product development testing, regulatory compliance, verification of glazed roof/floor solutions, and establishing fire-resistance ratings used in building design and specification.

Related standards

- EN 1363-1:2012 - Fire resistance tests - Part 1: General requirements (used in conjunction)

- EN 1363-2 - Alternative/additional procedures

- EN ISO 13943 - Fire safety - Vocabulary

Keywords: EN 1365-2:2014, fire resistance tests, floors and roofs, loadbearing elements, fire-resistant glazing, CEN, EN 1363-1, fire testing, fire safety in buildings.

Frequently Asked Questions

SIST EN 1365-2:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Fire resistance tests for loadbearing elements - Part 2: Floors and roofs". This standard covers: This European Standard specifies a method for determining the fire resistance of: - floor constructions, without cavities or with unventilated cavities; - roof constructions, with or without cavities (ventilated or unventilated); - floor and roof constructions incorporating glazing; with fire exposure from the underside. This European Standard is used in conjunction with EN 1363-1.

This European Standard specifies a method for determining the fire resistance of: - floor constructions, without cavities or with unventilated cavities; - roof constructions, with or without cavities (ventilated or unventilated); - floor and roof constructions incorporating glazing; with fire exposure from the underside. This European Standard is used in conjunction with EN 1363-1.

SIST EN 1365-2:2014 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements; 91.060.20 - Roofs; 91.060.30 - Ceilings. Floors. Stairs. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1365-2:2014 has the following relationships with other standards: It is inter standard links to SIST EN 1365-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1365-2:2014 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/117. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1365-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Preskusi požarne odpornosti nosilnih elementov - 2. del: Stropi in streheFeuerwiderstandsprüfungen für tragende Bauteile - Teil 2: Decken und DächerEssais de résistance au feu des éléments porteurs - Partie 2: Planchers et toituresFire resistance tests for loadbearing elements - Part 2: Floors and roofs91.060.30Stropi. Tla. StopniceCeilings. Floors. Stairs91.060.20StreheRoofs13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 1365-2:2014SIST EN 1365-2:2014en,fr,de01-december-2014SIST EN 1365-2:2014SLOVENSKI

STANDARDSIST EN 1365-2:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1365-2

November 2014 ICS 13.220.50; 91.060.20; 91.060.30 Supersedes EN 1365-2:1999English Version

Fire resistance tests for loadbearing elements - Part 2: Floors and roofs

Essais de résistance au feu des éléments porteurs - Partie 2: Planchers et toitures

Feuerwiderstandsprüfungen für tragende Bauteile - Teil 2: Decken und Dächer This European Standard was approved by CEN on 27 September 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1365-2:2014 ESIST EN 1365-2:2014

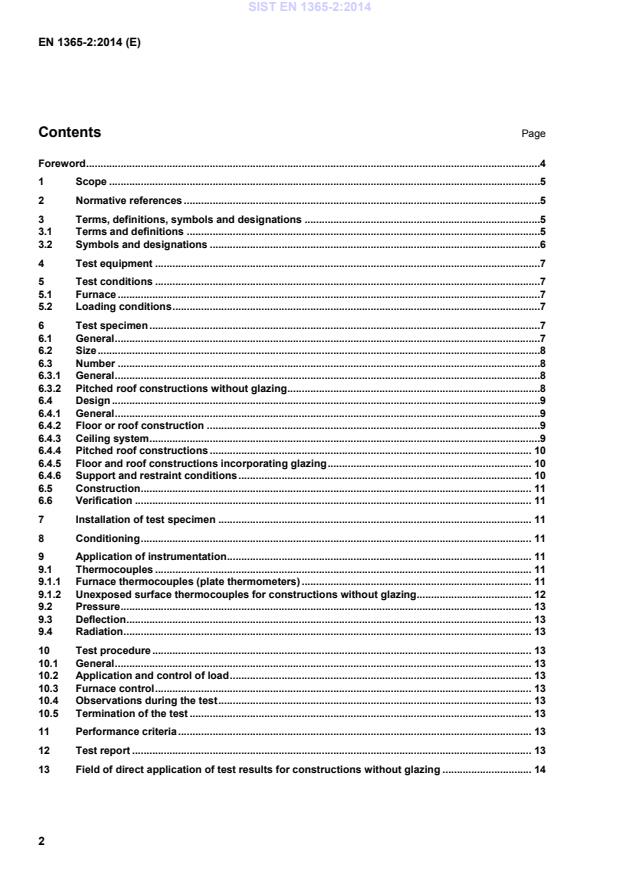

Specific requirements for testing floor and roof constructions incorporating glazing . 20 A.1 General . 20 A.2 Test specimen design . 20 A.3 Test specimen instrumentation . 21 A.3.1 General . 21 A.3.2 Average temperature rise . 21 A.3.2.1 Uniform glazing . 21 A.3.2.2 Non-uniform glazing . 21 A.3.3 Maximum temperature rise . 21 A.3.3.1 General . 21 A.3.3.2 Sloped constructions . 21 A.3.3.3 Horizontal constructions . 22 A.3.4 Deflection . 22 A.3.5 Radiation measurement . 23 A.4 Performance criteria . 23 A.5 Field of direct application of test results . 23 A.5.1 General . 23 A.5.2 Shapes of flat glass panes . 23 A.5.3 Span length . 23 A.5.4 Extension of width in direction perpendicular to the span . 23 A.5.5 Inclination angle . 24 A.5.6 Supporting constructions. 24 A.5.6.1 General . 24 A.5.6.2 Standard supporting constructions . 24 A.5.6.3 Non-standard supporting construction . 24

The heating and pressure conditions and the furnace atmosphere shall conform to those given in EN 1363-1 or, if applicable, EN 1363-2. b)

In addition to a) the following applies: -

The furnace pressure conditions shall be established 100 mm below the pressure reference line, see Figure 1. -

For inclined test specimen, the furnace pressure conditions shall be established 100 mm below the pressure reference line at the highest possible position, see Figures 1 and 2. 5.2 Loading conditions The test specimen shall be subjected to loads determined in accordance with EN 1363-1. The determination of the load shall be clearly indicated in the test report. The magnitude and the distribution of the load shall be such that the maximum moments and shear forces produced in the test specimen are representative of, or higher than those expected in practice. The load shall be applied uniformly, e.g. by a point loading system. Point loads shall be transferred to the test specimen through distribution plates; the total contact area between these and the floor surface shall be not more than 0,09 m2 individually, or 16 % of the total surface area collectively. If the plates are made of steel or of materials with a similar high conductivity, they shall be insulated from the surface of the test specimen. The loading equipment shall not inhibit the free movement of air at the top of the test specimen and, other than at the loading points, no part of the loading equipment shall be closer than 60 mm to the unexposed surface of the test specimen. 6 Test specimen 6.1 General Additional guidance on design of roof and floor constructions incorporating glazing is given in Annex A. SIST EN 1365-2:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...